When exploring the intricacies of agricultural machinery, having a clear visual representation of its elements can significantly enhance comprehension. This knowledge allows operators and technicians to maintain and troubleshoot equipment effectively, ensuring optimal performance.

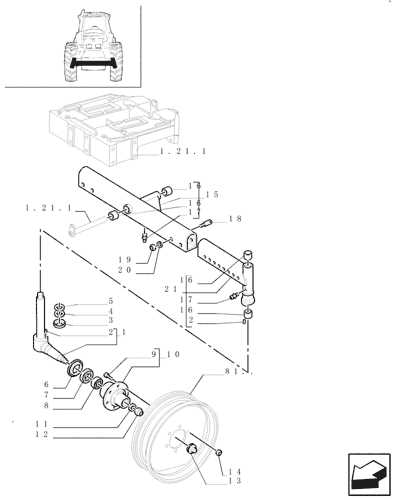

Visual aids serve as invaluable tools, providing insights into the assembly and functionality of various sections. By examining these representations, one can easily identify the relationships between different components, leading to a deeper understanding of the overall system.

Delving into the specifics of machinery assemblies not only streamlines maintenance tasks but also empowers users to make informed decisions regarding repairs and replacements. Ultimately, mastering these details can greatly enhance the longevity and efficiency of your equipment.

Understanding the New Holland TL90

This section explores the intricacies of a specific agricultural machine, focusing on its components and functionality. By examining its design and operational features, users can gain valuable insights into its overall efficiency and reliability in various farming applications.

The machine is renowned for its robust construction and versatility, making it suitable for a range of tasks from tilling to hauling. Its engine delivers impressive power, ensuring optimal performance even under demanding conditions. Furthermore, the user-friendly interface simplifies operation, allowing both seasoned professionals and newcomers to navigate its features with ease.

Maintenance is crucial for prolonging the lifespan of this equipment. Understanding its assembly will aid in identifying potential issues and ensuring timely repairs. By delving into the details of each component, operators can ensure that their machinery remains in peak condition, ultimately enhancing productivity.

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for efficient maintenance and repair. Visual representations serve as essential tools, enabling operators and technicians to identify each element accurately, ensuring optimal performance and longevity of equipment.

Facilitating Repairs

Clear visual aids simplify the repair process by providing a reference point for disassembly and reassembly. When technicians can easily locate specific components, they can address issues more effectively, reducing downtime and enhancing productivity.

Enhancing Communication

Using detailed illustrations improves communication among team members. It allows everyone to discuss and understand intricate parts without confusion, fostering collaboration and ensuring that all parties are aligned during maintenance tasks.

Key Components of TL90 Tractor

The efficient operation of agricultural machinery relies on various integral elements that work in harmony. Understanding these components is essential for optimal performance and maintenance.

Engine: The powerhouse of the machinery, the engine converts fuel into mechanical energy, driving all operations. Its design ensures high efficiency and reliability in various conditions.

Transmission: This system transfers power from the engine to the wheels, enabling speed control and torque management. A well-functioning transmission is vital for maneuverability and performance.

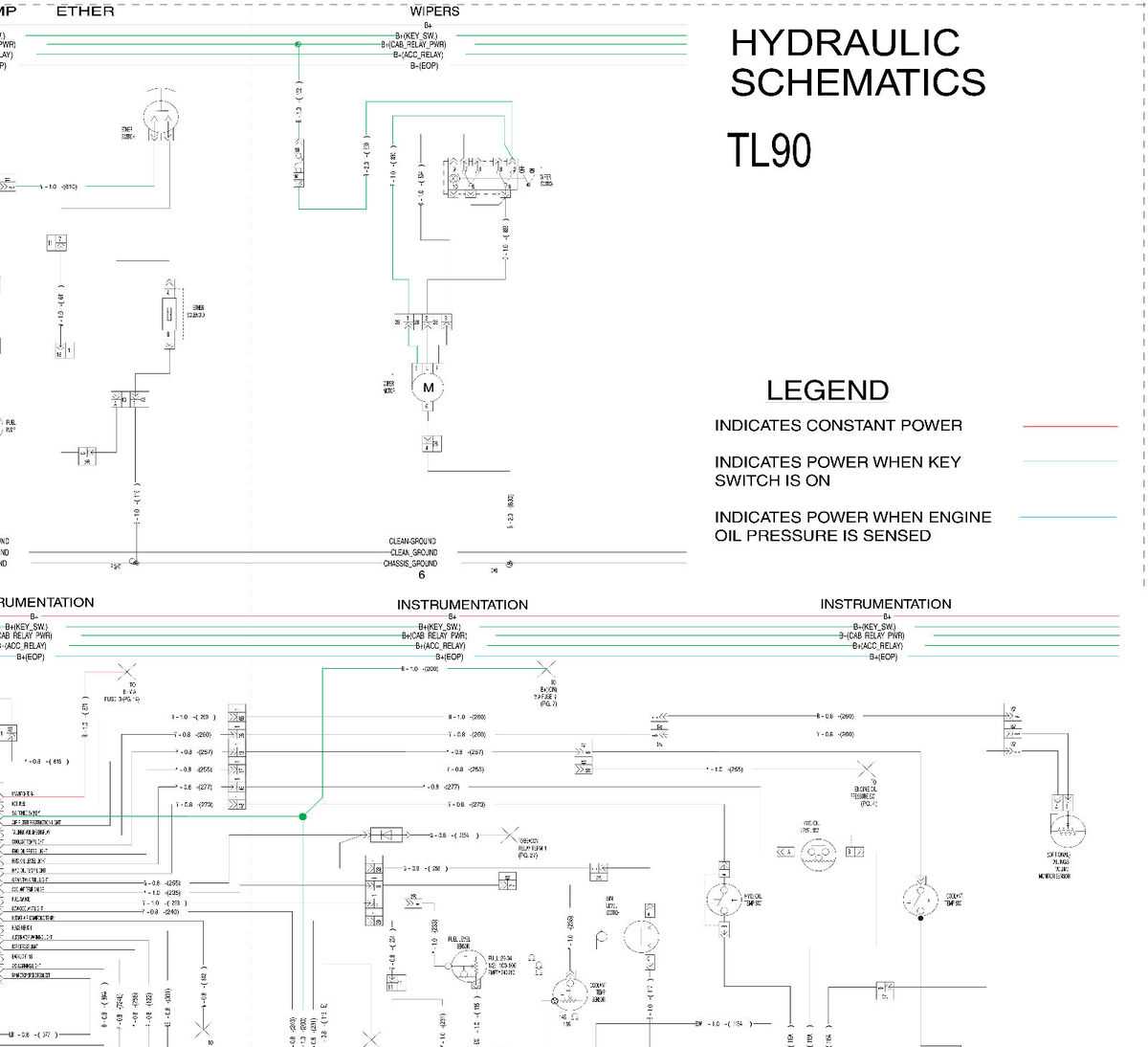

Hydraulic System: The hydraulic components facilitate lifting and lowering implements, providing necessary force for various tasks. A robust hydraulic system enhances productivity by allowing for precise control of attachments.

Chassis: The chassis serves as the foundation, supporting all other components. Its design ensures stability and durability, essential for handling heavy loads and rough terrains.

Wheels and Tires: These elements are crucial for traction and mobility across different surfaces. The right combination of size and tread pattern can significantly impact performance in the field.

Electrical System: This system powers lights, controls, and sensors, ensuring smooth operation and safety. A reliable electrical network is fundamental for modern machinery efficiency.

By familiarizing oneself with these critical components, operators can ensure their equipment runs smoothly and effectively, maximizing productivity on the farm.

How to Read a Parts Diagram

Understanding an assembly blueprint is crucial for anyone involved in maintenance or repair. These visual guides provide a comprehensive overview of components, illustrating how they fit together and function within a machine. Familiarity with these schematics enhances efficiency when sourcing replacements or undertaking repairs.

Step 1: Begin by familiarizing yourself with the legend or key. This section typically explains the symbols and markings used throughout the schematic, helping you identify different components quickly.

Step 2: Observe the layout carefully. Most blueprints will organize parts in a logical manner, often grouped by function or location within the machine. This organization assists in understanding the overall assembly.

Step 3: Pay attention to the numbering system. Each component is usually assigned a unique identifier, which can be cross-referenced with a parts list. This feature is essential for accurate ordering and replacement.

Step 4: Take note of any connections or relationships between components. Understanding how parts interact can provide insights into potential issues and the order of disassembly or reassembly.

By mastering these techniques, you can effectively navigate any assembly schematic, ensuring that repairs are carried out with precision and confidence.

Common Replacement Parts for TL90

Understanding the essential components for machinery maintenance is crucial for optimal performance. Identifying frequently needed items can help ensure seamless operation and longevity. This section highlights key elements often replaced to maintain efficiency and reliability.

Key Components

Filters play a significant role in keeping the engine clean and functioning effectively. Regularly changing oil and fuel filters helps prevent contaminants from causing damage.

Wear Parts

Additionally, belts and hoses are critical for the proper functioning of various systems. Over time, these components can deteriorate, leading to potential failures if not addressed promptly. Regular inspection and timely replacement are essential for maintaining machinery integrity.

Where to Find Parts Diagrams

Locating detailed schematics for machinery components is essential for maintenance and repair. Understanding where to access these valuable resources can significantly enhance efficiency and accuracy in handling equipment issues.

Online Resources

The internet offers a wealth of information, with numerous websites dedicated to providing visual representations and manuals. Manufacturer sites often host comprehensive guides, while forums and community pages can yield user-shared insights.

Local Dealers and Distributors

Your nearest authorized dealer can be a reliable source for obtaining technical illustrations. Many of these distributors maintain extensive archives and are equipped to assist with specific inquiries about machinery.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components offers several advantages that enhance the overall performance and longevity of machinery. These elements are specifically designed to fit and function seamlessly, ensuring optimal operation and reducing the likelihood of malfunctions.

Quality Assurance: OEM components undergo rigorous testing to meet strict standards, providing peace of mind regarding durability and reliability.

Compatibility: Original components are tailored to the specifications of the machinery, which minimizes the risk of fitting issues and promotes efficient performance.

Warranty Protection: Many manufacturers extend warranties on equipment when OEM components are used, safeguarding your investment and mitigating potential repair costs.

Long-Term Cost Savings: Although initially more expensive, these components often prove to be more economical over time due to their longevity and reduced maintenance needs.

Identifying TL90 Model Variants

Understanding the various iterations of this agricultural machine is essential for users and technicians alike. Each version may feature unique specifications, adaptations, and functionalities tailored for different tasks. Recognizing these differences helps in ensuring the correct application and maintenance practices are followed.

When examining the variants, it is crucial to pay attention to specific characteristics such as engine type, transmission options, and design enhancements. These aspects not only impact performance but also influence compatibility with various implements and accessories.

Documentation and visual references can aid in distinguishing between the models. Familiarity with the production year and serial numbers will also streamline the identification process, ensuring that users have accurate information at their disposal.

In summary, delving into the distinctions among the models allows for more effective usage and servicing, ultimately enhancing productivity and longevity of the equipment.

Maintenance Tips for TL90 Owners

Regular upkeep is essential for ensuring optimal performance and longevity of your machinery. By following a systematic maintenance routine, you can avoid unexpected breakdowns and costly repairs while enhancing efficiency.

Routine Inspections

Conduct frequent checks of fluid levels, filters, and belts. Keeping these components in good condition can prevent major issues. Don’t underestimate the importance of inspecting for leaks or wear and tear.

Scheduled Servicing

Adhere to a comprehensive service schedule. Regularly changing oils and filters, along with other key maintenance tasks, will significantly improve your machine’s reliability. Staying proactive will ultimately save you time and money in the long run.

DIY Repairs: Safety First

When tackling maintenance tasks on your machinery, prioritizing safety is essential. Understanding the potential hazards and implementing protective measures can significantly reduce the risk of accidents. Proper preparation and the right tools not only enhance efficiency but also ensure a secure working environment.

Essential Safety Gear

Before starting any repair work, equip yourself with the necessary safety gear. This includes gloves, goggles, and sturdy footwear. Wearing protective equipment minimizes the likelihood of injuries from sharp objects or chemicals.

Work Environment Considerations

Ensure your workspace is well-lit and free of clutter. A tidy area reduces the chances of tripping or misplacing tools. Additionally, always have a first aid kit on hand to address minor injuries promptly, keeping you focused on the task at hand.

Cost-Effective Parts Sourcing Strategies

Finding economical solutions for acquiring components is essential for maintaining equipment without breaking the bank. By exploring various avenues for sourcing, users can ensure both reliability and affordability. Strategic planning and informed decision-making are key to optimizing expenses while maximizing quality.

Research and Comparison: Start by investigating different suppliers. Comparing prices and quality can reveal significant savings. Utilize online resources to gather information and reviews about various vendors.

Bulk Purchasing: Buying in larger quantities often results in discounts. If feasible, consider collaborating with other users to place bulk orders, ensuring reduced costs while sharing the load.

Refurbished Options: Explore the possibility of acquiring reconditioned components. These items often come at a lower price point yet can offer excellent performance if sourced from reputable sellers.

Local Dealerships: Establishing a relationship with nearby dealerships can lead to better deals and quicker access to necessary items. Local vendors may offer personalized service and insights that online retailers cannot match.

Community Forums: Engaging with online communities or forums can provide valuable insights. Fellow users often share their experiences, tips, and recommendations, helping you find the best sourcing options.

DIY Solutions: When possible, consider undertaking repairs or modifications yourself. This can drastically reduce labor costs, allowing for investment in higher-quality components.

Impact of Proper Maintenance

Regular upkeep of machinery significantly influences its performance and longevity. Ensuring that all components function optimally not only enhances efficiency but also reduces the risk of unexpected failures. A well-maintained machine operates smoothly, providing the ultimate productivity required for demanding tasks.

Neglecting maintenance can lead to serious consequences, including increased wear and tear, reduced output, and costly repairs. By taking proactive measures, operators can prevent breakdowns and extend the lifespan of their equipment. Ultimately, this results in better investment returns and sustained operational success.

Implementing a routine maintenance schedule allows for early detection of potential issues. This approach not only saves time but also minimizes disruptions during critical work periods. The benefits of maintaining machinery extend beyond immediate performance, fostering a culture of responsibility and care within the operation.

Frequently Asked Questions About TL90

This section addresses common inquiries regarding a specific agricultural machine, providing clarity on its functionality, maintenance, and troubleshooting. Here, users can find answers to enhance their understanding and experience.

| Question | Answer |

|---|---|

| What are the key features of this model? | It boasts a powerful engine, efficient fuel consumption, and advanced hydraulic systems for optimal performance. |

| How can I improve its longevity? | Regular maintenance, proper lubrication, and timely replacements of worn components are essential for durability. |

| What should I do if it won’t start? | Check the battery, fuel levels, and electrical connections; consulting the manual may provide further insights. |

| Are there any common issues? | Some users report hydraulic leaks and electrical malfunctions; regular checks can help identify these early. |

| Where can I find reliable support? | Authorized dealers and online forums dedicated to agricultural machinery offer valuable resources and assistance. |