When it comes to ensuring the proper functionality of your cooling unit, understanding its internal structure is essential. Each component has a unique role, working in harmony to maintain an optimal environment for food preservation. In this section, we’ll explore how these essential elements interact to keep everything running smoothly.

Efficient organization within these systems is key to their performance. Knowing the configuration of each component helps in maintaining and troubleshooting, allowing you to identify potential issues quickly. Whether it’s the cooling mechanism or storage compartments, every part contributes to the overall efficiency of the system.

By gaining insights into the structural layout, you can better manage maintenance and optimize the longevity of your appliance. Let’s take a closer look at the core elements that make up this sophisticated cooling technology.

Frigidaire Refrigerator Components: An Overview

Understanding the various elements that make up a modern cooling system is essential for efficient maintenance and repair. Each unit is designed with precision, featuring a combination of mechanical and electronic parts that work together to regulate temperature, manage airflow, and preserve food quality. Below is a closer look at the key components that form this intricate system.

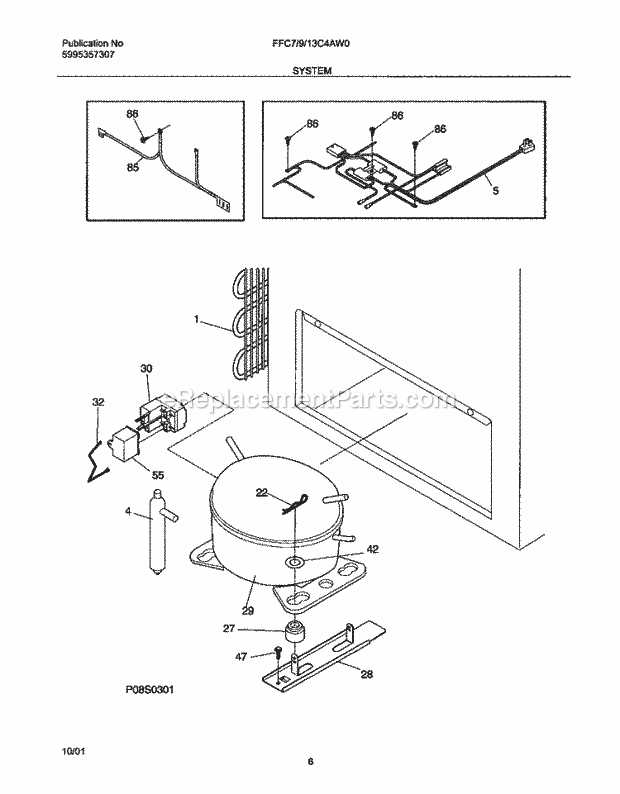

Cooling System

The cooling mechanism is the heart of the unit. It controls the temperature inside, ensuring a balanced environment for keeping food fresh. This system includes several important elements:

- Compressor – responsible for circulating refrigerant through the system.

- Condenser coils – help release the heat absorbed by the refrigerant.

- Evaporator – absorbs heat from the interior, cooling the air inside.

Control and

Key Elements of Frigidaire Cooling Systems

The essential components in modern cooling systems are designed to ensure efficient temperature control and energy savings. These systems work by coordinating several mechanisms that maintain a stable internal environment, making sure that food and beverages stay fresh over extended periods.

At the core of the system lies the compressor, which pressurizes the refrigerant to initiate the cooling cycle. This component is crucial for the continuous movement of the coolant, transforming low-pressure gas into high-pressure vapor. The evaporator coils, another vital element, absorb heat from inside the unit, allowing for temperature reduction. This heat is then expelled to the surroundings through the condenser, helping to maintain optimal conditions.

Fans are also an integral part, as they ensure the distribution of cold air across the storage compartments, while thermostats monitor and regulate the system’s performance. All these components work in unison to provide consistent and reliable cooling, contributing to the overall longevity and functionality of the system

Understanding the Function of Compressor Units

The compressor is a crucial component responsible for maintaining the temperature in cooling systems. Its primary role involves managing the circulation of a specific substance within the system, allowing the device to perform its cooling function efficiently. By understanding how the compressor operates, one can gain insights into the overall performance and maintenance of cooling appliances.

Main Components of a Compressor

- Piston or Rotary Mechanism: A key feature that drives the flow of the cooling medium through the system.

- Motor: Powers the movement of the compression unit, ensuring continuous operation.

- Valves: Control the direction and flow of the substance, allowing for a proper cycle.

How the Compressor Operates

Evaporator Coil: How It Maintains Cold Air

The evaporator coil plays a crucial role in the cooling process, ensuring that the internal environment remains at the desired low temperature. This component absorbs heat from the air, allowing it to be cooled effectively before being circulated back into the system. By facilitating the exchange of heat, the coil helps create the cold air that maintains the overall efficiency of the unit.

The coil itself works by transferring thermal energy as a refrigerant passes through it. As warm air comes into contact with the surface, the heat is absorbed, and the cooler air is released back into circulation. This process is continuous, ensuring that the air inside stays consistently cold, regardless of external conditions.

Proper maintenance of the evaporator coil is essential for optimal performance. Over time, dirt and debris can accumulate on the surface, reducing its ability to absorb

Replacing the Defrost Heater for Optimal Performance

Ensuring consistent cooling performance is essential for maintaining the efficiency of your cooling system. One crucial component that directly impacts this process is the defrost heater. This element helps prevent ice buildup, which can reduce overall system performance. Understanding how to properly replace it can restore full functionality and prolong the life of your cooling device.

Steps for Safe Removal

Before starting, it’s important to disconnect the unit from the power supply. Afterward, access the area where the defrost heater is installed by removing any protective covers. Once visible, carefully detach the connections from the heater, taking note of the placement to ensure correct reinstallation later.

Installation of the New Heater

With the old component removed, install the new heater by securing it into the proper location and reconnecting all elec

Temperature Control Mechanisms in Frigidaire Models

The ability to maintain optimal temperature levels is crucial for ensuring the longevity and efficiency of cooling appliances. Various mechanisms have been developed to regulate and stabilize the internal climate, allowing for efficient operation and energy savings. Understanding these mechanisms can aid users in troubleshooting and optimizing their units for better performance.

Thermostatic Control

One of the primary methods for regulating temperature involves a thermostatic control system. This component continuously monitors the internal environment and adjusts cooling levels accordingly. When the temperature deviates from the desired setting, the system activates the compressor to restore balance, ensuring that food items are kept at optimal freshness.

Electronic Sensors

Modern units often incorporate advanced electronic sensors to enhance temperature regulation. These sensors provide real-time data, allowing for precise adjustments. By communicating with the control board, they help maintain a consistent internal climate, reducing energy consumption and minimizing fluctuations that could affect food preservation.

Water Dispenser Parts and Their Maintenance

The efficient functioning of a water dispensing system is crucial for ensuring a steady supply of clean drinking water. Understanding the various components involved in this mechanism is essential for maintaining optimal performance. Regular upkeep and awareness of these elements can prevent malfunctions and prolong the lifespan of the unit.

One of the primary components is the water filter, which purifies the incoming water by removing impurities and contaminants. It is recommended to replace this filter every six months or as specified by the manufacturer to ensure the quality of the dispensed water. A clogged filter can lead to reduced water flow and may even cause damage to the system.

The water reservoir is another vital element. This tank stores the filtered water before it is dispensed. Regular cleaning of the reservoir is necessary to prevent bacterial growth. It is advisable to empty and sanitize the tank periodically using a mixture of vinegar and water.

Additionally, the dispenser lever or button is essential for operation. Ensuring it is clean and free from debris will facilitate smooth functioning. Lubricating moving parts, if applicable, can also help maintain ease of use.

Lastly, it is important to monitor the tubing that connects the water source to the dispenser. Inspect for any signs of wear, leaks, or blockages. Replacing worn-out or damaged tubing promptly will prevent water wastage and maintain proper pressure in the system.

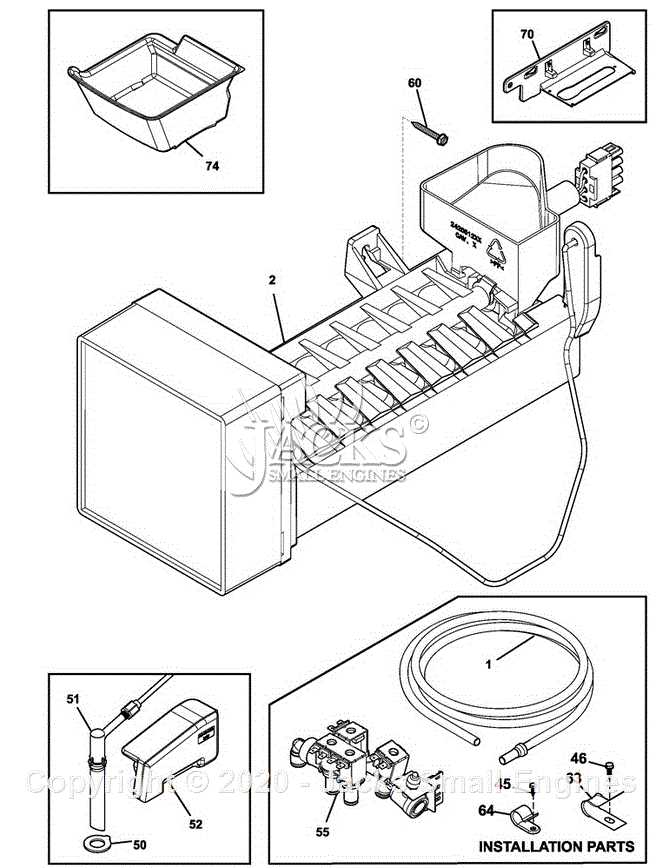

Fixing the Ice Maker in Your Frigidaire

If your ice maker is not functioning as it should, troubleshooting the issue can save you time and money. Whether it’s producing insufficient ice or none at all, identifying the root cause is essential for effective repairs. Here’s a guide to help you address common problems and restore your ice-making capabilities.

Common Issues and Solutions

- No Ice Production: Check if the ice maker is turned on. Ensure that the water supply is connected and the shut-off valve is open.

- Ice Blockages: Inspect for ice clogs in the mold or chute. Clear any obstructions gently to restore proper flow.

- Low Ice Production: If ice production is slow, examine the water filter. A clogged filter may reduce water flow.

Steps to Fix the Ice Maker

- Unplug the appliance and turn off the water supply.

- Remove the ice bin and inspect for any blockages or damage.

- Check the water line for kinks or leaks that may restrict flow.

- Replace the water filter if it’s old or clogged.

- Reconnect everything, plug the unit back in, and turn the water supply on.

By following these steps, you can troubleshoot and potentially resolve issues with your ice maker. Regular maintenance and prompt attention to problems will ensure consistent ice production for your household needs.

Interior Shelving and Door Seals: What to Know

Understanding the functionality and maintenance of internal storage surfaces and sealing mechanisms is crucial for optimal performance. These components play a significant role in preserving food freshness and energy efficiency. Regular inspection and upkeep can prevent common issues that arise from wear and tear.

When it comes to internal surfaces, consider the following aspects:

- Material Quality: Shelving is typically made from glass, plastic, or wire. Each material has its pros and cons regarding durability and ease of cleaning.

- Adjustability: Many shelves can be repositioned to accommodate various items. Understanding how to adjust them can enhance storage flexibility.

- Cleaning: Regular cleaning helps prevent odors and bacteria buildup. Use mild detergents to avoid damaging surfaces.

Door seals, also known as gaskets, are equally important. Here are some key points to keep in mind:

- Function: These seals create an airtight barrier, ensuring that cool air remains inside and preventing energy loss.

- Inspection: Regularly check for cracks or wear. A damaged seal can lead to increased energy consumption and compromised food safety.

- Replacement: If you notice a decline in performance, consider replacing the gaskets. This is a straightforward process that can significantly improve efficiency.

By paying attention to internal storage surfaces and sealing mechanisms, you can enhance the longevity and effectiveness of your unit, ensuring optimal functionality and energy savings.

Drainage System Maintenance for Frigidaire Units

Proper upkeep of the drainage system is essential for optimal functioning and longevity of your cooling appliance. Regular maintenance ensures that water can flow freely and prevents potential issues such as leaks and odors. By taking a few simple steps, you can keep the drainage system in good condition and avoid costly repairs.

Regular Cleaning and Inspection

Routine cleaning is crucial to prevent clogs that can lead to drainage problems. Check the drainage channels and remove any debris or buildup that might obstruct water flow. Use a mixture of warm water and vinegar to clean the drain line effectively. Additionally, inspect the drainage pan for cracks or damage that could cause leaks.

Checking for Blockages

It is important to periodically check for blockages in the drainage pathway. A blocked drain can lead to water pooling, which may cause mold and mildew growth. Use a flexible brush or a wet/dry vacuum to clear any obstructions. Regularly checking and maintaining the drainage system can help ensure a smooth operation.

Troubleshooting Common Refrigerator Issues

Addressing typical cooling appliance problems can save time and money. Understanding the most common issues and their solutions helps ensure your unit operates efficiently and lasts longer. This section outlines frequent concerns and provides practical steps to resolve them.

-

Temperature Fluctuations:

If your appliance isn’t maintaining a consistent temperature, check the following:

- Ensure the door seals are intact and close properly.

- Verify that the thermostat is set correctly.

- Inspect for any blockages in the air vents.

- Clean the condenser coils, as dust buildup can affect performance.

-

Unusual Noises:

Strange sounds may indicate an underlying issue. To address this:

- Check if the appliance is level; uneven surfaces can cause noise.

- Inspect the fan and compressor for any signs of malfunction.

- Listen for ice buildup in the evaporator, which may need defrosting.

-

Water Leaks:

Leaks can stem from various sources. Consider the following:

- Check the water supply line for damage.

- Ensure the drainage pan is correctly positioned.

- Look for clogged defrost drains that may need clearing.

-

Interior Light Not Working:

If the light doesn’t illuminate, investigate these possibilities:

- Replace the bulb if it has burned out.

- Check the door switch for proper operation.

- Inspect the wiring for any signs of damage.

By following these guidelines, you can identify and rectify common issues effectively, enhancing the longevity and efficiency of your cooling appliance.