Understanding the structure and organization of machinery is crucial for effective maintenance and operation. By breaking down each essential element, we can gain a clearer insight into how various parts function together, ensuring optimal performance. Familiarity with the placement and interaction of different components helps in addressing potential issues efficiently.

Identifying individual elements is the first step in maintaining reliability. Each segment plays a significant role in the overall operation, and knowing where each piece fits is vital for both regular upkeep and troubleshooting. Whether you’re looking to enhance functionality or simply keep things running smoothly, recognizing these elements ensures success.

For anyone seeking to improve their understanding of the device’s core elements, exploring a clear overview can be a valuable tool. It provides a foundation for better handling and managing, leading to longer-lasting, efficient use.

Generac GP3500iO Component Breakdown

The inner workings of this equipment consist of several key elements that come together to ensure smooth operation and reliability. Each piece plays a critical role in maintaining functionality, from the power source to the control systems.

Power Source Assembly includes crucial elements responsible for generating energy and delivering it to other components efficiently. The combination of these units ensures a consistent flow of electricity, enabling the machine to run seamlessly.

Cooling Mechanism is essential for maintaining optimal temperatures during operation. It helps dissipate heat, ensuring that the system functions without overheating, thereby extending the lifespan of various parts.

The Control Interface serves as the main point of interaction, allowing users to easily manage performance settings. This interface includes switches and indicators that help monitor and adjust the machine’s behavior according to specific needs.

Internal Mechanisms and Functionality

The internal workings of this type of machine are designed to convert fuel into usable power efficiently. The process begins with the ignition system, which starts the combustion within the engine, generating the necessary energy. This energy then flows through a series of mechanical components that regulate and distribute it to ensure smooth performance.

At the core, a robust engine structure powers the entire operation, with various systems working in harmony to manage airflow, fuel intake, and exhaust release. These elements function together to maintain optimal performance and prevent overheating, making sure the energy produced is steady and reliable for different applications.

Engine Parts Overview and Structure

The design of the engine is centered around a well-coordinated system of interconnected components. Each element plays a crucial role in ensuring the smooth operation and efficiency of the machine. Understanding the arrangement and interaction of these elements provides valuable insights into the overall functionality of the system. This section outlines the essential components, focusing on their roles and structural relationships.

| Component | Function |

|---|---|

| Cylinder | Houses the combustion process, generating power for movement. |

| Piston | Moves within the cylinder to convert fuel energy into mechanical force. |

| Crankshaft | Transforms the linear motion of the piston into rotational energy. |

| Valves | Regulate the flow of air and fuel into the cylinder and exhaust out. |

| Spark Plug | Ignites the air-fuel mixture to start the combustion process. |

Exploring the Control Panel Layout

The control panel is designed to offer an intuitive and accessible interface for managing the essential features of the equipment. Understanding the placement and function of each component on the panel allows for smooth operation and quick adjustments.

- Power Switch: The primary control for turning the system on or off. It is centrally located for easy access.

- Indicator Lights: Visual indicators that provide real-time feedback on the operational status. These are typically aligned near the power switch.

- Output Connections: Ports and sockets for connecting external devices. These are arranged to minimize clutter and ensure straightforward connectivity.

- Reset Button: A dedicated control for resetting the system in case of an overload or malfunction, placed prominently for quick use.

- Fuse Holders: Protective components that prevent damage by cutting off power during electrical faults, easily accessible for maintenance.

Fuel System Parts Identification

The fuel system plays a crucial role in ensuring the smooth operation of any power equipment. Understanding how different components work together is key to maintaining efficient fuel delivery and engine performance. Each element, from the storage tank to the lines and filters, contributes to the overall process, ensuring that fuel reaches the engine without disruption.

Fuel tank serves as the main reservoir, storing the necessary supply. Fuel lines transport the liquid from the tank to other sections, while various filters ensure the purity of the fuel, keeping contaminants out. Proper connections and seals prevent leaks and maintain pressure, allowing the system to function efficiently.

Exhaust and Cooling System Diagram

The exhaust and cooling mechanisms play a crucial role in maintaining the efficiency and longevity of power generation equipment. Understanding the layout and interaction of these components is essential for effective maintenance and operation. This section provides an overview of the essential parts involved in the exhaust and cooling systems, highlighting their functions and interconnections.

Key Components of the Exhaust System

The exhaust assembly comprises several vital elements designed to direct harmful gases away from the engine. This includes the manifold, which collects gases from multiple cylinders, and the muffler, which reduces noise levels while expelling gases safely. Additionally, heat shields may be utilized to protect surrounding parts from excessive temperatures, ensuring optimal performance.

Cooling Mechanism Overview

The cooling system is engineered to regulate the engine’s temperature and prevent overheating. Central to this system are the coolant passages, which circulate a fluid to absorb heat from the engine. The radiator facilitates heat dissipation, while fans aid airflow, further enhancing the cooling efficiency. Regular inspection and maintenance of these components are crucial to ensure the smooth operation of the equipment.

Power Generation and Output Components

In the realm of energy production, the efficiency and reliability of power systems heavily depend on their generation and output elements. These components play a crucial role in converting various energy sources into usable electrical power, ensuring a seamless supply to meet diverse demands. Understanding the functionality and interconnections of these parts is essential for maintaining optimal performance.

Energy Conversion Mechanisms are at the core of any power generation setup. They facilitate the transformation of mechanical energy into electrical energy, which is fundamental for various applications. Different types of engines or turbines are commonly employed to harness kinetic energy from fuels or natural resources, leading to electricity generation.

Output Systems are equally important, as they dictate how generated power is delivered to the end-users. This involves the use of inverters and transformers, which convert and regulate voltage levels to ensure compatibility with household or industrial requirements. Proper configuration of these systems enhances overall efficiency and safety during energy distribution.

Moreover, incorporating control units enables real-time monitoring and adjustments to the operational parameters, thereby maximizing output stability. By understanding the integral components involved in energy generation and output, users can make informed decisions regarding maintenance and upgrades, ultimately extending the lifespan of their equipment.

Maintenance and Replacement Parts Guide

Regular upkeep and timely substitutions are crucial for ensuring optimal performance and longevity of your equipment. This section provides essential insights into maintaining your machine and identifying necessary components for replacement, helping you keep everything running smoothly.

Essential Maintenance Tips

- Perform routine inspections to check for wear and tear.

- Keep the engine clean and free from debris.

- Change the oil as recommended by the manufacturer.

- Inspect air filters and replace them when necessary.

- Check spark plugs for damage and replace if needed.

Identifying Replacement Components

When it’s time to replace parts, knowing which components are available is key. Here are some common elements to consider:

- Fuel system components, including filters and hoses.

- Electrical elements such as starters and batteries.

- Cooling system components like fans and coolant reservoirs.

- Structural parts, including frames and mounts.

Always refer to the product manual for specific details about your equipment’s needs and consult with professionals for guidance on maintenance and replacements.

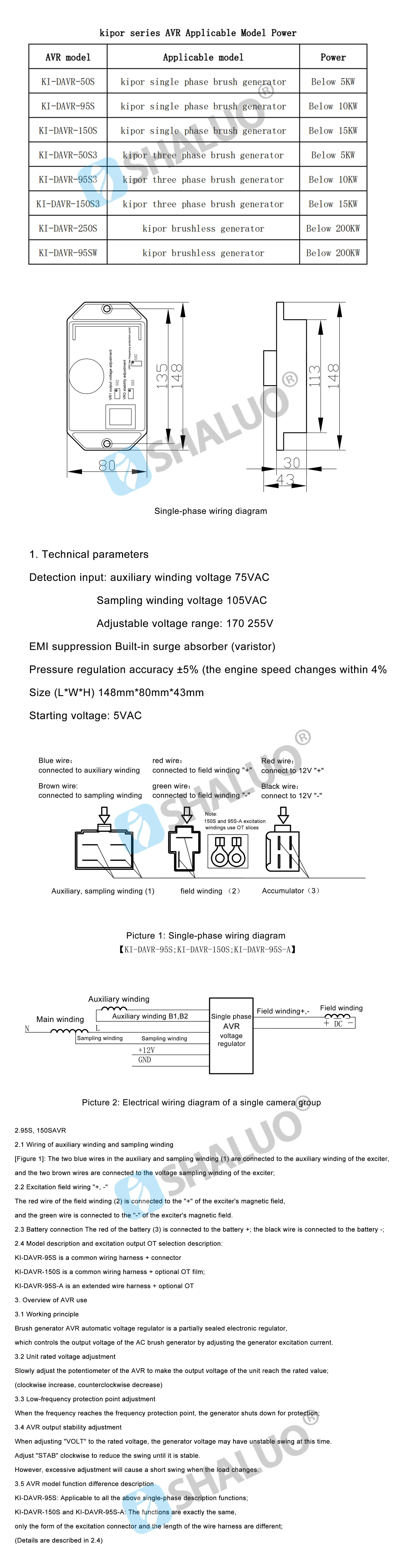

Electrical Connections and Wiring Map

This section provides a comprehensive overview of the electrical connections and wiring layout necessary for optimal functionality. Understanding the interconnections between various components is crucial for ensuring efficient operation and troubleshooting.

Below is a breakdown of key electrical connections:

- Power Input: The main power source connects to the unit, providing the necessary voltage for operation.

- Ground Connections: Proper grounding is essential for safety and performance, minimizing the risk of electrical faults.

- Control Wiring: This includes connections for switches and control panels that manage the operation of the unit.

- Output Wiring: Connections leading to external devices or systems that utilize the generated power.

For proper installation and maintenance, follow these guidelines:

- Ensure all connections are secure and free from corrosion.

- Refer to the specific wiring instructions for each component.

- Test the connections with a multimeter to verify proper voltage levels.

By adhering to these recommendations, users can maintain reliable electrical performance and enhance the longevity of the unit.

Chassis and Frame Components

The chassis and frame play a crucial role in providing stability and support for various devices. These structural elements not only contribute to the overall integrity but also influence the performance and mobility of the unit. Understanding the components that make up this framework is essential for effective maintenance and operation.

Key components of the chassis and frame include:

- Main Frame: This is the foundational structure that supports the entire system.

- Side Panels: These components enclose the sides, providing protection and enhancing aesthetics.

- Mounting Brackets: These are used to secure different parts to the main frame, ensuring stability during operation.

- Wheels: For portable models, wheels are essential for ease of movement and transport.

- Handles: These facilitate easy handling and maneuvering of the unit.

Regular inspection and maintenance of these elements are vital for ensuring optimal functionality and longevity of the entire system.

Common Parts for Repairs and Upgrades

When it comes to maintaining and enhancing equipment performance, understanding the essential components is crucial. These elements not only contribute to the overall functionality but also play a significant role in ensuring longevity. Whether for routine maintenance or upgrades, familiarizing oneself with commonly used items can lead to more efficient repairs and improvements.

Among the vital components, fuel tanks and carburetors stand out as frequent targets for replacement due to wear and tear. Additionally, filters, including air and oil types, are essential for keeping the system running smoothly and preventing damage from contaminants. Upgrading spark plugs can also enhance performance, providing better ignition and efficiency.

Moreover, batteries and voltage regulators are key parts that may require attention over time. Ensuring that these components are in optimal condition can significantly impact performance and reliability. By being aware of these common items, users can effectively plan for maintenance or enhancements, thereby maximizing the lifespan of their equipment.