Exploring the intricate connections and individual elements of a classic vehicle can be both exciting and informative. Understanding how various components come together to ensure the optimal performance of an iconic model is essential for both enthusiasts and restorers alike. This section aims to provide a detailed examination of crucial mechanical elements, offering insight into how each piece plays a role in the overall function.

Restoring or maintaining a vintage two-wheeler requires knowledge of the internal mechanisms and how they interact. From engine components to smaller intricate pieces, each element is essential to keeping the machine in top condition. This guide will help you navigate the structural layout, ensuring that every part is accounted for during your restoration journey.

Whether you’re repairing or simply looking to understand the mechanics better, this resource will serve as a valuable reference for identifying and organizing key elements of your vintage two-wheeler. Dive into the detailed breakdown of essential components to better appreciate the engineering that has stood

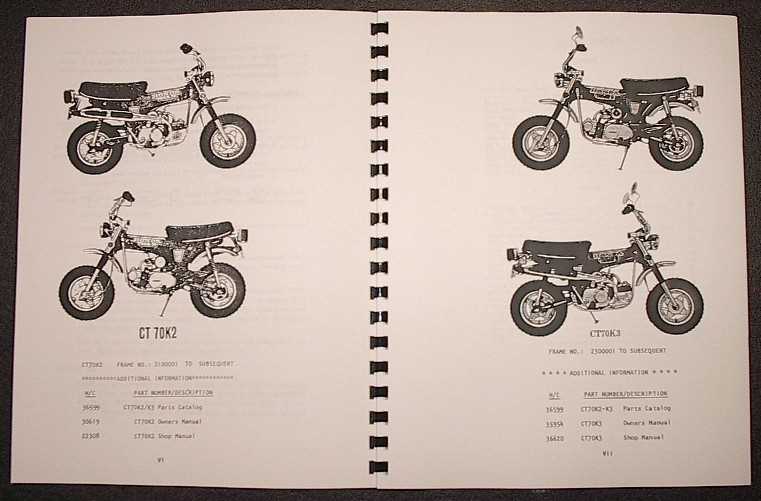

Overview of the 1972 Honda CT70 Components

The iconic mini motorcycle is composed of several essential elements that work together to provide smooth functionality and an enjoyable riding experience. Understanding these key components is crucial for proper maintenance, repair, and overall performance enhancement.

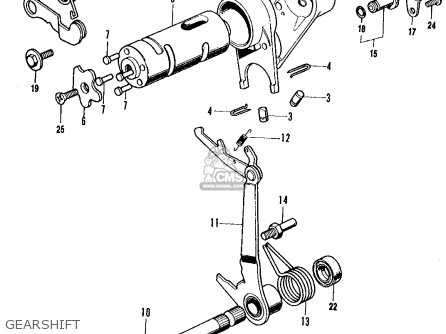

Engine and Transmission System

The power unit is the heart of the vehicle, driving it forward with efficiency and precision. Paired with a well-designed transmission, the system ensures a smooth transfer of power to the wheels, optimizing both speed and control.

Chassis and Suspension

The frame and suspension play a vital role in the overall handling and stability. These elements are engineered to absorb shocks and provide a comfortable ride, even on rough terrain. Proper care of these components ensures the longevity and safety of the vehicle.

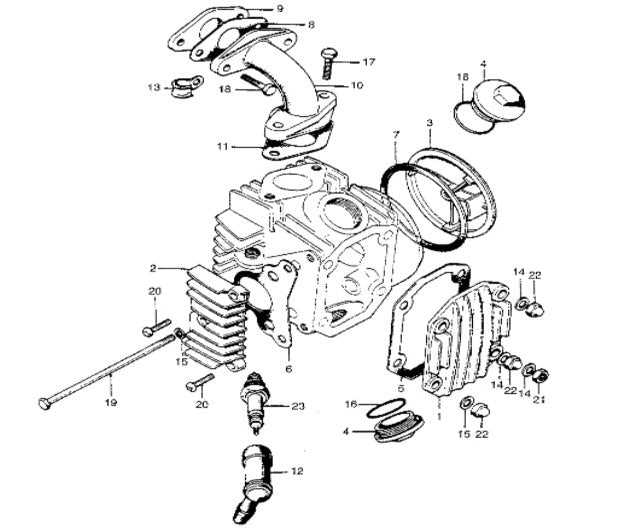

Engine Assembly Breakdown

The internal structure of a small engine consists of several key components working in harmony to ensure proper operation. Understanding the various elements and how they fit together helps in maintaining and troubleshooting the system effectively. Each section of the assembly is designed to perform a specific function, contributing to the overall performance of the machine.

- Cylinder Block: This is the foundation of the engine, housing the combustion process and supporting essential moving parts.

- Piston and Crankshaft: The piston moves within the cylinder, transferring force to the crankshaft, which converts linear motion into rotational movement.

- Valves and Camshaft: Valves regulate the intake of fuel and air, as well as the exhaust, while the camshaft controls their timing.

- Carburetor and Fuel System: Responsible for mixing fuel with air in the correct ratio for combustion, ensuring efficient energy output.

- Ignition System: This system generates the spark needed to ignite the

Frame and Body Structure Details

The framework and overall design of this model play a crucial role in both its stability and performance. The robust build ensures durability, while the compact body allows for enhanced maneuverability. Understanding the different components and their placement helps to maintain and optimize the vehicle’s function.

Component Description Chassis Provides the foundation for all major elements, designed for strength and support. Suspension System Absorbs shocks from uneven surfaces, ensuring a smoother ride. Fuel Tank Located centrally, its placement aids in weight distribution and balance. Seat Frame Suspension System Components

The suspension system is vital for ensuring a smooth and controlled ride. It absorbs shocks from uneven surfaces and helps maintain stability by connecting the vehicle’s frame to its wheels. Understanding how these components work together is essential for keeping the machine operating safely and comfortably.

Main Support Structures

The core elements of the suspension include springs and shock absorbers, which are designed to cushion the impact of rough terrain. Springs primarily manage the load and absorb energy, while shock absorbers dissipate this energy, preventing excessive movement and maintaining balance.

Connecting Mechanisms

The system also includes various linkages that join the wheels to the frame. These parts ensure that the suspension functions properly by allowing for controlled motion and reducing unwanted vibrations. Maintaining these connections is key to ensuring smooth operation and extending the life of the system.

Electrical System Layout

The arrangement of components within the electrical setup plays a crucial role in ensuring smooth operation and reliability. Understanding how these elements connect and interact helps maintain optimal performance, while also making it easier to diagnose and resolve potential issues.

The layout typically consists of key elements such as the power source, switches, and wiring that link everything together. Below is a basic overview of the essential components involved:

Component Description Power Supply Provides the necessary energy for the system to function. Switches Control the flow of electricity to various parts of the system. Wiring Connects the power source to all other components, allowing for efficient energy distribution. Fuses Protects the system from electrical overload by breaking the circuit if necessary. Braking Mechanism Parts

The braking system is crucial for ensuring safety and control while operating a two-wheeled vehicle. Understanding the components that make up this system can help in maintaining optimal performance and addressing any potential issues. Each element works in harmony to facilitate smooth stopping and responsiveness during rides.

Key Components

Among the primary elements of the braking system are the brake lever, cable, and drum or disc. The brake lever, typically located on the handlebars, allows the rider to engage the brakes with ease. The cable connects the lever to the braking mechanism, transmitting force when activated. The drum or disc plays a pivotal role in the actual stopping process, providing the necessary friction to slow down or halt the motion.

Maintenance Considerations

Regular inspection and maintenance of these components are essential for safety and performance. Checking for wear and tear on the cable and ensuring proper tension can prevent brake failure. Additionally, inspecting the drum or disc for grooves or damage will help in maintaining effective braking capabilities. Proper upkeep not only enhances performance but also extends the lifespan of the braking system.

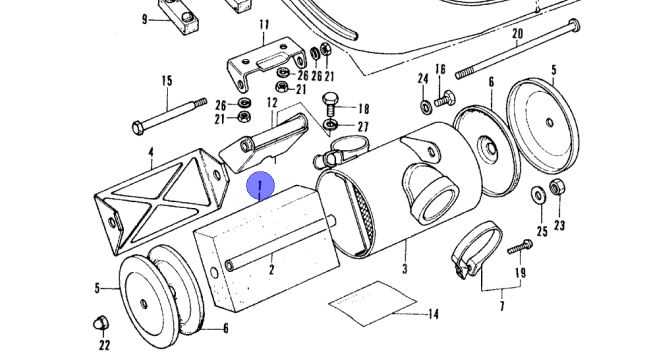

Fuel System Overview

The fuel system is a crucial component of any internal combustion engine, responsible for delivering the necessary fuel for combustion. It consists of various parts that work in unison to ensure optimal performance and efficiency. Understanding the functioning and configuration of this system is essential for effective maintenance and troubleshooting.

Components of the Fuel System

This system typically includes several key elements that facilitate the flow and management of fuel:

Component Description Fuel Tank Stores fuel until it is needed by the engine. Fuel Pump Moves fuel from the tank to the engine. Fuel Filter Removes impurities from the fuel before it reaches the engine. Carburetor Mixes fuel with air for optimal combustion. Fuel Lines Transport fuel between the tank, pump, and engine. Importance of Proper Functioning

Maintaining the efficiency of the fuel system is vital for the overall performance of the vehicle. Regular checks on the components can prevent issues such as fuel leaks, clogs, and engine misfires. Understanding how each part contributes to the system allows for more informed decisions regarding repairs and upgrades.

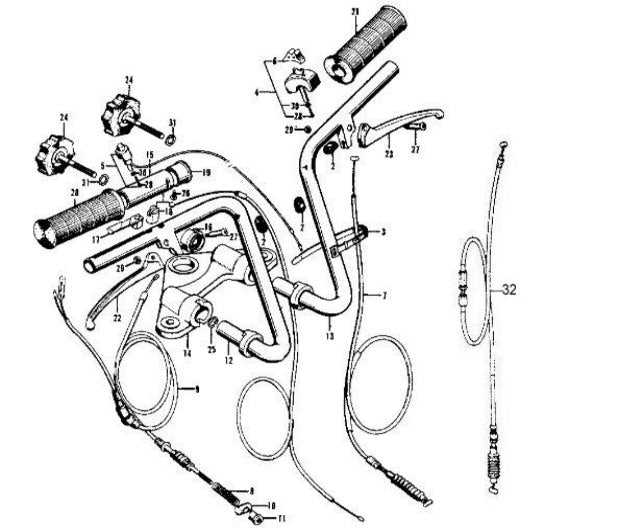

Handlebar and Control Elements

The handlebar assembly serves as the primary interface for the rider, facilitating control and navigation of the vehicle. It encompasses various components that contribute to the overall functionality and comfort during operation. Understanding these elements is essential for maintenance and optimization of performance.

At the core of this assembly lies the handlebar itself, which provides leverage and stability. Attached to the handlebar are various control elements, including throttle and brake levers, which allow the operator to regulate speed and ensure safety. The placement and design of these controls are crucial for ergonomic efficiency and ease of access.

Additionally, the inclusion of switches for lights and horn enhances functionality, allowing for a comprehensive control system within easy reach. The integration of these components reflects thoughtful engineering aimed at creating a user-friendly experience while ensuring responsiveness and reliability on the road.

Exhaust System Configuration

The configuration of the exhaust assembly plays a crucial role in the overall performance and efficiency of any vehicle. A well-designed exhaust system not only enhances the engine’s power output but also contributes to a smoother and quieter operation. Understanding the components and their arrangement is essential for anyone looking to maintain or upgrade this vital aspect of their machinery.

Components of the Exhaust Assembly

The exhaust assembly typically comprises several key elements, including the manifold, pipes, muffler, and tailpipe. The manifold collects exhaust gases from the engine cylinders and directs them through the system. Each pipe serves to transport these gases while minimizing back pressure, which can hinder engine performance. The muffler is designed to reduce noise levels, ensuring a more pleasant driving experience, while the tailpipe expels the gases into the atmosphere.

Importance of Proper Configuration

Proper alignment and secure attachment of these components are essential to prevent leaks and ensure optimal performance. Regular inspections can help identify any wear or damage, allowing for timely repairs or replacements. An efficiently configured exhaust assembly not only improves the power and efficiency of the engine but also contributes to lower emissions, aligning with environmental standards.

Wheel and Tire Specifications

The selection of wheels and tires plays a crucial role in enhancing both the performance and aesthetic appeal of any two-wheeled vehicle. Understanding the specific dimensions, types, and materials involved is essential for achieving optimal handling and comfort. This section delves into the essential characteristics that define the wheel and tire setup for this classic machine.

Wheel Dimensions

The wheels are vital for providing stability and support. The appropriate measurements ensure a perfect fit and effective performance on various terrains. Below are the key specifications:

Specification Measurement Diameter 10 inches Width 3 inches Material Aluminum Alloy Tire Specifications

Choosing the right tires is essential for traction and ride quality. Here are the critical details for the tires suited for this model:

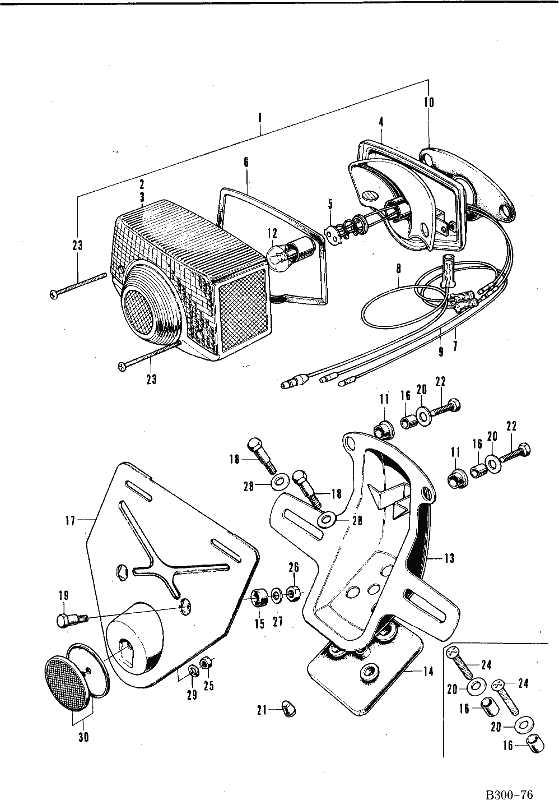

Specification Measurement Type Knobby Size 3.00-10 Pressure 24 psi Lighting and Indicator Components

Effective illumination and signaling systems are vital for enhancing visibility and communication on the road. These elements play a crucial role in ensuring the safety of riders and the proper functioning of the vehicle. From headlights to turn signals, each component is designed to fulfill specific purposes, contributing to the overall functionality of the machine.

The primary source of illumination, typically found at the front, is responsible for providing clear visibility during nighttime travel and adverse weather conditions. Complementing this are tail lights that enhance rear visibility, alerting other road users to the vehicle’s presence. Additionally, indicator lights serve as essential signaling devices, allowing operators to communicate their intentions to others, thereby promoting safe maneuvering in traffic.

Furthermore, components such as reflectors enhance safety by increasing visibility from various angles. The integration of these systems not only adheres to safety regulations but also improves the aesthetic appeal of the vehicle, making it a well-rounded unit for both function and style.

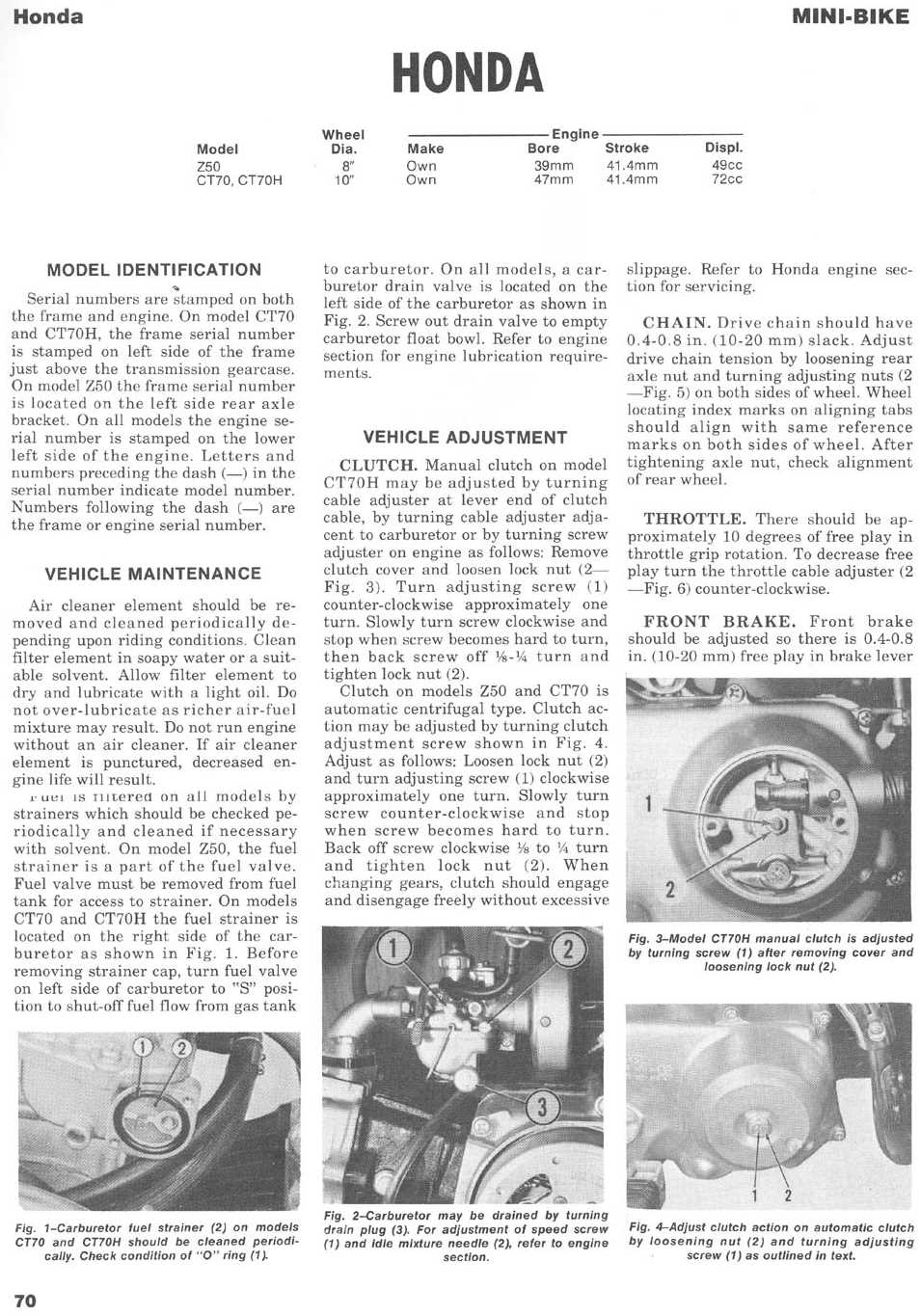

Replacement and Maintenance Tips

Ensuring the longevity and optimal performance of your two-wheeled vehicle requires attention to detail and regular upkeep. Understanding how to properly replace components and maintain your machine can significantly enhance its reliability and efficiency. This section offers essential advice to help you keep your ride in excellent condition.

Regular Inspections

Conducting routine checks is crucial for identifying potential issues before they escalate. Examine critical elements such as the engine, brakes, and electrical systems for any signs of wear or damage. Timely detection allows for swift replacements, minimizing the risk of further complications.

Utilizing Quality Components

When replacing any part, opting for high-quality alternatives is vital. While cheaper options may seem appealing, they often compromise performance and longevity. Investing in reliable components ensures that your vehicle operates smoothly and reduces the likelihood of future repairs. Always refer to the specifications to guarantee compatibility.