When dealing with cooling appliances, it’s important to familiarize yourself with the internal structure. This helps in maintaining the device properly, identifying any potential issues, and ensuring that it continues to run smoothly for a long period. Every element inside plays a crucial role in the overall function, so knowing where each one is located can be incredibly useful.

Having a clear visual reference of the key components within these units allows users to troubleshoot more efficiently. A structured layout helps in understanding how the different sections work together to maintain the desired temperature. Whether you are looking to replace a specific element or perform a thorough cleaning, recognizing these components ensures a more seamless process.

By studying the arrangement of the individual sections and mechanisms, users can better approach maintenance tasks. This information is invaluable for those who want to enhance the longevity and performance of their cooling devices.

Frigidaire Freezer Components Overview

This section provides a comprehensive look at the essential elements that make up a modern cooling unit. Understanding the various mechanisms is crucial to maintaining efficiency and ensuring long-term performance. Each component plays a unique role in the cooling process, from managing temperatures to preserving stored items.

Key Elements of the Cooling System

The internal structure of a cooling appliance consists of several critical components that work in harmony to regulate the environment inside. Each element, from the cooling coils to the control panel, has a specific function that ensures optimal operation and energy use.

Component Functions

| Component | Function | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thermostat | Regulates temperature settings to maintain consistent cooling levels. | ||||||||||||||||||||||

| Evaporator Coils | Absorb heat from the interior and help in lowering the temperature. | ||||||||||||||||||||||

| Maintenance Task | Frequency |

|---|---|

| Cleaning the gasket | Every 3 months |

| Inspecting for wear and tear | Every 6 months |

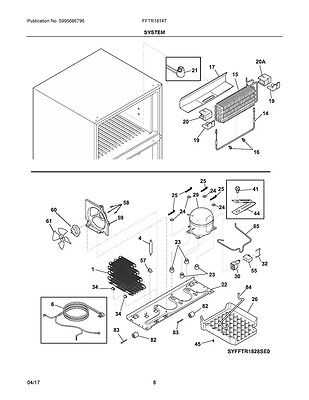

Evaporator Fan and Its Role

The evaporator fan plays a critical role in maintaining optimal cooling performance within refrigeration units. Its function ensures the consistent distribution of cold air throughout the storage area, helping to maintain a stable temperature and prevent uneven cooling. By circulating air, the fan aids in enhancing the efficiency of the cooling system.

Without proper airflow, the cooling coils can become ineffective, leading to potential temperature fluctuations. This component ensures that the system operates at peak performance, which is essential for preserving stored items. Below is a basic overview of its structure and function:

| Component | Function |

|---|---|

| Fan Motor | Powers the fan blades to circulate air. |

| Fan Blades | Move air across the cooling coils to maintain temperature balance. |

| Mounting Bracket | Holds the fan securely in place within the unit. |

Thermostat Adjustment for Optimal Performance

Adjusting the temperature control is crucial for ensuring efficient operation and preserving the quality of stored items. A well-calibrated control unit helps maintain a consistent environment, preventing issues related to spoilage or frost accumulation.

To achieve the best results, begin by locating the temperature adjustment mechanism, usually found inside the unit. Make incremental changes, typically starting with a setting between 0°F and 10°F. Allow the system to stabilize for several hours before making further adjustments, as immediate results may not be evident.

Monitor the internal temperature with a reliable thermometer to confirm the effectiveness of your adjustments. If the temperature fluctuates significantly or fails to reach the desired range, further calibration may be necessary. Regular checks and minor tweaks can enhance overall efficiency and prolong the lifespan of the appliance.

In conclusion, effective management of the temperature setting can significantly impact the performance and efficiency of your cooling appliance. Staying proactive in monitoring and adjusting the control ensures optimal functionality and helps avoid potential problems.

Compressor Unit Troubleshooting Tips

When dealing with issues related to the cooling mechanism, it’s essential to understand common symptoms and potential causes. A malfunctioning compressor unit can lead to inadequate cooling, increased energy consumption, or unusual noises. By systematically examining the components and functionality of the compressor, you can identify and resolve many of these issues effectively.

Common Symptoms to Look For

Start by observing any noticeable signs that indicate a problem with the compressor unit. These may include the appliance not cooling adequately, the compressor running continuously without shutting off, or unusual sounds like clicking or rattling. Identifying these symptoms early can prevent further complications and costly repairs.

Troubleshooting Steps

To troubleshoot the compressor unit, follow a series of logical steps. Begin by checking the power supply to ensure that the unit is receiving electricity. Inspect the compressor for any visible damage or wear, and listen for unusual sounds during operation. Additionally, examine the surrounding components, such as the start relay and capacitor, as these can also affect performance. If necessary, consult a professional technician for a comprehensive evaluation.

Defrost Heater Assembly Explanation

The defrost heater assembly plays a crucial role in maintaining optimal conditions within a cooling unit. This component is responsible for melting frost and ice that can accumulate over time, ensuring efficient operation and preventing damage to the system. By understanding its function and significance, users can better appreciate the importance of regular maintenance and timely replacements.

Function of the Defrost Heater

The primary function of the defrost heater is to generate heat during the defrost cycle. This process is essential for removing ice buildup from the evaporator coils, which can obstruct airflow and reduce cooling efficiency. The heater is typically activated at intervals, allowing it to effectively melt any frost or ice that has formed. Once the ice is cleared, the cooling unit can resume normal operation, promoting energy efficiency and extending the lifespan of the appliance.

Common Issues and Maintenance

Over time, the defrost heater may encounter various issues, such as breaks in the heating element or electrical malfunctions. These problems can lead to inadequate defrosting, resulting in excessive ice buildup and compromised performance. Regular inspections and timely replacements are essential to ensure the heater functions correctly. Keeping an eye on the defrost cycle’s efficiency can help users identify potential issues before they escalate, maintaining optimal performance and prolonging the life of the cooling unit.

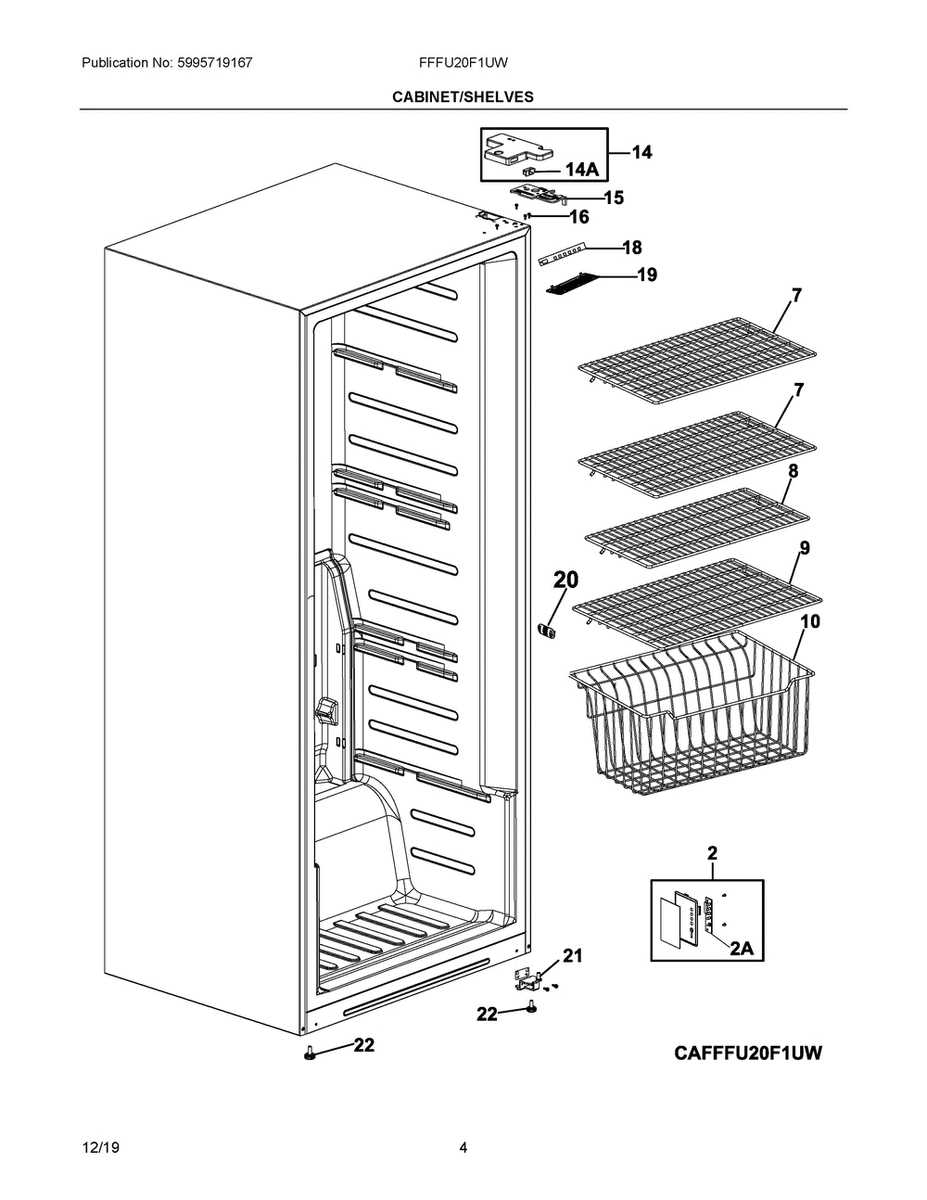

Freezer Shelves and Storage Racks

Effective organization is crucial for maximizing the efficiency of your cold storage unit. Utilizing appropriate shelving and storage solutions enhances accessibility and optimizes the use of space, allowing for better arrangement of food items and other products. Properly designed racks ensure that everything is easily visible and within reach, minimizing the time spent searching for items.

Various types of shelves and racks are available to suit different needs, accommodating various sizes and weights of items. They play a significant role in maintaining order and preventing clutter. By selecting the right configurations, users can create a more functional environment that promotes convenience and efficiency.

| Type | Description |

|---|---|

| Adjustable Shelves | These versatile shelves can be repositioned to accommodate items of different heights, making them ideal for various storage needs. |

| Wire Racks | Wire construction allows for airflow, reducing moisture accumulation and keeping items fresh. These racks are lightweight yet sturdy. |

| Plastic Bins | Ideal for organizing smaller items, plastic bins help prevent items from rolling around and keep everything neatly contained. |

| Sliding Baskets | These baskets provide easy access to frequently used items, making it simple to retrieve and store products without hassle. |

Temperature Sensor Replacement Guide

Replacing the temperature sensor in your appliance is crucial for maintaining optimal performance. This component ensures that the internal environment is properly regulated, preventing spoilage and enhancing energy efficiency. In this guide, we will outline the steps required to successfully replace this essential element, ensuring your unit operates at its best.

Tools and Materials Needed

Before beginning the replacement process, gather the necessary tools and materials. You will typically need a screwdriver, a replacement sensor, and possibly pliers for wire manipulation. Having these items ready will make the procedure smoother and more efficient.

Step-by-Step Instructions

1. Disconnect Power: Always ensure your appliance is unplugged to avoid electrical hazards.

2. Locate the Sensor: The temperature sensor is usually situated near the evaporator coils. Consult your user manual for the exact location.

3. Remove the Old Sensor: Carefully detach any screws or clips holding the sensor in place. Gently pull it out, taking care not to damage any surrounding components.

4. Install the New Sensor: Position the new sensor in the same location as the old one. Secure it with screws or clips as necessary.

5. Reconnect Power: Once the new sensor is installed, plug the appliance back in and monitor its performance to ensure everything is functioning correctly.

By following these steps, you can effectively replace the temperature sensor and restore your appliance’s functionality.

How to Replace the Start Relay

Replacing the start relay is a crucial step in maintaining the functionality of your appliance. This component plays a vital role in the starting mechanism, ensuring that the compressor operates effectively. When issues arise, such as the compressor failing to start, it may indicate that the relay requires replacement.

To begin the process, ensure that the appliance is unplugged to avoid any electrical hazards. Next, locate the relay, typically found near the compressor at the back or bottom of the unit. You may need to remove a cover or access panel to reach it. Once located, carefully disconnect the old relay by gently pulling it out of its socket.

Before installing the new relay, compare it with the old one to ensure compatibility. Align the new relay in the same position as the old one and firmly push it into place until it clicks. After securing the relay, replace any covers or panels that were removed earlier.

Finally, plug the appliance back into the power source and observe its operation. If the compressor starts without issues, the replacement was successful. Regular maintenance of this component can enhance the performance and longevity of your unit.

Seals and Insulation Efficiency

The effectiveness of a cold storage unit largely depends on the integrity of its sealing and insulation. Properly designed seals prevent the escape of cold air, while effective insulation materials ensure minimal heat transfer, thus maintaining a consistent internal temperature. This efficiency is crucial for preserving the quality of stored items and optimizing energy consumption.

Importance of Quality Seals

Quality seals play a vital role in maintaining temperature by creating a barrier against outside elements. Over time, these seals may wear out or become damaged, leading to increased energy costs and temperature fluctuations. Regular inspection and timely replacement of seals are essential for ensuring optimal performance and efficiency.

Role of Insulation Materials

Insulation materials are equally important in enhancing energy efficiency. They minimize heat exchange between the interior and exterior, allowing the cooling system to operate effectively. Selecting high-quality insulation not only improves performance but also reduces operational costs, making it a key component in effective temperature maintenance.