The efficient functioning of agricultural machinery relies on a comprehensive understanding of its essential components. This knowledge not only aids in maintenance but also enhances the overall performance of the equipment. By exploring the various elements involved, operators can ensure optimal operation and longevity.

Identifying and familiarizing oneself with these vital elements can significantly impact productivity in the field. Every machine has unique characteristics and configurations, making it crucial for users to grasp how these pieces work together. This exploration helps in troubleshooting issues and planning necessary repairs.

In this section, we will delve into a detailed overview of the essential components involved in a specific type of agricultural machinery. This understanding will empower users to make informed decisions and take the necessary steps for upkeep and improvement, ultimately leading to better results during harvest seasons.

Understanding the New Holland BR7060 Baler

This section explores the essential aspects of a widely used agricultural machine, focusing on its design, functionality, and operational efficiency. By examining its components and how they interact, users can enhance their understanding and optimize usage.

| Component | Function |

|---|---|

| Pickup Header | Collects the material from the field |

| Feeding System | Guides the material into the processing chamber |

| Compression Chamber | Compresses the material into bales |

| Tying Mechanism | Secures the bales for easy transport |

Understanding these components provides the ultimate insight into maximizing productivity and maintenance of the machine.

Key Features of the BR7060 Model

This model stands out in its category, offering a range of attributes that enhance efficiency and performance. Designed for optimal productivity, it integrates advanced technology and user-friendly features, making it a reliable choice for operators.

| Feature | Description |

|---|---|

| Durability | Constructed with high-quality materials, ensuring longevity and resistance to wear and tear. |

| Compact Design | Streamlined structure allows for easy maneuverability in various field conditions. |

| High Capacity | Designed to handle large volumes of material, increasing overall productivity during operation. |

| User-Friendly Controls | Intuitive interface simplifies operation, allowing for quick adjustments and easy management. |

| Efficient Tying Mechanism | Advanced tying system ensures secure bales, minimizing the risk of breakage during transport. |

| Maintenance Accessibility | Thoughtful design allows for straightforward maintenance, reducing downtime and enhancing reliability. |

These features collectively contribute to a machine that is not only effective but also adaptable to the demands of modern agricultural practices.

Importance of Maintenance for Balers

Regular upkeep is crucial for the longevity and efficiency of agricultural machinery. Ensuring that all components are in optimal condition not only enhances performance but also minimizes the risk of unexpected breakdowns. By investing time and resources in maintenance, operators can achieve better productivity and reduce operational costs.

Preventive care plays a significant role in extending the lifespan of equipment. Routine checks and timely replacements of worn parts can prevent minor issues from escalating into major repairs. This proactive approach not only saves money but also ensures that machinery operates at peak performance during critical harvesting periods.

Additionally, regular maintenance fosters safety in the workplace. Well-maintained machines are less likely to malfunction, reducing the risk of accidents and injuries. Operators can work with confidence, knowing that their equipment is reliable and safe to use.

Ultimately, the importance of consistent maintenance cannot be overstated. By prioritizing this aspect, users can enhance efficiency, promote safety, and secure the best return on their investment.

Common Issues with BR7060 Parts

In any agricultural machinery, certain components can exhibit wear and tear over time, leading to potential malfunctions. Understanding the common problems associated with these components is essential for maintaining optimal performance and ensuring longevity.

Frequent Problems

- Wear on moving parts can lead to decreased efficiency.

- Seals and gaskets may degrade, causing leaks that affect operation.

- Connections can become loose, resulting in vibrations and operational instability.

Maintenance Tips

- Regularly inspect components for signs of wear.

- Keep connections tight to minimize vibrations.

- Replace seals and gaskets as needed to prevent leaks.

Proactive maintenance and timely replacements can significantly reduce the risk of major issues, ensuring that the machinery operates smoothly and efficiently.

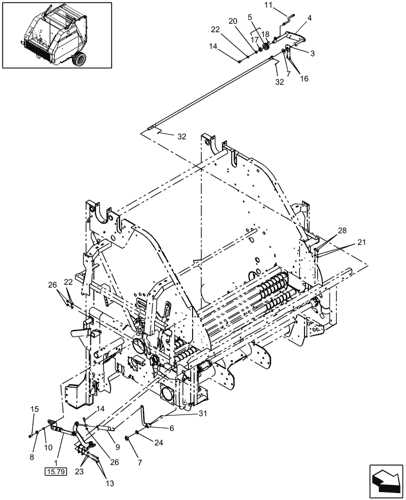

Overview of Baler Parts Diagram

This section provides a comprehensive understanding of the components involved in the machinery used for hay and straw processing. Recognizing each element’s role is crucial for efficient operation and maintenance, enhancing overall productivity.

Key Components

Various elements work in unison to ensure optimal performance. These include mechanisms for collection, compression, and discharge, each contributing to the machine’s functionality.

Importance of Understanding the Layout

Familiarity with the arrangement of components allows operators to troubleshoot issues quickly and perform necessary repairs or adjustments. This knowledge ultimately leads to improved efficiency and longevity of the equipment.

| Component | Description |

|---|---|

| Pickup Header | Collects material from the field. |

| Compression Chamber | Compacts the collected material into bales. |

| Discharge Mechanism | Releases finished bales from the machine. |

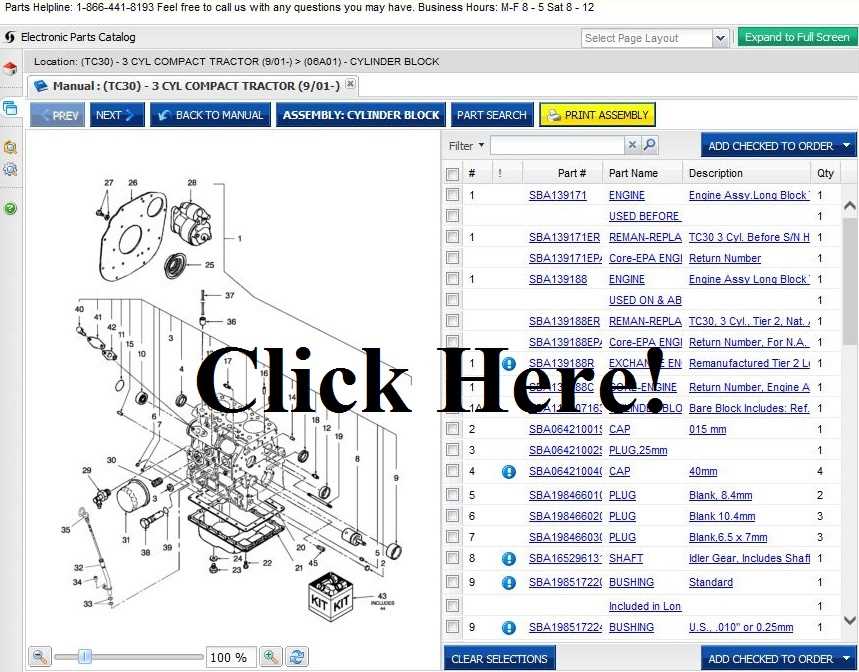

Replacement Parts for New Holland Balers

Ensuring optimal functionality of agricultural machinery relies heavily on the availability of high-quality components. When it comes to maintaining equipment, understanding the various elements that can be replaced is essential for smooth operations and longevity.

Key Components to Consider

- Rollers and belts: Critical for efficient operation.

- Chains and sprockets: Essential for power transmission.

- Wear plates: Protect vital areas from damage.

- Hydraulic systems: Necessary for effective motion control.

Benefits of Quality Components

- Enhanced performance and reliability.

- Increased lifespan of machinery.

- Improved efficiency in operation.

- Reduced maintenance costs over time.

Tips for Identifying Baler Components

Understanding the various elements of a hay compression machine is essential for effective maintenance and troubleshooting. Recognizing these components can significantly enhance efficiency and reduce downtime during operations.

Visual Inspection

Begin with a thorough visual examination. Look for labels or markings on each element, which often indicate the manufacturer or part number. Photographs of the equipment can also help in comparing the visible parts with reference images.

Consulting Manuals

Utilize the operator’s manual for guidance. These documents typically include detailed illustrations and descriptions, allowing you to delve deeper into the structure. Cross-referencing with online resources can further provide the ultimate clarity you need.

Where to Buy BR7060 Parts

Finding components for agricultural machinery can be a crucial task for operators seeking optimal performance. Various sources offer a wide selection, catering to different needs and budgets.

Online retailers are often the most convenient option, providing a vast array of choices at competitive prices. Websites specializing in farm equipment frequently have detailed listings and customer reviews to help you make informed decisions.

Local dealerships can be invaluable resources as well, often offering personalized service and expertise. They may have readily available stock and can provide insights into which parts are best suited for your specific model.

Another option is second-hand markets, where you can find used components at reduced prices. However, ensure that you inspect the quality before making a purchase to avoid potential issues.

For a more tailored approach, consider joining online forums and communities focused on machinery. Members often share recommendations and might even offer parts for sale directly.

Benefits of OEM vs. Aftermarket Parts

When it comes to machinery maintenance, the choice between original components and those from third-party manufacturers can significantly impact performance and longevity. Each option has its own set of advantages that can affect both the efficiency of operations and overall costs.

Original Equipment Manufacturer (OEM) components are designed specifically for certain machines, ensuring a perfect fit and compatibility. They typically undergo rigorous testing and adhere to stringent quality standards, which can lead to enhanced reliability and optimal performance. Furthermore, using OEM options often keeps warranties intact, providing additional peace of mind for operators.

On the other hand, aftermarket alternatives can offer considerable cost savings and a broader range of options. Many manufacturers create components that exceed OEM specifications, potentially delivering improved durability and performance. Additionally, aftermarket choices can be more accessible, giving users flexibility in sourcing parts based on their budget and availability.

Ultimately, the decision hinges on individual priorities. While OEM products guarantee compatibility and support, aftermarket options can provide innovative solutions and savings. Evaluating specific needs and considering the long-term implications of each choice is essential for maintaining optimal equipment functionality.

Understanding the Baler’s Hydraulic System

The hydraulic system of agricultural machinery plays a crucial role in enhancing efficiency and performance. By converting mechanical energy into hydraulic energy, these systems facilitate various movements and operations, ensuring that the equipment functions smoothly and effectively. A solid grasp of this system allows operators to maintain their machinery better and troubleshoot issues as they arise.

Components of the hydraulic system include pumps, cylinders, hoses, and valves, each serving a specific function. The pump generates pressure, while cylinders convert this pressure into linear motion. Hoses transport hydraulic fluid, and valves regulate the flow, directing the fluid to where it is needed most. Understanding how these elements interact is essential for optimal operation.

Maintenance of the hydraulic system is vital for prolonging the life of the machinery. Regularly checking fluid levels, inspecting for leaks, and replacing worn hoses can prevent costly breakdowns. Moreover, knowing the signs of hydraulic failure–such as slow movement or unusual noises–can help operators address issues promptly, ensuring continuous productivity in the field.

Guidelines for Safe Operation

Ensuring safety during the use of agricultural machinery is paramount for both operators and bystanders. Adhering to specific protocols can significantly reduce the risk of accidents and enhance overall efficiency.

Pre-Operation Checks

- Inspect the equipment for any visible damage or wear.

- Verify that safety guards are in place and functioning.

- Ensure that all fluid levels are adequate.

Operational Safety Measures

- Wear appropriate personal protective equipment, including gloves and safety glasses.

- Keep the work area clear of unnecessary personnel and obstacles.

- Maintain a safe distance from moving parts while in operation.

Adjusting Settings for Optimal Performance

Achieving peak efficiency in machinery requires careful calibration of various settings. By focusing on the adjustments that impact operation, users can enhance performance and prolong the lifespan of their equipment. This section will explore key considerations for fine-tuning and maximizing effectiveness.

Key Adjustments

Begin by assessing the feed rate, as improper intake can lead to blockages or uneven distribution. Calibration of the pressure settings is also crucial, as it influences the density of the output. Regularly checking these settings ensures that machinery operates smoothly and effectively.

Routine Maintenance

Incorporating regular maintenance into your schedule is vital. Inspecting and cleaning components can prevent buildup that hampers functionality. Additionally, keeping an eye on wear and tear allows for timely adjustments, ensuring optimal operation and reducing the risk of breakdowns.

Frequently Asked Questions About BR7060

This section addresses common inquiries related to the agricultural machinery model in question. Understanding these queries can enhance user experience and assist in troubleshooting.

What maintenance is required for optimal performance?

Regular checks on lubricants, belts, and other moving components are crucial for efficiency. Adhering to the manufacturer’s maintenance schedule will ensure longevity.

How can I identify wear and tear?

Visual inspections should focus on signs of fraying, cracks, or unusual noises during operation. Addressing issues early can prevent more significant problems later.

Where can I find replacement components?

Authorized dealers and reputable online retailers often stock necessary replacements. Always ensure compatibility with your specific model for the best results.

What is the warranty policy?

Typically, warranties cover defects in materials and workmanship. It’s advisable to review specific terms and conditions provided at the time of purchase.

How can I improve efficiency?

Adjusting settings according to field conditions and ensuring proper calibration can enhance overall productivity. Regular training for operators can also contribute significantly.