For anyone working in the agricultural sector, maintaining machinery is a critical aspect of ensuring efficient operations. The equipment used in the field requires regular upkeep and a deep understanding of its individual elements. This allows for quick repairs, seamless performance, and the ability to minimize downtime during the busiest times of the year.

Identifying and familiarizing yourself with the specific elements of your field machinery can significantly improve productivity. Knowing how these components work together helps to maintain the functionality of the tool over long periods of time. In the next section, we will explore how these elements are structured and the role each one plays in the overall functionality of the machinery.

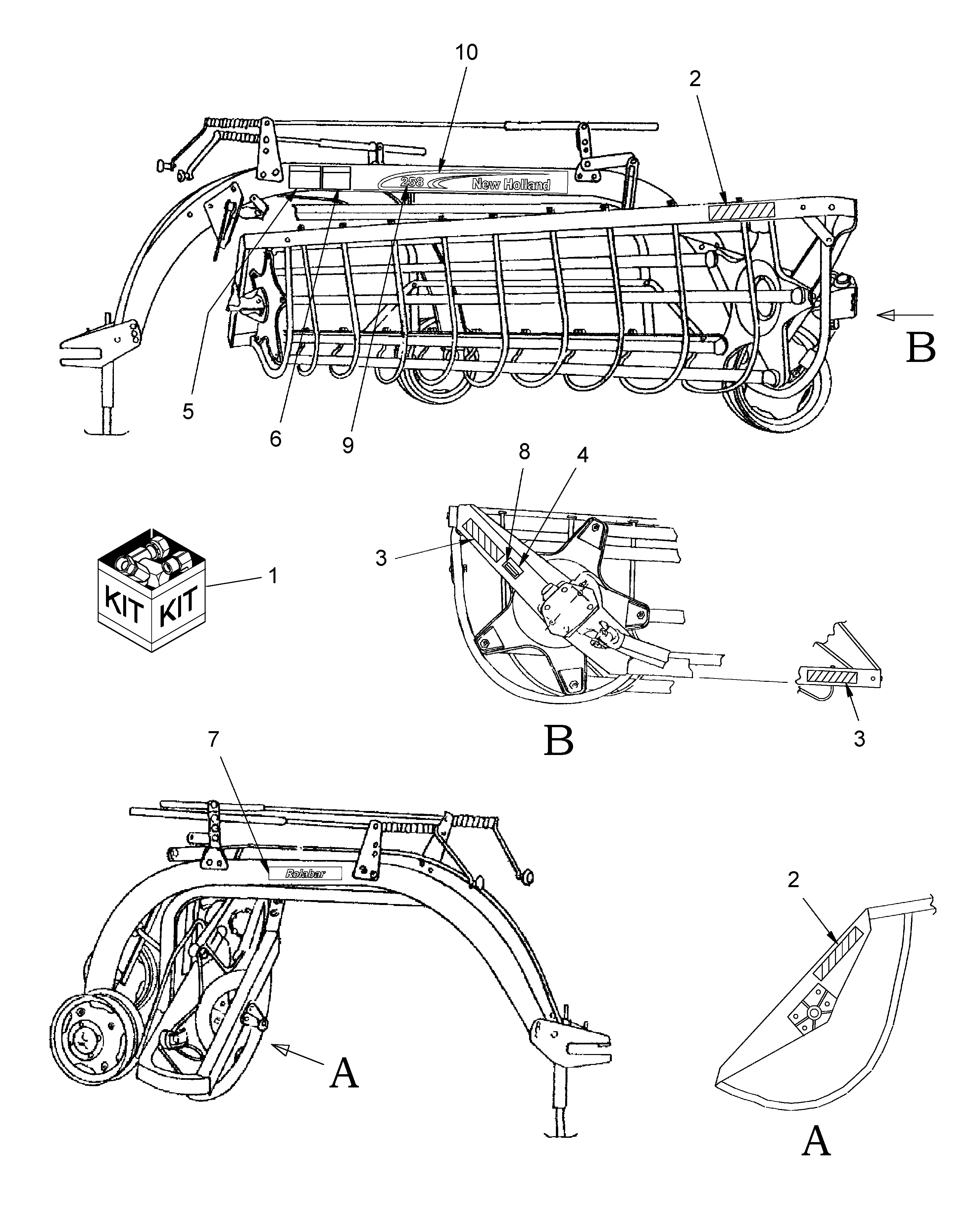

Overview of the New Holland 258 Hay Rake

This agricultural tool is designed to efficiently gather cut vegetation into rows for easier collection. Known for its reliability and smooth operation, it has been a staple for many farmers. The mechanism is engineered to handle large amounts of material with precision, ensuring consistent and clean results during each use.

Key Features

- Durable frame for long-lasting use in various field conditions

- Adjustable settings to accommodate different types of crops

- Simple maintenance with accessible components

Performance Benefits

- Increases efficiency by reducing time spent on gathering vegetation

- Prevents unnecessary damage to crops while raking

- Adaptable to diverse terrain for consistent output

Key Components of the 258 Model

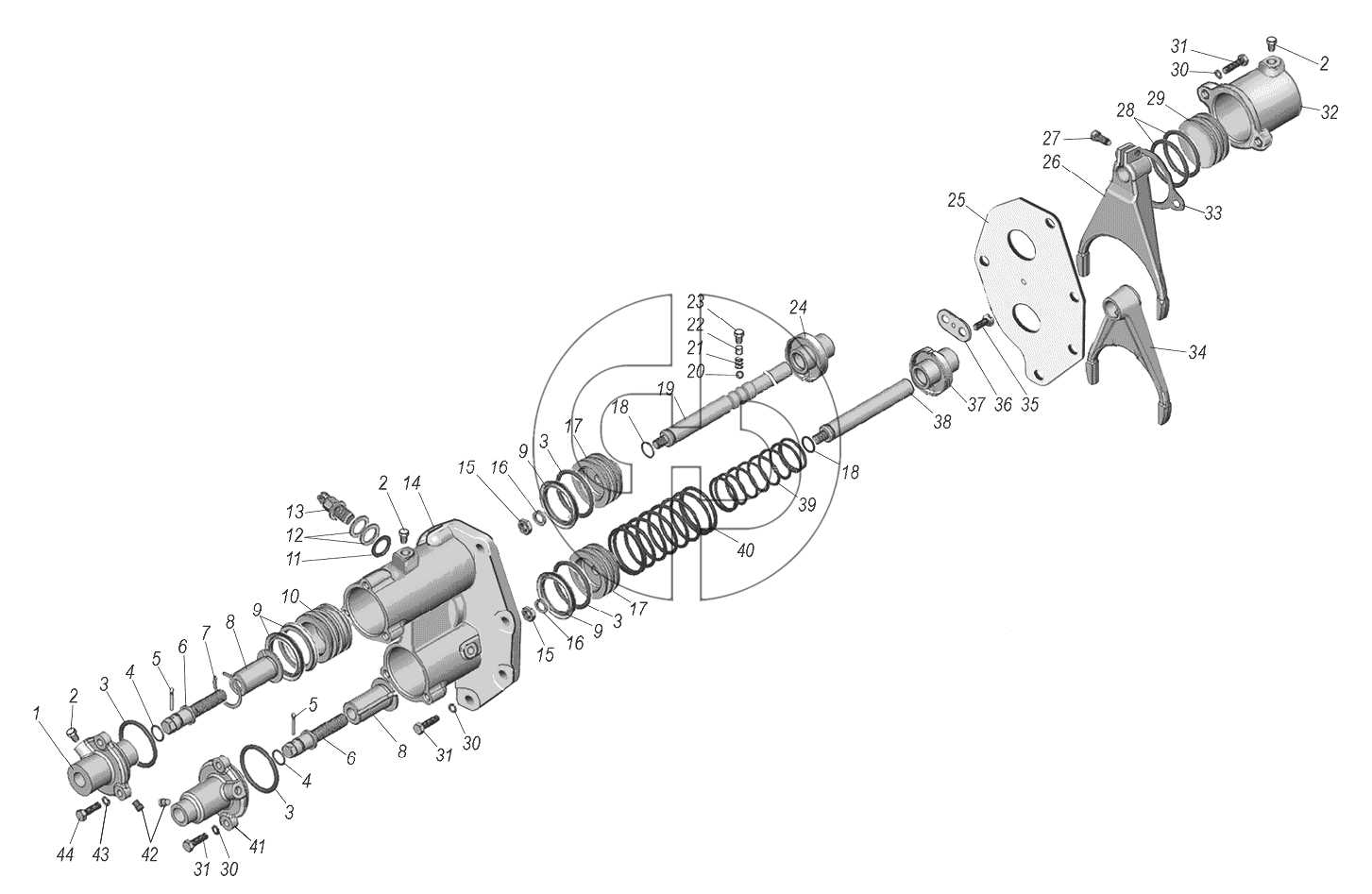

The machinery in question relies on a combination of essential parts that work together to ensure efficient performance in field operations. These components, each designed for specific tasks, contribute to the smooth functioning and durability of the equipment. Understanding the structure and role of these elements helps in proper maintenance and troubleshooting.

One of the crucial elements is the frame, which provides stability and support. Another vital part is the wheel assembly, responsible for mobility and control. Additionally, the mechanical arm plays a significant role in the overall movement of the system, allowing it to operate effectively on different terrains. These parts, along with other key features, work in unison to achieve the desired results during operation.

Understanding the Hay Rake Mechanism

The operation of a mechanical tool for gathering crop material requires an understanding of its core structure. The tool’s movement, driven by both rotational and linear forces, ensures efficient collection and arrangement of agricultural materials. Recognizing how different components work together to form an organized system is essential for maximizing performance and ensuring longevity.

Core Functions of the Mechanism

The primary function of this type of equipment is to collect and arrange loose crop material into a manageable formation. It does so by utilizing a rotating assembly that systematically sweeps the ground while maintaining consistent pressure. This action reduces time and labor in managing harvested materials and ensures that they are prepared for further processing or storage.

Key Components and Their Roles

| Component | Function | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Rotating Teeth | Engage with

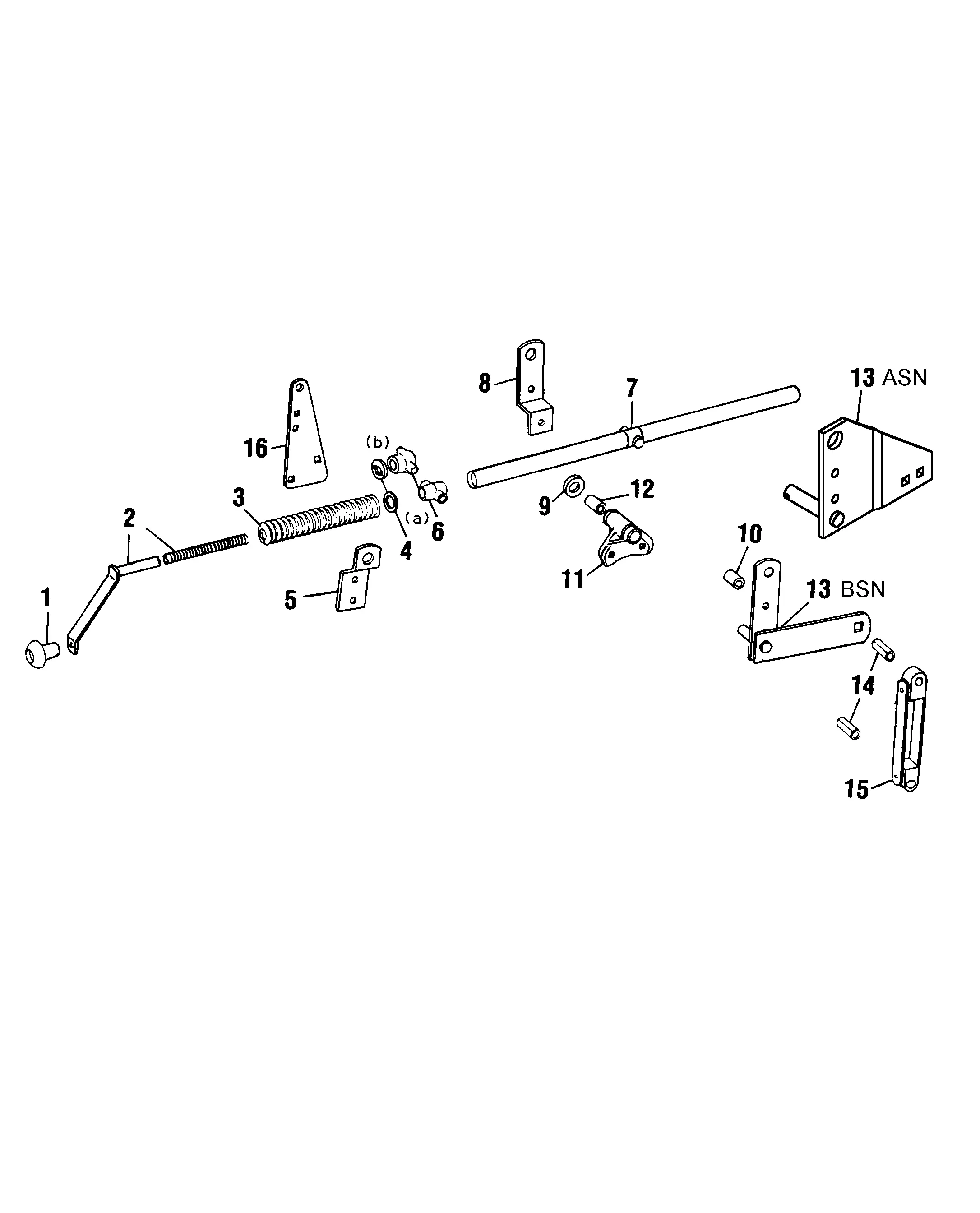

How to Identify Different Parts

Understanding the various components of your equipment is essential for maintaining its functionality and efficiency. Recognizing each part can help you troubleshoot issues, perform routine maintenance, and ensure smooth operation over time. To begin, familiarize yourself with the primary sections of the machine, focusing on the structure, key mechanisms, and connections. Recognizing Key Mechanisms

The central mechanical systems, such as the rotating elements and adjustment levers, play a critical role in the equipment’s performance. Pay attention to how these parts interact with one another, ensuring they are properly aligned and in good working order. Identifying Structural ComponentsLook at the frame, arms, and other support structures, which are designed to provide stability and ensure the machine operates smoothly. Regular inspection of these elements will help prevent wear and ensure the equipment functions as intended. Maintenance Tips for Longer Part Life

To ensure the longevity of your equipment’s components, regular upkeep is essential. By following a few simple maintenance practices, you can prevent premature wear and extend the service life of crucial elements, ultimately leading to better performance and fewer repairs. Keep Moving Elements LubricatedLubricating all moving mechanisms is a critical step in preventing friction and minimizing wear. Make sure to apply the appropriate type of lubricant as recommended by the manufacturer, and inspect these areas regularly to ensure that the lubricant hasn’t dried up or become contaminated with debris. Regular Cleaning and Inspection

Consistently removing dirt, grass, and other debris that can accumulate during operation helps to avoid blockages or damage to sensitive components. Additionally, regular inspections for signs of damage or excessive wear allow you to address issues before they become serious, ensuring continued functionality and efficiency. Common Issues with Hay Equipment Components

Over time, machinery used in the field can experience a range of wear and tear, leading to performance problems. Proper maintenance is essential, but even well-cared-for tools may face common challenges that affect their efficiency. Component wear is one of the most frequent problems, especially with moving parts. Regular use can lead to friction and eventual damage, reducing operational quality. Keeping an eye on these elements and performing timely replacements is crucial to prevent further breakdowns. Another typical issue arises from misalignment. If the equipment is not correctly adjusted, it can cause uneven performance, leading to more significant damage over time. Regular inspections can help identify misalignment early, ensuring smoother operation. Lastly, debris buildup can obstruct the Replacing Worn-Out Parts Safely

When components of agricultural equipment begin to show signs of wear, it is essential to replace them with care to maintain optimal functionality and avoid accidents. Ensuring proper handling and installation techniques can greatly enhance both efficiency and safety during the replacement process.

Regular maintenance and proper handling during part replacement not only extend the lifespan of the equipment but also minimize the risk of operational failures. Compatibility of Parts with Other ModelsUnderstanding the interchangeability of components is essential for efficient maintenance and repairs. Many users seek to identify whether specific elements from one machine can be effectively utilized in another. This knowledge not only aids in cost-saving but also enhances the overall performance of agricultural equipment. Interchangeable Components Overview

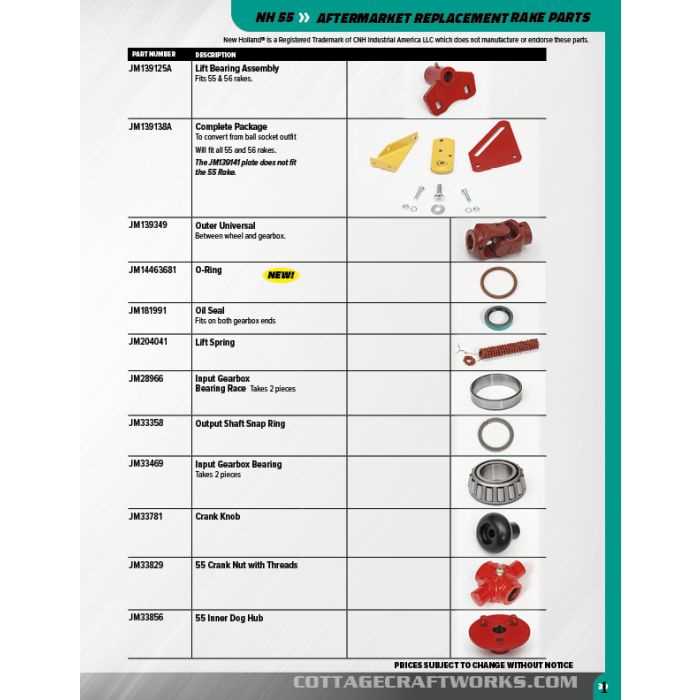

Several elements are designed with versatility in mind, allowing compatibility across different machines. This feature is particularly beneficial for operators who own multiple models, as it minimizes the need to stock an extensive inventory of individual components. By analyzing the specifications and design of each element, users can determine the suitability for various systems. Factors Influencing Compatibility

When assessing the potential for cross-compatibility, it is crucial to consider factors such as size, shape, and mounting mechanisms. Additionally, the material composition can affect performance and durability. It is advisable to consult technical manuals or engage with experts to ensure that selected components will function optimally within the desired framework. Buying Genuine Replacement PartsWhen it comes to maintaining your equipment, opting for authentic components is crucial. Genuine replacements not only ensure compatibility but also enhance the longevity and performance of your machinery. Investing in quality pieces can save you from frequent repairs and inefficient operation, ultimately leading to better productivity in your tasks. Benefits of Authentic ComponentsChoosing original items over generic alternatives comes with numerous advantages:

Where to Purchase Genuine Components

To ensure you are buying authentic replacements, consider the following sources:

Detailed Look at the Wheel AssemblyThe wheel assembly plays a crucial role in the functionality and efficiency of agricultural equipment. Understanding its components and mechanics is essential for maintaining optimal performance during operations. This section delves into the various elements that comprise this assembly, highlighting their significance and interconnections. Key components of the wheel assembly include:

Each of these parts contributes to the effective operation of the machinery. Regular inspection and maintenance of the wheel assembly ensure longevity and reliable performance. Here are some maintenance tips:

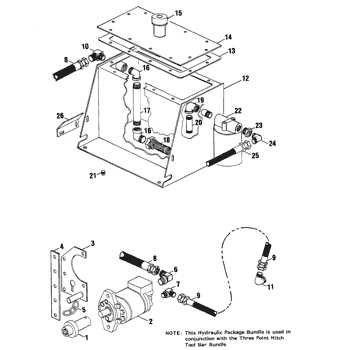

By focusing on the wheel assembly, operators can enhance the overall functionality of their equipment, leading to improved productivity in the field. How to Assemble the Gear System

Putting together the gear mechanism of your machinery requires careful attention and precision. Proper assembly ensures optimal performance and longevity of the equipment. Following a structured approach can simplify the process and help avoid common pitfalls. Here are the essential steps to effectively assemble the gear system:

By following these steps, you can successfully assemble the gear system, enhancing the efficiency of your machinery. |