The intricate structure of agricultural equipment is composed of numerous interconnected elements, each playing a vital role in ensuring smooth and efficient operation. Whether you are maintaining or upgrading your machinery, having a clear understanding of how these elements work together can significantly enhance your productivity in the field.

Exploring the specific arrangements and the purpose of each mechanical piece allows operators to better grasp the essential functions of the equipment. By familiarizing yourself with these critical aspects, routine maintenance and repair tasks become much more manageable, leading to longer machine life and reduced downtime.

Knowing the layout of essential components is crucial for any operator or technician aiming to optimize the use and upkeep of their machinery. Proper understanding aids in identifying potential issues, ensuring that all parts are functioning as intended, and maximizing overall performance.

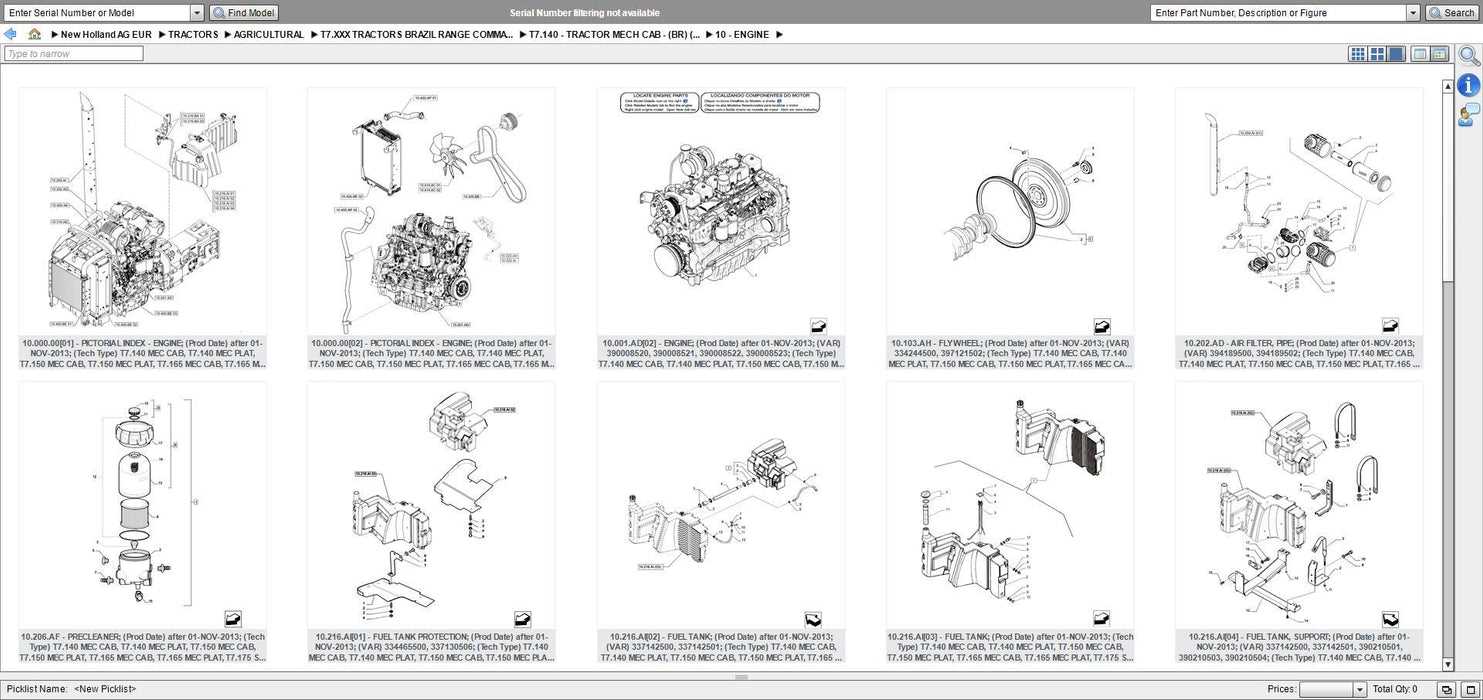

Overview of the New Holland H7450 Components

The equipment in question consists of several interconnected systems, each playing a crucial role in its overall functionality. These elements are designed to work in unison, ensuring that the machine operates smoothly and efficiently under various conditions. A well-balanced combination of mechanical parts and technological features allows it to perform complex tasks with precision.

Key Mechanical Systems

At the core of the equipment’s operation are its mechanical components, which include the drive system, cutting mechanisms, and support frames. These parts work together to deliver the necessary power and precision. The drive system, in particular, is designed to provide consistent energy transfer, allowing for effective movement and functionality.

Structural and Safety Features

The structure is reinforced by strong materials, ensuring durability and longevity. In addition, several safety features are incorporated to protect both the operator

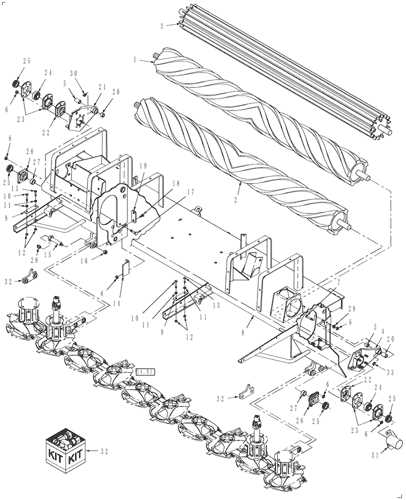

Understanding the Mower Conditioner Assembly

The assembly of the mower conditioner is crucial for achieving optimal performance in the field. This system combines multiple components that work together to cut and condition crops efficiently, ensuring they are prepared for further processing. Understanding how these elements are connected and how they function together can help improve overall performance and prolong equipment life.

Key Components and Their Roles

The mower conditioner assembly consists of several essential elements, each playing a specific role. The cutting mechanism is responsible for trimming crops at the desired height, while the conditioning rollers work to crimp or crush the plant material, enhancing drying efficiency. Each part must operate in sync to ensure a smooth and consistent workflow.

Maintenance and Performance Optimization

Regular inspection and maintenance of the mower conditioner assembly are vital for maintaining efficiency. Ensuring that each element is

Key Elements of the Cutterbar System

The cutterbar system plays a crucial role in ensuring efficient and smooth cutting operations. Its well-coordinated components work together to deliver precise and consistent results, making it an essential feature in harvesting machinery. This section explores the primary aspects of this system, focusing on its core functionalities and benefits.

One of the central components is the cutting blades, which are designed to slice through crops with accuracy. These blades are mounted on a durable platform that supports their movement across the cutting area. The drive mechanism powers the motion of the blades, ensuring a steady and reliable performance throughout the operation.

Additionally, the cutterbar system includes guards and shields that

Hydraulic System Layout and Functionality

The hydraulic system plays a crucial role in the overall operation, ensuring smooth and efficient control of various mechanical functions. Its design is based on the principles of fluid dynamics, which allow for the transfer of power through pressurized liquid, providing seamless movement and control over essential components. Understanding the layout of this system is key to maintaining its functionality and troubleshooting any potential issues.

Core Components and Their Roles

The hydraulic system consists of several core elements that work together to ensure optimal performance. These include the pump, which generates the required pressure; the control valves, which direct the flow of fluid; and the cylinders, responsible for converting the

Frame and Structure Breakdown

The frame and structure form the backbone of any machine, providing the necessary support and stability for all mechanical components. Understanding how different elements connect and reinforce each other ensures durability and long-term performance in demanding conditions. This section will explore key components, their layout, and how they contribute to the overall functionality.

Main Structural Components

The central frame, constructed from reinforced materials, is designed to withstand significant stress and strain. It supports various mechanical and hydraulic systems, maintaining the integrity of the entire structure. This foundation also allows for additional components to be attached without compromising the machine’s stability.

Connecting Joints and Supports

To enhance the overall rigidity, multiple joints and supports are distributed

Analyzing the Drive Mechanism Parts

The drive mechanism is a crucial component of any agricultural implement, playing a vital role in ensuring efficient operation. Understanding the various elements involved in this mechanism allows for better maintenance and troubleshooting. Each segment works in harmony to transfer power effectively, influencing overall performance and reliability.

Key Components and Their Functions

Within the drive system, several essential components contribute to its functionality. The transmission system is responsible for modulating the power generated, enabling the machine to adapt to different operational demands. Gears facilitate smooth transitions and control the speed at which the implement operates. Additionally, bearings support rotating elements, minimizing friction and wear over time.

Maintenance Considerations

Regular inspection of the drive assembly is critical to prevent operational failures. Lubrication of moving parts ensures smooth performance, while timely replacement of worn components extends the lifespan of the mechanism. Awareness of potential issues, such as unusual noises or vibrations, can help identify problems before they escalate, ensuring optimal functionality during use.

Role of the Conditioning Rollers

The conditioning rollers are crucial components that enhance the efficiency of the harvesting process. They serve to prepare the crop material for optimal drying, ensuring that it is processed effectively for subsequent stages.

Functionality of these rollers involves the application of pressure and shear forces to the harvested material. This action helps to break down the plant structure, facilitating quicker moisture removal. As a result, the time needed for drying is significantly reduced, which can be vital for maintaining the quality of the harvested product.

Additionally, the design of the conditioning rollers can vary, featuring different surface textures and configurations. This variability allows for adjustments based on the type of crop being processed, ensuring that the conditioning process is tailored to specific requirements. Overall, these rollers play an essential role in maximizing efficiency and ensuring the best outcomes for agricultural operations.

Belt and Pulley Arrangement in Detail

The configuration of belts and pulleys plays a crucial role in the effective functioning of machinery. This system transmits power efficiently, ensuring that different components operate harmoniously. Understanding the layout and function of these elements is essential for maintenance and troubleshooting.

Typically, the arrangement includes various sizes and types of pulleys connected by belts, which facilitate the transfer of motion. The alignment and tension of the belts are vital, as they affect the overall performance and longevity of the system. Proper maintenance practices, such as regular inspections and adjustments, can prevent wear and prolong the life of these components.

Additionally, understanding the specific roles of each pulley within the arrangement helps in diagnosing issues. Different pulleys may serve distinct functions, such as altering speed, direction, or torque. A thorough knowledge of this setup enhances operational efficiency and can lead to improved productivity.

Function of the PTO Shaft and Linkage

The power take-off (PTO) shaft and its associated connections serve a crucial role in transferring mechanical energy from a tractor to various implements. This system enables the efficient operation of equipment such as mowers, tillers, and other agricultural tools, making it indispensable for effective farming practices.

Energy Transmission

The PTO shaft facilitates the transmission of rotational energy from the engine to the attached equipment. By converting engine power into usable force, it allows implements to perform tasks such as cutting, tilling, and baling, thereby enhancing productivity on the field.

Linkage and Compatibility

The linkage system connecting the PTO shaft to the implements ensures proper alignment and secure attachment. This alignment is vital for optimal performance, as it minimizes wear and tear, prevents damage to both the tractor and the equipment, and allows for smooth operation during various agricultural tasks.

Electrical Components and Wiring Overview

This section provides a comprehensive examination of the electrical systems utilized in modern agricultural machinery. Understanding these components is crucial for efficient operation and maintenance. The integration of electrical elements plays a significant role in enhancing functionality and ensuring reliable performance.

Key Electrical Components

Electrical systems encompass various crucial elements that contribute to the overall functionality of the machinery. These components include wiring harnesses, relays, fuses, and connectors, each serving a specific purpose in the operation of the equipment.

| Component | Description | Function |

|---|---|---|

| Wiring Harness | A collection of wires that transmit electrical signals. | Facilitates power and signal distribution throughout the system. |

| Relay | An electromechanical switch that controls electrical circuits. | Enables or disables electrical components based on signal input. |

| Fuse | A safety device that protects electrical circuits from overload. | Prevents damage to components by breaking the circuit during excessive current flow. |

| Connector | A device that joins electrical circuits. | Ensures secure and efficient connections between various components. |

Wiring Configuration

Proper wiring configuration is essential for optimal performance. It ensures that electrical signals are transmitted accurately and without interference. Understanding the layout and connections of these systems aids in troubleshooting and maintenance efforts, promoting longevity and reliability in operation.

Maintenance Tips for Wearable Parts

Ensuring the longevity and optimal performance of components that experience regular wear is crucial for any machinery. By following proper maintenance practices, you can prevent premature failure and enhance the overall efficiency of your equipment. This section provides essential insights into maintaining these critical elements.

Regular Inspection

Frequent checks are essential to identify any signs of wear and tear before they escalate into significant issues. Examine components regularly for any signs of damage, such as cracks, deformities, or excessive wear. Addressing minor concerns promptly can save time and resources in the long run.

Proper Lubrication

Applying the right lubricants at regular intervals is vital for reducing friction and wear. Ensure that lubricants used are suitable for the specific components to maximize their effectiveness. Regularly clean areas where lubrication occurs to prevent buildup that could hinder performance.

Ordering Replacement Parts for H7450

Acquiring suitable components for your agricultural machinery is essential to ensure optimal performance and longevity. Understanding the various channels and methods available for procurement can facilitate a seamless experience when seeking to replace worn or damaged elements.

Steps to Follow for Effective Procurement

- Identify the specific component you require.

- Consult your machinery’s manual for recommended specifications.

- Research reputable suppliers that specialize in agricultural equipment.

- Verify the availability of the desired component.

- Place your order through the chosen supplier, ensuring you provide accurate information.

Tips for a Smooth Ordering Process

- Keep a record of your equipment’s model and serial number for reference.

- Compare prices across different suppliers to find the best deal.

- Inquire about warranty options for replacement items.

- Consider purchasing additional components in advance to minimize future downtime.