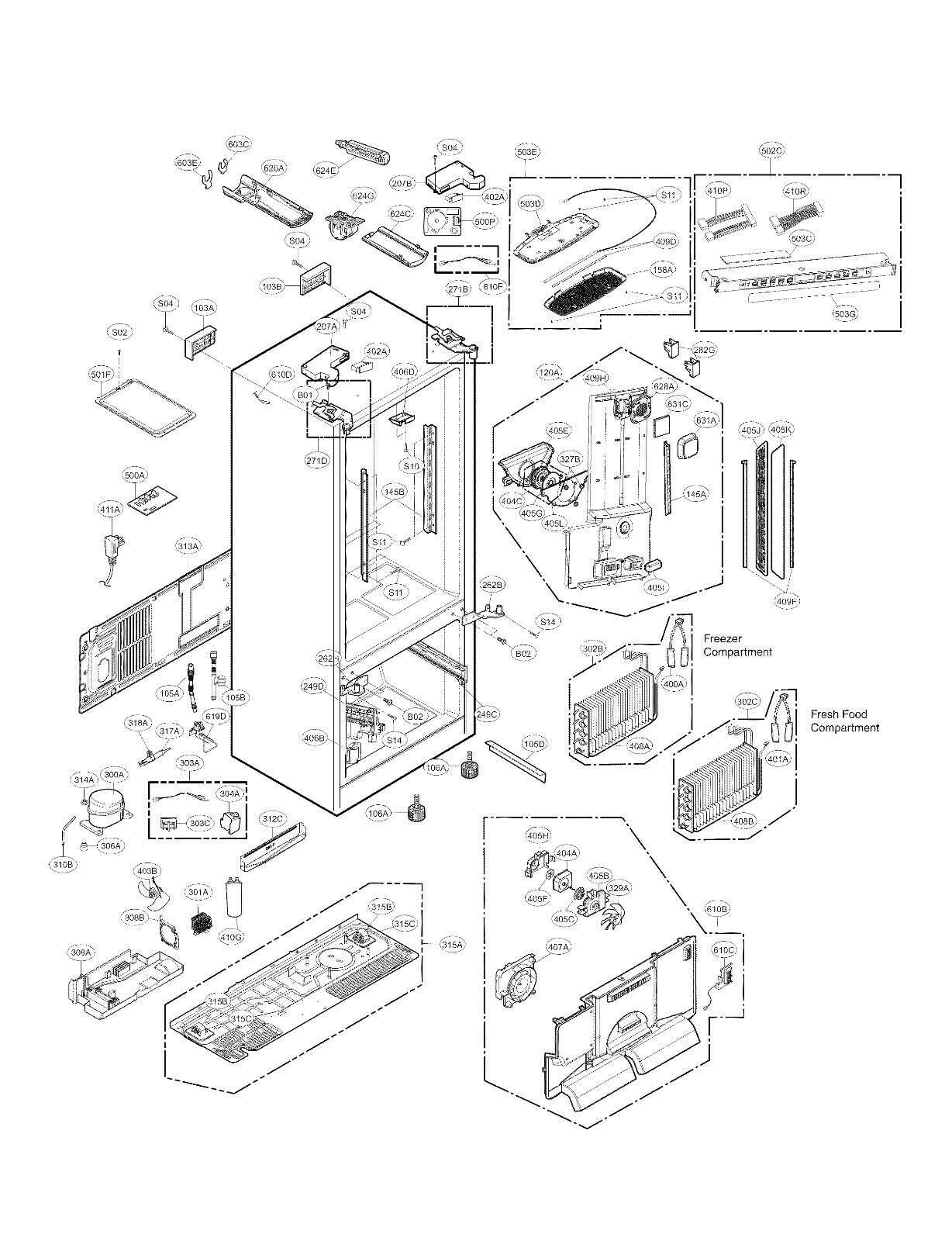

The inner workings of a cooling device involve a series of interconnected elements that function together to maintain optimal temperatures for food preservation. Each piece plays a crucial role in ensuring that the appliance operates efficiently, from the cooling system to storage compartments. By understanding how these components fit and work together, it becomes easier to address potential issues and ensure proper maintenance.

In this section, we will explore the various structural elements and their functions. Knowing how these pieces connect will help you make informed decisions when it comes to repairs or upgrades. Whether you are performing routine checks or troubleshooting, a deeper understanding of the system’s configuration can save time and effort in the long run.

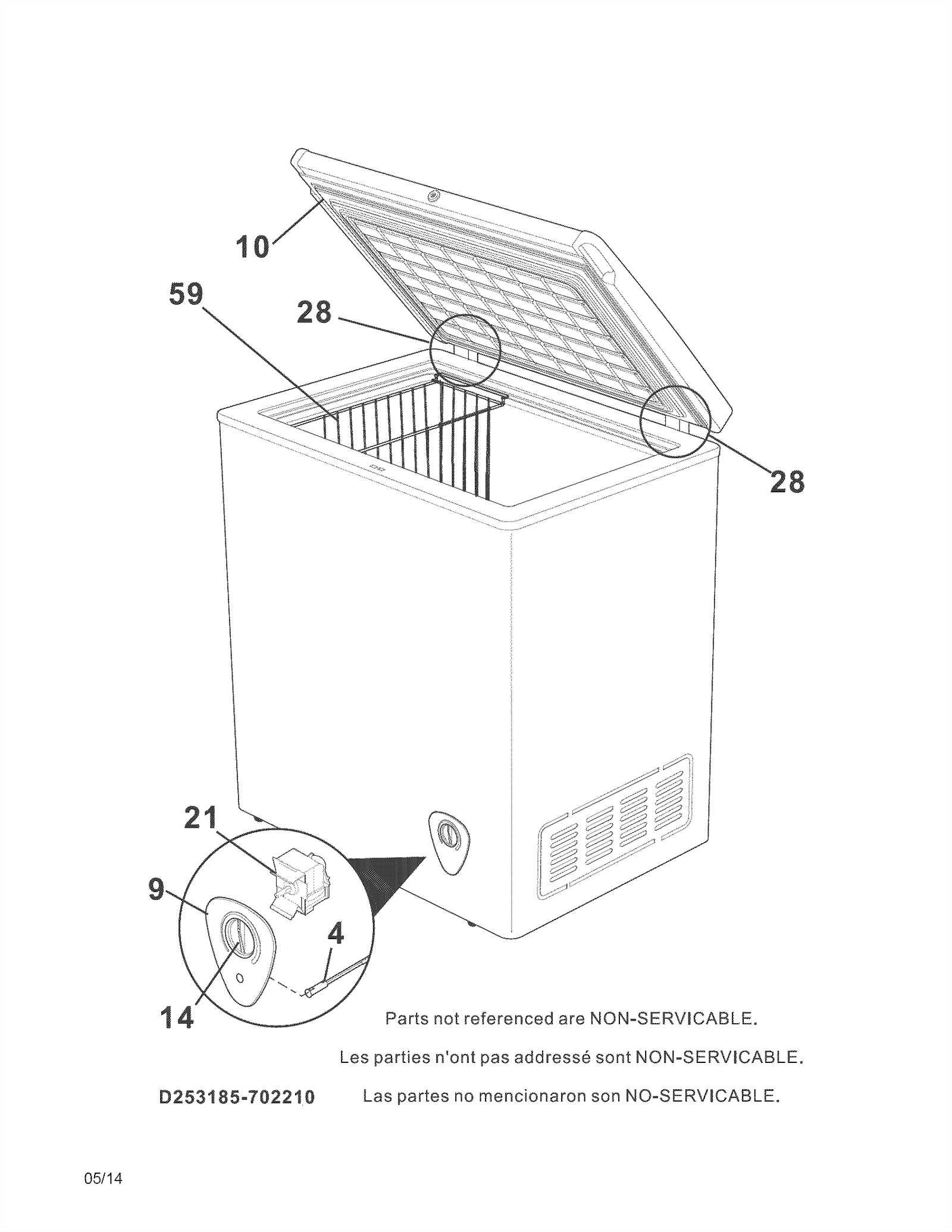

Kenmore Freezer Components Overview

Understanding the various components of a cooling appliance is essential for maintaining its efficiency and ensuring long-term functionality. The unit’s internal and external elements work together to regulate temperature, ensuring optimal storage conditions. Each part plays a crucial role in the overall performance, and recognizing these elements can help troubleshoot issues or enhance usage.

Cooling System

- Compressor: Responsible for compressing refrigerant, allowing it to cycle through the system and provide cooling.

- Condenser Coils: Dissipate heat absorbed from inside the appliance, ensuring proper temperature regulation.

- Evaporator Coils: Absorb heat from inside the storage area, keeping contents at the desired cool levels.

Temperature Control and Safety Features

- Thermostat: Monitors and adjusts internal temperatures to maintain consistency.

- Defrost Timer: Automates defrost cycles to prevent frost buildup and maintain efficient operation.

- Door Seal: Ensures an airtight closure, preventing external warm air from entering.

Essential Elements of Kenmore Freezer

Understanding the main components of a cooling appliance is crucial for proper maintenance and efficient operation. Each element plays a specific role in ensuring consistent temperature control, energy efficiency, and overall performance.

The system relies on a network of interconnected parts that include the cooling mechanism, insulation, and control panel. These key elements work together to maintain the desired environment, preventing temperature fluctuations and ensuring the long-term preservation of stored items.

Additionally, the proper alignment and condition of these components directly affect the longevity and reliability of the appliance. Regular checks and timely repairs can help avoid costly breakdowns and ensure smooth functionality.

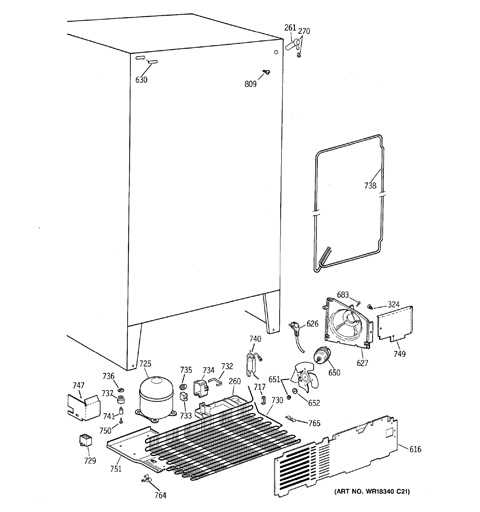

Understanding the Freezer’s Cooling Mechanism

Effective cooling systems are designed to maintain low temperatures by utilizing a series of processes that regulate the flow of refrigerant. These systems rely on a balance of temperature exchange, circulation, and pressure control to ensure that items remain properly chilled. Understanding how these mechanisms work can help diagnose issues or improve efficiency.

Key Components of the Cooling Process

The primary elements involved in the cooling operation include the compressor, condenser, evaporator, and expansion valve. Together, these components work in a continuous cycle to move refrigerant, change its state, and transfer heat from the interior to the exterior of the unit.

The Cooling Cycle

The cooling process starts when the compressor pressurizes the refrigerant, converting it from a gas to a high-temperature liquid. This liquid flows into the condenser, where it releases heat and turns into a cooler liquid. Next, the refrigerant enters the evaporator, where it absorbs heat from the internal environment, transforming back into a gas. The cycle repeats, constantly removing warmth and maintaining a cold environment.

| Component | Function |

|---|---|

| Compressor | Pressurizes and heats the refrigerant. |

| Condenser | Removes heat and cools the refrigerant. |

| Evaporator | Absorbs heat from the interior, cooling the air. |

| Expansion Valve | Controls the flow of refrigerant into the evaporator. |

Compressor Functionality in Kenmore Freezers

The compressor plays a critical role in refrigeration systems by maintaining the right temperature for food preservation. It ensures the cooling process by compressing refrigerant, which then circulates through various components, enabling heat exchange and cooling. Understanding how this component operates is key to diagnosing performance issues and optimizing efficiency.

- The compressor increases the pressure of the refrigerant, raising its temperature.

- Once compressed, the hot gas moves through the condenser coils where it cools and turns into a liquid.

- The cooled refrigerant passes through the evaporator, absorbing heat and producing the necessary cooling effect.

Regular maintenance of this component is essential to ensure proper cooling performance and to prevent overheating or breakdowns.

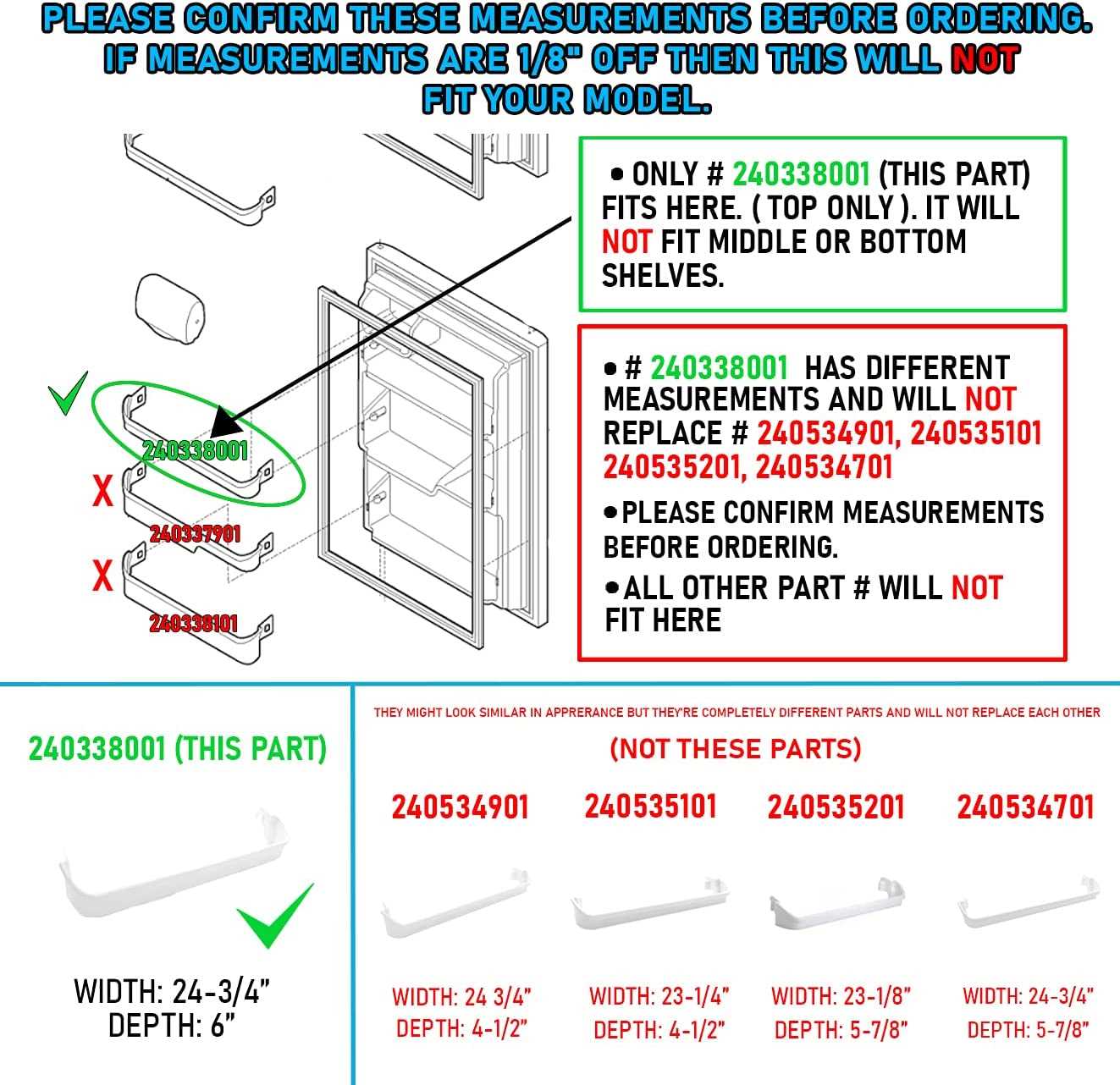

Door Seal and Insulation Role

The door seal and insulation play a crucial role in maintaining the internal temperature, ensuring efficient energy use and preserving the stored items. Proper sealing prevents air leaks, which can compromise the cooling process and increase energy consumption.

- Temperature Control: A tight seal ensures that external warm air doesn’t enter, maintaining stable internal conditions and reducing the need for additional cooling cycles.

- Energy Efficiency: Insulation helps keep the cold air inside, reducing the workload on the cooling system and ultimately saving on electricity costs.

- Preventing Condensation: Good insulation prevents moisture from forming around the door, which can lead to frost buildup or even damage over time.

- Extended Lifespan: By keeping the system running efficiently, the door seal and insulation help prolong the lifespan of the entire cooling system.

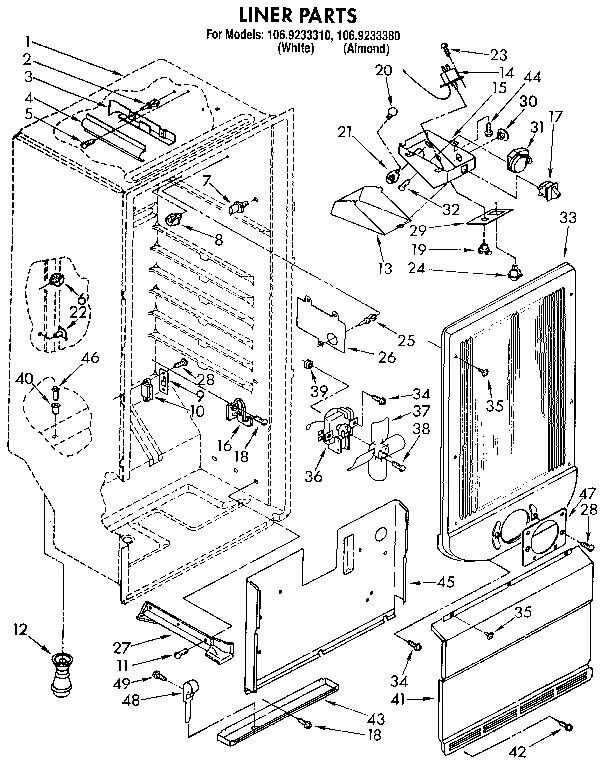

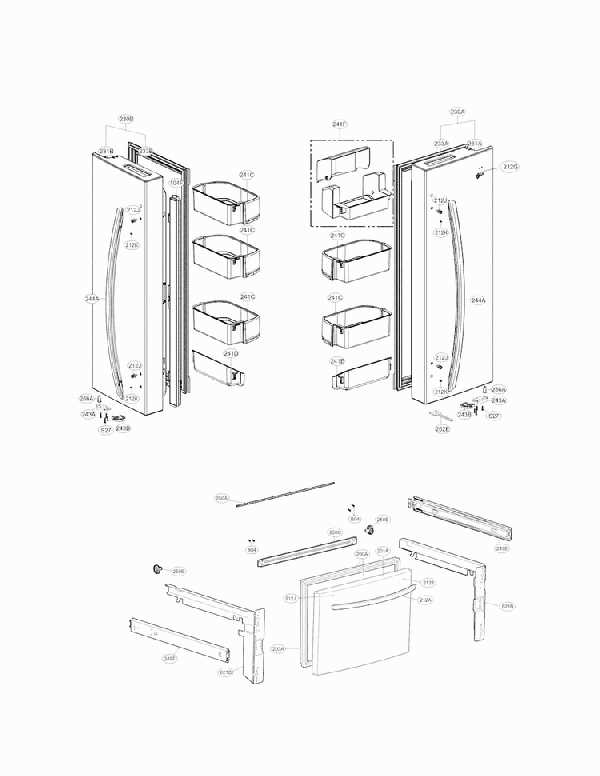

Internal Shelving Layout and Design

The arrangement and structure of internal compartments significantly influence the functionality and efficiency of any cold storage unit. A well-designed shelving system allows for optimal organization, accessibility, and maximization of available space, enabling users to store various items effectively.

Effective internal shelving should cater to diverse storage needs. By incorporating adjustable and versatile shelves, users can customize the space according to their specific requirements, ensuring that both large and small items are accommodated seamlessly.

| Feature | Description |

|---|---|

| Adjustability | Allows users to modify shelf heights for different item sizes. |

| Material Quality | Durable materials ensure longevity and resistance to cold conditions. |

| Spacing Design | Optimized spacing prevents overcrowding and promotes airflow. |

| Ease of Cleaning | Smooth surfaces facilitate quick and efficient maintenance. |

Temperature Control and Sensors

The regulation of thermal conditions within a storage unit is vital for preserving the quality of items stored. Effective management of these conditions relies heavily on various mechanisms designed to maintain an optimal environment, ensuring the longevity of perishable goods.

At the core of this system are temperature sensors, which continuously monitor the internal atmosphere. These sensors send real-time data to the control unit, allowing for precise adjustments. The thermostat plays a critical role in interpreting this information and activating the necessary components to either cool or warm the interior.

Moreover, the functionality of these systems can be influenced by factors such as placement, calibration, and external temperature variations. Proper installation and maintenance of these devices are essential for achieving reliable performance and energy efficiency.

Defrost System and Drainage

The defrost mechanism plays a crucial role in maintaining optimal functionality in cold storage appliances. This system prevents the accumulation of frost, ensuring efficient operation and extending the lifespan of the unit. Understanding the components and their interactions is essential for effective maintenance and troubleshooting.

Key components of the defrost system include:

- Defrost heater: Responsible for melting ice buildup during the defrost cycle.

- Defrost thermostat: Monitors the temperature and signals the heater to activate when needed.

- Drainage system: Ensures that the water generated during defrosting is properly channeled away.

Effective drainage is vital to prevent water pooling and potential damage. The drainage system typically consists of:

- Drain pan: Collects water from the defrosting process.

- Drain line: Directs water away from the appliance to a designated location.

- Drain hole: Facilitates the flow of water out of the appliance.

Regular maintenance of these components can prevent operational issues and enhance performance. Periodic checks and cleaning of the drainage system are recommended to avoid clogs and ensure smooth operation.

Fan and Air Circulation System

The fan and air circulation system plays a crucial role in maintaining optimal temperature and ensuring uniform cooling within the appliance. By efficiently distributing cold air, this system helps preserve the freshness of stored items, preventing spoilage and enhancing overall performance.

Key components of the air circulation system include:

- Fan: The primary component responsible for moving air throughout the interior.

- Air Vents: Openings that allow cold air to flow into various sections of the unit.

- Ducts: Channels that guide air to different areas, ensuring even distribution.

- Temperature Sensors: Devices that monitor and regulate airflow based on the internal environment.

Effective air circulation enhances energy efficiency, reduces the risk of frost buildup, and extends the lifespan of the appliance. Regular maintenance of these components is essential to ensure they function optimally and deliver consistent results.

To maintain the effectiveness of the air circulation system, consider the following tips:

- Regularly clean the fan blades to prevent dust accumulation.

- Check air vents for blockages and ensure they are unobstructed.

- Inspect the ducts for any signs of damage or disconnection.

- Replace faulty temperature sensors promptly to maintain accurate readings.

Power Supply and Electrical Connections

This section focuses on the essential components that ensure proper functioning of the appliance. Understanding how electrical supply and connections work is crucial for maintaining efficiency and safety during operation.

Electrical supply is the lifeblood of any device, providing the necessary power for its components to function. Proper voltage and current levels are vital to prevent damage and ensure optimal performance. It is important to use reliable sources of power that meet the specifications outlined by the manufacturer.

Connections play a significant role in the overall functionality. Each connection must be secure and free of corrosion to allow uninterrupted flow of electricity. Regular inspections can help identify potential issues before they escalate, ensuring the longevity of the device.

For troubleshooting, it is essential to familiarize oneself with the various electrical components, including switches, relays, and wiring harnesses. Understanding their functions can assist in diagnosing problems and making informed decisions about repairs or replacements.

Maintenance Tips for Kenmore Freezer Parts

Ensuring the longevity and efficiency of your cooling appliance requires regular attention and care. Simple maintenance practices can significantly enhance performance and prevent potential issues, leading to better preservation of your food items.

Regular Cleaning: Keep the interior clean by wiping it down with a mild detergent. This prevents the buildup of bacteria and odors that can affect the freshness of stored goods.

Check Seals: Inspect door seals for any cracks or damage. A tight seal is essential for maintaining optimal temperature, so replace any worn seals promptly to enhance energy efficiency.

Defrosting: If frost buildup occurs, consider defrosting the appliance to maintain airflow and efficiency. Regular defrosting can help avoid excessive energy consumption and improve cooling performance.

Temperature Settings: Monitor and adjust temperature settings according to your storage needs. Keeping an appropriate temperature not only ensures food safety but also optimizes energy usage.

Periodic Inspections: Conduct routine checks on the cooling unit and any electrical components. Early detection of issues can prevent costly repairs and ensure reliable operation.

Professional Servicing: Consider scheduling professional maintenance at least once a year. Experts can identify and rectify issues that may not be apparent during regular inspections, providing peace of mind and ensuring your unit runs efficiently.

Troubleshooting Common Part Failures

When appliances experience issues, it can often be traced back to specific components not functioning as intended. Identifying these failures is crucial for restoring proper operation. This section will explore typical malfunctions, their symptoms, and potential solutions.

One frequent problem involves temperature irregularities. If the internal environment becomes too warm or too cold, it may indicate a malfunctioning thermostat or a compromised seal. Checking the calibration of the temperature control and inspecting door seals for gaps can often resolve this issue.

Another common concern is unusual noises. These can signal issues with the compressor, fans, or other moving parts. Listening for abnormal sounds can help pinpoint the source, allowing for targeted repairs or replacements.

Additionally, if there are water leaks, it may be due to clogged defrost drains or damaged gaskets. Regular maintenance, such as cleaning the drainage system, can prevent this from becoming a recurring issue.

By understanding these common failures, users can take proactive steps to maintain their appliances and ensure long-lasting performance.