For anyone looking to maintain or upgrade their vehicle, having a clear understanding of the internal and external layout of its various elements is essential. Knowing where each component is located and how they interact helps ensure smooth repairs and replacements, reducing the risk of damage or misalignment.

Exploring the detailed structure of different sections of a car provides valuable insights for both experienced mechanics and enthusiastic beginners. It allows you to visualize how specific elements function together, making the maintenance process more intuitive and efficient.

Diagrams are key in visualizing the intricate network of connections under the hood and throughout the vehicle’s body. With a focus on clarity and accuracy, these visual aids help guide users through even the most complex repairs and replacements, offering a comprehensive view of how each piece fits into the larger system.

Overview of 2009 Honda Fit Components

The various mechanical and electrical elements in a vehicle work together to ensure functionality and performance. Each system, whether related to power delivery, safety, or control, has specific components that interact with one another. Understanding the layout and role of these components is essential for proper maintenance and repair.

Mechanical Structures

The core mechanical systems include the engine, transmission, and suspension. These units are responsible for converting fuel into motion and ensuring the smooth operation of the vehicle on different terrains. Regular maintenance of these elements helps in achieving optimal performance and extending the life of the vehicle.

Electrical Systems

The electrical systems are vital for powering various features, from lighting to onboard computers. This network of wires, sensors, and batteries ensures that everything from safety features to convenience functions operates as intended. Proper inspection and upkeep of electrical components can prevent potential failures.

Engine Bay Parts Layout

The configuration of components within the engine compartment plays a crucial role in the overall performance and functionality of the vehicle. This section provides an overview of the various elements typically found in this area, highlighting their positions and relationships with one another. Understanding the layout can assist in maintenance, repairs, and enhancing the vehicle’s efficiency.

| Component | Description |

|---|---|

| Engine | The primary power source that converts fuel into mechanical energy. |

| Battery | Supplies electrical energy to start the engine and powers electrical systems. |

| Radiator | Dissipates heat from the engine coolant to maintain optimal operating temperature. |

| Air Intake | Draws air into the engine for combustion, often equipped with a filter. |

| Cooling System | Includes hoses and a water pump to circulate coolant through the engine and radiator. |

| Fuel System | Consists of components that deliver fuel from the tank to the engine. |

| Exhaust System | Channels exhaust gases away from the engine and reduces harmful emissions. |

| Electrical Components | Includes various wiring, sensors, and control modules essential for engine management. |

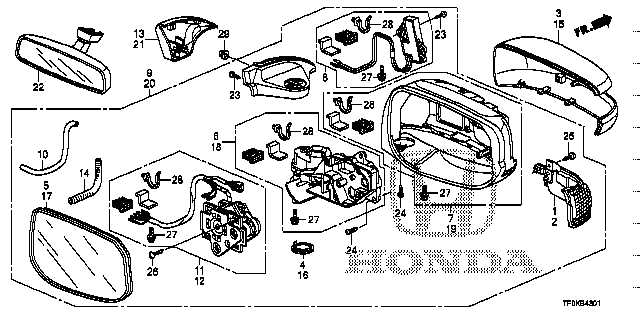

Interior Electrical System Diagram

The interior electrical framework of a vehicle plays a crucial role in ensuring the proper functioning of various components. This intricate network is responsible for powering essential features such as lighting, entertainment systems, and climate control. Understanding the layout and connections within this system can assist in troubleshooting and repairs, enhancing the overall driving experience.

Key Components: The main elements of the interior electrical structure include switches, fuses, and wiring harnesses. Each component interacts seamlessly to facilitate the operation of devices within the cabin. For instance, switches control the activation of lights and accessories, while fuses protect the circuit from overloads.

Wiring Layout: A comprehensive examination of the wiring configuration reveals the interconnections between various components. Color-coded wires often indicate different functionalities, aiding in the identification of specific circuits. This organization simplifies maintenance and modifications, enabling users to address issues efficiently.

Importance of Maintenance: Regular inspection of the interior electrical system is vital to prevent malfunctions. Corroded connections or damaged wires can lead to failures in crucial systems. Keeping this framework in optimal condition ensures safety and reliability for all occupants.

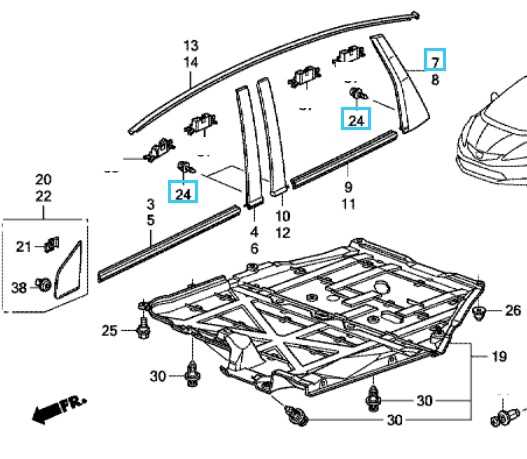

Suspension and Steering Configuration

The arrangement of suspension and steering components plays a crucial role in vehicle dynamics and handling. A well-engineered setup enhances ride comfort, stability, and responsiveness, ensuring that the vehicle performs optimally under various driving conditions. This section delves into the key elements that constitute this vital system, highlighting their functions and interconnections.

Key Components of the Suspension System

The suspension system comprises several integral parts, each contributing to the overall functionality. Shock absorbers help to dampen vibrations, providing a smoother ride by controlling the movement of the springs. Coil springs support the vehicle’s weight and absorb shocks from the road, maintaining the proper height and posture. Additionally, the control arms facilitate the connection between the chassis and wheels, allowing for smooth vertical movement.

Importance of Steering Mechanism

The steering mechanism is vital for maneuverability and control. It consists of several components, including the steering rack, which translates the rotational motion of the steering wheel into lateral movement of the wheels. The tie rods connect the steering rack to the wheels, ensuring accurate tracking and responsiveness. Furthermore, an alignment of these parts is essential for even tire wear and effective handling, directly influencing the vehicle’s performance and safety.

Brake System Components and Placement

The braking system of a vehicle is crucial for ensuring safety and control while driving. It comprises various elements that work in unison to provide effective stopping power. Understanding the components and their respective locations can help in maintenance and troubleshooting, ensuring optimal performance during operation.

Brake Pads are essential friction components located within the brake calipers. They press against the brake rotors when the brake pedal is engaged, creating the necessary friction to slow down or stop the vehicle.

Brake Rotors are circular discs that are attached to the wheel hubs. The pads clamp down on these rotors, generating the friction needed for deceleration. Proper alignment and thickness of the rotors are critical for efficient braking.

Brake Calipers house the brake pads and are positioned over the rotors. When the brake pedal is pressed, hydraulic fluid is sent to the calipers, causing them to squeeze the pads against the rotors.

Brake Lines are essential for transferring hydraulic fluid from the master cylinder to the calipers. These lines must be free from leaks and damages to maintain effective brake pressure.

Master Cylinder serves as the heart of the braking system. It converts the force applied to the brake pedal into hydraulic pressure, sending fluid through the brake lines to the calipers.

Each of these components plays a vital role in the overall functionality of the braking system, and their correct placement is crucial for ensuring safety and reliability on the road.

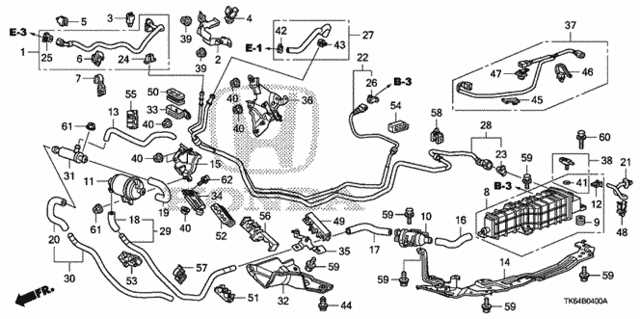

Fuel System Parts Overview

The fuel system is a vital component of any vehicle, responsible for delivering the necessary energy to the engine. Understanding the elements that comprise this system is essential for maintaining optimal performance and efficiency. This overview will provide insights into the various components that work together to ensure the smooth operation of the fuel delivery process.

Key Components

- Fuel Tank: The storage container for fuel, typically located at the rear of the vehicle.

- Fuel Pump: Responsible for transferring fuel from the tank to the engine under high pressure.

- Fuel Filter: Ensures that impurities are removed from the fuel before it reaches the engine.

- Fuel Injectors: Deliver precise amounts of fuel into the combustion chamber, allowing for efficient combustion.

- Fuel Pressure Regulator: Maintains the appropriate fuel pressure in the system, ensuring optimal performance.

Supporting Elements

- Fuel Lines: Hoses that transport fuel between the tank, pump, and engine.

- Throttle Body: Controls the airflow into the engine, affecting fuel delivery.

- Electronic Control Unit (ECU): Monitors and adjusts the fuel system for optimal performance based on various engine conditions.

Understanding these components and their functions is crucial for diagnosing issues and ensuring the fuel system operates effectively. Regular maintenance and inspection can help prevent fuel-related problems, contributing to the overall longevity of the vehicle.

Transmission Assembly Breakdown

The transmission assembly plays a crucial role in the operation of any vehicle, facilitating the transfer of power from the engine to the wheels. Understanding the components involved in this system is essential for maintenance and repairs. This section will provide a detailed overview of the key elements within the transmission assembly.

- Gear Set: The gear set includes various gears that help change the speed and torque transmitted to the wheels.

- Clutch Assembly: This component engages and disengages the engine from the transmission, allowing for smooth gear shifts.

- Torque Converter: The torque converter allows for the transfer of engine power to the transmission fluid, enabling the vehicle to move without stalling.

- Valve Body: The valve body controls the flow of hydraulic fluid within the transmission, directing it to various components as needed.

- Transmission Oil Pump: This pump circulates transmission fluid, ensuring that all components receive proper lubrication.

- Sensors and Solenoids: These electronic components monitor and control various functions within the transmission for optimal performance.

Each of these parts works in harmony to ensure efficient vehicle operation. Regular inspection and maintenance of the transmission assembly are vital to prolonging the lifespan of the vehicle and enhancing its performance.

Cooling System Layout and Parts

The cooling mechanism in an automobile is essential for maintaining optimal operating temperatures within the engine. This system ensures that the engine does not overheat, which can lead to significant damage and decreased performance. Understanding the layout and components of this system is crucial for effective maintenance and repair.

Key Components of the Cooling Mechanism

At the heart of the cooling mechanism is the radiator, which dissipates heat from the engine coolant. The coolant circulates through the engine, absorbing heat and carrying it back to the radiator. A water pump plays a vital role by circulating the coolant throughout the system, ensuring efficient heat exchange. Additionally, the thermostat regulates the flow of coolant based on temperature, allowing for optimal engine performance.

Layout Overview

The overall layout of the cooling system includes interconnected components such as hoses and connections that facilitate the flow of coolant. Proper routing of these hoses is critical to prevent leaks and ensure efficient operation. Furthermore, the integration of cooling fans aids in airflow over the radiator, enhancing its ability to dissipate heat effectively.

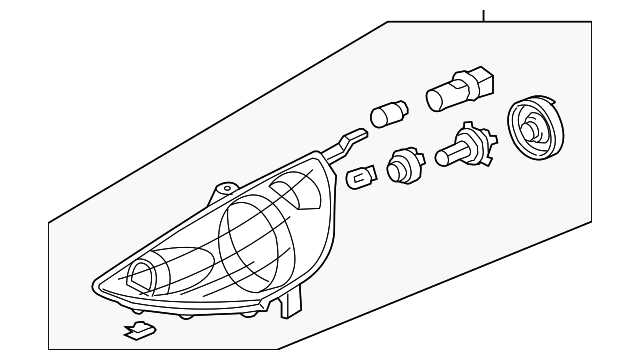

Exterior Lighting Diagram

The arrangement of outdoor illumination components plays a crucial role in ensuring safety and visibility while driving. Understanding how these elements work together can enhance both functionality and aesthetics of the vehicle. This section provides an overview of the various lighting elements and their positions on the vehicle, contributing to effective illumination in different driving conditions.

Headlights are the primary source of forward illumination, essential for nighttime driving. They often feature high and low beam options to adapt to varying visibility needs. Fog lights are typically positioned lower on the front of the vehicle, designed to cut through mist and rain, improving visibility in adverse weather conditions.

Turn signals are crucial for indicating directional changes to other road users. These lights are usually located at the front corners and the rear sides of the vehicle, ensuring clear communication of intentions. Meanwhile, taillights are vital for signaling the presence of the vehicle to those behind, especially in low-light situations. They are generally positioned at the rear, alongside brake lights that become brighter when the vehicle is slowing down.

Additionally, the incorporation of license plate lights ensures that the vehicle’s registration is visible at night. Understanding the layout and functionality of these outdoor lighting elements is essential for maintenance and safety, allowing drivers to ensure their vehicle is equipped for optimal performance in all lighting conditions.

Exhaust System Structure

The exhaust system is a crucial component of any vehicle, responsible for directing harmful gases away from the engine and reducing noise. Its design plays a significant role in maintaining optimal engine performance and enhancing fuel efficiency. Understanding the various elements within this system can help in diagnosing issues and ensuring proper maintenance.

Key Components

The structure consists of several key components that work together seamlessly. The manifold collects exhaust gases from the engine and directs them into the pipes. These pipes transport the gases through the system, often incorporating bends and joints to facilitate smooth flow. A catalytic converter is included to reduce harmful emissions, while the muffler serves to minimize noise produced by the escaping gases.

Functionality and Maintenance

Regular inspection and maintenance of the exhaust structure are essential for optimal performance. Any blockages or leaks can lead to decreased efficiency and increased emissions. Ensuring that all components are functioning correctly not only enhances the vehicle’s performance but also contributes to a cleaner environment.

Air Intake and Filtration Parts

The efficiency and performance of an engine are significantly influenced by its air intake and filtration system. This system plays a crucial role in regulating the flow of air into the engine, ensuring that only clean air reaches the combustion chamber. Proper functioning of this system is essential for maintaining optimal engine performance and longevity.

Key components involved in this system include:

- Air Filter: This element is responsible for trapping dirt, debris, and contaminants from the incoming air, protecting the engine from potential damage.

- Intake Manifold: This part directs the flow of air from the filter to the engine cylinders, ensuring an even distribution of air for efficient combustion.

- Throttle Body: Located between the air intake and the engine, this component controls the amount of air that enters the engine based on the accelerator position.

- Mass Air Flow Sensor: This sensor measures the amount of air entering the engine, allowing the engine control unit to adjust the fuel injection accordingly.

- Intake Duct: This pathway connects the air filter to the throttle body, facilitating smooth airflow into the engine.

Regular maintenance and timely replacement of these components can lead to improved fuel efficiency and enhanced engine performance. It is advisable to follow manufacturer recommendations for inspection and service intervals to ensure the system operates effectively.

Wiring Harness and Electrical Connectors

The wiring harness serves as a crucial network, facilitating the transmission of electrical signals throughout a vehicle. This complex assembly of wires, connectors, and terminals ensures seamless communication between various components, allowing for the proper functioning of systems such as lighting, ignition, and onboard electronics. Understanding the layout and connections within this framework is essential for diagnosing issues and performing effective repairs.

Importance of Quality Connectors

Electrical connectors play a vital role in maintaining reliable connections within the wiring harness. High-quality connectors are designed to withstand environmental factors, such as moisture and temperature fluctuations, which can compromise electrical integrity. Utilizing connectors made from durable materials can prevent corrosion and ensure long-lasting performance, thereby reducing the likelihood of electrical failures.

Common Issues and Maintenance

Over time, wear and tear can lead to problems such as loose connections or frayed wires within the harness. Regular inspection of the wiring harness and connectors is essential for identifying potential issues early on. Proper maintenance may involve cleaning connectors and securing any loose connections, which can significantly enhance the reliability of the electrical system.