The efficiency of farming machinery plays a crucial role in modern agriculture, impacting productivity and operational success. A comprehensive exploration of machinery elements allows users to gain insights into functionality, maintenance, and overall performance. Recognizing how each segment interacts within the whole can significantly enhance user experience and machine longevity.

In the realm of hay and forage processing, understanding the intricate workings of these machines is essential. Identifying individual components and their specific roles can lead to more effective troubleshooting and repair strategies. This knowledge empowers operators to make informed decisions, ensuring their equipment remains in optimal condition.

This article delves into the intricate design of a popular model, offering a visual representation of its various sections. By examining these components, users can grasp the ultimate operational mechanics behind effective forage management. Armed with this understanding, both seasoned professionals and newcomers can better navigate their maintenance and enhancement efforts.

Understanding New Holland 268 Baler

This section aims to provide an overview of a specific type of agricultural machinery designed for the efficient processing of crop materials. Recognizing the key components and their functions is essential for optimal operation and maintenance of the equipment. A thorough comprehension of its design can enhance productivity and ensure durability in various farming conditions.

Key Features and Functionality

The machine is engineered to facilitate the compacting and binding of harvested plant material into manageable bundles. Its robust construction is complemented by various mechanisms that work in unison to streamline the baling process. Understanding each component’s role is vital for maximizing efficiency and minimizing wear and tear.

Maintenance Tips

Regular upkeep is crucial for sustaining the performance of this machinery. Key practices include routine inspections, lubrication of moving parts, and timely replacement of worn components. Implementing a systematic maintenance schedule can prevent unexpected breakdowns and extend the lifespan of the equipment.

Components of the Baler Machine

This section explores the essential elements that make up a compression device used for agricultural applications. Each component plays a crucial role in the machine’s functionality, contributing to its overall efficiency and effectiveness in handling materials.

Main Elements

- Feed System

- Compression Chamber

- Binding Mechanism

- Power Transmission

- Chassis

Supporting Parts

- Pulleys and Belts

- Hydraulic System

- Wheels and Axles

- Control Panel

Understanding these components allows for better maintenance and troubleshooting, ensuring optimal performance during operations.

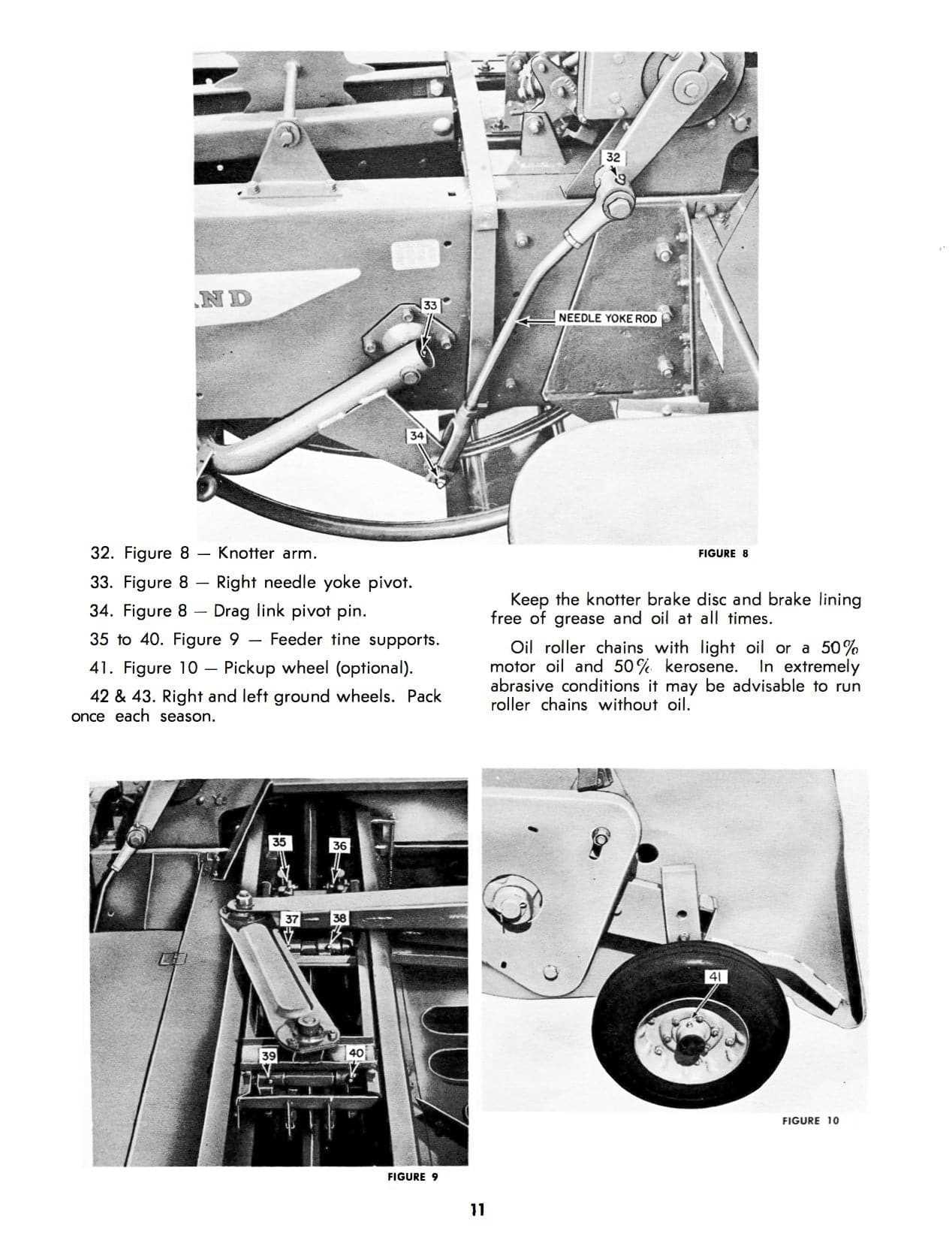

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools, providing clarity on how different elements interact and function together. They enable operators and technicians to identify issues quickly and make informed decisions regarding repairs or replacements.

Facilitating Troubleshooting

Having access to detailed visuals simplifies the troubleshooting process. When an issue arises, being able to refer to an illustrated guide allows for faster diagnosis. Users can easily pinpoint malfunctioning components, reducing downtime and enhancing productivity.

Enhancing Maintenance Efficiency

Regular upkeep is vital for machinery longevity. Clear illustrations assist in understanding the correct procedures for inspections and replacements. This knowledge not only streamlines the maintenance process but also minimizes the risk of errors, ensuring that equipment remains in optimal condition.

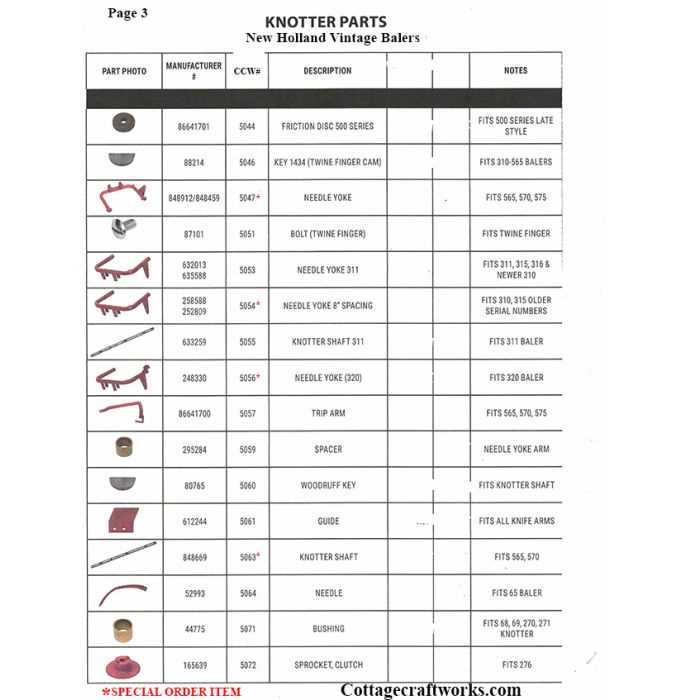

Common Replacement Parts Overview

When operating agricultural machinery, understanding the essential components that often require replacement is crucial for maintaining efficiency and productivity. This section provides an overview of frequently needed items that ensure smooth operation and longevity of the equipment.

Key Components

Regular maintenance may necessitate the replacement of specific items that are prone to wear and tear. Here are some of the most commonly replaced elements:

| Component | Description |

|---|---|

| Belt | Essential for driving various mechanisms; prone to fraying and breakage. |

| Chain | Connects different parts; can stretch or wear over time, affecting performance. |

| Roller | Facilitates smooth operation; often experiences damage from debris. |

| Bearings | Support rotational movement; may seize or wear out, leading to malfunction. |

Maintenance Tips

Regular inspection and timely replacement of these components can prevent unexpected breakdowns and prolong the lifespan of your machinery. Keeping a stock of these key items is advisable for optimal performance.

How to Interpret Diagrams Effectively

Understanding visual representations is crucial for grasping complex information quickly. These graphical tools condense intricate systems into manageable formats, allowing users to extract essential details and relationships effortlessly. Mastering this skill can enhance your ability to troubleshoot, repair, or optimize machinery.

Familiarize Yourself with Symbols

Every schematic employs specific icons and notations to convey meaning. Take time to study the legend or key associated with the illustration, as this will provide clarity on the components and their functions. Recognizing these symbols will streamline your interpretation process.

Analyze Relationships and Flow

Look for connections between various elements in the representation. Arrows, lines, and other markers indicate interactions and sequences. Understanding these relationships can significantly aid in diagnosing issues and planning maintenance strategies effectively.

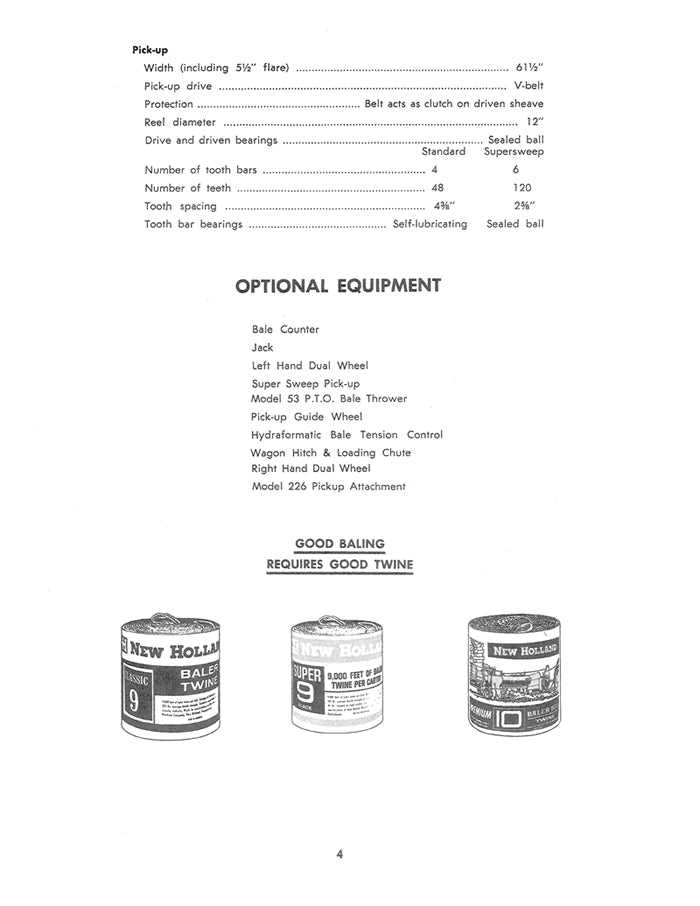

Key Features of the New Holland 268

This model is renowned for its robust design and efficiency, making it a preferred choice for agricultural operations. Its innovative features streamline the process of harvesting and compacting materials, enhancing productivity and reducing operational downtime.

Durability and Reliability

The construction of this equipment emphasizes longevity, utilizing high-quality materials that withstand rigorous conditions. Users can depend on its consistent performance across various terrains and weather situations, ensuring that it meets the demands of heavy-duty use.

Operational Efficiency

Equipped with advanced technology, this model optimizes the collection and compression of materials. Features such as adjustable settings allow operators to tailor performance to specific crop types, resulting in higher output and reduced waste. The user-friendly controls further enhance the overall experience, making it accessible for operators of all skill levels.

Maintenance Tips for Baler Parts

Proper upkeep of machinery components is crucial for optimal performance and longevity. Regular attention to essential elements not only enhances efficiency but also prevents costly breakdowns. Adopting a proactive approach ensures that your equipment operates smoothly and reliably.

1. Routine Inspections: Conduct frequent checks on key components to identify wear or damage early. Look for signs of fraying or rust, which can indicate potential failures.

2. Lubrication: Ensure that all moving parts are well-lubricated to minimize friction. This reduces wear and tear and helps maintain smooth operation.

3. Cleanliness: Keep the machinery clean from debris and dust. Accumulation can lead to overheating and impede performance, so regular cleaning is essential.

4. Replacement of Worn Components: Replace any parts that show significant wear. Timely replacements prevent further damage and maintain operational efficiency.

5. Follow Manufacturer Guidelines: Adhere to maintenance schedules provided by the manufacturer for best practices. These guidelines offer invaluable insights into keeping your equipment in top shape.

By implementing these tips, you can delve deeper into the mechanics of your equipment, ensuring that it serves you well for years to come.

Finding Quality Replacement Parts

When it comes to maintaining agricultural machinery, sourcing high-quality components is essential for optimal performance and longevity. Understanding where to find reliable substitutes can significantly enhance the efficiency of your equipment, ensuring that it operates smoothly under demanding conditions.

Begin by considering reputable suppliers who specialize in agricultural equipment. They often have extensive inventories and can provide guidance on the best alternatives available in the market. Online marketplaces and dedicated websites can also be valuable resources, offering a wide range of options with user reviews that help in assessing quality.

Another effective approach is to connect with local dealers or mechanics. Their expertise can be instrumental in identifying durable components that meet your specific needs. Networking within agricultural communities can also lead to recommendations for trustworthy manufacturers and suppliers.

| Source Type | Benefits |

|---|---|

| Reputable Suppliers | Extensive inventories and expert guidance |

| Online Marketplaces | Wide selection and user reviews |

| Local Dealers | Expertise and personalized service |

| Agricultural Communities | Recommendations and networking opportunities |

Finally, always prioritize quality over cost. Investing in superior components may lead to long-term savings by reducing the frequency of replacements and minimizing downtime. A thorough search for reliable substitutes will ultimately ensure that your machinery remains in peak condition.

Upgrades for Enhanced Performance

Improving the efficiency and functionality of agricultural machinery is essential for optimizing productivity. By implementing specific enhancements, operators can achieve superior results, ensuring that their equipment operates at peak levels.

Key Enhancements to Consider

- Advanced Control Systems

- High-Quality Blades

- Enhanced Hydraulic Components

- Improved Drive Mechanisms

- Durable Frame Reinforcements

Benefits of Upgrading

- Increased Operational Efficiency

- Reduced Downtime and Maintenance Costs

- Enhanced Durability and Longevity

- Better Adaptability to Various Conditions

Troubleshooting Common Issues

Understanding and resolving typical challenges can significantly enhance the efficiency and longevity of your machinery. This section aims to guide operators through frequent problems encountered during operation, offering practical solutions to ensure optimal performance.

1. Poor Bale Formation: If you notice irregular shapes or incomplete bales, check for proper tension settings. Ensure that the material being processed is consistent in size and moisture content, as variations can affect the compaction.

2. Blockages: A common issue that can lead to delays is blockage within the feeding mechanism. Regularly inspect for debris or dense clumps of material that could obstruct flow. Cleaning out any accumulated residue can often resolve this problem.

3. Twine Breakage: Frequent twine snapping can indicate issues with tension or worn components. Verify that the twine is correctly threaded and that tension mechanisms are functioning properly. Replacing worn parts may also be necessary.

4. Hydraulic Problems: If you experience sluggish operation or leaks, inspect the hydraulic system for any signs of wear or damage. Ensure all connections are secure, and replace any faulty hoses or seals to maintain efficient operation.

5. Unusual Noises: Any unexpected sounds during operation can signal underlying mechanical issues. Conduct a thorough inspection of moving parts and bearings. Lubrication might be required, or certain components may need replacement to prevent further damage.

By addressing these common issues proactively, you can maintain peak functionality and minimize downtime, ultimately leading to a more productive experience.

Resources for Baler Owners

Owning and operating a harvesting machine requires access to various tools and information for effective maintenance and troubleshooting. Understanding where to find reliable resources can enhance efficiency and prolong the lifespan of the equipment.

Online Forums and Communities

Engaging with fellow owners through online forums can provide valuable insights and solutions. These platforms often feature discussions on common issues, allowing users to share experiences and tips. Participating in these communities fosters a sense of camaraderie among operators.

Manufacturer’s Manuals and Guides

Consulting official manuals is crucial for understanding the specifications and operational procedures of your equipment. These documents typically include detailed instructions, maintenance schedules, and troubleshooting tips, serving as an ultimate resource for owners aiming to keep their machines in peak condition.

FAQs about New Holland 268 Baler

This section addresses common inquiries regarding a specific agricultural implement known for its efficiency and reliability. Here, users can find answers to frequently asked questions that enhance understanding and operation of this machine.

- What are the key features of this machine?

The implement boasts durability, adjustable settings for different materials, and ease of maintenance.

- How do I troubleshoot common issues?

Start with checking the tension, ensuring proper lubrication, and inspecting for wear and tear on essential components.

- Where can I find replacement components?

Parts can be sourced from authorized dealers, online retailers, or local machinery shops specializing in agricultural equipment.

- What maintenance is required?

Regular checks on belts, bearings, and lubrication are essential, along with seasonal inspections before heavy use.

- Can I use this equipment for different crops?

Yes, it is versatile and can handle various types of forage and straw, depending on the settings used.