In the realm of agricultural equipment, comprehending the various elements that contribute to operational efficiency is essential for effective maintenance and repair. This section delves into the intricate relationships between the different components of a specific type of cutting apparatus, highlighting their functions and interactions.

By analyzing the layout and arrangement of these components, users can better appreciate how each part plays a crucial role in the overall performance of the machinery. A well-structured overview facilitates not only troubleshooting but also enhances the understanding of how to optimize the equipment for various agricultural tasks.

Furthermore, recognizing the importance of each element can lead to more informed decisions regarding repairs and upgrades. This knowledge empowers operators to maintain their equipment effectively, ensuring longevity and reliability in their operations.

This section provides a comprehensive look at the essential elements that make up a typical mowing machine. Understanding these components is crucial for maintenance, repairs, and overall functionality. Each part plays a significant role in ensuring efficiency and effectiveness during operation.

Key Components and Their Functions

Below is a table summarizing the main components along with their respective functions:

| Component | Function |

|---|---|

| Cutter Bar | Responsible for cutting grass and hay. |

| Drive System | Transfers power from the engine to the cutting mechanism. |

| Auger | Helps in gathering and transporting cut material. |

| Hitch | Connects the machine to the tractor for towing. |

Maintenance Tips

Regular upkeep of these components ensures optimal performance and longevity of the machine. It is advisable to check for wear and tear, lubricate moving parts, and replace any damaged elements promptly.

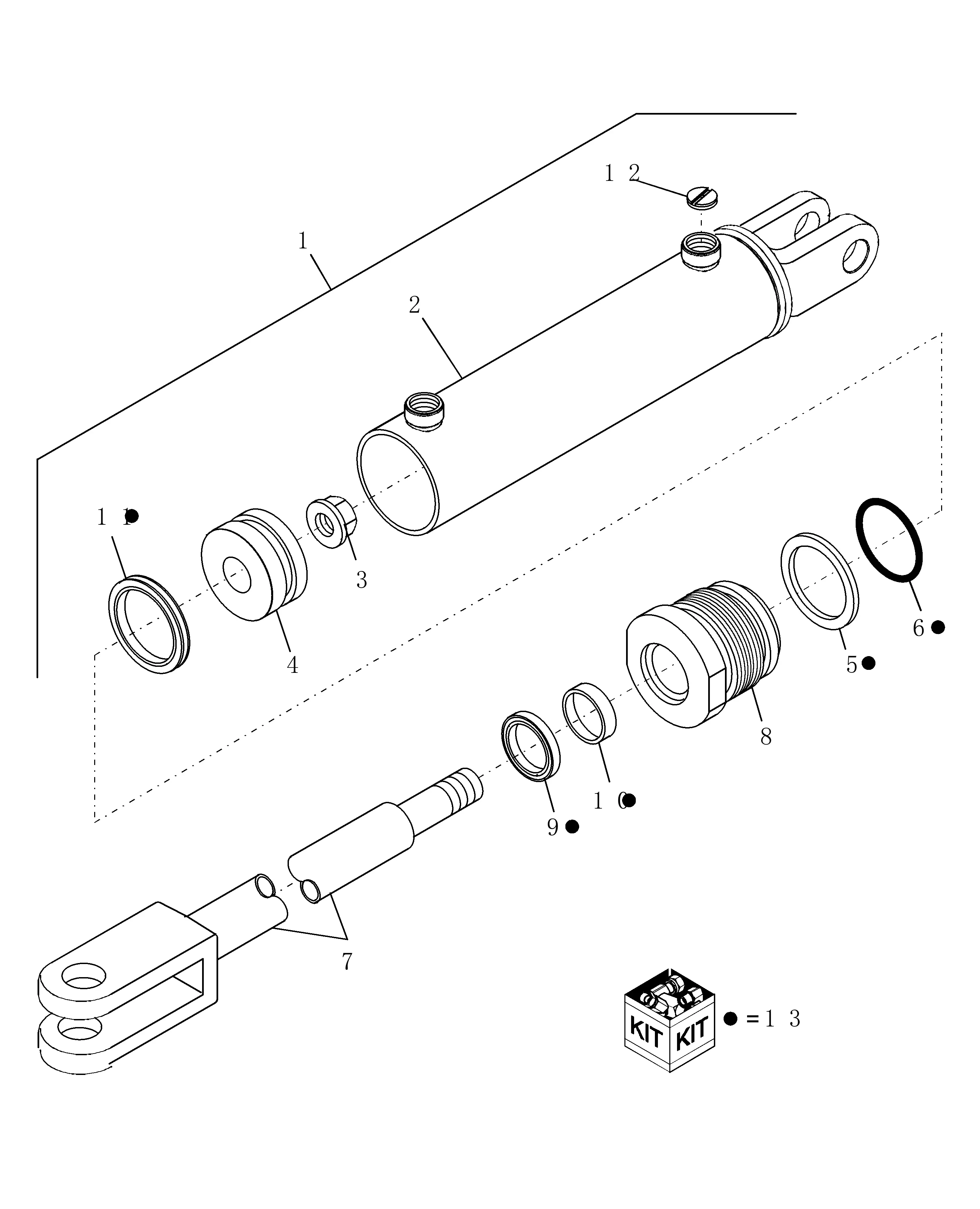

Functionality of Cutting Mechanism

The cutting mechanism plays a vital role in the efficiency of agricultural equipment designed for harvesting forage. This system is engineered to facilitate the swift and precise severing of crops, ensuring optimal collection and processing. By employing a series of sharp blades and innovative designs, it enables effective operation even in challenging conditions.

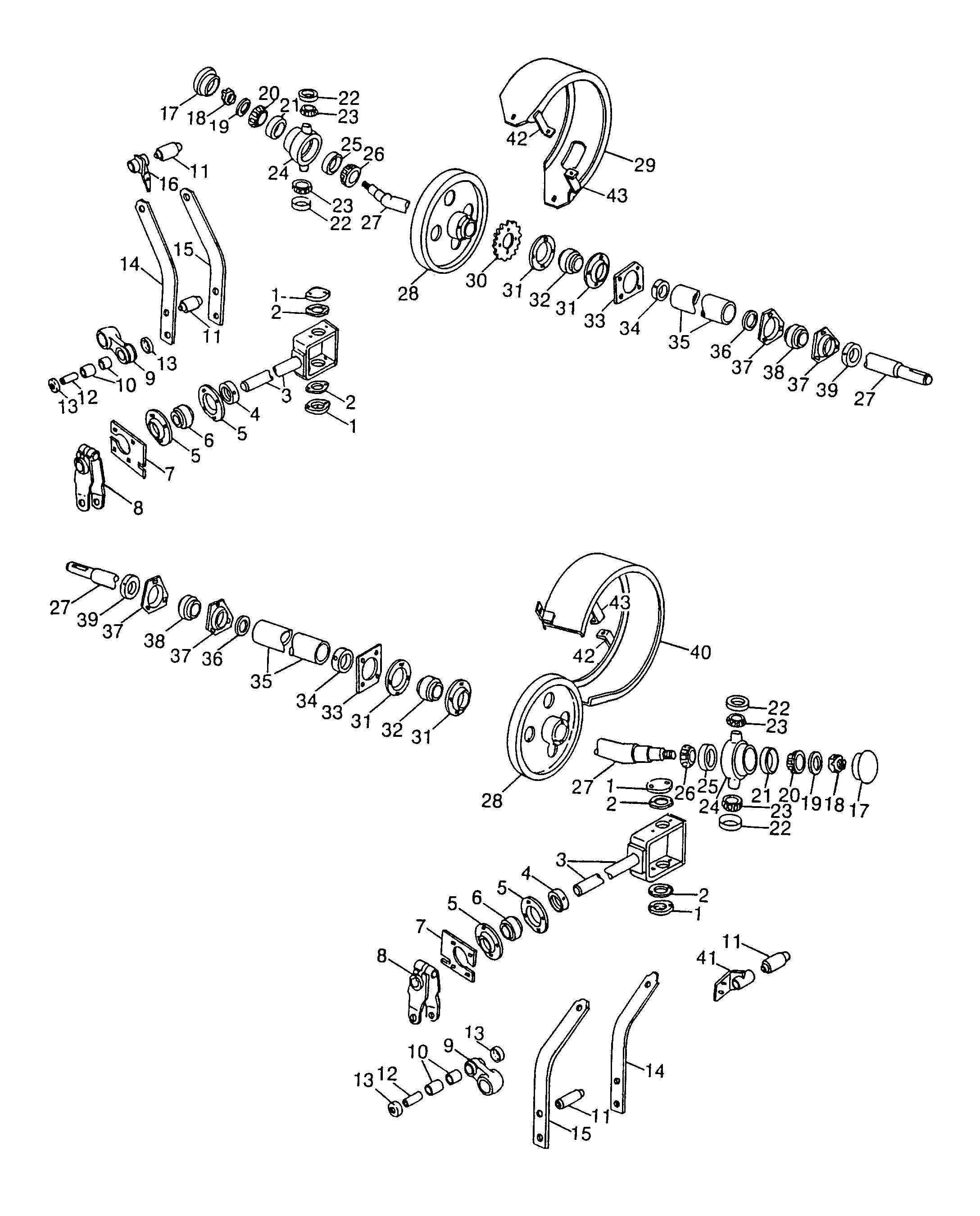

Components of the Cutting System

The assembly comprises several essential components, including sickle bars, guard plates, and drive mechanisms. The sickle bar is responsible for the actual cutting action, utilizing its sharp blades to slice through the material. Guard plates serve to stabilize the blades and protect them during operation, while the drive mechanism ensures that the cutting elements move seamlessly, enhancing productivity.

Operational Efficiency

Efficient cutting not only increases yield but also reduces the strain on the machine. A well-designed cutting system minimizes crop loss by ensuring a clean cut, which is crucial for maintaining the quality of harvested forage. Furthermore, regular maintenance and adjustment of the cutting components are necessary to preserve optimal performance and prolong the equipment’s lifespan.

Maintenance Tips for Haybine Parts

Regular upkeep of your mowing equipment is essential for optimal performance and longevity. Proper maintenance not only enhances efficiency but also minimizes the likelihood of unexpected breakdowns. By following a few key practices, you can ensure your machinery operates smoothly throughout its lifecycle.

Routine Inspections

Conduct frequent examinations of all components to identify any wear or damage. Focus on checking belts, blades, and bearings. Addressing issues early can prevent larger problems down the line.

Lubrication and Cleaning

Keeping your equipment clean and well-lubricated is vital. Remove debris and dirt after each use, and apply appropriate lubricants to moving parts. This practice not only extends the life of the machine but also enhances its efficiency.

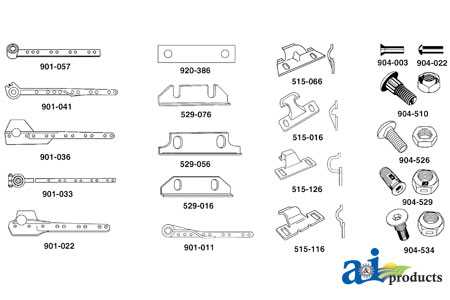

Identifying Common Replacement Parts

Understanding the essential components of agricultural machinery is crucial for maintaining optimal performance. Various elements may require attention over time, leading to the need for timely replacements to ensure efficient operation. Recognizing these components can aid in efficient maintenance and reduce downtime.

Key Components to Monitor

Regularly inspecting critical components such as belts, blades, and rollers is essential. These parts are subject to wear and tear due to constant use and environmental factors. Staying informed about their condition can prevent unexpected failures and costly repairs.

Common Signs of Wear

Identifying symptoms of wear, like unusual noises or reduced performance, can signal the need for replacements. For instance, frayed belts or damaged blades can significantly impact functionality. Addressing these issues promptly ensures the machinery operates smoothly and efficiently.

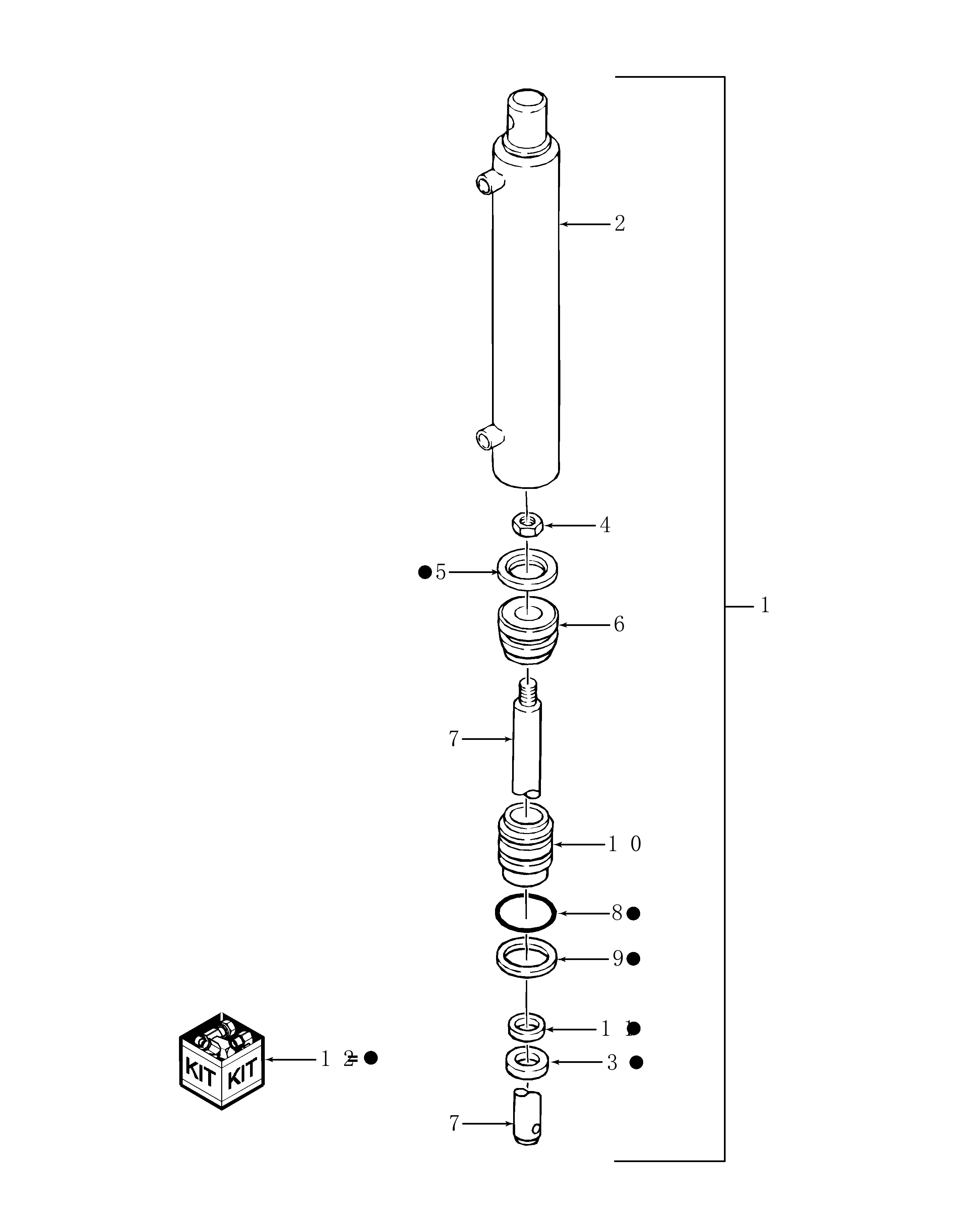

Understanding the Gearbox Assembly

The gearbox assembly plays a crucial role in the efficient operation of agricultural machinery. It is responsible for transmitting power and ensuring that various components function smoothly. A thorough understanding of its structure and functionality is essential for effective maintenance and troubleshooting.

Key Components of the Gearbox

Several vital parts contribute to the overall efficiency of the gearbox assembly:

- Gears: These are critical for changing the speed and torque of the machinery.

- Shafts: These components connect different gears and transmit power throughout the assembly.

- Bearings: They reduce friction between moving parts, enhancing the longevity of the gearbox.

- Casing: This outer shell protects the internal components from dirt and damage.

Maintenance Tips

To ensure the gearbox operates effectively, consider the following maintenance practices:

- Regularly check for fluid levels and top up as needed.

- Inspect gears for wear or damage.

- Ensure seals are intact to prevent leaks.

- Clean the casing to remove any accumulated debris.

Common Issues with Haybine Parts

Machinery used for cutting and conditioning grass can experience various challenges over time. Understanding these frequent problems is essential for maintaining efficiency and prolonging the lifespan of the equipment. Operators should be aware of signs indicating potential issues to address them promptly.

Wear and Tear

Continuous operation often leads to wear on components. This can result in decreased performance and efficiency. Regular inspections can help identify parts that may need replacement or adjustment to ensure optimal functionality.

Improper Alignment

Misalignment of machinery components can cause excessive strain on moving parts. This misalignment may lead to uneven cutting and increased energy consumption. It is crucial to routinely check the alignment to avoid these complications and maintain a smooth operation.

Safety Features in Haybine Design

The design of modern mowing equipment incorporates various safety mechanisms to protect operators and ensure efficient operation. These features are essential in minimizing risks during use and maintenance, ultimately enhancing user confidence and productivity.

Protective Shields and Guards

One of the primary safety elements in such machinery is the inclusion of protective shields and guards. These barriers help to prevent accidental contact with moving parts, reducing the likelihood of injury. Proper placement of these features is crucial, as they should cover areas where operators might inadvertently reach during operation.

Emergency Shut-off Mechanisms

Another vital aspect is the integration of emergency shut-off mechanisms. These systems allow the operator to quickly halt the machine’s operation in case of an emergency, such as equipment malfunction or personal injury. Quick access to these controls is essential for effective safety management, ensuring that operators can respond swiftly to potential hazards.

Benefits of Using Original Parts

Utilizing authentic components for machinery ensures optimal performance and longevity. These elements are specifically designed to work seamlessly with the equipment, leading to improved functionality and reduced wear and tear over time.

Enhanced Reliability

Original components are manufactured to meet strict quality standards, resulting in greater dependability. This reliability minimizes the risk of breakdowns, allowing operators to focus on productivity rather than maintenance issues.

Cost-Effectiveness

Although authentic components may have a higher initial cost, their durability often translates into lower long-term expenses. Investing in quality materials can lead to fewer repairs and replacements, ultimately saving money in the future.

| Advantage | Description |

|---|---|

| Quality Assurance | Manufactured to high standards for durability. |

| Compatibility | Designed to fit perfectly with existing machinery. |

| Long-Term Savings | Reduced maintenance and replacement costs over time. |

Upgrading Your Haybine Equipment

Enhancing your harvesting machinery can significantly improve efficiency and performance. By integrating modern components and technologies, you can streamline operations and reduce downtime during the busy harvesting season.

Assessing Current Equipment: Begin by evaluating the existing machinery to identify areas for improvement. Look for outdated parts that may be affecting productivity and consider upgrading to more advanced alternatives.

Investing in Quality Components: Choose high-quality replacements that offer durability and reliability. Upgrading to better machinery can lead to improved functionality and extended lifespan, ultimately saving money in the long run.

Implementing New Technologies: Incorporate cutting-edge innovations such as precision controls and enhanced safety features. These advancements can enhance user experience and make operations smoother.

Regular maintenance and timely upgrades will ensure your equipment remains competitive and efficient, ready to tackle the challenges of the harvesting process.

Finding Reliable Parts Suppliers

Identifying trustworthy sources for components is crucial for maintaining equipment efficiency. Ensuring quality and reliability can significantly impact performance and longevity.

Researching Suppliers

Begin by gathering information on potential vendors. Utilize the following strategies:

- Online Reviews: Check customer feedback on platforms like Google and Yelp.

- Industry Forums: Engage with communities to learn from others’ experiences.

- Trade Shows: Attend events to meet suppliers and evaluate their offerings firsthand.

Evaluating Quality and Service

Once you have a list of candidates, assess their quality and service standards:

- Product Warranty: Inquire about guarantees on their offerings.

- Return Policy: Ensure they have a fair policy for unsatisfactory items.

- Customer Support: Test their responsiveness to inquiries and issues.