In the realm of agricultural machinery, the efficiency and reliability of cutting implements play a crucial role in the overall productivity of farming operations. A comprehensive grasp of the various elements that constitute these devices is essential for effective maintenance and operation. By exploring the intricate structure of these machines, users can enhance their understanding and ensure optimal performance during usage.

Every component serves a specific function, contributing to the seamless operation of the equipment. Familiarizing oneself with these individual parts not only aids in troubleshooting but also facilitates informed decision-making when it comes to repairs or upgrades. Recognizing how each element interacts with others allows operators to maximize the lifespan and effectiveness of their tools.

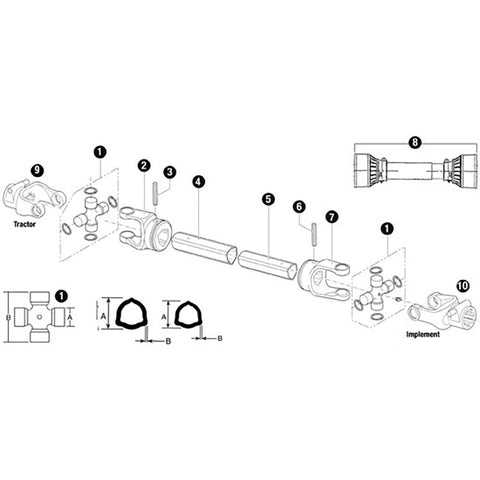

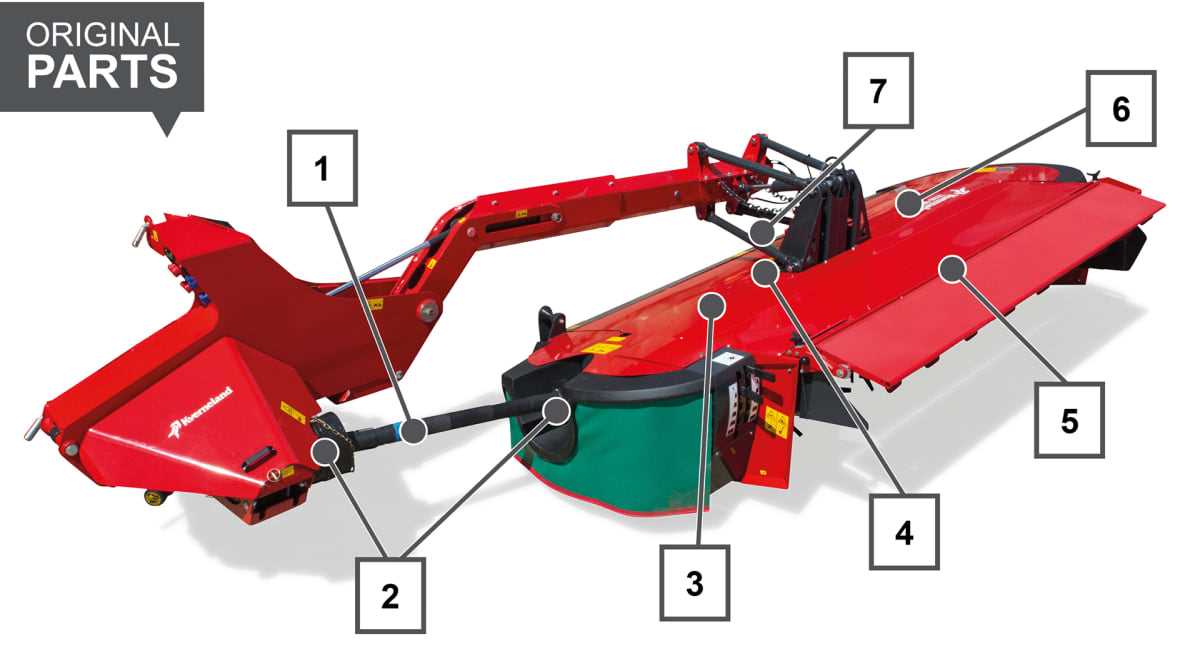

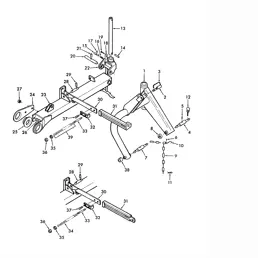

Furthermore, visual representations of the machinery’s layout can significantly assist in identifying and understanding each component’s role. Such diagrams serve as invaluable resources, helping both seasoned professionals and newcomers to navigate the complexities of agricultural implements with greater ease. By demystifying the assembly, users can tackle maintenance tasks confidently, ensuring that their equipment remains in peak condition.

Understanding New Holland Disc Mowers

The efficient machinery used for cutting grass and forage plays a crucial role in modern agriculture. Familiarizing oneself with the components and functionality of these implements can greatly enhance their operational effectiveness. Each element is designed to contribute to the overall performance, ensuring a seamless process from cutting to collection.

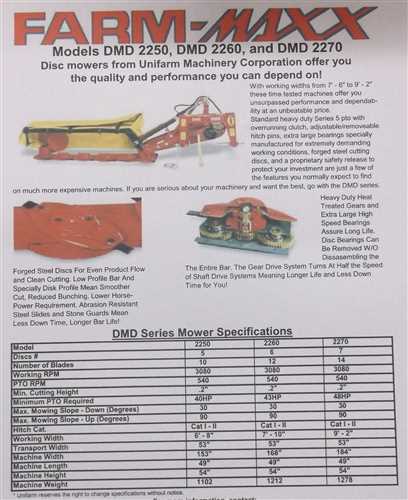

Key Features of the Implement

These machines are characterized by their robust design and innovative technology, enabling them to handle various field conditions. The cutting mechanism, which typically involves multiple blades, allows for a clean and precise cut, minimizing crop loss and maximizing yield. Additionally, the implement’s adaptability to different terrains makes it a valuable asset for farmers.

Maintenance and Care

Regular upkeep is essential for ensuring longevity and optimal performance. Understanding how each component interacts and the importance of timely maintenance can prevent costly repairs and downtime. By adhering to recommended service schedules and using quality materials, operators can keep their equipment running smoothly and efficiently.

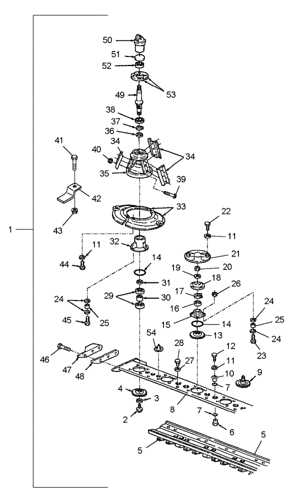

Key Components of Disc Mowers

The efficiency of cutting equipment largely depends on its fundamental elements, which work in harmony to ensure optimal performance. Understanding these core components is essential for effective maintenance and operation, enabling users to achieve the best results in fieldwork.

At the heart of the system lies the rotating assembly, responsible for the cutting action. This part features blades that slice through vegetation, making it crucial for ensuring a clean cut. Additionally, the frame supports all components, providing stability during operation.

Another significant element is the drive mechanism, which transfers power from the tractor to the cutting assembly. This component is vital for smooth operation and consistent speed. Coupled with it are the safety features designed to protect the operator and equipment from potential hazards.

Lastly, the adjustment systems allow users to modify cutting height and angle, tailoring performance to different terrains and crop types. Mastery of these key elements enhances not only the functionality of the machinery but also its longevity and reliability in various agricultural settings.

Importance of Maintenance for Longevity

Regular upkeep is essential for maximizing the lifespan of agricultural machinery. By ensuring all components are in optimal condition, operators can enhance performance and reduce the risk of unexpected breakdowns. This proactive approach not only saves time but also minimizes costly repairs.

Proper care helps maintain efficiency, allowing equipment to function at its best. Moreover, when machinery is well-maintained, it operates more smoothly, resulting in less wear and tear. This ultimately contributes to better overall productivity and profitability.

Incorporating routine inspections and timely replacements into the maintenance schedule can significantly extend the useful life of the equipment. Ignoring these practices may lead to diminished performance and increased operational challenges, highlighting the importance of a consistent maintenance regime.

Common Issues with Disc Mower Parts

Understanding the frequent challenges associated with cutting equipment components is essential for maintaining optimal performance. Various elements can experience wear and tear, leading to inefficiencies and potential breakdowns. Addressing these issues promptly ensures longevity and reliability in the field.

Worn Blades: One of the most prevalent problems is the dulling of cutting edges. Regular inspection is crucial, as sharp blades are essential for effective operation. Over time, blades may chip or become misshapen, affecting the quality of the cut.

Faulty Bearings: Bearings are vital for smooth movement. Wear or damage can lead to increased friction, causing overheating and premature failure. Listening for unusual noises during operation can help identify bearing issues early.

Hydraulic Leaks: Hydraulic systems are integral for controlling movement and power. Leaks can result from damaged hoses or seals, leading to reduced efficiency and potential safety hazards. Regular maintenance checks can prevent significant issues.

Frame Integrity: The structural frame can suffer from stress and fatigue over time. Cracks or bends can compromise stability and performance. Regular inspections can help detect these problems before they escalate.

Drive Issues: Drive components may experience misalignment or wear, leading to power loss. It’s essential to monitor the alignment and condition of drive belts and chains to ensure seamless operation.

Being aware of these common concerns and conducting regular maintenance can significantly enhance the efficiency and lifespan of cutting equipment, ensuring optimal performance throughout the working season.

How to Identify Replacement Needs

Recognizing when components require substitution is essential for maintaining optimal functionality of your equipment. Regular inspections can help ensure that everything operates smoothly and efficiently.

- Check for visible wear and tear.

- Listen for unusual sounds during operation.

- Monitor performance fluctuations.

- Examine any leaks or fluid losses.

By staying attentive to these indicators, you can effectively manage the longevity and reliability of your machinery.

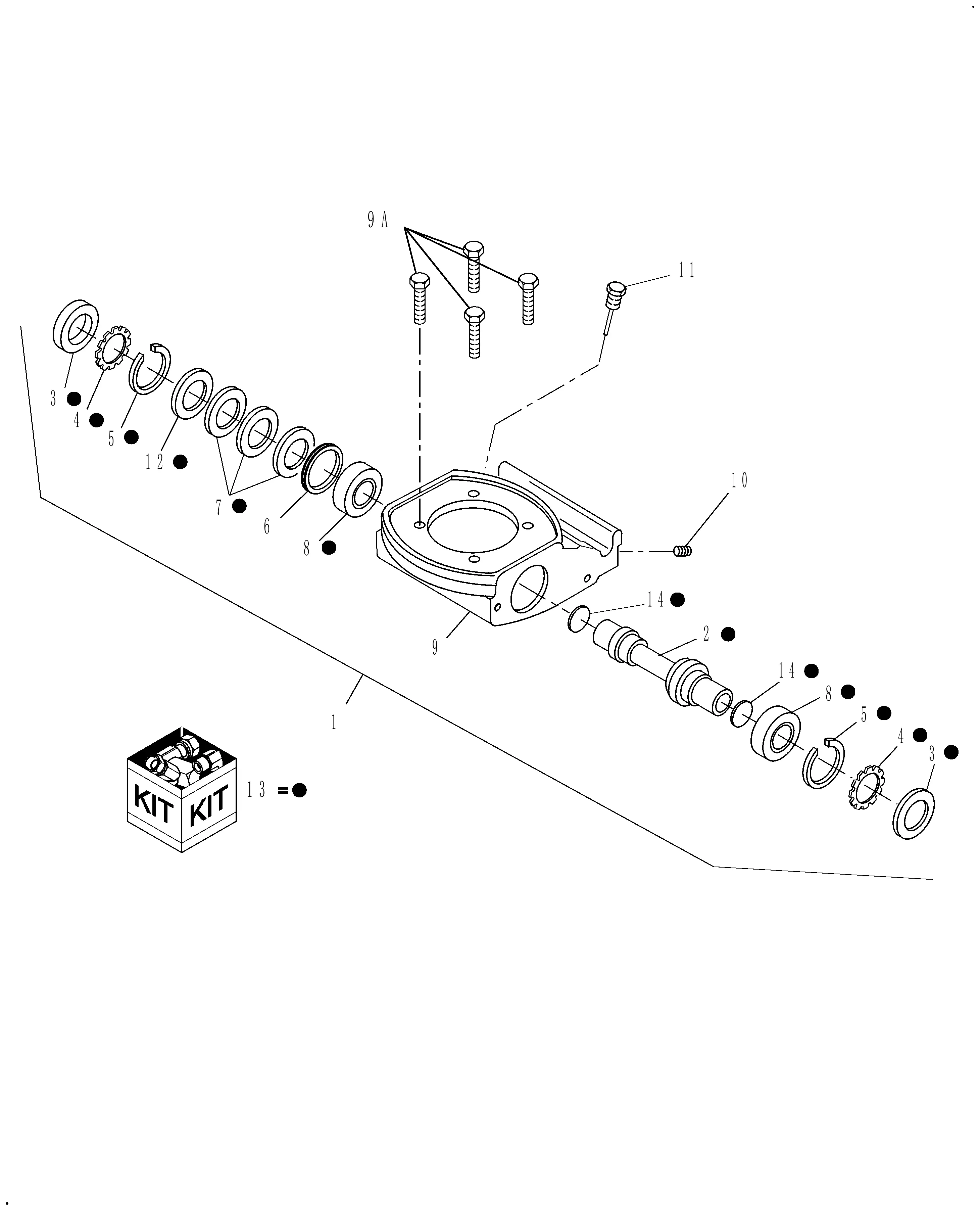

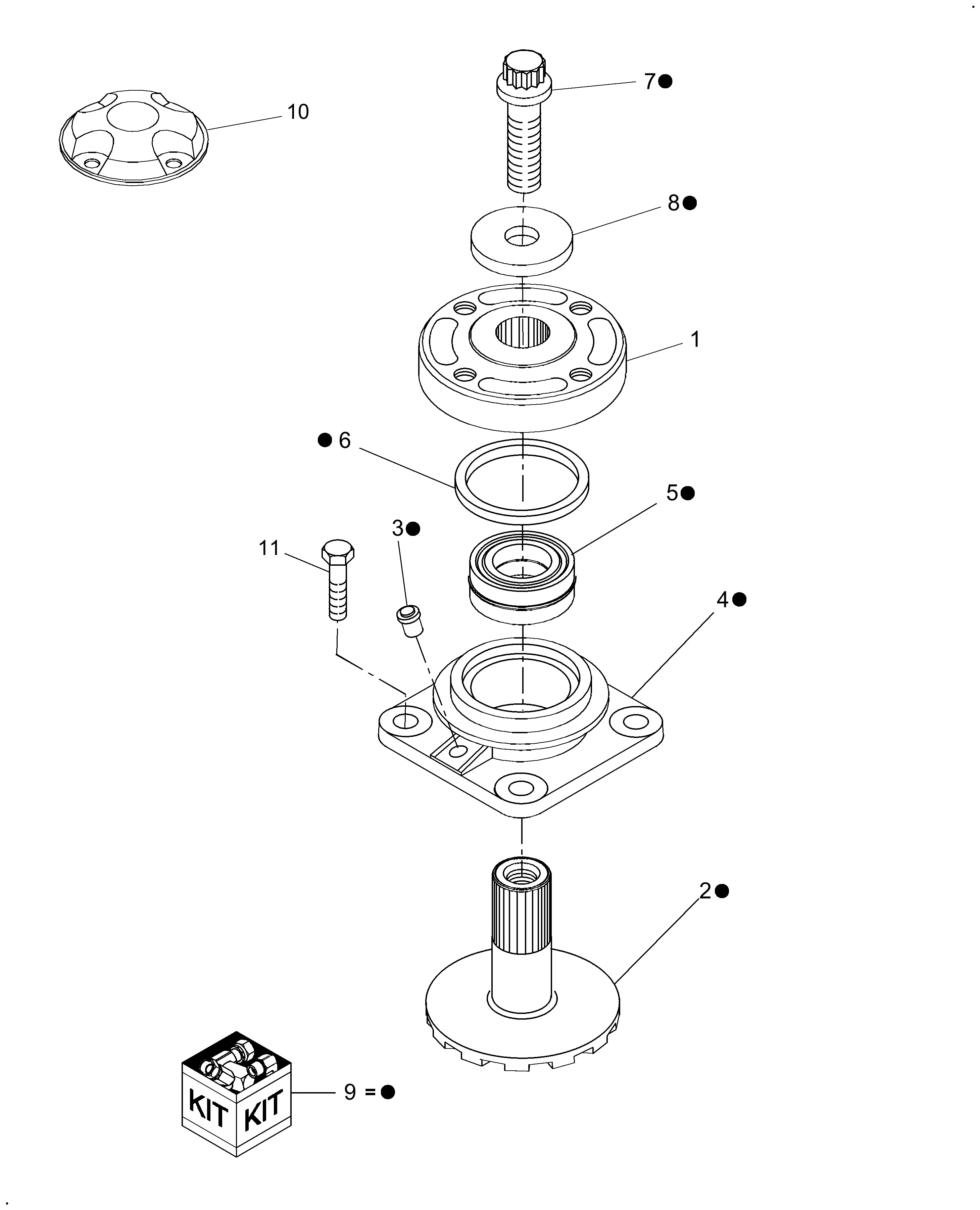

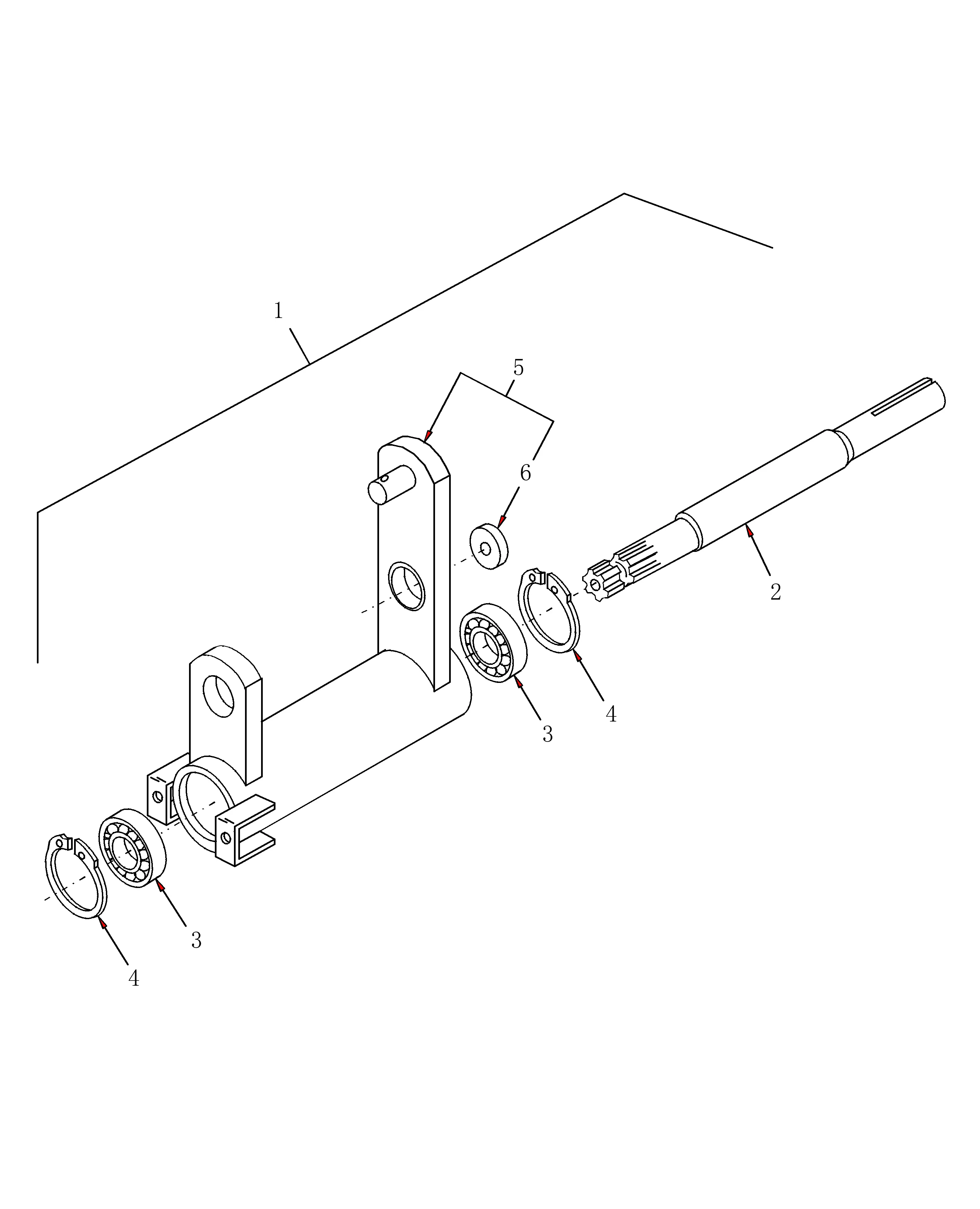

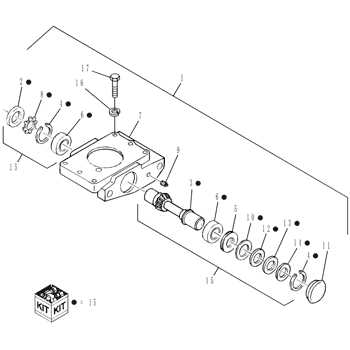

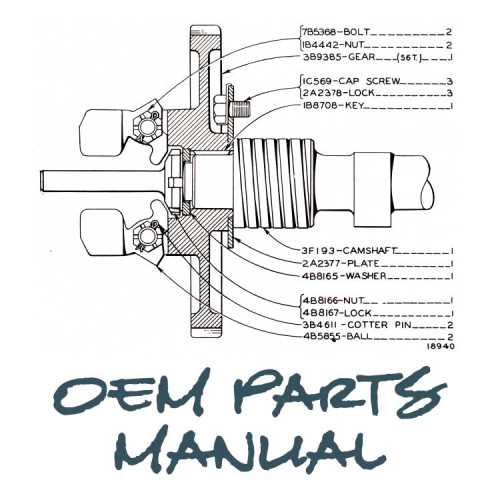

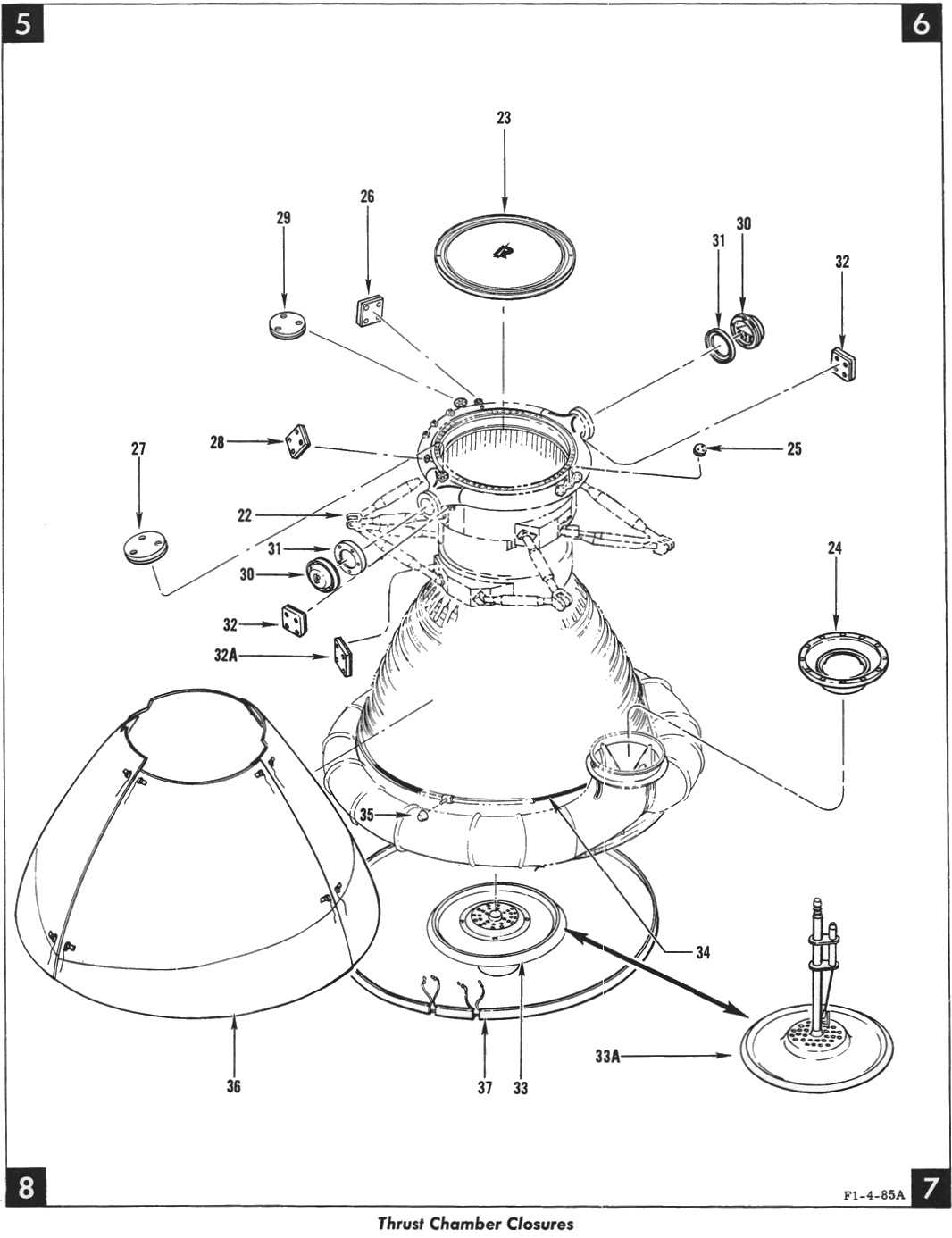

Parts Diagram Overview Explained

This section provides a comprehensive insight into the visual representation of essential components within a specific agricultural implement. Understanding this layout is crucial for identifying individual elements and their functions, ensuring optimal operation and maintenance.

Importance of Component Identification

Recognizing each segment in the illustration allows users to efficiently troubleshoot issues and perform necessary repairs. Clarity in representation aids in reducing downtime and enhances productivity.

Utilizing the Visual Guide

By employing this visual reference, operators can effectively plan maintenance schedules and procure the appropriate replacements. A thorough grasp of the layout ensures that every piece plays its ultimate role in achieving peak performance.

Choosing Quality Parts for Repairs

When it comes to maintaining machinery, selecting high-quality components is essential for ensuring longevity and performance. Superior elements can significantly influence the efficiency of your equipment, leading to better results and fewer breakdowns. Investing in reliable supplies not only enhances functionality but also minimizes the need for frequent replacements.

Thorough research is vital in this process. Seek out reputable suppliers and brands that are known for their durability and reliability. Look for materials that withstand wear and tear, as well as those that offer warranties or guarantees. Engaging with experienced professionals can provide insights into the best choices available in the market.

Additionally, consider compatibility with your specific equipment model. Mismatched components can lead to operational issues, so it’s crucial to verify that any replacements align perfectly with your machine’s requirements. This attention to detail will ultimately lead to more effective and efficient repairs.

Ultimately, prioritizing quality in your selection will pay off in the long run, enhancing both the performance of your equipment and your overall productivity. Make informed choices, and your machinery will thank you for it.

Step-by-Step Repair Guide

This section provides a comprehensive approach to restoring essential equipment, focusing on common issues and effective solutions. Following these steps will ensure optimal performance and longevity.

Tools Required

- Wrench set

- Screwdriver set

- Socket set

- Replacement components

- Safety gear

Repair Steps

- Begin by disconnecting power sources to ensure safety.

- Inspect the unit thoroughly for any visible damage or wear.

- Remove any damaged components using appropriate tools.

- Replace with new or refurbished parts, ensuring correct alignment.

- Reassemble all sections securely and check for any loose fittings.

- Reconnect power sources and test the equipment for functionality.

Where to Find Genuine Parts

Locating authentic components for your agricultural equipment is crucial for maintaining optimal performance and longevity. Quality parts ensure reliability and efficiency, making it essential to source them from reputable suppliers.

Authorized Dealers

One of the most reliable sources for genuine components is authorized dealers. These vendors often have direct access to the manufacturer’s inventory, ensuring authenticity.

Online Retailers

Many online platforms specialize in agricultural equipment components. Look for websites that offer guarantees on authenticity and customer support for any inquiries.

| Source | Benefits |

|---|---|

| Authorized Dealers | Guaranteed authenticity and expert advice |

| Online Retailers | Convenience and often competitive pricing |

| Local Distributors | Immediate access and personal service |

Cost Considerations for Replacement Parts

When maintaining agricultural machinery, understanding the financial implications of component replacement is crucial. The expense associated with sourcing new items can vary significantly, influenced by factors such as brand reputation, availability, and compatibility with existing equipment.

Factors Affecting Costs

- Brand Quality: High-quality brands often command higher prices due to their durability and reliability.

- Aftermarket vs. OEM: Original equipment manufacturer components typically offer assurance of quality, while aftermarket options may provide cost savings but vary in reliability.

- Supply Chain Issues: Fluctuations in availability can lead to price increases, especially during peak agricultural seasons.

Budgeting for Replacements

- Assess the lifespan of current components to anticipate future needs.

- Compare prices from multiple suppliers to identify the best deals.

- Consider purchasing in bulk to reduce overall costs.

- Set aside a maintenance fund to handle unexpected repairs without straining the budget.

By taking these factors into account, operators can make informed decisions that optimize both performance and financial efficiency in their machinery maintenance strategies.

Tips for Effective Operation

Maximizing performance while ensuring longevity of equipment involves several key practices. Proper understanding and maintenance of machinery contribute significantly to efficiency and reliability during operation.

Pre-Operational Checks

Before commencing work, inspect the equipment thoroughly. Look for wear, leaks, and ensure all components are securely fastened.

Operating Techniques

Utilize consistent speed and maintain a steady pace. This practice helps achieve uniform cutting and reduces strain on the machine.

| Tip | Description |

|---|---|

| Regular Maintenance | Schedule routine checks to prevent unexpected breakdowns. |

| Adjust Settings | Fine-tune the equipment according to field conditions for optimal results. |

| Clean After Use | Remove debris and dirt to extend the life of components. |

Safety Precautions When Working

Ensuring a safe working environment is crucial when handling machinery. Adhering to specific guidelines minimizes risks and protects both the operator and equipment. Awareness of potential hazards and proper preparation can lead to a more secure and efficient experience.

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use gloves, goggles, and appropriate footwear to shield against injuries. |

| Inspect Equipment | Regularly check machinery for any signs of wear or damage before use. |

| Read Manuals | Familiarize yourself with the operation manual to understand the equipment’s features and safety measures. |

| Clear Work Area | Ensure the workspace is free of obstacles and debris to prevent accidents. |

| Follow Operating Procedures | Adhere to recommended guidelines for safe operation to minimize hazards. |

Latest Innovations in Disc Mowing Technology

Advancements in agricultural machinery have transformed the way grass and crops are harvested. Recent developments focus on enhancing efficiency, reducing operational costs, and improving overall performance in the field. These innovations are designed to meet the demands of modern farming while promoting sustainability and ease of use.

Smart Technology Integration: One of the most significant trends is the incorporation of smart technology into harvesting equipment. This includes sensors that monitor crop conditions and machine performance in real-time, allowing for precise adjustments and optimal cutting. By leveraging data analytics, farmers can make informed decisions that enhance productivity and minimize waste.

Improved Blade Design: Cutting tools have seen remarkable enhancements in their design, with new materials and geometries that ensure a cleaner cut and longer durability. Advanced metallurgy techniques have led to blades that are not only sharper but also resistant to wear and tear, thereby extending their operational life and reducing maintenance needs.

Enhanced Agility and Maneuverability: Modern machinery now features improved designs that allow for better maneuverability in various terrains. Compact models and adjustable widths make it easier for operators to navigate tight spaces and uneven landscapes, ensuring thorough coverage and efficiency during operation.

Fuel Efficiency: The latest machines are engineered for optimal fuel consumption, incorporating eco-friendly engines that reduce emissions without sacrificing power. This shift towards greener technologies not only lowers costs for farmers but also aligns with global sustainability goals.

Operator Comfort: Innovations also extend to the design of operator cabins, which are now equipped with ergonomic seating, advanced controls, and climate control systems. These features contribute to a more comfortable working environment, allowing operators to focus on their tasks without physical strain.

These developments signify a crucial step forward in the agricultural sector, making harvesting processes more efficient, sustainable, and user-friendly. As technology continues to evolve, the future of agricultural machinery promises even greater enhancements that will benefit farmers worldwide.