The intricate design of machinery requires a comprehensive understanding of its individual elements and how they interconnect. Each component plays a crucial role in the overall functionality, making it essential for users to familiarize themselves with the specific arrangements of these parts. A detailed representation serves as a valuable resource for maintenance and repair, ensuring optimal performance.

By examining a visual outline of the various sections, operators can gain insight into the organization and operation of their equipment. Such illustrations not only assist in troubleshooting but also enhance the efficiency of assembly and disassembly tasks. Knowledge of the layout empowers users to make informed decisions regarding upgrades and replacements, ultimately prolonging the life of their machinery.

Precision in visual representations is crucial for effective assembly and maintenance processes. Clear and detailed illustrations serve as essential tools for understanding complex mechanisms and ensure that all components fit together seamlessly. When users rely on accurate visuals, they can avoid costly mistakes and reduce the time spent on repairs.

Furthermore, well-structured visuals enhance communication among technicians and facilitate training for new personnel. By providing a common reference point, these illustrations help streamline workflows and improve overall productivity in the workshop.

| Benefit | Description |

|---|---|

| Enhanced Understanding | Clear visuals improve comprehension of assembly processes. |

| Cost Efficiency | Accurate representations reduce the likelihood of errors, saving time and resources. |

| Improved Communication | Common references facilitate collaboration among team members. |

| Training Aid | Effective visuals are valuable tools for onboarding new staff. |

Common Issues and Solutions

This section addresses frequent problems encountered with compact agricultural machinery and offers practical solutions for each. Understanding these common challenges can enhance the maintenance and efficiency of your equipment, ensuring optimal performance in various tasks.

| Issue | Possible Cause | Solution |

|---|---|---|

| Engine not starting | Insufficient fuel or battery failure | Check fuel levels and battery connections; recharge or replace the battery if necessary. |

| Poor hydraulic performance | Low fluid levels or leaks in the system | Inspect hydraulic fluid levels and check for leaks; refill or repair as needed. |

| Unresponsive controls | Worn or damaged linkages | Examine control linkages for wear; replace any damaged components to restore functionality. |

| Overheating engine | Clogged radiator or low coolant | Clean the radiator and check coolant levels; add coolant if low and ensure proper airflow. |

| Excessive vibration | Imbalanced or damaged components | Inspect all moving parts for balance; repair or replace damaged components as needed. |

Where to Find Replacement Parts

Locating suitable components for your equipment can enhance its performance and longevity. Various resources are available to assist in sourcing the necessary items efficiently. Here are some reliable options to consider when searching for quality replacements.

| Source | Description |

|---|---|

| Authorized Dealers | These retailers specialize in original items and offer expert advice on compatibility and installation. |

| Online Marketplaces | Websites like eBay or Amazon feature a broad selection, often with user reviews to guide your decision. |

| Local Repair Shops | Professionals in your area can provide guidance on obtaining components and may have stock on hand. |

| Manufacturer Websites | Official sites often have dedicated sections for ordering items directly, ensuring authenticity. |

| Salvage Yards | These locations may have used items at a fraction of the cost, ideal for budget-conscious repairs. |

Maintenance Tips for TC35

Regular upkeep is essential for ensuring the longevity and optimal performance of your machinery. Implementing a consistent maintenance routine can prevent potential issues and enhance the efficiency of your equipment. By following a few fundamental practices, you can keep your machine in excellent working condition.

Routine Inspections

Conducting periodic inspections is crucial for identifying wear and tear before it becomes a significant problem. Check fluid levels, examine belts and hoses, and ensure that all moving parts are adequately lubricated. Addressing minor issues promptly can save time and resources in the long run.

Proper Cleaning

Keeping the exterior and interior of the machinery clean is vital. Remove dirt and debris to prevent corrosion and other damage. Regularly wash components to maintain visibility and functionality, allowing for better performance and safety during operations.

Manufacturer Specifications and Guidelines

This section outlines the essential criteria and recommendations provided by the manufacturer to ensure optimal performance and longevity of the equipment. Adhering to these specifications is crucial for maintaining operational efficiency and safety.

Key Performance Standards

Performance standards delineate the operational capabilities that the machinery must meet. These benchmarks encompass aspects such as power output, fuel efficiency, and load capacity. Familiarity with these standards enables users to effectively gauge the suitability of the equipment for specific tasks.

Maintenance Recommendations

Regular upkeep is vital for sustaining the functionality of the machinery. The manufacturer offers guidelines on maintenance intervals, necessary tools, and replacement procedures. Following these recommendations will help prevent breakdowns and extend the equipment’s service life.

Online Resources for Parts Information

Accessing detailed information regarding equipment components has become increasingly convenient with the growth of digital platforms. Various online tools offer comprehensive data that assist users in locating the necessary elements for their machinery.

Websites dedicated to agricultural machinery often provide searchable catalogs, enabling users to find specific items quickly. Additionally, forums and community groups can serve as valuable resources, allowing individuals to share insights and experiences related to various equipment models.

Manufacturer websites frequently feature technical specifications and manuals, which are essential for understanding the functionality of different components. Furthermore, online retailers often include user reviews that can help gauge the quality and reliability of available options.

Incorporating these digital resources into your search can greatly enhance the efficiency of finding the right components, ensuring that your machinery remains in optimal condition.

Customer Reviews and Feedback

This section highlights the experiences and insights shared by users regarding the equipment and its components. Feedback from customers provides valuable perspectives on performance, reliability, and usability, helping potential buyers make informed decisions.

Many users appreciate the efficiency and ease of operation, noting how it enhances productivity in various tasks. The robust construction and dependability are often mentioned, indicating a high level of satisfaction among owners.

On the other hand, some customers express concerns about specific features, suggesting areas for improvement. These reviews serve as constructive criticism, offering manufacturers a chance to enhance future models and address user needs more effectively.

Overall, the testimonials reveal a mix of positive experiences and constructive feedback, reflecting a well-rounded view of the equipment’s capabilities and potential areas for enhancement.

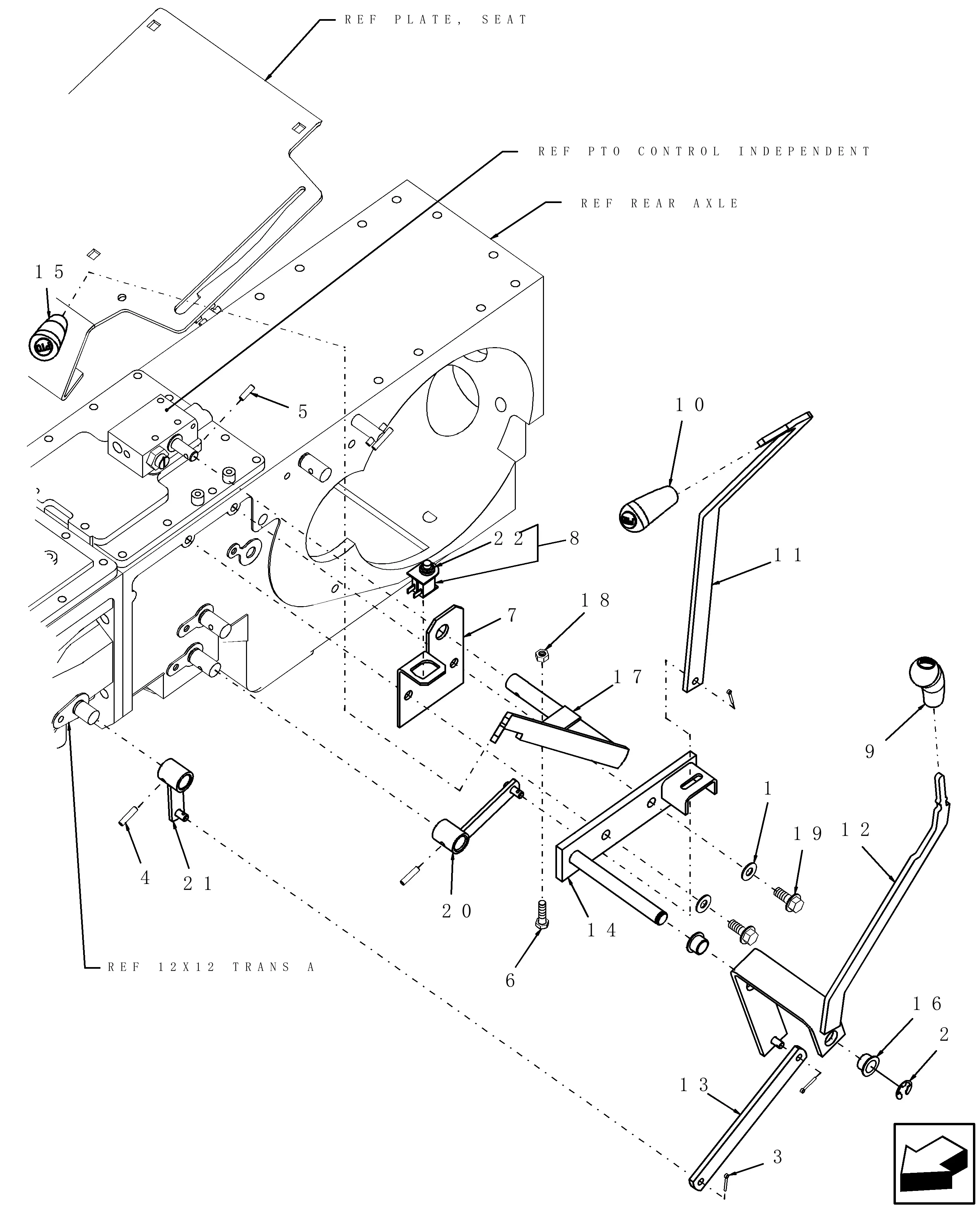

How to Use the Diagram Effectively

Understanding the visual representation of components is crucial for any mechanical task. By familiarizing yourself with this illustration, you can identify individual elements and their functions, leading to a more efficient workflow.

To utilize this illustration effectively, start by familiarizing yourself with the layout. Take time to examine each section and understand how the components interact. Highlight key areas that pertain to your specific needs, as this will help you navigate the illustration more easily when troubleshooting or conducting maintenance.

When following a repair or assembly guide, reference the illustration regularly to ensure you are correctly positioning each element. By cross-referencing the visual guide with written instructions, you can avoid errors and save time, ultimately enhancing your overall productivity.