Efficient machinery plays a crucial role in modern farming, ensuring the timely and effective harvesting of crops. By breaking down the various mechanisms and structures of farm equipment, farmers can optimize their operations and maintain their tools for longer periods. This section provides an in-depth look at the key components involved in these machines, helping users better comprehend the intricate workings of their agricultural tools.

Each machine is built with a range of interlocking elements that perform specific functions,

Key Components Overview

The system is made up of several essential elements that ensure efficient operation. Each part plays a critical role in the overall functionality, allowing for smooth and consistent performance during agricultural tasks.

Cutting Mechanism: The primary function of this component is to handle the crop effectively, ensuring clean and precise cuts. Its design allows for a steady flow of material into the processing area, reducing any interruptions.

Drive System: This section is responsible for powering the equipment, transferring energy from the main source to the active parts. Proper alignment and maintenance are key to avoiding breakdowns and ensuring smooth operation.

Rollers: These ensure the material is processed evenly and smoothly. By exerting pressure and guiding the flow, the rollers help achieve uniform results, reducing potential issues in later stages.

Frame Structure:

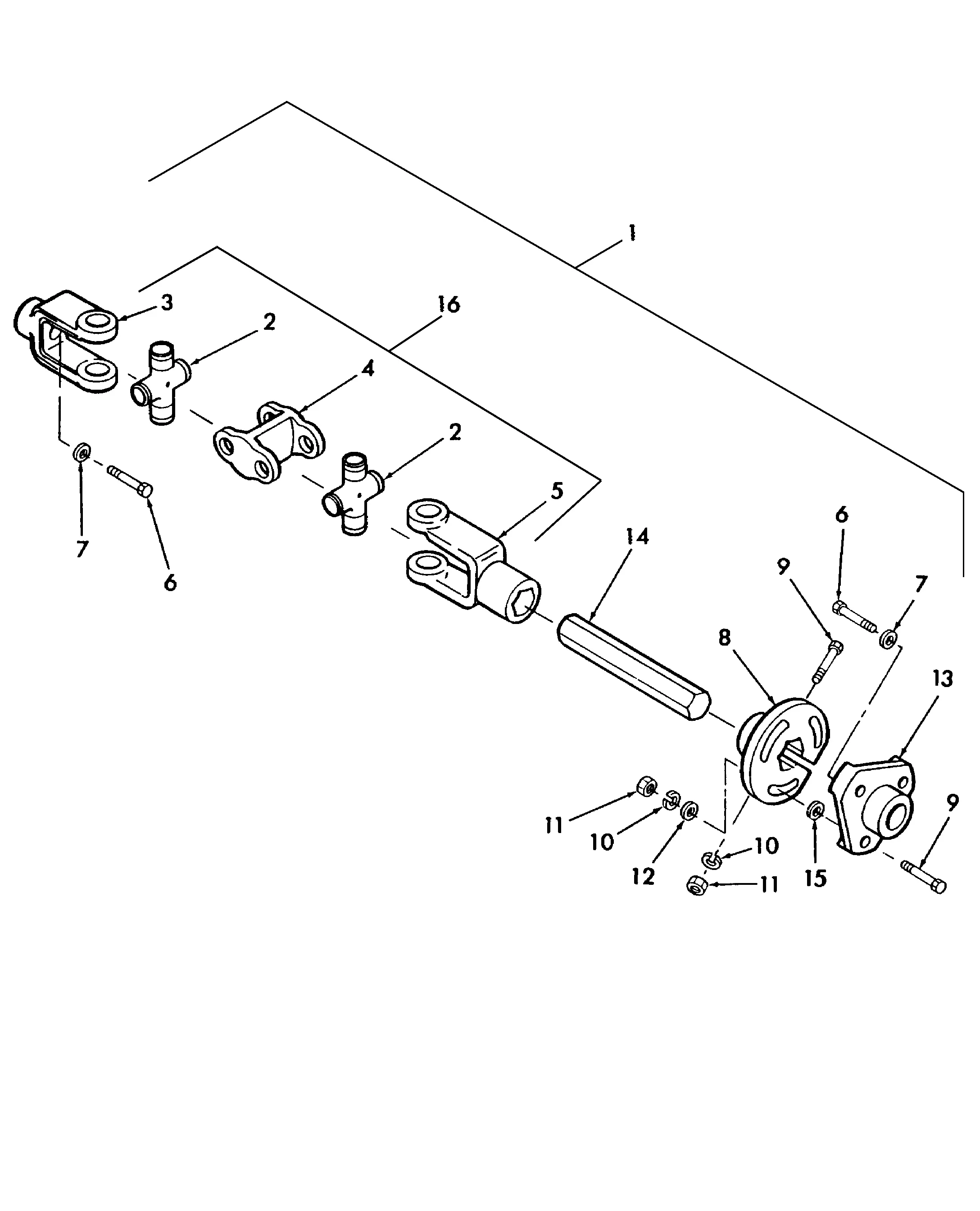

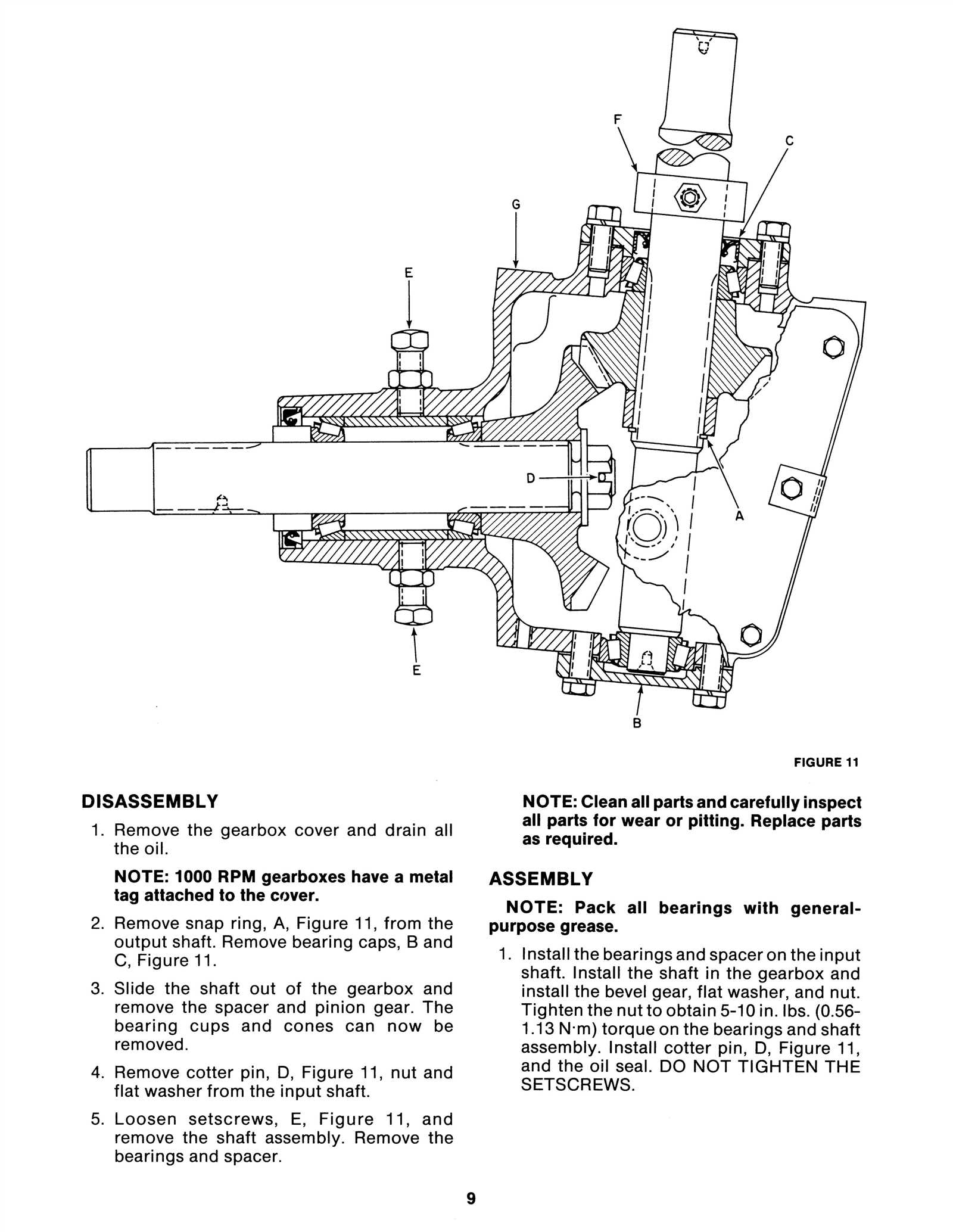

Understanding the Drive System

The drive mechanism plays a crucial role in ensuring smooth and efficient operation of the equipment. It is responsible for transferring power from the engine to the cutting and conditioning components, enabling precise and consistent performance in the field. A thorough understanding of how the drive operates can help in maintaining optimal function and identifying potential issues before they escalate.

Power Transmission is facilitated through a combination of belts, pulleys, and shafts, which work together to channel energy where it’s needed. Each part has a specific purpose, contributing to the overall efficiency of the machine. Regular inspections and maintenance of these components are essential to avoid unnecessary downtime.

Key to longevity is ensuring that all drive elements are aligned correctly and free from wear. Misalignment or damage can lead to a decrease in performance or, worse, a complete breakdown. Familiarizing oneself with the common signs of wear and keeping an eye on tension levels can significantly extend the lifespan of the system.

Cutting Mechanism Layout

The cutting mechanism is an essential component in agricultural machinery designed to efficiently trim and manage crops. It functions by utilizing a series of precisely arranged blades and moving parts, ensuring a clean and uniform cut. This mechanism plays a pivotal role in maximizing productivity and maintaining the quality of harvested crops.

Main Components and Structure

The cutting system consists of a blade assembly and supporting structures that maintain the proper alignment and tension for optimal cutting efficiency. The drive system powers the movement, ensuring a continuous and smooth operation. Each component is carefully positioned to provide consistent performance across different

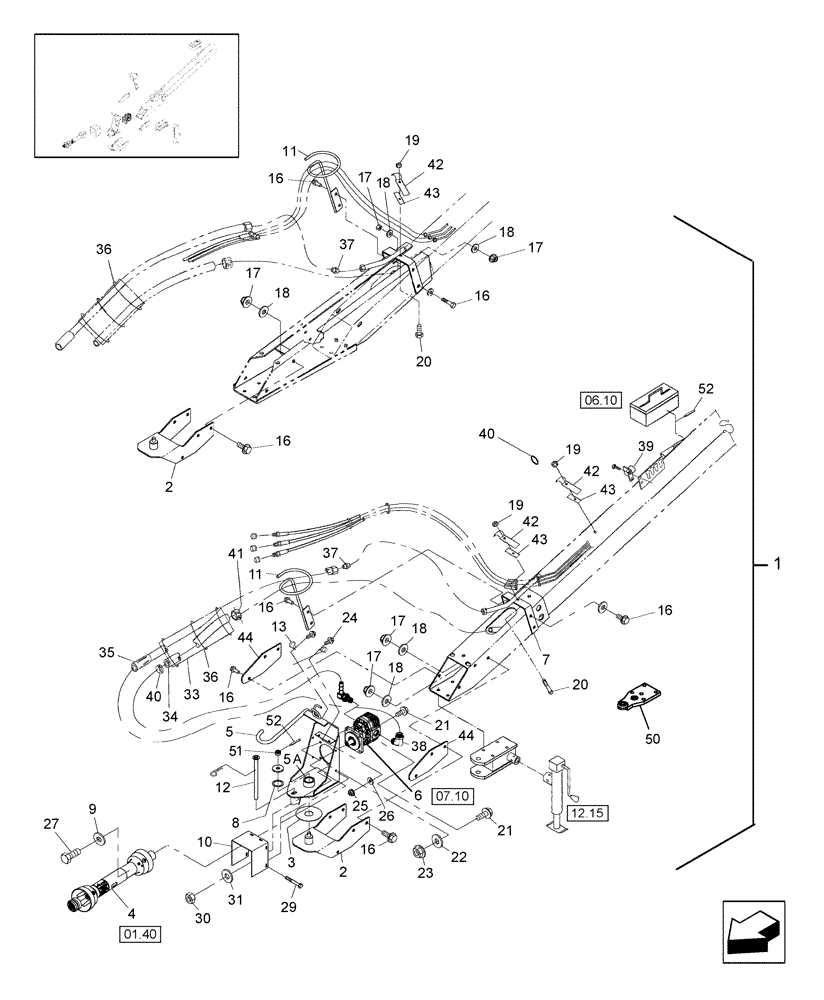

Hydraulic Assembly Breakdown

The hydraulic system is a crucial component that ensures the smooth operation of various mechanical functions. Understanding how the different elements interact is key to maintaining efficiency and avoiding malfunctions. This section provides a detailed overview of the hydraulic assembly, focusing on its main parts and their roles within the system.

Main Components of the Hydraulic System

- Pump: Responsible for generating the fluid pressure needed to power the hydraulic mechanisms.

- Cylinders: These convert hydraulic energy into mechanical force, allowing the movement of components.

- Control Valves: These direct the flow of hydraulic fluid,

Roller Mechanism Parts

The roller mechanism is essential for handling materials efficiently and smoothly. It consists of various components designed to work in tandem, ensuring that the process is seamless and minimizes wear. This section explores the primary elements involved in this mechanism, highlighting their functions and interactions.

- Upper and Lower Rollers: These cylindrical parts compress the material as it moves through, ensuring uniform pressure and an even cut.

- Bearings: Positioned at both ends of the rollers, these allow smooth rotation and reduce friction, which helps prolong the lifespan of the mechanism.

- Drive Belts: Responsible for transferring power to the rollers, enabling them to rotate consistently and efficiently during operation.

- Tension Adjusters: These components allow fine-tuning of the pressure applied by the rollers, ensuring optimal performance based on the material being processed.

- Regular Inspections: Conduct frequent checks to identify any wear or damage early. Look for signs of corrosion, cracks, or loosened bolts.

- Lubrication: Keep moving parts well-lubricated to reduce friction. Use the recommended grease or oil as specified in the user manual.

- Cleaning: Remove debris and dirt from all surfaces, particularly around moving parts. This helps prevent blockages and overheating.

- Sharpening Blades: Ensure that cutting implements are sharp to improve efficiency. Dull blades can lead to excessive strain on the machinery.

- Fluid Levels: Regularly check and maintain appropriate levels of hydraulic and engine fluids. Low levels can cause significant damage over time.

Frame Structure Analysis

The analysis of the framework within agricultural machinery plays a crucial role in understanding its overall performance and durability. A robust structure not only supports various components but also contributes to the efficiency of the equipment during operation. By examining the materials and design of the framework, one can assess how it withstands stress and strain while providing stability in demanding environments.

Material Composition

Evaluating the materials used in the framework is essential for determining its strength and longevity. High-quality alloys and steel are often employed to enhance resistance to wear and corrosion. Understanding the selection process of these materials can reveal insights into the machine’s resilience and maintenance requirements.

Design Considerations

The design of the framework is critical for optimizing performance. Features such as weight distribution, joint configuration, and reinforcements play a significant role in how effectively the structure can handle operational loads. Analyzing these aspects helps in identifying potential areas for improvement and innovation in future models.

Maintenance Tips for Key Areas

Proper upkeep of essential components is vital for the optimal performance and longevity of your equipment. By focusing on specific areas, you can ensure smooth operation and prevent unexpected failures.

By following these tips, you can maintain the functionality of your machinery and extend its service life, ultimately enhancing your productivity.

Knife Assembly Configuration

The configuration of the cutting mechanism is crucial for achieving optimal performance in grass and forage management. Proper assembly ensures that the blades function effectively, providing a clean cut and enhancing overall efficiency. Each component plays a significant role in maintaining the alignment and functionality of the cutting system.

In this context, the arrangement of the knife assembly involves several key elements that must work harmoniously. The blades are typically mounted on a bar, which allows for precise cutting action as the machine moves through the crop. Understanding the interplay between these parts is essential for ensuring that the cutting action is smooth and efficient.

Regular maintenance and correct installation of the knife assembly can prevent premature wear and extend the lifespan of the equipment. It is important to refer to the manufacturer’s guidelines for specific details on the assembly process, as well as to identify any necessary adjustments to suit different operational conditions.

Belt System Diagram

The belt assembly is a crucial component in agricultural machinery, playing a vital role in the transfer of power between different parts of the equipment. Understanding the arrangement and functionality of these belts can enhance maintenance practices and ensure optimal performance. This section provides an overview of the belt configuration and its significance in efficient operation.

Components of the Belt Assembly

The belt system consists of several key elements that work in harmony to facilitate movement. Each part has a specific role that contributes to the overall effectiveness of the machinery. Proper identification of these components is essential for effective troubleshooting and repairs.

Component Description Belt Transmits power from the engine to various parts of the equipment. Pulleys Redirect the motion of the belts, ensuring proper alignment and tension. Tensioner Maintains the correct tension in the belt to prevent slippage. Idler Guides the belt and helps in maintaining proper routing. Importance of Maintenance

Regular inspection and maintenance of the belt system are crucial to prevent wear and ensure reliable operation. Timely identification of any issues can save time and resources in the long run. Keeping the belts properly adjusted and in good condition helps maintain the efficiency of the overall machinery.