The functionality of a robust power supply is largely influenced by its internal elements. Each component plays a vital role in ensuring the system operates efficiently and reliably. Gaining insights into these intricate parts not only enhances the comprehension of overall performance but also aids in maintenance and troubleshooting efforts.

When exploring the structure of these systems, it’s essential to identify how various elements interconnect. Each piece contributes to the seamless operation of energy generation, and understanding their roles is crucial for anyone involved in energy management. This knowledge empowers users to make informed decisions regarding repairs and upgrades.

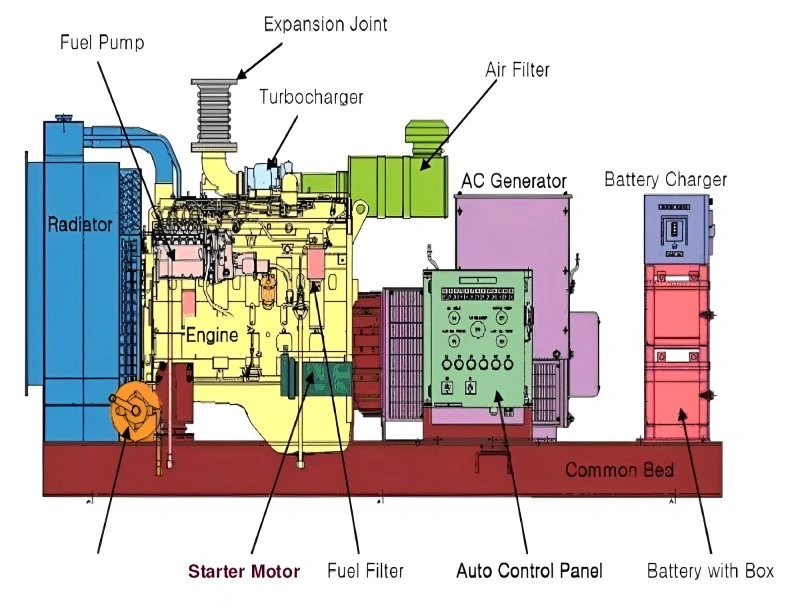

Moreover, a clear visual representation of these components can significantly aid in grasping their functions. Visual aids serve as effective tools for learning, allowing individuals to quickly reference specific elements and understand their contributions to the overall system. Whether for educational purposes or practical applications, having a clear outline of these components is invaluable.

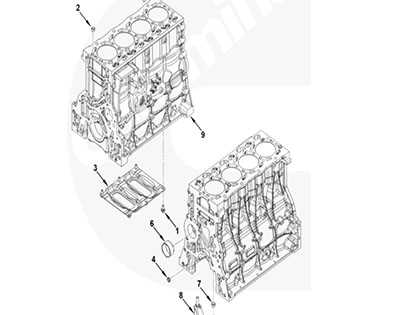

This section aims to provide a comprehensive understanding of the robust systems designed for reliable energy production. These engines are renowned for their efficiency and durability, playing a vital role in various applications where uninterrupted power is essential. Exploring the fundamental components of these power units reveals their intricate design and engineering excellence, which ensure optimal performance in demanding conditions.

Key Components of the Power Systems

The essential elements of these systems work in harmony to deliver reliable electricity. Each component contributes uniquely to the overall functionality, ensuring that the unit operates smoothly under various loads.

| Component Name | Description | Function |

|---|---|---|

| Engine Block | The main structure housing key mechanical parts. | Supports all components and contains the combustion chamber. |

| Fuel System | Includes pumps and injectors responsible for fuel delivery. | Ensures the correct amount of fuel is supplied for combustion. |

| Cooling System | Utilizes a radiator and coolant to manage engine temperatures. | Prevents overheating, maintaining optimal operating temperatures. |

| Electrical System | Comprises batteries and wiring to power essential electrical components. | Supplies energy to start the engine and operate electrical accessories. |

Maintenance and Care

Regular upkeep of these systems is crucial for longevity and reliability. Adhering to maintenance schedules and checking vital components can prevent unexpected failures and costly repairs.

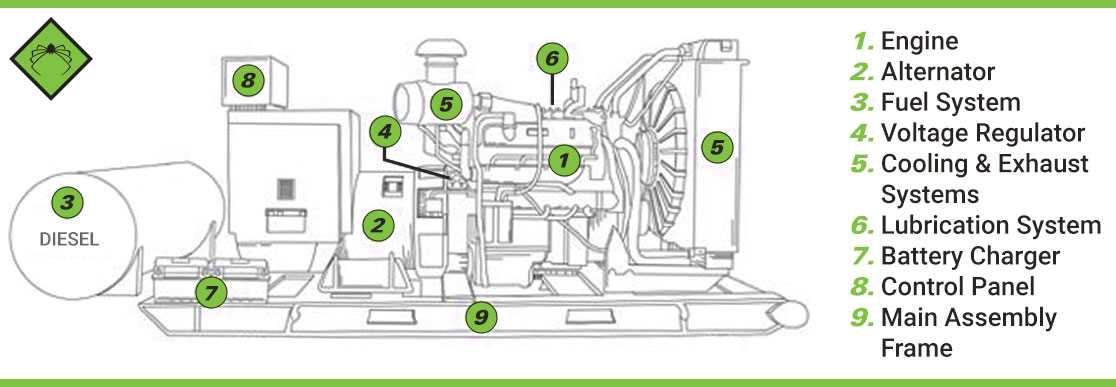

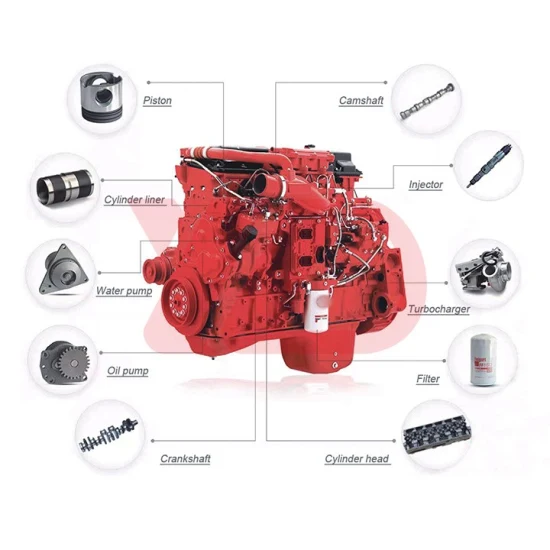

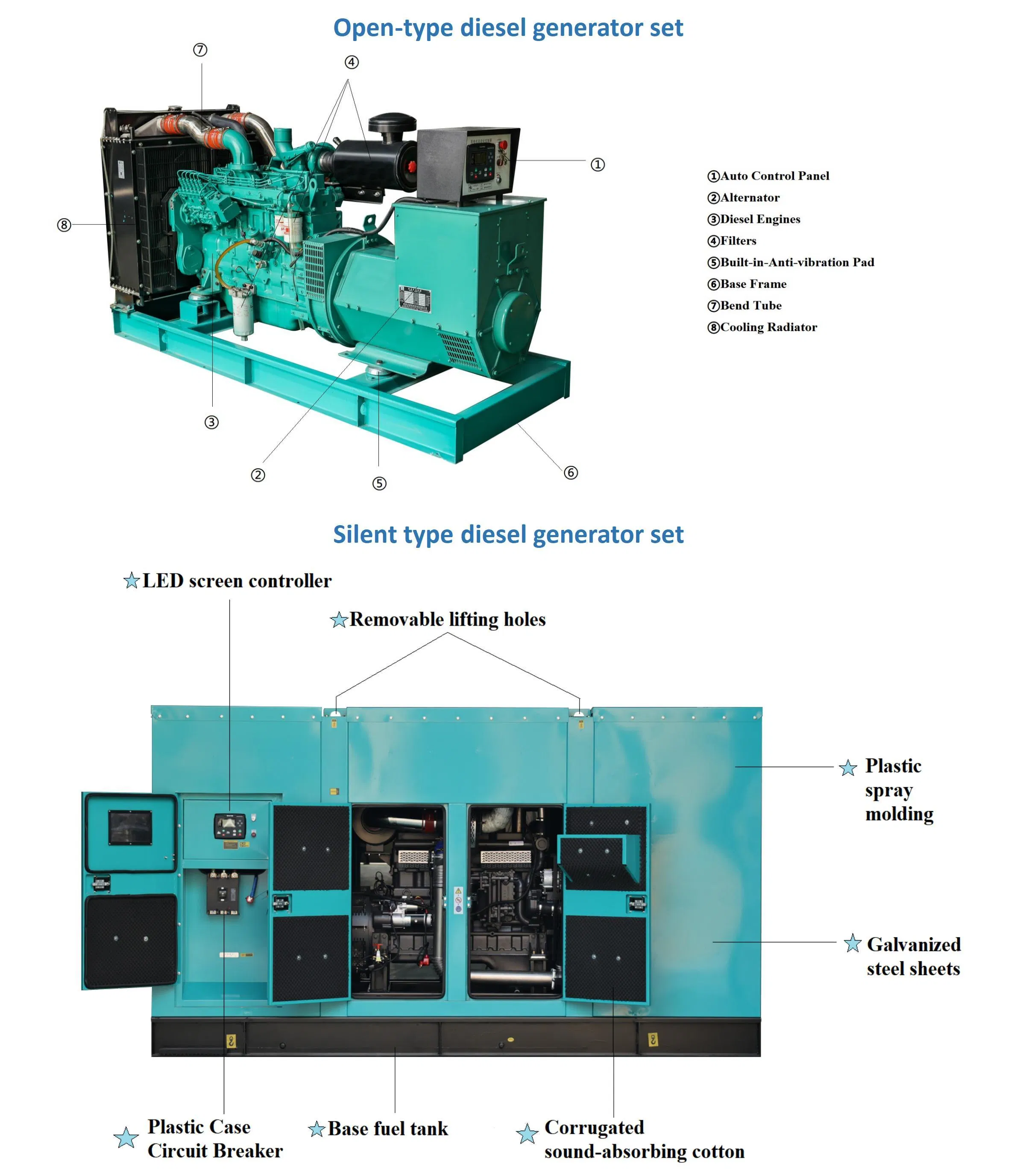

Key Components of Diesel Generators

Understanding the essential elements of power-producing machinery is crucial for effective operation and maintenance. Each component plays a significant role in ensuring efficiency, reliability, and longevity of the equipment.

Engine: The heart of the system, responsible for converting fuel into mechanical energy. Its design impacts overall performance and operational capabilities.

Alternator: This device transforms mechanical energy into electrical energy. Its efficiency is vital for optimizing power output and ensuring stable voltage levels.

Cooling System: Essential for maintaining optimal operating temperatures, preventing overheating, and ensuring the longevity of the internal mechanisms.

Fuel System: This includes tanks, pumps, and filters that deliver fuel to the engine. Proper management of this system ensures a steady supply and optimal combustion.

Control Panel: The interface for monitoring and managing the operation. It provides crucial data, such as voltage, frequency, and operating hours, allowing for timely adjustments and maintenance.

Exhaust System: Designed to safely expel gases produced during combustion. Effective management of emissions is crucial for compliance with environmental regulations.

Base Frame: The foundation that supports all components, providing stability and reducing vibrations during operation. A robust frame enhances the overall durability of the machinery.

Understanding Generator Part Functions

This section explores the various components that contribute to the efficient operation of power-producing machines. Each element plays a crucial role in ensuring that energy generation is reliable and effective, facilitating a seamless power supply for various applications.

Below are some of the essential components and their respective functions:

- Engine: The heart of the system, responsible for converting fuel into mechanical energy.

- Alternator: Converts mechanical energy into electrical energy, ensuring a steady power output.

- Control Panel: Acts as the brain, managing the system’s operations and providing vital information to the user.

- Fuel System: Delivers the necessary fuel to the engine for combustion, critical for generating energy.

- Cooling System: Maintains optimal operating temperatures, preventing overheating and ensuring longevity.

- Exhaust System: Safely channels harmful gases away from the unit, promoting a safer operating environment.

Each component must function harmoniously to achieve optimal performance. Understanding these roles can aid in maintenance and troubleshooting, ensuring sustained efficiency over time.

Common Issues and Solutions

Understanding the frequent challenges encountered in the operation of industrial power systems is crucial for maintaining optimal performance. Addressing these concerns effectively can enhance reliability and extend the lifespan of the equipment.

Frequent Challenges

Various obstacles may arise during the operation of these systems, impacting efficiency and functionality. Identifying these issues early allows for timely interventions and effective resolutions.

| Issue | Description | Solution |

|---|---|---|

| Overheating | Excessive temperatures can lead to damage and reduced efficiency. | Regularly check coolant levels and ensure proper airflow. |

| Fuel Contamination | Impurities in fuel can cause performance issues. | Implement routine fuel filtration and quality checks. |

| Electrical Failures | Malfunctions in the electrical system can disrupt operations. | Inspect wiring and connections regularly for wear and tear. |

| Excessive Vibration | Unusual vibrations can indicate misalignment or wear. | Conduct alignment checks and replace worn components as needed. |

Preventive Measures

Adopting preventive strategies can significantly reduce the likelihood of encountering these challenges. Regular maintenance and monitoring are essential for ensuring reliable operation and minimizing downtime.

Importance of Regular Maintenance

Consistent upkeep is crucial for ensuring optimal performance and longevity of any machinery. Regular checks and servicing help identify potential issues before they escalate, thus preventing costly repairs and downtime.

Benefits of Routine Upkeep

- Enhances reliability and efficiency of operations.

- Increases the lifespan of components.

- Ensures safety for operators and surroundings.

- Minimizes the risk of unexpected failures.

Key Maintenance Practices

- Conduct regular inspections to assess condition.

- Change fluids and filters as recommended.

- Monitor performance metrics to detect anomalies.

- Keep records of maintenance activities for future reference.

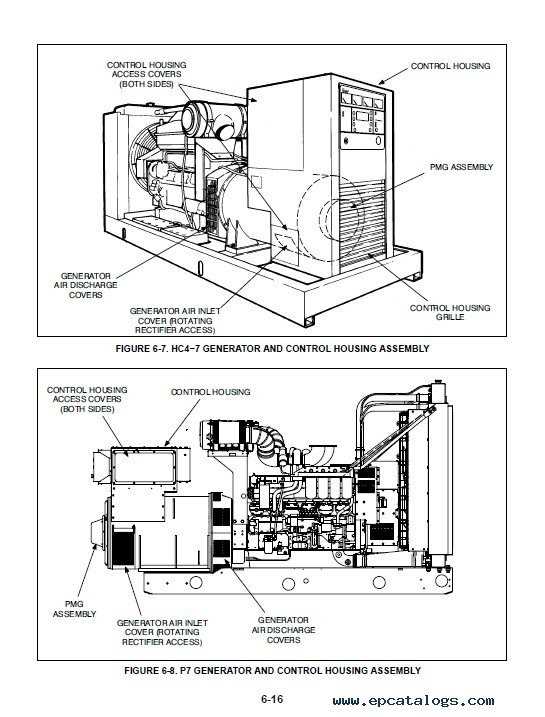

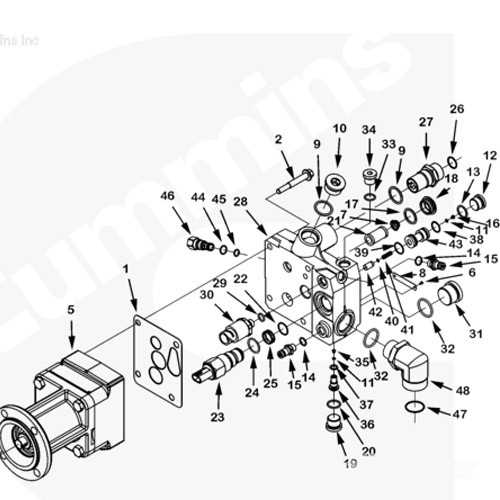

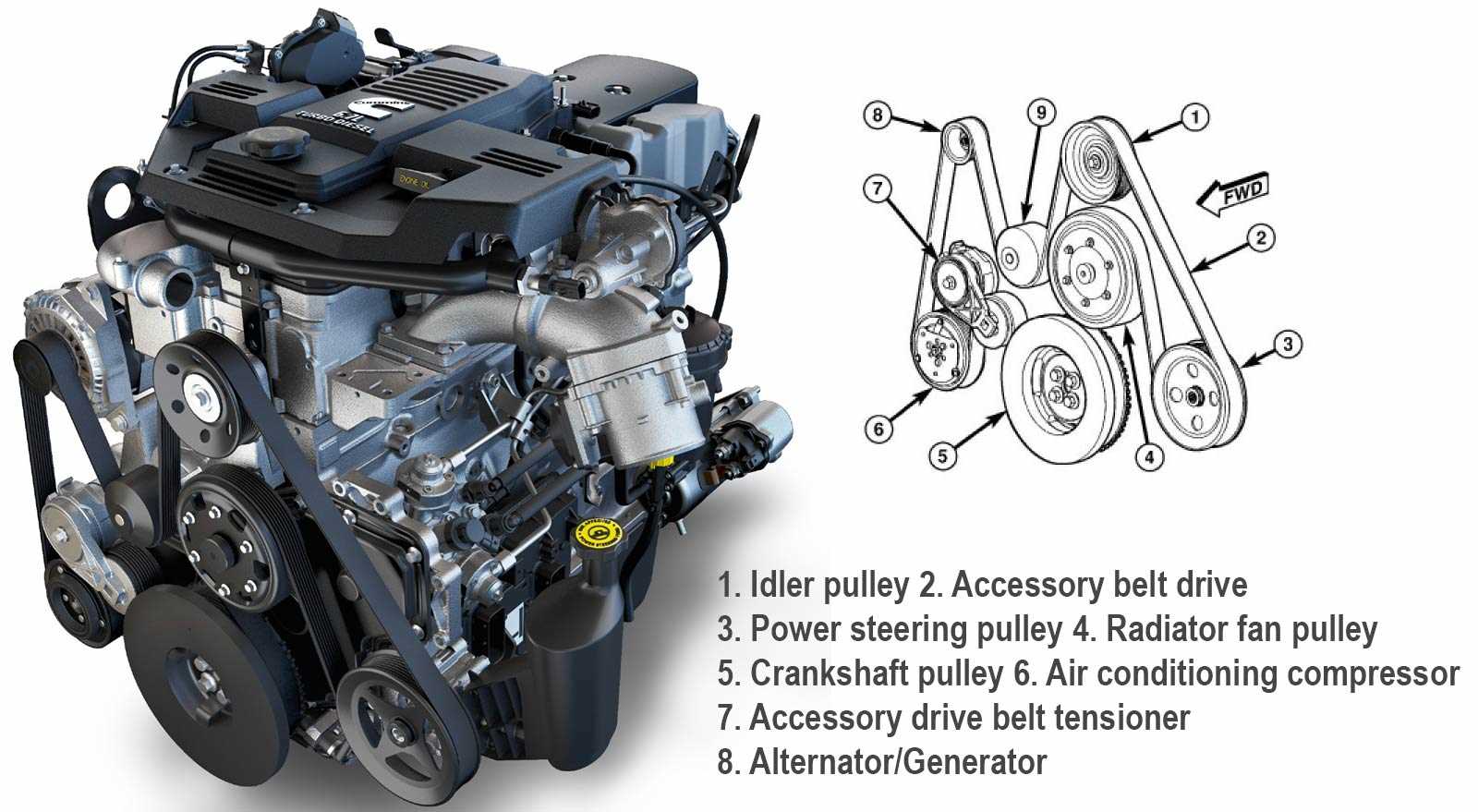

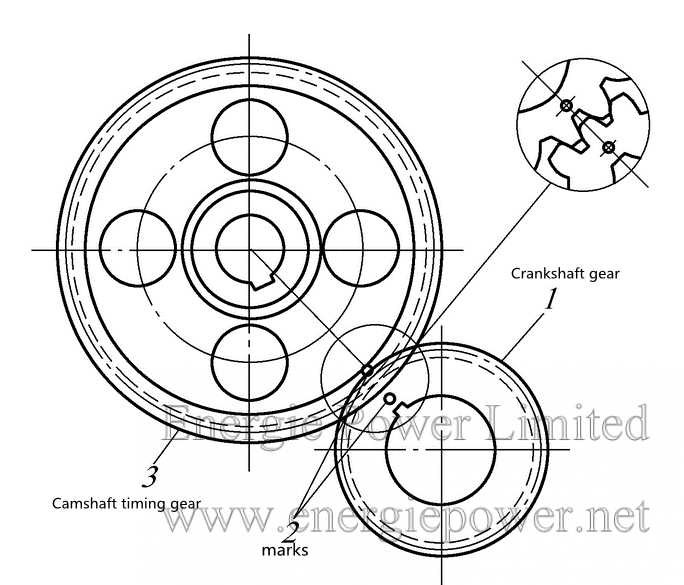

How to Read Parts Diagrams

Understanding technical illustrations can greatly enhance your ability to work with mechanical systems. These visual representations serve as essential tools for identifying components, understanding their relationships, and ensuring proper assembly or maintenance. Grasping the basics of these illustrations will enable you to navigate complex machinery more efficiently.

Identifying Symbols and Notations

Every technical representation utilizes a set of symbols and annotations that convey specific information. Familiarizing yourself with these can simplify the interpretation process:

- Shapes: Different geometrical forms often represent various elements. For example, circles may denote moving parts, while squares could indicate fixed components.

- Lines: Solid lines typically represent physical connections, whereas dashed lines might indicate hidden or conceptual relationships.

- Labels: Identifiers next to components provide crucial details, such as part numbers, names, or specifications.

Understanding Layout and Flow

The arrangement of components within the illustration can reveal their functional relationships:

- Flow Direction: Look for arrows or indicators showing the flow of energy or materials, guiding you on how the system operates.

- Groupings: Components that work together are often clustered. Recognizing these groups can help in troubleshooting and assembly tasks.

- Color Coding: Some illustrations may use color to differentiate between types of components, such as electrical versus mechanical parts.

By applying these techniques, you can enhance your proficiency in interpreting technical illustrations, leading to more effective maintenance and repair efforts.

Identifying Replacement Parts

When it comes to maintaining machinery, recognizing the components that require substitution is crucial for ensuring optimal performance. This process involves a thorough understanding of each element’s functionality and how they contribute to the overall operation of the equipment. By familiarizing oneself with various segments and their specifications, one can easily pinpoint which items need attention.

Visual Inspection Techniques

Conducting a visual examination of the equipment is the first step in identifying necessary replacements. Look for signs of wear, such as cracks, leaks, or discoloration. These indicators often suggest that a component has reached the end of its lifecycle and should be replaced. Utilizing reference materials, such as schematics or online resources, can further aid in recognizing components that may be malfunctioning.

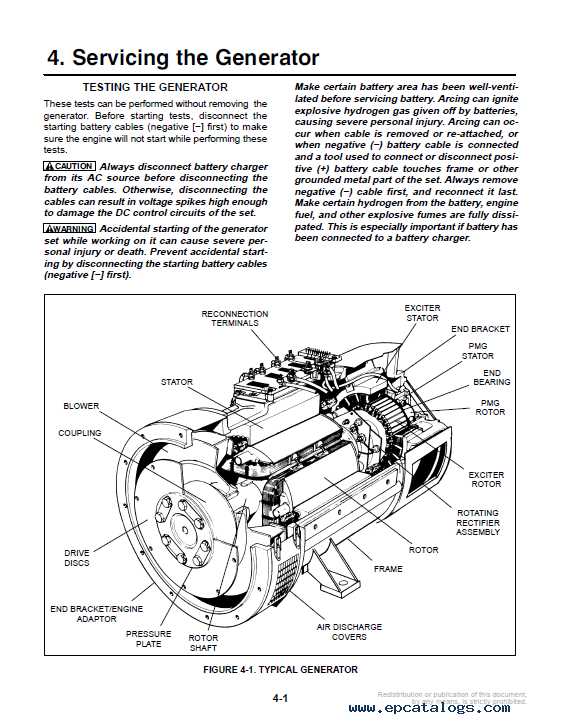

Consulting Technical Manuals

Technical manuals provide valuable insights into the specifications and compatibility of various components. These documents typically include part numbers, descriptions, and installation instructions, which are essential for acquiring the correct items. Always refer to the appropriate manual when considering replacements to ensure that you obtain the right match for your specific model.

Utilizing Service Manuals Effectively

Understanding the nuances of maintenance literature can significantly enhance the efficiency and longevity of machinery. These documents provide crucial insights, helping users navigate troubleshooting, repair, and upkeep procedures with confidence.

Key Components of Service Manuals

- Specifications: Detailed information regarding technical requirements and configurations.

- Illustrations: Diagrams and images that visually represent components and assemblies.

- Procedures: Step-by-step guidelines for performing maintenance and repair tasks.

- Safety Guidelines: Important precautions and safety measures to follow during servicing.

Best Practices for Effective Use

- Familiarize yourself with the layout to locate essential sections quickly.

- Utilize the index and table of contents for efficient navigation.

- Refer to troubleshooting sections for common issues and their solutions.

- Regularly update your manuals to ensure you have the latest information.

Comparative Analysis of Models

This section explores the distinctions and similarities among various designs, emphasizing performance, efficiency, and application suitability. By analyzing specifications and features, one can determine the most appropriate choice for specific operational needs.

Performance Metrics

When evaluating different configurations, performance metrics play a crucial role. Factors such as output capacity, fuel consumption, and operational longevity are essential in understanding the overall effectiveness. Variances in these areas may influence the decision-making process, leading to a more informed selection based on individual requirements.

Application Versatility

Each model possesses unique characteristics that determine its adaptability for diverse settings. Understanding how specific configurations respond under varying environmental conditions is vital. This versatility ensures that users can select a system tailored to their particular demands, enhancing productivity and operational success.

Safety Precautions for Repairs

When conducting maintenance or repair work on machinery, adhering to safety guidelines is paramount. These measures ensure the protection of personnel and equipment, reducing the risk of accidents or injuries during the process.

First and foremost, always disconnect the power source before beginning any repairs. This precaution helps prevent electrical shock and unintended machine activation. Additionally, wear appropriate personal protective equipment (PPE), such as gloves, goggles, and hard hats, to shield against potential hazards.

Furthermore, familiarize yourself with the specific equipment being serviced. Understanding the operational aspects and potential risks associated with each component is crucial. Ensure that your workspace is clean and organized, minimizing clutter that could lead to slips or falls.

Lastly, follow the manufacturer’s guidelines and use the correct tools for the job. Using improper tools can result in equipment damage or personal injury. By prioritizing safety, you create a secure environment for effective maintenance and repair activities.