The efficient functioning of agricultural machinery relies heavily on the precise arrangement and maintenance of its various elements. A clear representation of how these components fit together plays a vital role in ensuring optimal performance and reducing downtime in the field. Whether for routine maintenance or repair, having a detailed guide on the configuration of different sections can save time and effort.

For those involved in maintaining or troubleshooting complex machines, familiarity with the internal structure is essential. This knowledge allows for quicker identification of potential issues and ensures smoother operation, contributing to the longevity of the equipment. Understanding the layout of each mechanism can also aid in sourcing replacements and upgrades when needed.

Understanding the New Holland 499 Mechanism

The operational system of this agricultural machine is intricate, built to maximize efficiency in the field. The machine is composed of several key components that work in unison to deliver optimal performance during harvesting tasks. Each element is meticulously engineered to handle various challenges, ensuring a smooth process.

Main Structural Components

The equipment relies on a combination of mechanical and hydraulic systems to carry out its functions. These systems enable precise control, helping operators adjust to different field conditions with ease.

- Hydraulic control systems for adjusting the height and angle

- Rotating blades for cutting

- Drive belts and pulleys for transmitting power

Adjustability and Customization

One of the defining features is its adaptability.

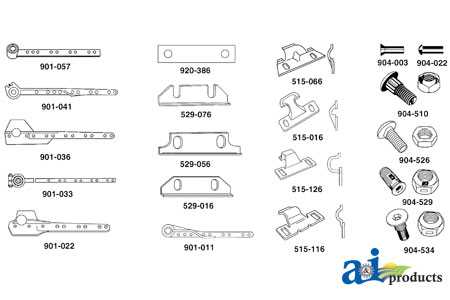

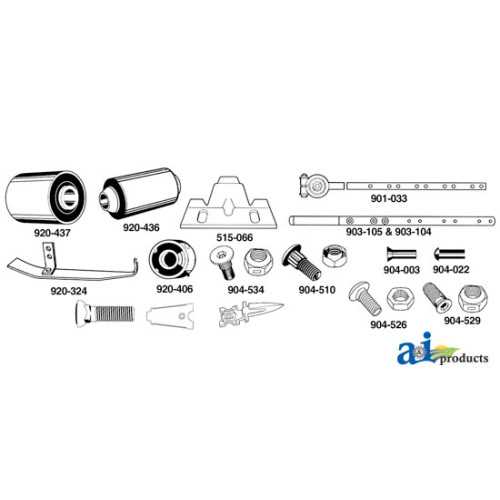

Key Components of the Mower

The mower is made up of several crucial elements that work together to ensure smooth and efficient operation. Each component plays a vital role in maintaining the performance, durability, and overall functionality of the machine. Understanding these parts can help in better maintenance and prolonging the equipment’s lifespan.

Cutting System

The cutting mechanism is at the heart of the mower’s operation. It consists of sharp blades that are designed to trim vegetation evenly and swiftly. Proper care of the blades is essential, as sharpness directly impacts cutting efficiency. Regular sharpening and checking for damage are recommended to maintain optimal performance.

Drive and Support Mechanisms

The drive system provides the power to move the mower, while the support framework keeps it stable during operation

Detailed Breakdown of Drive System

The drive system plays a crucial role in ensuring the machine’s smooth and efficient operation. Understanding its components and functionality is essential for proper maintenance and repair. This section provides an in-depth overview of how the drive mechanism functions, highlighting its key parts and interactions that allow for power transmission and movement.

Main Components of the Drive System

At the core of the system is the power source, which transfers energy to a series of gears, shafts, and pulleys. These components work together to ensure synchronized movement across the machine. Proper alignment and regular lubrication of these parts are critical to prevent wear and ensure long-term performance.

Power Transmission

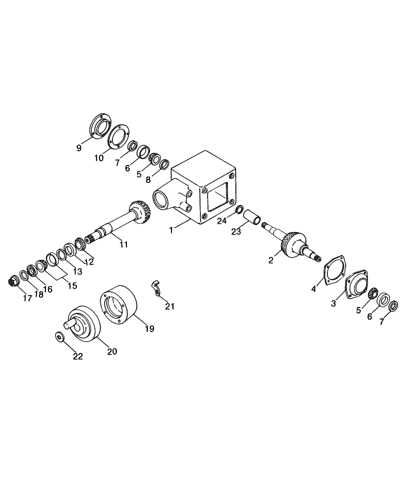

Hydraulic Assembly Parts Overview

The hydraulic system plays a crucial role in the overall functionality of many machines, providing the necessary force for various mechanical operations. This section focuses on the key elements of the hydraulic assembly, ensuring smooth and efficient movement in different mechanical processes. Understanding the components and their relationships is essential for maintaining optimal performance.

Main Hydraulic Components

The core of the hydraulic assembly consists of various interconnected parts designed to generate and control fluid pressure. These elements include pumps, valves, and cylinders, all of which are essential for converting hydraulic energy into mechanical power.

Detailed Component Breakdown

Each part of the hydraulic system has a specific function that contributes to the overall operation. Below is a table outlining the key components and their purposes:

| Component Type | Importance Level | Common Issues |

|---|---|---|

| Engine | High | Overheating, oil leaks |

| Hydraulic System | High | Fluid leaks, pressure loss |

| Transmission | Medium | Slipping gears, noise |

| Electrical System | Medium | Wiring issues, battery failures |

Ensuring Optimal Performance with Adjustments

Achieving peak efficiency in machinery operation is essential for maximizing productivity and prolonging equipment lifespan. Regular adjustments play a vital role in maintaining optimal performance. This section explores the importance of fine-tuning components to enhance functionality and ensure smooth operations.

Key Areas for Adjustment

Several critical areas warrant attention when making adjustments:

- Engine Settings: Proper tuning can significantly improve fuel efficiency and power output.

- Hydraulic Systems: Ensuring correct pressure levels optimizes performance and responsiveness.

- Drive Components: Regular checks and adjustments can reduce wear and improve handling.

Benefits of Regular Maintenance

Routine adjustments offer numerous advantages:

- Increased reliability and safety during operation.

- Reduced likelihood of breakdowns, minimizing downtime.

- Enhanced operational efficiency, leading to cost savings.

Where to Source Replacement Parts

Finding reliable sources for component replacements is crucial for maintaining equipment functionality. Various options exist that cater to different needs, ensuring you can procure the necessary items efficiently.

- Authorized Dealers: Purchasing from official representatives guarantees authenticity and support.

- Online Marketplaces: Websites specializing in machinery often provide a wide range of components at competitive prices.

- Local Suppliers: Community-based shops can be a great resource for quick acquisitions and personalized service.

- Salvage Yards: For those seeking budget-friendly options, visiting salvage yards can yield valuable finds.

- Manufacturer’s Website: Many producers have online platforms where you can directly order items.

Exploring these avenues will help ensure that you find quality replacements to keep your machinery running smoothly.