The intricacies of farming machinery can often seem overwhelming, yet comprehending their functionalities is essential for optimal performance. This section will explore a specific model’s assembly, providing insights into its crucial elements and their relationships.

Each segment plays a vital role in ensuring efficiency during harvesting, contributing to the overall productivity of the equipment. By examining a detailed representation of these components, users can gain valuable knowledge that aids in maintenance and troubleshooting.

Furthermore, understanding these assemblies allows operators to make informed decisions regarding repairs and upgrades, ultimately enhancing the effectiveness of their agricultural operations. As we delve into the specifics, we will uncover the ultimate significance of each part in the harvesting process.

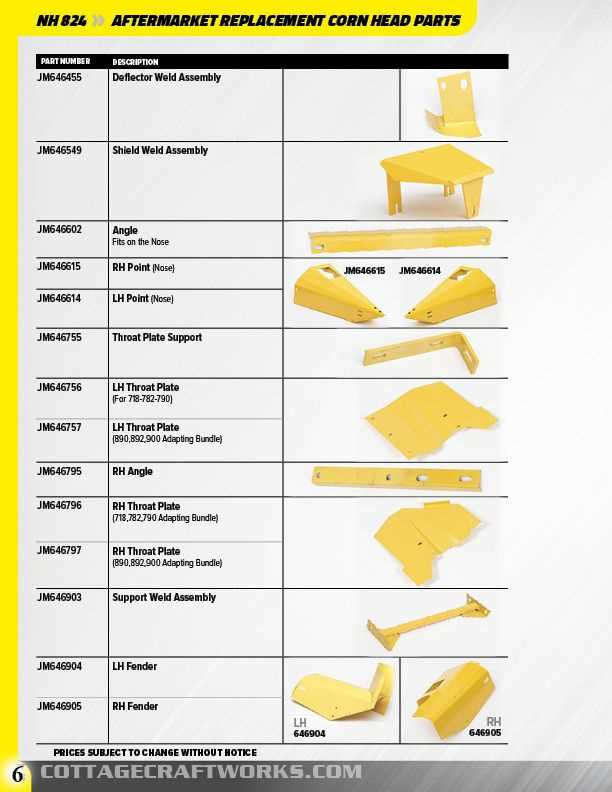

Understanding New Holland 824 Corn Head

This section provides insight into a vital component used in agricultural machinery, designed to enhance efficiency during harvesting. The focus will be on its structure, functionality, and key elements that contribute to optimal performance.

These attachments are engineered to facilitate the process of gathering crops from the field. Familiarity with their design is essential for operators aiming to maximize productivity and reduce downtime.

- Structure: The assembly consists of several critical components that work in harmony.

- Functionality: Understanding how each element interacts can lead to improved operation.

- Maintenance: Regular upkeep is crucial for longevity and efficiency.

In addition, recognizing common issues and troubleshooting methods can greatly enhance the user experience.

- Check for wear and tear on blades and other moving parts.

- Ensure proper alignment during operation to avoid damage.

- Regularly inspect hydraulic systems for leaks or malfunctions.

By comprehensively understanding this essential agricultural tool, operators can ensure they are well-prepared for the demands of harvesting season.

Overview of Corn Head Components

This section explores the essential elements of harvesting equipment designed for grain collection. Understanding these components is crucial for effective operation and maintenance, ensuring optimal performance during the harvest season.

Key Elements

Each unit consists of several critical parts that contribute to its functionality. The gathering mechanisms are responsible for efficiently drawing in crops, while the cutting elements ensure a clean and precise harvest. Additionally, the support framework plays a vital role in maintaining structural integrity during operation.

Maintenance and Upkeep

Regular inspection and replacement of worn components are essential for maximizing efficiency. Identifying potential issues early can prevent costly repairs and downtime. Familiarity with each element will aid operators in keeping their equipment in optimal condition.

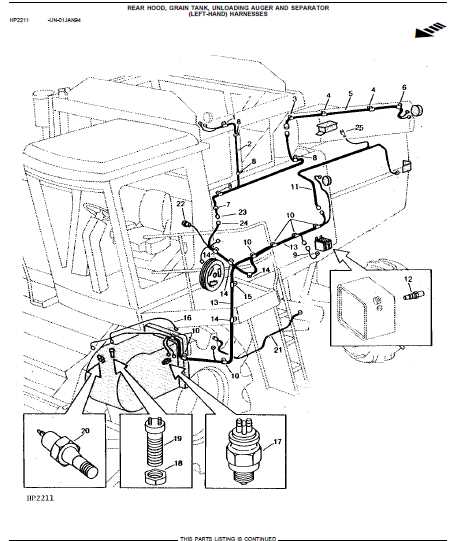

Importance of Parts Diagrams

Understanding the layout and components of machinery is essential for effective maintenance and repair. Visual representations of elements facilitate quick identification and streamline the troubleshooting process. These illustrations serve as invaluable tools for technicians, enabling them to grasp complex systems swiftly.

Enhanced Efficiency

Utilizing detailed visuals improves operational efficiency. Technicians can locate specific components rapidly, reducing downtime and enhancing productivity. Clear depictions also minimize the risk of errors during assembly or disassembly.

Facilitating Communication

Visual guides foster better communication among team members. When everyone can refer to the same representation, it ensures a unified understanding of the system. This alignment is crucial for collaborative efforts in repairs and upgrades.

Common Issues with New Holland 824

Farm equipment can encounter various challenges that may affect performance and efficiency. Understanding these common problems is essential for maintaining optimal functionality and ensuring a smooth harvesting process. Below are some frequently reported issues and their potential solutions.

Mechanical Failures

- Wear and tear of components leading to reduced efficiency.

- Misalignment of parts causing excessive vibrations.

- Clogging due to debris accumulation affecting operation.

Hydraulic System Problems

- Leaks in hoses or fittings leading to loss of fluid pressure.

- Malfunctioning pumps causing inconsistent performance.

- Overheating of hydraulic components, resulting in failures.

Addressing these common issues promptly can prevent more severe damage and costly repairs. Regular maintenance checks and timely replacements are key to ensuring longevity and reliability.

Replacement Parts for Optimal Performance

Ensuring top functionality of agricultural machinery hinges on the quality and suitability of components utilized. Regularly updating essential elements is crucial for maintaining efficiency and prolonging equipment lifespan.

Key Components to Consider

- Cutting Blades

- Drive Chains

- Gears and Bearings

- Hydraulic Cylinders

Benefits of Quality Replacements

- Enhanced Durability

- Improved Yield Efficiency

- Minimized Downtime

- Cost-Effectiveness Over Time

Investing in high-quality replacements is the ultimate strategy for achieving optimal performance in the field.

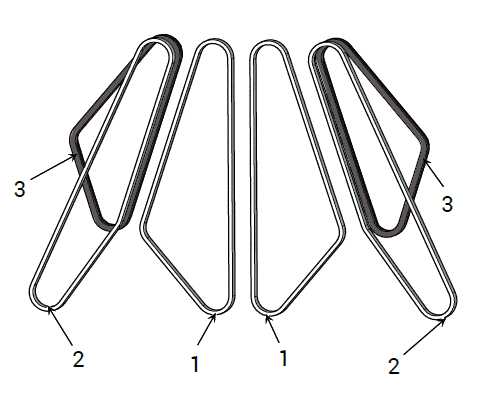

How to Read Parts Diagrams

Understanding illustrations that represent components of machinery is essential for effective maintenance and repair. These visual aids provide crucial information, helping users identify various elements and their relationships within a system. Mastering the interpretation of these graphics enhances efficiency and ensures accurate replacements or repairs.

Key Elements of the Illustration

When analyzing these visuals, pay attention to the following components:

| Element | Description |

|---|---|

| Labels | Designations indicating specific components or assemblies. |

| Numbers | References corresponding to parts in the accompanying list or catalog. |

| Connections | Lines or arrows showing how components interact or are linked. |

| Views | Different perspectives (e.g., top, side) that offer a comprehensive understanding. |

Steps for Effective Interpretation

To effectively read these visual aids, follow these steps:

- Familiarize yourself with the overall layout.

- Identify labeled components and match them with the reference list.

- Examine the connections to understand how parts fit together.

- Use the provided views to grasp the spatial arrangement.

By practicing these techniques, you can enhance your ability to interpret complex illustrations and streamline your repair processes.

Maintenance Tips for Longevity

Ensuring the durability of agricultural machinery requires consistent care and attention. By implementing a few essential practices, operators can significantly extend the lifespan of their equipment and enhance overall performance.

Regular Inspections: Conducting routine checks allows you to identify wear and tear early. Look for signs of damage or loose components that may require immediate attention.

Lubrication: Keeping moving parts well-lubricated minimizes friction and prevents premature deterioration. Follow the manufacturer’s guidelines for appropriate lubrication intervals and types of oils.

Cleaning: After each use, remove debris, dirt, and residue from surfaces. A clean machine operates more efficiently and reduces the risk of corrosion.

Storage: When not in use, store equipment in a sheltered environment. Protecting machinery from harsh weather conditions can prevent rust and other environmental damage.

Professional Servicing: Schedule regular maintenance with qualified technicians. Professional servicing ensures that all systems are functioning correctly and can help uncover hidden issues.

Implementing these strategies will not only enhance the longevity of your equipment but also improve its reliability during critical operational periods.

Identifying Wear and Tear Signs

Recognizing the signs of deterioration in agricultural equipment is crucial for maintaining optimal performance and preventing costly repairs. Regular inspections can help operators detect issues early, ensuring that machinery operates efficiently throughout the harvesting season.

Common Indicators of Damage

Several visual and functional cues can indicate wear on key components. Paying attention to these signs can aid in timely maintenance and replacement.

| Indicator | Description |

|---|---|

| Cracks | Visible fractures on metal surfaces may compromise structural integrity. |

| Deformation | Misshapen parts can result from excessive stress or impact, affecting performance. |

| Excessive Wear | Surface erosion on blades or teeth indicates the need for replacement. |

| Rust | Corrosion can weaken components, necessitating inspection for further damage. |

Importance of Timely Inspection

Regular evaluations not only enhance the lifespan of machinery but also improve efficiency. Operators should develop a routine maintenance schedule, focusing on high-wear areas to ensure continued productivity in the field.

Where to Find Authentic Parts

Locating genuine components for agricultural machinery is crucial for ensuring optimal performance and longevity. Relying on authentic supplies not only enhances the efficiency of the equipment but also helps in maintaining safety standards during operation. Below are some reliable sources to consider when searching for quality elements.

| Source | Description |

|---|---|

| Manufacturer’s Website | Visiting the official website of the machinery producer often provides access to the most accurate and high-quality components. |

| Authorized Dealers | Partnering with certified dealers ensures that you receive genuine items along with professional advice and support. |

| Online Marketplaces | Reputable online platforms often feature a range of authentic components, but be sure to check seller ratings and reviews. |

| Local Agricultural Supply Stores | Local shops specializing in farming equipment can be valuable resources for genuine parts, often providing personalized service. |

| Equipment Shows and Expos | Attending industry events can connect you with vendors and manufacturers, offering firsthand access to original components. |

By exploring these avenues, you can ensure that your machinery operates at peak efficiency with the right authentic components.

DIY Repairs and Modifications

Engaging in self-repairs and enhancements can significantly improve the efficiency and lifespan of agricultural machinery. By understanding the mechanics and components involved, operators can address common issues and tailor equipment to better suit their needs. This not only saves costs but also fosters a deeper connection with the tools that aid in their work.

Before starting any modifications, it’s essential to gather all necessary tools and a clear understanding of the parts involved. Consider researching common problems and potential upgrades that can enhance performance. Documenting the process will also help in troubleshooting future issues and can serve as a valuable reference for others in the field.

Utilizing aftermarket components can offer greater flexibility for upgrades. Exploring community forums and user experiences can guide decisions on modifications that provide the ultimate benefits. Emphasizing safety and proper techniques will ensure successful outcomes while maintaining the integrity of the equipment.

Cost Considerations for Replacement Parts

When evaluating the expenses associated with necessary components, several factors come into play that can significantly impact overall investment. Understanding these considerations can help optimize budget allocations and ensure efficient machinery operation.

Quality vs. Price: It is essential to balance quality and affordability. While cheaper alternatives may seem appealing, they often result in more frequent replacements, ultimately increasing costs.

Availability: The accessibility of specific components can also influence pricing. Parts that are in high demand or limited supply may command higher prices due to their scarcity.

Compatibility: Ensuring that components are compatible with existing machinery is crucial. Investing in the right fit can prevent further expenses linked to adjustments or modifications.

Long-Term Savings: Consideration of durability and longevity can lead to long-term savings. Investing in high-quality components may yield a lower total cost of ownership over time.

In conclusion, understanding these financial factors is vital for making informed decisions that enhance efficiency and reduce unexpected expenditures.

Resources for Further Learning

Exploring the intricacies of agricultural machinery can significantly enhance your understanding and maintenance capabilities. A variety of resources are available to assist you in deepening your knowledge, whether you are a novice or a seasoned expert. This section highlights useful materials and platforms that provide valuable insights and technical guidance.

Online Platforms and Forums

Engaging with online communities is a great way to connect with other enthusiasts and professionals. Websites such as Reddit and specialized forums offer spaces to ask questions, share experiences, and access firsthand information from users with practical expertise. Additionally, YouTube hosts numerous channels dedicated to machinery tutorials and repair guides, making it easier to visualize complex processes.

Books and Manuals

Investing in comprehensive literature can provide in-depth knowledge about machinery systems and operations. Look for service manuals and technical guides specific to your equipment model. Many agricultural publishers also release books focusing on maintenance practices and troubleshooting techniques, which can serve as essential references in your learning journey.