Understanding how various elements fit together in home systems can be essential for troubleshooting and maintenance. A deeper look at individual modules provides clarity on how everything operates in unison, ensuring smooth performance and long-term reliability.

Identifying each element’s role within complex home equipment simplifies repairs and helps locate potential failures. When the right resources are available, replacing faulty components becomes a manageable task, making sure that systems continue running efficiently.

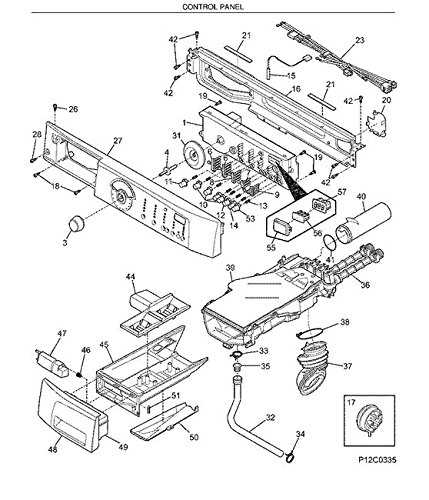

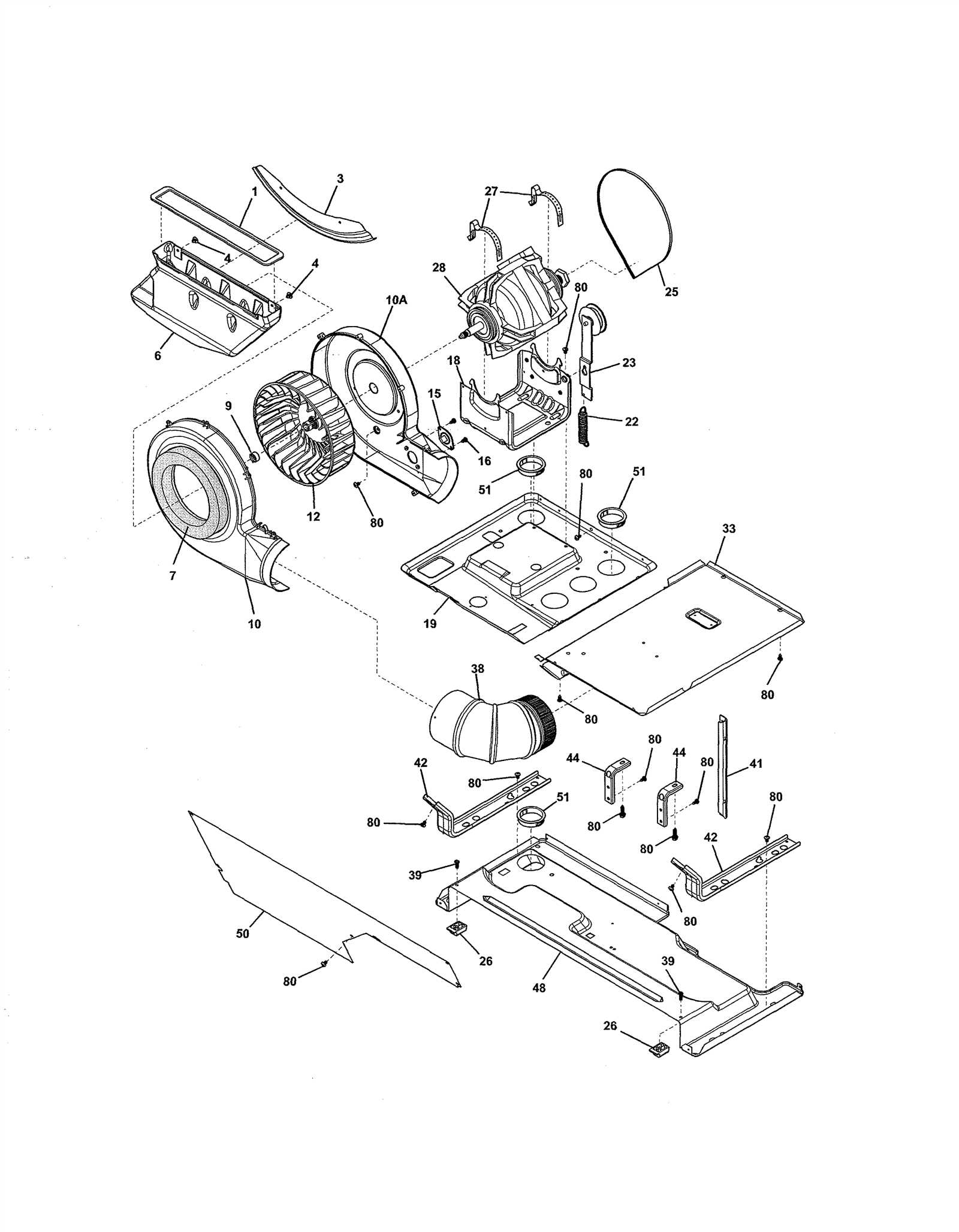

Diagrams offer a structured view of how individual pieces align with one another. These visual references guide users in disassembling or reassembling sections, aiding both professionals and homeowners in performing maintenance with greater confidence.

Frigidaire Laundry Center Parts Overview

This section offers a general insight into the key components that make up an efficient home appliance for washing and drying clothes. Each element plays a specific role, ensuring smooth operation, convenience, and longevity. Understanding these elements can help in identifying any issues that may arise over time and maintaining peak performance.

Key Functional Units

These machines combine various mechanical and electrical units designed to handle different phases of the cleaning process. Controls, motors, and water flow mechanisms work in harmony to ensure consistent results, whether dealing with delicate fabrics or heavy loads. The proper alignment of these units is essential to avoid disruptions during use.

Mechanical and Electrical Elements

Moving parts, such as drums and belts, are subject to wear and need regular inspection. Electrical units like sensors, timers, and heaters ensure precision and safety during each cycle. Timely maintenance and replacement of these elements ensure the machine functions smoothly and extends its lifespan.

How the Dryer System Operates

The drying mechanism functions by channeling heated air through fabrics to eliminate moisture efficiently. This process ensures clothes are ready for use without the need for prolonged exposure to air. The system utilizes a combination of temperature control and air circulation to achieve optimal results.

- Heating Element: A core component that raises air temperature, ensuring effective evaporation of water from garments.

- Airflow System: A blower or fan directs warm air through the drum, maintaining a consistent drying environment.

- Moisture Sensors: These sensors detect the remaining moisture and adjust the operation time accordingly to prevent over-drying.

- Exhaust Vent: Excess moisture and air are expelled through vents, keeping the drum interior dry and efficient.

Temperature regulation ensures the drying process is safe and energy-efficient. Additionally, lint filters play a crucial role in preventing blockages and maintaining smooth airflow throughout each cycle.

Common Washing Machine Components Explained

Every washing machine relies on a variety of essential parts working together to ensure smooth operation. Understanding these elements helps users troubleshoot issues more effectively and maintain their appliance for long-term performance. Though specific designs may vary, most machines share core features that perform similar tasks.

Drum: The main section where clothes are placed. It rotates during cycles, allowing water and detergent to circulate through fabrics.

Motor: Powers the rotation of the drum. Different speeds are used depending on the wash or spin cycle selected.

Pump: Moves water in and out of the machine, ensuring proper drainage and filling throughout the process.

Control Panel: Lets users select settings such as temperature, spin speed, and cycle duration. Modern systems often include digital displays and advanced options.

Valves: Regulate the flow of water entering the machine, adjusting for cold or hot water as needed.

Suspension System: Reduces vibration and stabilizes the machine during high-speed spins to prevent excessive movement.

Knowing how these components interact can simplify maintenance and repairs, making it easier to spot issues early. A clear understanding of the internal structure also improves the efficiency of routine care and prolongs the life of the appliance.

Troubleshooting with Electrical System Parts

Identifying issues within an electrical setup requires a clear understanding of the connections and components involved. When something malfunctions, it’s essential to look for signs like unusual sounds, power failures, or system interruptions that point toward the source of the problem. This section will guide you through key steps to evaluate and address common electrical issues efficiently.

Inspecting Power Supply Components

A sudden outage often indicates a disrupted energy flow. Begin by checking fuses and breakers to ensure they are intact. Look for any visible damage or loose wiring. If the system uses switches or relays, verify their condition and replace them if necessary. Identifying a faulty connection early can prevent further issues.

Testing Control Units and Sensors

Control modules and sensors manage the operation and timing of various elements. When troubleshooting, inspect these units for overheating or irregular signals. Use a multimeter to measure voltage and continuity, ensuring each element operates within its expected range. If readings fall outside normal values, consider replacing the component to restore proper functionality.

Replacing Water-Related Mechanisms in Washers

Maintaining the proper flow and control of water is essential to ensure efficient operation in any washing machine. Over time, certain components responsible for regulating water movement may experience wear or malfunction, requiring timely replacement to prevent performance issues.

Identifying Common Issues with Valves and Seals

Water intake valves and rubber seals are among the most frequent culprits when problems arise. A damaged valve may restrict water entry or cause leakage, leading to cycles that don’t function as intended. Similarly, worn seals can allow unwanted drips, potentially damaging surrounding parts. Inspecting these elements regularly can help detect issues early and reduce repair costs.

Steps to Replace Key Water Mechanisms

Replacing faulty water components typically involves disconnecting hoses, removing screws, and installing a new unit in place of the defective one. Ensure the machine is unplugged and water supply turned off before beginning. Carefully align the new valve or seal to avoid installation errors. After finishing the replacement, it’s important to run a short test cycle to confirm the problem has been resolved.

Maintenance Tips for Control Panels

Ensuring the optimal performance of control interfaces is crucial for efficient operation. Regular upkeep not only extends the lifespan of these components but also enhances the overall user experience. Following a few simple practices can help maintain the functionality and appearance of these essential units.

Regular Cleaning Procedures

Keeping control surfaces clean is vital. Use a soft, damp cloth to wipe away dust and spills. Avoid using abrasive cleaners that may damage the finish. For stubborn stains, a mild detergent diluted in water can be effective. Ensure the area is completely dry before reapplying power.

Inspecting Connections and Components

Periodic checks of electrical connections and internal components can prevent operational issues. Look for signs of wear or damage, and ensure all connections are secure. If any irregularities are detected, addressing them promptly can avert larger problems in the future.

The Role of Belts and Pulleys

Belts and pulleys are essential components that facilitate the transfer of motion and power within various mechanical systems. They play a crucial role in ensuring smooth operation and efficiency. By connecting different parts, these elements help in transmitting energy from one component to another, enabling the machine to function effectively.

How Belts Function

Belts serve as flexible connectors that can adapt to the movement of various parts. Their primary functions include:

- Transmitting rotational force between shafts

- Reducing friction during operation

- Maintaining the alignment of components

The Importance of Pulleys

Pulleys are wheels that aid in guiding the belts and altering the direction of movement. They are significant for:

- Changing the speed of rotation

- Providing mechanical advantage

- Allowing for the adjustment of tension in the system

Filters and Their Maintenance Importance

Maintaining the efficiency of various appliances is crucial for their longevity and performance. Among the essential components are filters, which play a vital role in ensuring optimal functionality. Regular attention to these elements can significantly impact the overall effectiveness of your equipment.

Filters serve to trap dust, debris, and other contaminants, preventing them from interfering with the appliance’s operation. Neglecting their maintenance can lead to reduced efficiency and potential damage. Here are key points to consider:

- Regular Inspection: Check filters frequently to identify any buildup or obstructions.

- Cleaning: Depending on the type, filters may need to be cleaned or replaced periodically to maintain airflow and effectiveness.

- Impact on Efficiency: Clogged filters can cause appliances to work harder, leading to increased energy consumption and wear.

- Preventive Measures: Implementing a routine maintenance schedule can help ensure filters remain in good condition.

By prioritizing filter maintenance, you can enhance performance, reduce operational costs, and extend the life of your appliances.

Identifying Issues with Motors and Pumps

Understanding how to recognize problems with electric motors and hydraulic devices is essential for efficient operation. By observing unusual signs, users can detect malfunctions early, preventing further damage and ensuring smooth functioning. This section will discuss common symptoms that may indicate underlying issues, along with possible solutions to rectify them.

Common Symptoms of Malfunctions

Several indicators can suggest that motors or pumps are not operating correctly. For instance, unusual noises such as grinding or squeaking may signify wear or misalignment of components. Additionally, decreased efficiency, such as slower operation or inadequate performance, can point to potential issues that require attention. Overheating is another critical sign, often resulting from prolonged use without adequate maintenance.

Troubleshooting Techniques

When faced with these symptoms, it is important to employ troubleshooting methods. Begin by checking electrical connections and ensuring they are secure. If unusual sounds persist, inspect moving parts for any signs of wear or obstruction. Regular maintenance can greatly reduce the likelihood of these issues, extending the lifespan of the equipment. Implementing a routine inspection schedule will help identify problems before they escalate.

Using Diagrams for Quick Repairs

Visual aids play a crucial role in simplifying the repair process for various household appliances. They provide a clear representation of components, making it easier to identify issues and understand the assembly of different elements. By utilizing these illustrations, individuals can perform repairs more efficiently, reducing downtime and frustration.

Benefits of Visual Guides

Employing visual guides offers numerous advantages. First, they enhance comprehension by presenting complex information in an accessible format. Second, they can significantly speed up the troubleshooting process, allowing users to locate problems quickly. Lastly, these resources empower users to conduct repairs confidently, promoting a sense of accomplishment.

Essential Components Overview

| Component Name | Description |

|---|---|

| Motor Assembly | The mechanism responsible for powering the machine’s functions. |

| Control Panel | The interface used to operate and set preferences for the appliance. |

| Drum | The cylindrical part where items are placed for cleaning or drying. |

| Water Inlet Valve | Controls the flow of water into the appliance during operation. |

| Drain Pump | Facilitates the removal of water from the drum after use. |

Difference Between Sensors and Switches

Sensors and switches play crucial roles in various systems, yet they serve distinct purposes. Understanding these differences can enhance the efficiency and functionality of devices.

Sensors are designed to detect specific environmental conditions or changes and convert that information into signals. They continuously monitor variables such as temperature, pressure, or motion, providing real-time data to the system. For instance, a sensor can sense when a machine is overheating and relay that information to prevent damage.

On the other hand, switches are primarily used to control the flow of electricity or signals within a circuit. They act as on/off devices, allowing or interrupting the current based on user input or predetermined conditions. A simple example is a light switch that toggles the light on or off, thus controlling the electrical circuit.

In summary, while sensors focus on detection and monitoring, switches are integral for controlling operations and managing electrical flow. Their unique functions contribute to the overall effectiveness of devices, making them essential components in numerous applications.

Preserving Longevity with Proper Upkeep

Ensuring the durability of your appliance requires consistent and careful maintenance. By adopting suitable practices, you can enhance its lifespan and efficiency, minimizing the need for repairs or replacements. Regular attention to details plays a crucial role in maintaining functionality and performance.

Routine cleaning is essential to prevent the buildup of dirt and debris. Regularly check and clear any filters, ensuring that all components operate smoothly. This simple step can significantly reduce wear and tear on internal mechanisms.

Moreover, scheduled inspections help identify potential issues before they escalate. Observing unusual sounds or performance fluctuations can alert you to necessary adjustments or repairs. Staying proactive can save time and resources in the long run.

Finally, using the appliance according to the manufacturer’s recommendations is vital. Following guidelines on load limits and operation modes ensures that your equipment functions optimally, thereby extending its operational life.