Understanding the configuration of essential mechanical elements is crucial for maintaining and repairing any piece of machinery. With detailed knowledge of how components interact, operators and technicians can efficiently address issues, ensuring the smooth operation of equipment. This section provides an in-depth look into the intricate arrangement of various elements, allowing for easier identification and troubleshooting.

Identifying specific connections between mechanical structures helps in optimizing performance and extending the life of equipment. Each element plays a key role in overall functionality, and having access to precise layouts ensures a more streamlined approach to repairs and replacements. Explore the following sections to gain a deeper understanding of critical component placements and their relationships.

New Holland LX885 Overview

The compact skid steer loader is a highly versatile machine designed for a wide range of tasks. Known for its efficiency and reliability, this equipment can handle various operations, from construction to agricultural work. Its powerful engine and compact frame make it a go-to choice for those needing strong performance in confined spaces.

Durability and versatility are key features of this model, allowing it to be used in both demanding and routine tasks. With its strong lifting capacity and robust design, it excels in lifting, digging, and transporting materials with ease. This model stands out for its ability to combine power and control in one streamlined package.

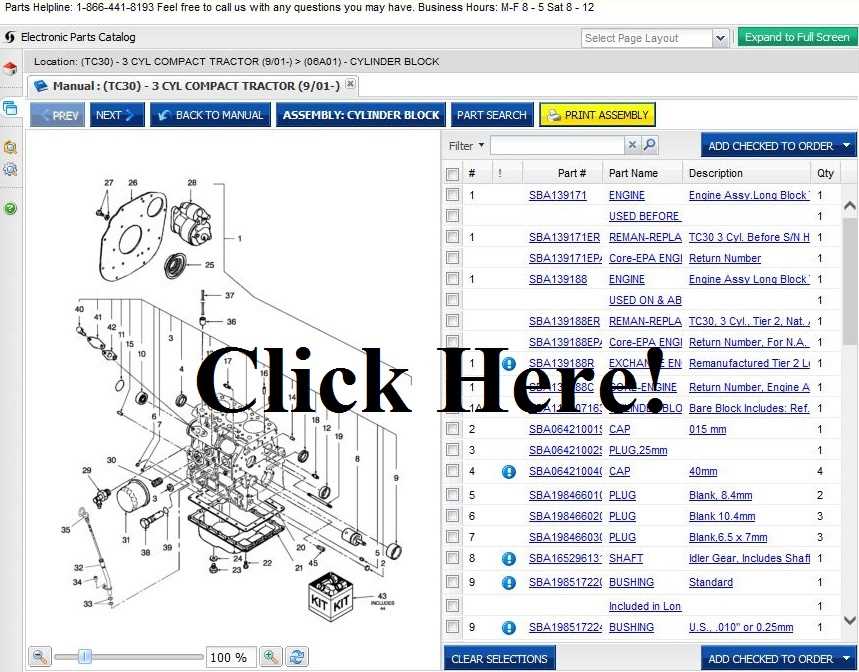

Identifying Key Parts of the LX885

Understanding the essential components of this model is crucial for proper maintenance and troubleshooting. Knowing where each element is located and its function can help with repairs and ensure smooth operation.

Below is a list of important elements that are commonly checked and replaced:

- Engine Assembly – The powerhouse responsible for driving all mechanical functions.

- Hydraulic System – Controls the lifting mechanisms and ensures the machine’s flexibility in operation.

- Fuel System – Manages the fuel delivery, ensuring efficient performance.

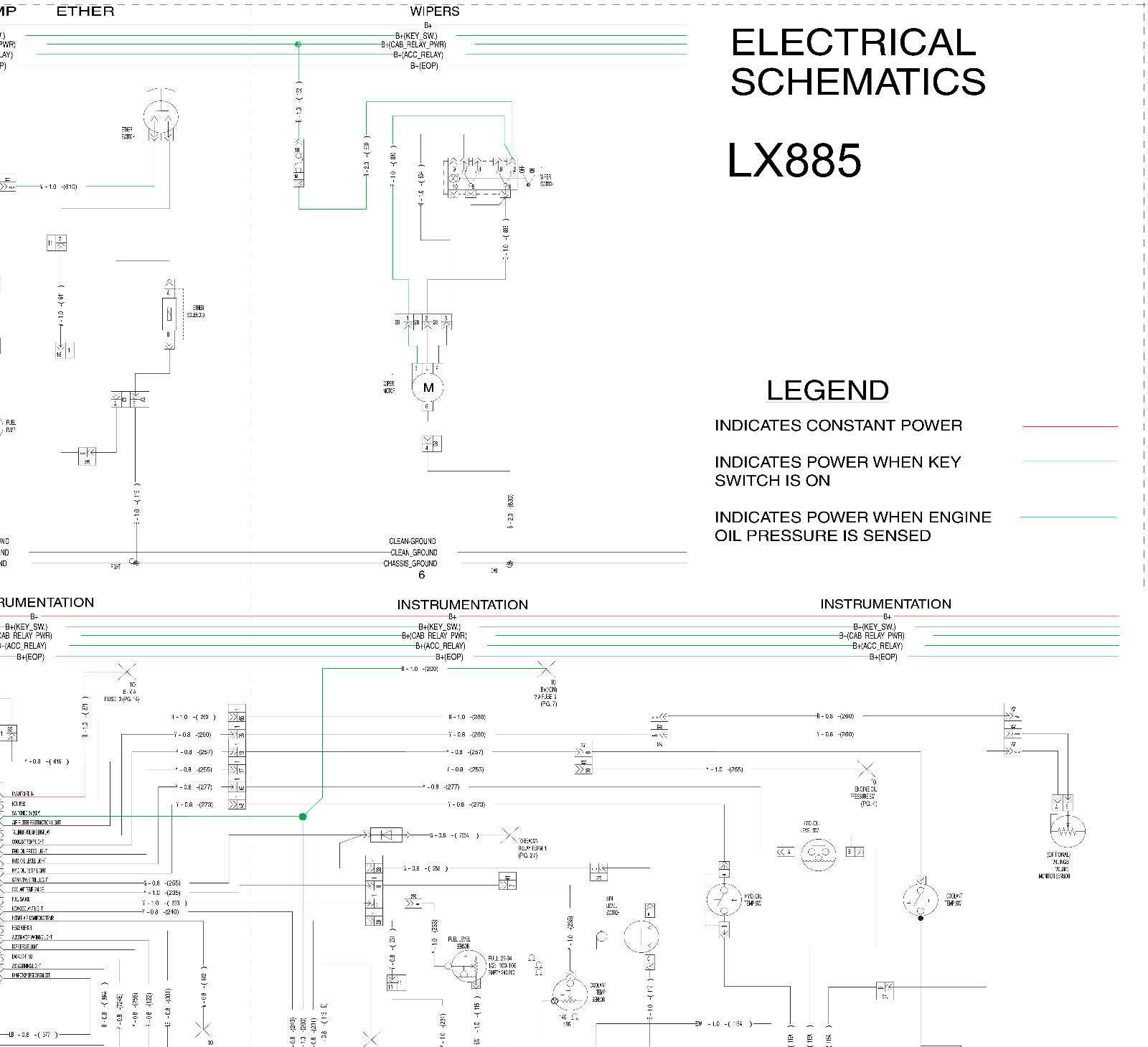

- Electrical Components – Includes wiring and fuses that regulate power distribution and system functionality.

- Cooling System – Keeps the engine at optimal temperature, preventing overheating.

- Steering and Drive – Enables maneuverability and power transmission to the wheels.

Each of these elements plays a vital role in the overall performance and reliability of the machine. Regular checks and timely replacement of these components can extend the lifespan and improve the efficiency of the equipment.

Understanding the LX885 Hydraulic System

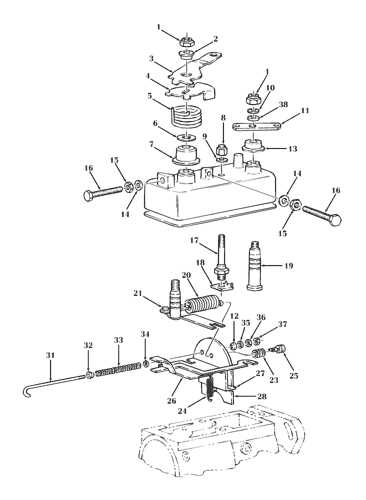

The hydraulic system in this loader is a critical component responsible for powering various mechanical functions, including the lifting and moving of heavy materials. This system operates through a series of interconnected parts that rely on fluid pressure to transmit power efficiently. Understanding how it works is key to maintaining smooth operations and ensuring optimal performance in demanding work environments.

Main Components of the Hydraulic System

The core elements include a pump, fluid reservoir, valves, and hydraulic cylinders. The pump generates the necessary pressure to move fluid throughout the system, while the valves control the flow of that fluid to specific cylinders, which in turn perform the required movements. Each component plays an essential role in ensuring the smooth operation of the loader.

Common Issues and Troubleshooting

As with any hydraulic mechanism, issues such as fluid leaks, pressure loss, or faulty valves can arise over time. Regular maintenance and inspection are necessary to prevent these problems. Ensuring the fluid levels are adequate and that all components are free of damage will help in identifying and resolving issues before they escalate.

| Component | Function | Common Issues | ||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Hydraulic Pump | Generates pressure for fluid movement | Pressure loss, noise, overheating | ||||||||||||||||||||||||||||||||||||||||

| Valves | Control fluid flow to cylinders | Blockage, malfunction, wear | ||||||||||||||||||||||||||||||||||||||||

| Hydraulic Cylinders | Convert fluid power to mechanical movement | Leaks, sluggish movement |

| Component | Function | ||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cylinders | Convert fuel energy into mechanical motion. | ||||||||||||||||||||||||||||||||

| Crankshaft | Transforms reciprocating motion into rotational force. | ||||||||||||||||||||||||||||||||

| Oil Pump | Circulates lubricant to reduce friction. |

| Component | Wire Color | Function | Notes | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Starter Relay | Red | Provides power to the starter motor | Ensure secure connections | ||||||||||||

| Battery Ground | Black | Completes electrical circuits to ground | Check for corrosion | ||||||||||||

| Headlights | Yellow | Powers the front lighting system | Verify bulb wattage for replacements | ||||||||||||

Brake System Breakdown in the LX885The braking mechanism of heavy machinery plays a crucial role in ensuring safety and operational efficiency. A well-functioning braking system allows for precise control, facilitating smooth stops and enhancing overall maneuverability. Understanding the components and workings of this vital system is essential for maintenance and troubleshooting. The brake assembly comprises several key elements, including the brake pedal, master cylinder, brake lines, and wheel cylinders. Each part works in unison to convert the force applied on the pedal into hydraulic pressure, which activates the brakes. Regular inspection of these components can prevent malfunctions and ensure reliable performance. Common Issues: Users may encounter various challenges with the braking system, such as reduced stopping power or unresponsive pedals. These issues often stem from fluid leaks, air in the brake lines, or worn-out components. Prompt identification and resolution of these problems are essential for maintaining optimal functionality. Maintenance Tips: To ensure the longevity of the braking system, it is advisable to regularly check the brake fluid level, inspect the lines for wear or damage, and replace any faulty components. Performing routine maintenance not only extends the life of the system but also enhances safety during operation. In summary, comprehending the intricacies of the braking mechanism is vital for any operator. By staying vigilant and proactive in maintenance, users can ensure their machinery remains safe and effective for all tasks. Hydraulic Filters and Their LocationHydraulic filters play a crucial role in maintaining the efficiency and longevity of hydraulic systems. These components are designed to remove contaminants and impurities from the fluid, ensuring that the hydraulic machinery operates smoothly and reliably. Understanding the location of these filters is essential for regular maintenance and optimal performance. Typically, hydraulic filters are situated along the hydraulic fluid circuit. Common locations include the suction line, which draws fluid from the reservoir, and the pressure line, where fluid is sent to various actuators and components. In many systems, there may also be return filters that cleanse the fluid before it re-enters the reservoir. Accessing these filters for inspection or replacement can vary based on the specific machinery model. Often, they are located near the hydraulic tank or integrated within the pump assembly. Familiarizing oneself with the layout of these filters helps ensure timely maintenance, ultimately enhancing the efficiency and lifespan of the hydraulic system. Regular maintenance of hydraulic filters is vital. Clogged or damaged filters can lead to increased wear on hydraulic components, reduced system efficiency, and costly repairs. It’s advisable to follow the manufacturer’s recommendations for filter replacement intervals and to conduct routine checks to identify any potential issues early. How to Replace LX885 Tires and WheelsReplacing tires and wheels on a compact loader is a crucial maintenance task that ensures optimal performance and safety. This process involves removing the old components and installing new ones to enhance traction and stability during operation. Below are the essential steps to carry out this procedure effectively. Gather Necessary Tools and Materials

Before beginning the replacement process, ensure you have the following tools at hand:

Steps for Replacement

Follow these steps to replace the tires and wheels:

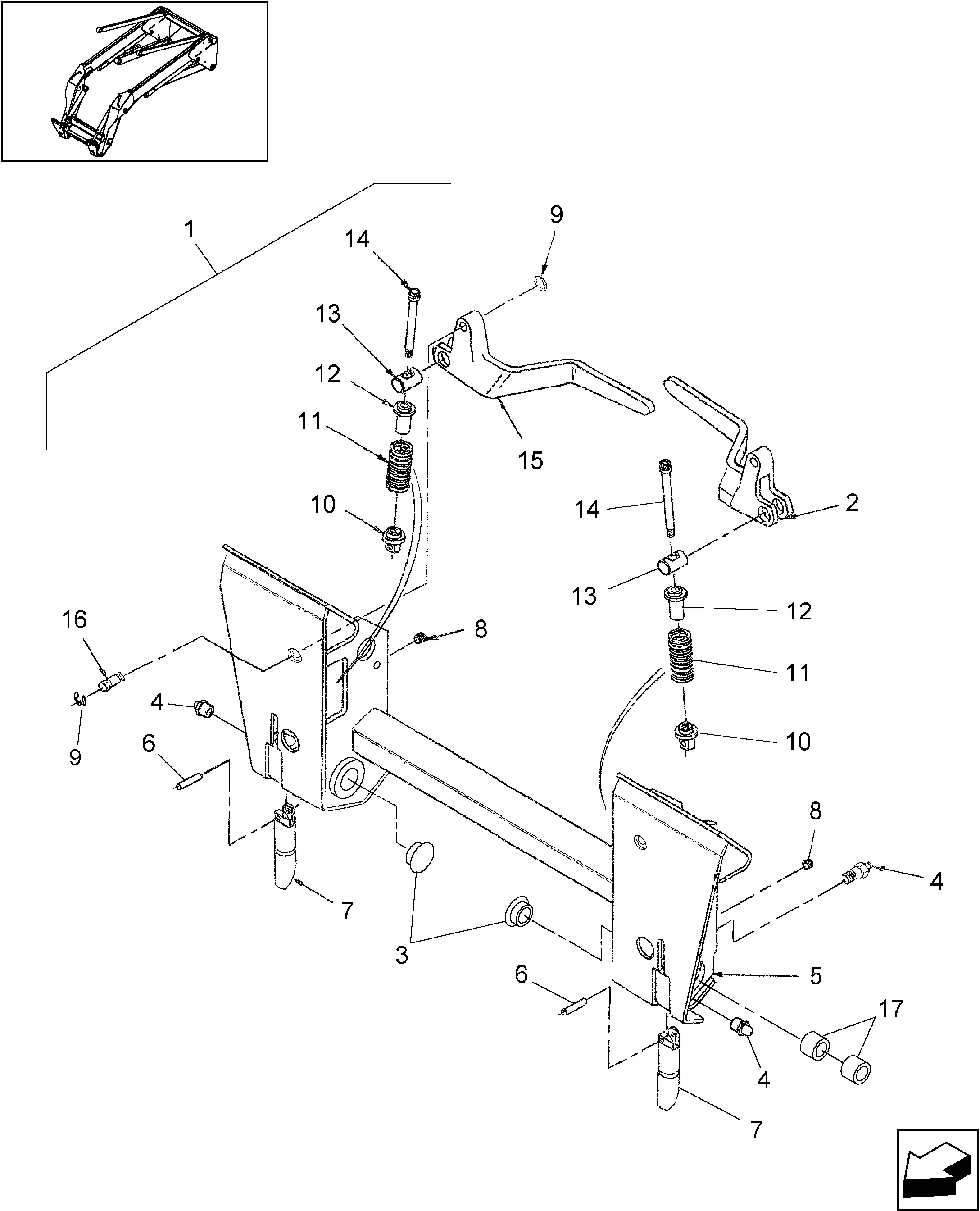

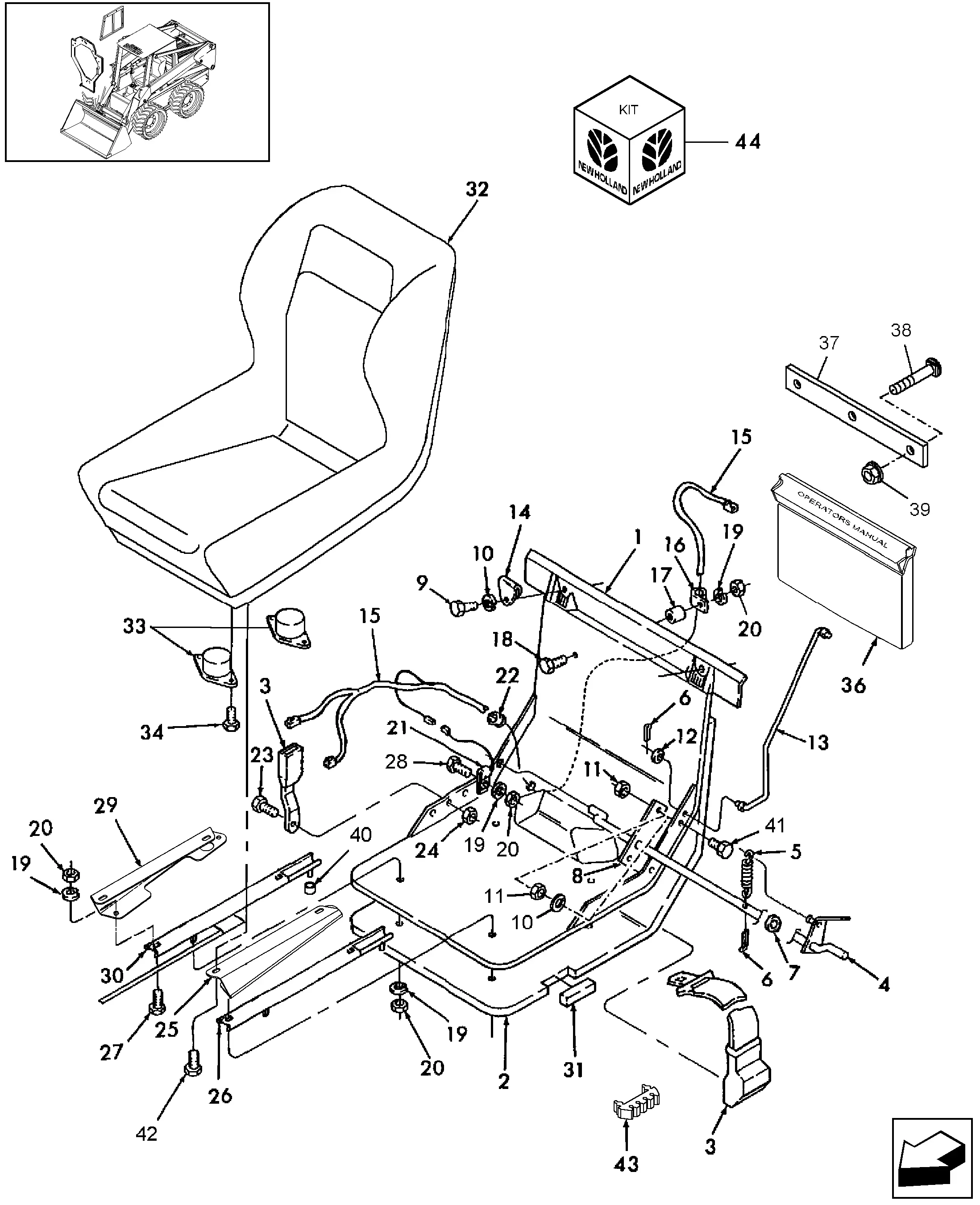

By following these guidelines, you can successfully replace the wheels and tires, enhancing the efficiency and longevity of your loader. Cooling System Components and LayoutThe efficiency of an engine largely depends on its ability to maintain optimal operating temperatures. A well-designed cooling mechanism ensures that the engine does not overheat, thereby prolonging its lifespan and enhancing performance. Understanding the various elements involved in this system is essential for effective maintenance and troubleshooting. The main components of the cooling system include the radiator, which dissipates heat from the coolant; the water pump, responsible for circulating the coolant throughout the engine; and the thermostat, which regulates the coolant flow based on temperature. Additional elements, such as hoses and cooling fans, play crucial roles in ensuring the system functions efficiently. The layout of these components is designed to facilitate optimal heat exchange and fluid movement. The radiator is typically positioned at the front of the vehicle, allowing for maximum airflow. The water pump is strategically located near the engine block to minimize the distance the coolant must travel. This systematic arrangement promotes effective thermal management and contributes to the overall reliability of the engine. Steering and Control Mechanism in the LX885The steering and control system of the LX885 is a crucial component that ensures precision handling and maneuverability. This mechanism plays a vital role in enabling operators to effectively navigate various terrains and execute tasks with accuracy. Understanding its components and functionality is essential for maintenance and optimal performance. Key Components of the Steering System

Control Mechanism Functionality

The control system in the LX885 is designed to provide intuitive operation. It incorporates various controls that allow the operator to manage speed, direction, and additional functions seamlessly. The combination of electronic and hydraulic systems ensures that responses are immediate and precise, contributing to the overall efficiency of the machine.

Maintaining the integrity of these components is essential for ensuring reliable performance. Regular inspections and timely repairs can significantly extend the lifespan of the steering and control mechanisms, ultimately enhancing productivity in the field. Common Wear Parts of the LX885When it comes to maintaining machinery, certain components are prone to regular deterioration due to consistent use. Understanding which elements typically experience wear can significantly enhance the longevity and efficiency of the equipment. This section highlights essential components that require attention and timely replacement to ensure optimal performance. Key Components to MonitorMonitoring specific elements can prevent unexpected breakdowns and costly repairs. Regular inspections and proactive maintenance on these crucial pieces can extend the operational life of the machine.

Maintenance TipsRegular maintenance and timely replacements of these critical elements are essential for smooth operation. Keeping a close eye on their condition and addressing issues promptly can help avoid more severe complications in the future. |