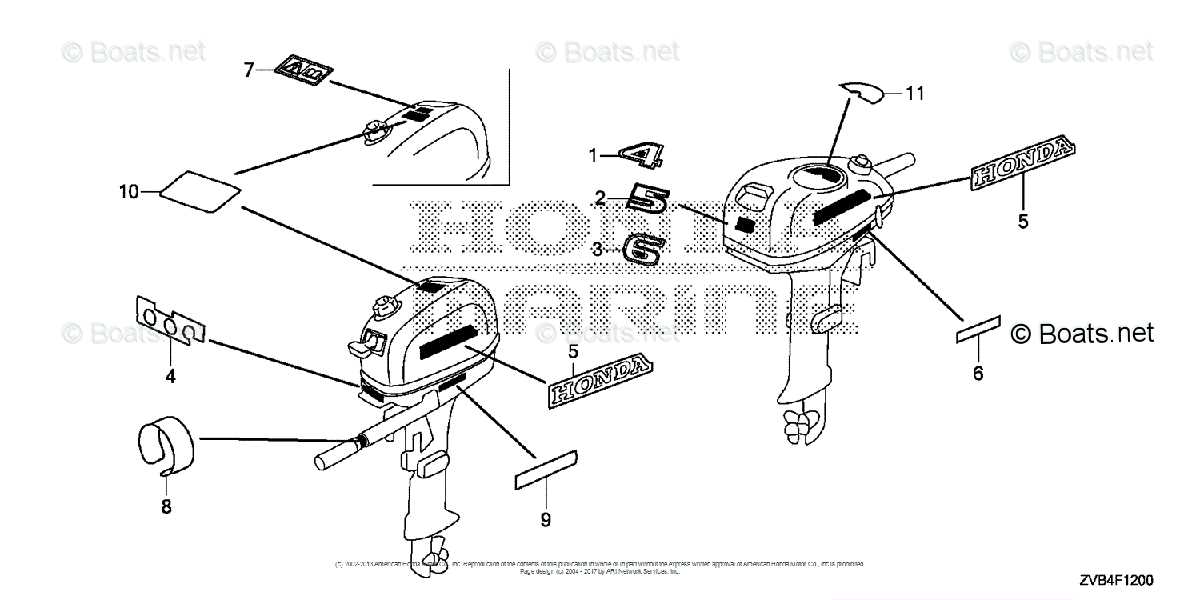

When dealing with marine propulsion systems, it is essential to have a clear understanding of how various elements are arranged and how they work together. Whether you are performing routine maintenance or addressing specific mechanical issues, knowing the layout of key components can make all the difference in ensuring smooth operation.

The internal structure of compact marine engines consists of several interconnected mechanisms. Each element plays a significant role in delivering reliable performance. Understanding their placement can simplify the process of repair and upkeep, ensuring that you approach each task with greater confidence.

Having a detailed visual reference of the engine’s inner workings allows for better preparation when sourcing replacements or conducting repairs. By familiarizing yourself with the assembly and configuration of these vital components, you can prolong the life of the equipment and maintain its efficiency on the water.

Overview of Key Engine Components

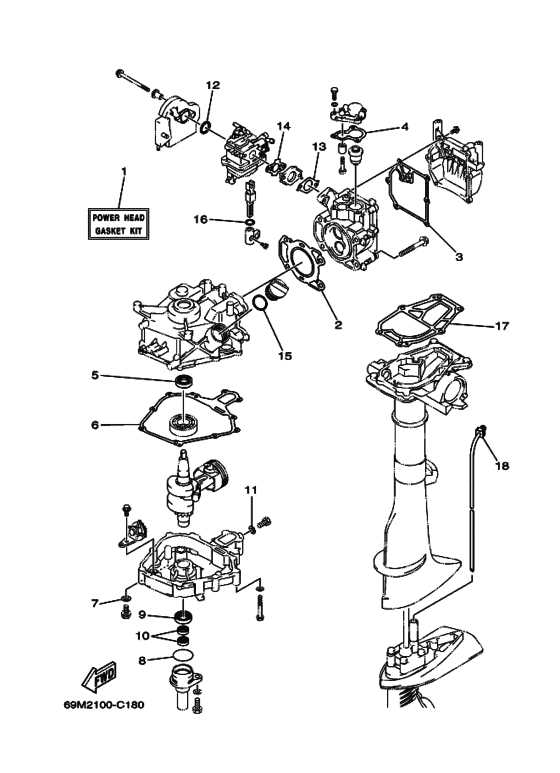

The core elements of this motor system are designed to ensure efficiency and long-term performance. Each component plays a crucial role in maintaining optimal functionality, allowing the system to operate smoothly under various conditions.

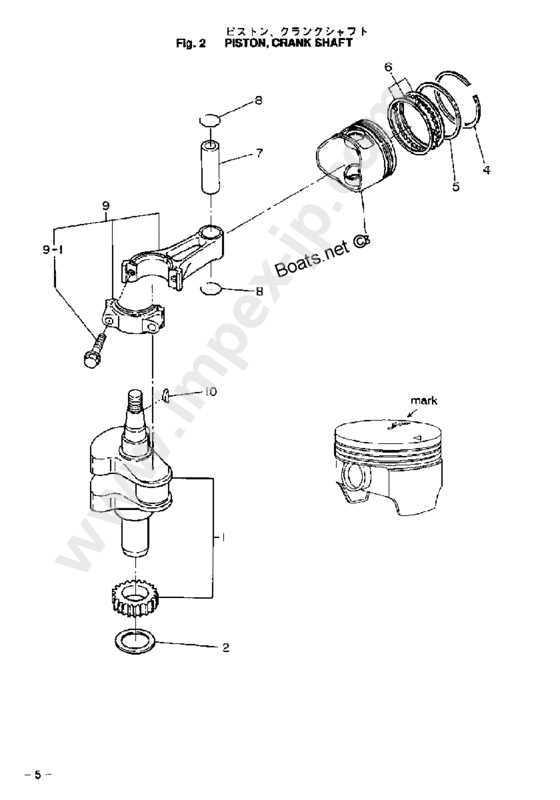

Power Generation Mechanism

The engine’s power unit is the central force behind its operation. It transforms energy into motion, providing the necessary drive for propulsion. Key parts involved in this process are built to withstand continuous use while maintaining a balance between strength and fuel efficiency.

Cooling and Lubrication Systems

These mechanisms are essential for regulating the engine’s temperature and reducing wear. Cooling prevents overheating during prolonged use, while lubrication minimizes friction between moving parts, ensuring smoother operation and extending the system’s life.

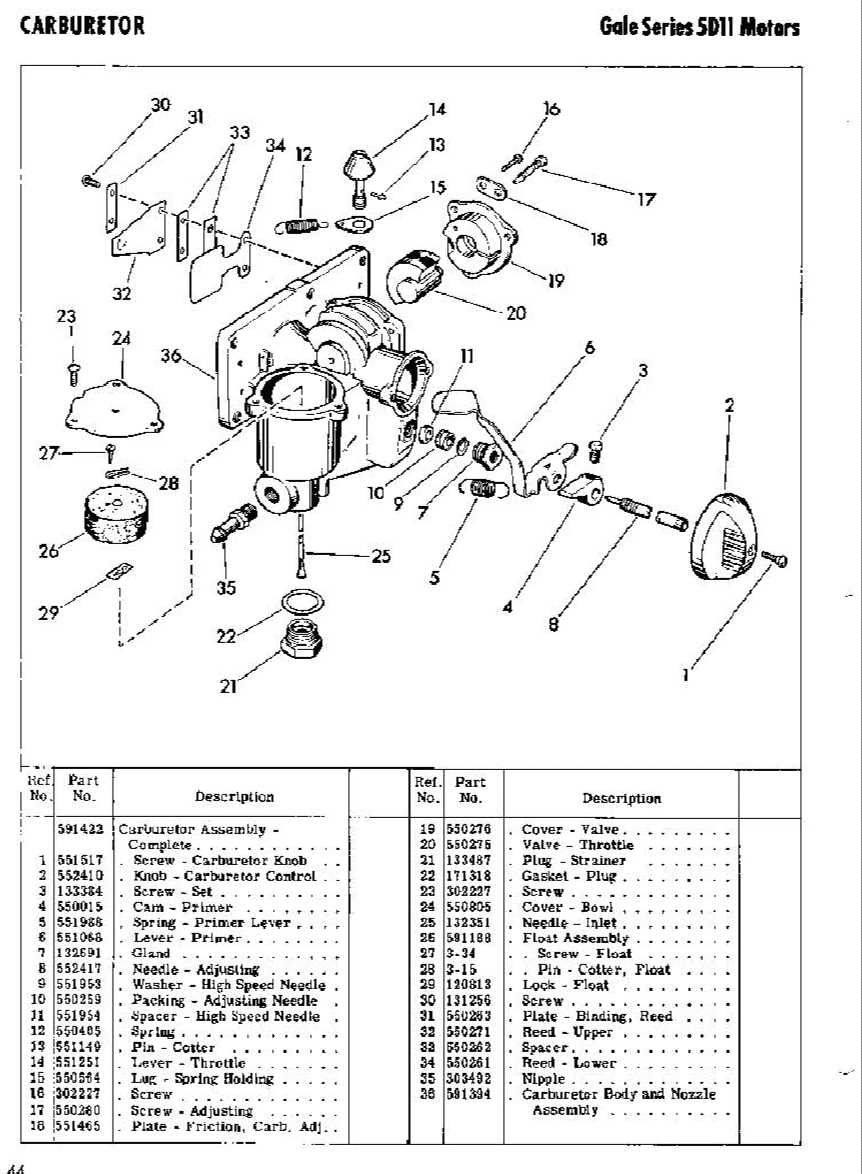

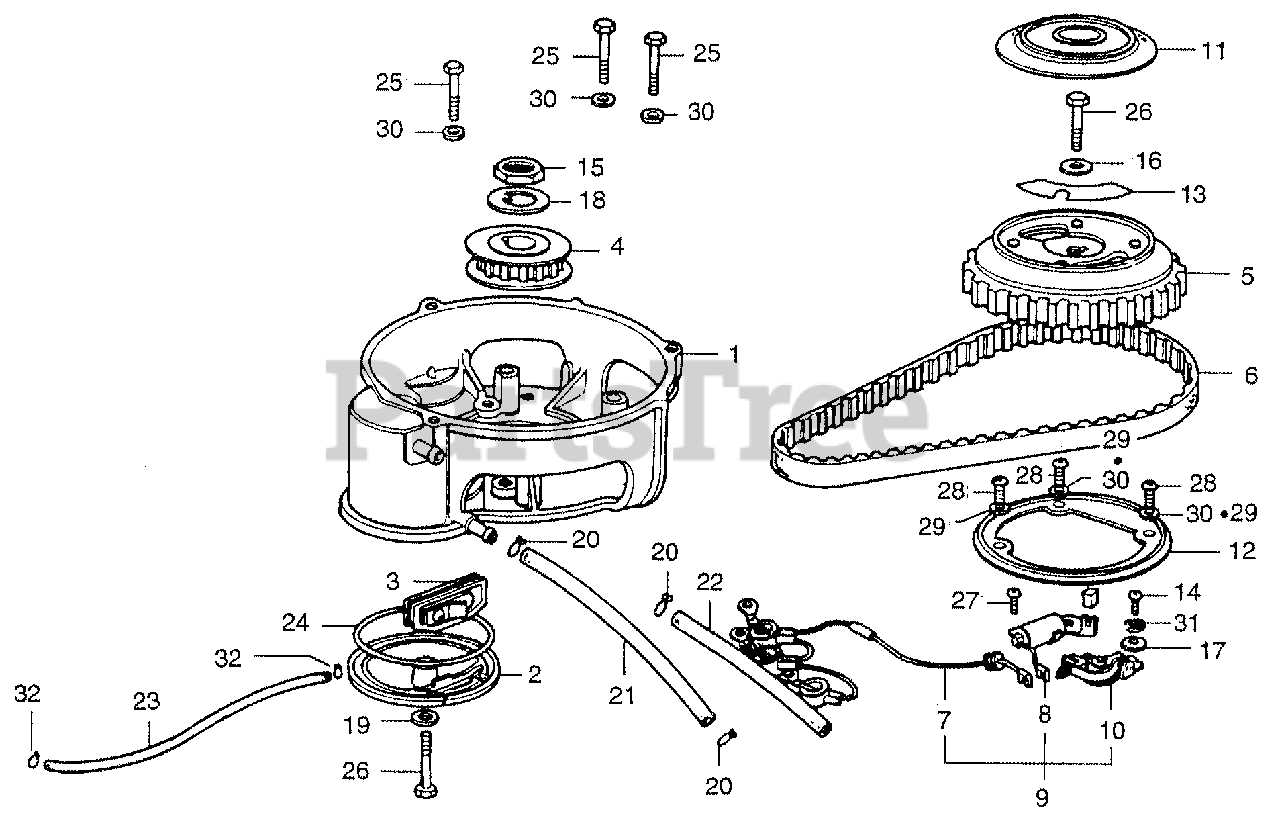

Understanding the Carburetor System

The carburetor plays a critical role in ensuring that the engine receives the right mixture of air and fuel for optimal performance. Its primary function is to regulate the amount of air that blends with the fuel before combustion, affecting overall efficiency and smooth operation. This delicate balance is key to keeping the engine running efficiently across different conditions.

How the System Works

At the heart of this mechanism is a complex network of passages and valves that manage air intake and fuel delivery. As air flows through the system, the pressure difference causes fuel to be drawn in and atomized, creating a mixture that is ready for ignition. The system must adjust continuously to meet varying engine demands, ensuring seamless performance.

Maintenance and Troubleshooting

Regular upkeep of the system is essential to prevent issues like fuel clogs or poor air-fuel balance. Cleaning the internal components and ensuring that the passages remain clear can drastically improve performance. When the system

Fuel Delivery and Filtration Explained

Understanding the mechanisms involved in fuel transportation and filtering is essential for ensuring optimal performance in small engine systems. The process involves multiple components working together to guarantee that the engine receives clean fuel efficiently, avoiding any contaminants that could disrupt operation.

Fuel Flow Management

The process begins with the transportation of fuel from the storage container to the combustion chamber. This flow is managed through a series of tubes and valves that regulate the amount of fuel reaching the engine, ensuring the right mixture of air and fuel is maintained for smooth ignition.

Effective Filtration Systems

To maintain engine longevity and performance, the fuel must be filtered to remove any particles or impurities. Filters are positioned along the fuel line to catch debris before it enters sensitive engine parts, minimizing wear and tear and preventing malfunctions caused by contaminated fuel.

How the Fuel Line Operates

The fuel system plays a vital role in ensuring smooth engine function by delivering the proper mixture of air and fuel. Understanding how this system works can help in maintaining efficiency and avoiding potential issues during operation.

- Fuel Flow: The line is designed to transport gasoline from the tank to the engine. This process relies on maintaining the right pressure to ensure the mixture is delivered consistently.

- Key Components: The system includes valves, filters, and connections, which help regulate flow, remove impurities, and maintain optimal performance.

- Importance of Maintenance: Regular inspection of the line is essential to prevent blockages, leaks, or damage that can interrupt the fuel supply and impact performance.

By keeping the system in good condition, you ensure that the engine operates efficiently and reliably in various conditions.

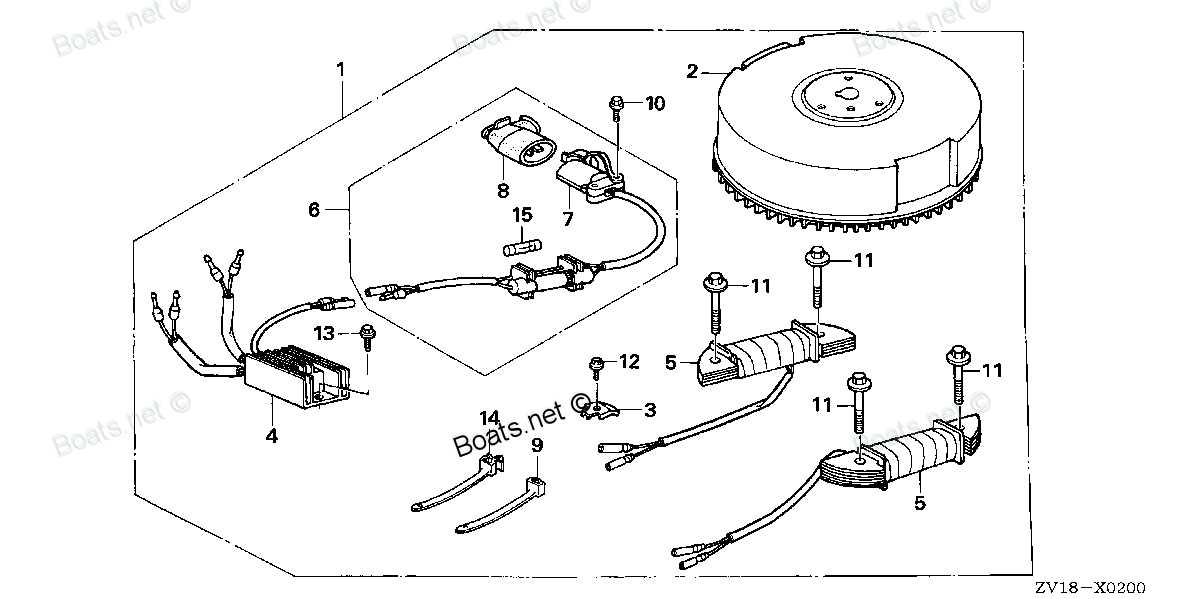

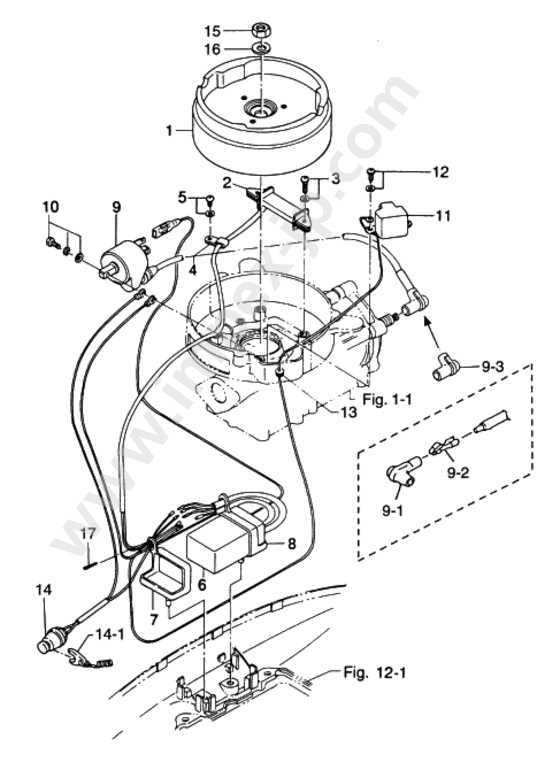

Ignition Parts and Their Function

The ignition system is a critical component that ensures the smooth operation of an engine by controlling the process of igniting fuel. Each element within this setup plays a unique role in creating the necessary spark to power the motor efficiently. Understanding how these elements work together is key to maintaining optimal performance.

Spark Generation Mechanism

One of the central components is the spark creation device, which is responsible for producing the electrical charge needed to ignite the fuel-air mixture. This device works in conjunction with other elements to ensure the precise timing and strength of the spark, directly impacting the engine’s efficiency.

Energy Transfer and Timing

Other vital components are involved in transferring energy and managing the timing of the ignition process. These elements regulate when and how energy is delivered to the spark generation device, ensuring that the motor runs smoothly

Maintaining the Spark Plug for Efficiency

Regular upkeep of the ignition component is crucial for optimal performance in marine engines. Ensuring its functionality can significantly enhance overall efficiency, fuel consumption, and smooth operation. A well-maintained ignition component contributes to reliable starting and effective combustion, reducing the risk of engine issues.

To achieve the best results, follow these essential maintenance steps:

| Task | Frequency | Description |

|---|---|---|

| Inspection | Every 50 hours | Check for signs of wear, corrosion, or damage to ensure effective operation. |

| Cleaning | As needed | Use a wire brush or specific cleaner to remove deposits and dirt. |

| Replacement | Every 100 hours | Replace the component if it shows signs of degradation or if performance drops. |

| Gap Adjustment | Every 50 hours | Ensure the gap between the electrodes meets manufacturer specifications for efficient spark generation. |

By adhering to these maintenance practices, users can prolong the lifespan of the ignition component and ensure peak performance of their marine engines. Regular attention to this aspect of engine care will lead to smoother operation and fewer mechanical problems.

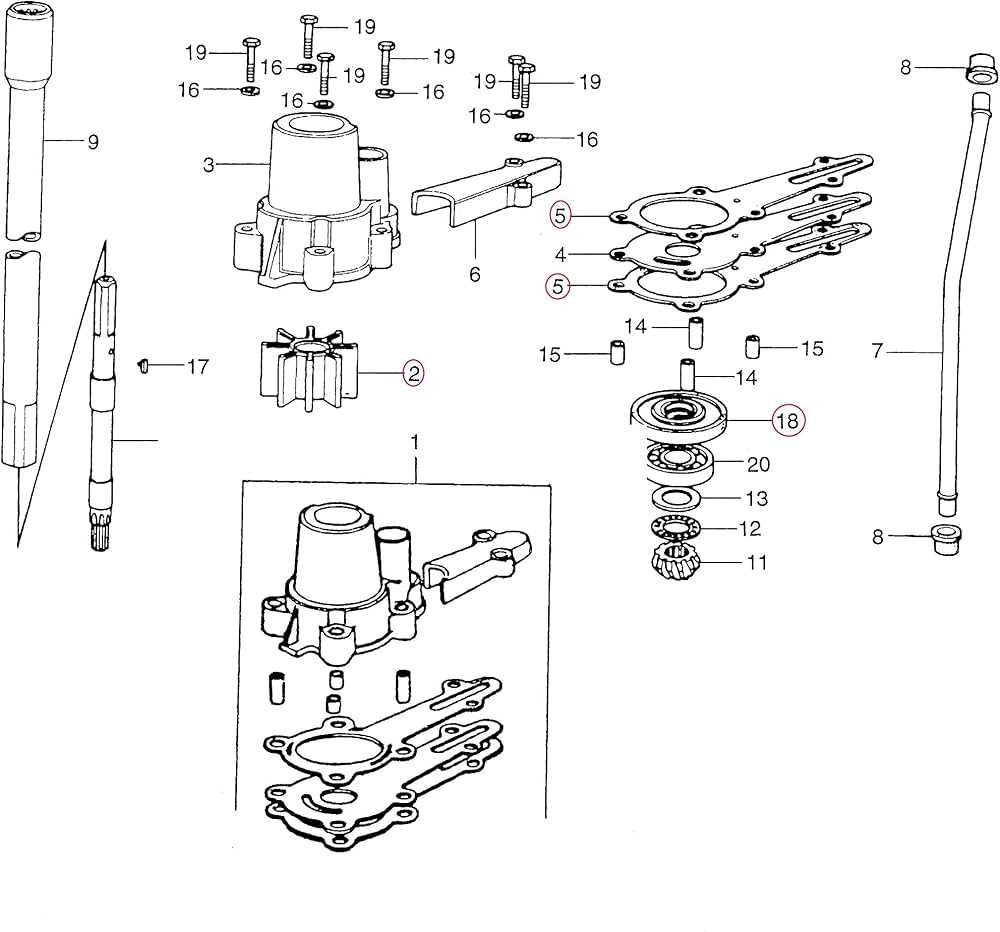

Cooling System Breakdown and Parts

The efficiency of any small marine engine significantly relies on its thermal regulation mechanism. Understanding the elements that contribute to this system is crucial for ensuring optimal performance and longevity. Proper management of temperature not only enhances engine operation but also prevents potential damages that could arise from overheating.

Key Components of the Cooling Mechanism

At the heart of the thermal regulation system are several critical components that work together seamlessly. These include the water pump, which draws coolant from the surrounding environment, and the thermostat, which regulates the flow based on temperature. Furthermore, the exhaust manifold plays a vital role in dissipating heat generated during operation, maintaining a balanced thermal environment.

Maintenance Considerations

Regular inspection and maintenance of the cooling apparatus are essential to ensure it functions effectively. Cleaning the intake screen and checking the condition of hoses can prevent blockages and leaks. Additionally, monitoring the coolant level and replacing it as necessary will help maintain the engine’s performance. Neglecting these tasks can lead to overheating and severe engine damage, emphasizing the importance of a proactive approach to maintenance.

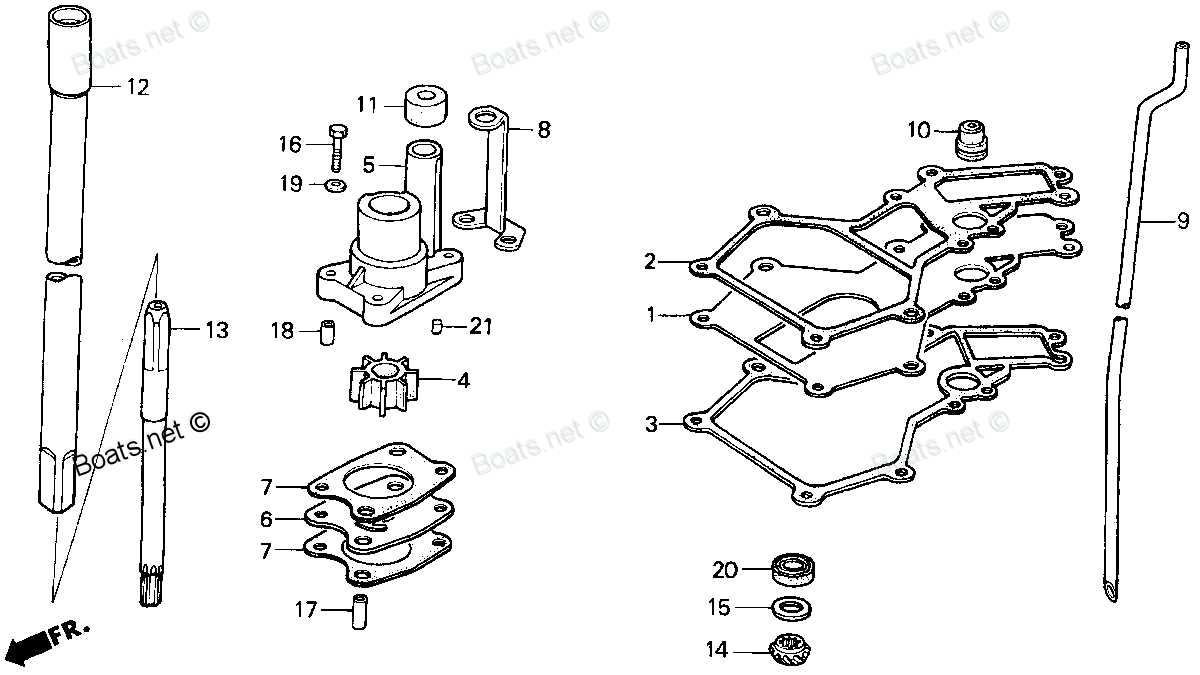

Water Pump’s Role in Engine Cooling

The cooling system in any internal combustion engine is essential for maintaining optimal operating temperatures, preventing overheating, and ensuring longevity. One of the critical components that facilitate this process is the circulation device responsible for moving coolant throughout the engine assembly. Its effective operation plays a vital role in regulating temperatures and preserving engine performance.

This circulation mechanism draws liquid from a reservoir and pushes it through various channels, including the engine block and cylinder head, where it absorbs excess heat. As the heated coolant exits the engine, it travels to a cooling unit, often located externally, where it dissipates heat before returning to the engine. This continuous loop not only prevents overheating but also enhances overall efficiency by ensuring that all parts of the engine receive adequate thermal regulation.

Regular maintenance and timely replacement of the circulation component are crucial for sustained performance. Signs of wear or failure may include reduced coolant flow, overheating, or visible leaks. Monitoring these indicators can help ensure the longevity and reliability of the entire cooling system, thereby supporting the engine’s overall health and functionality.

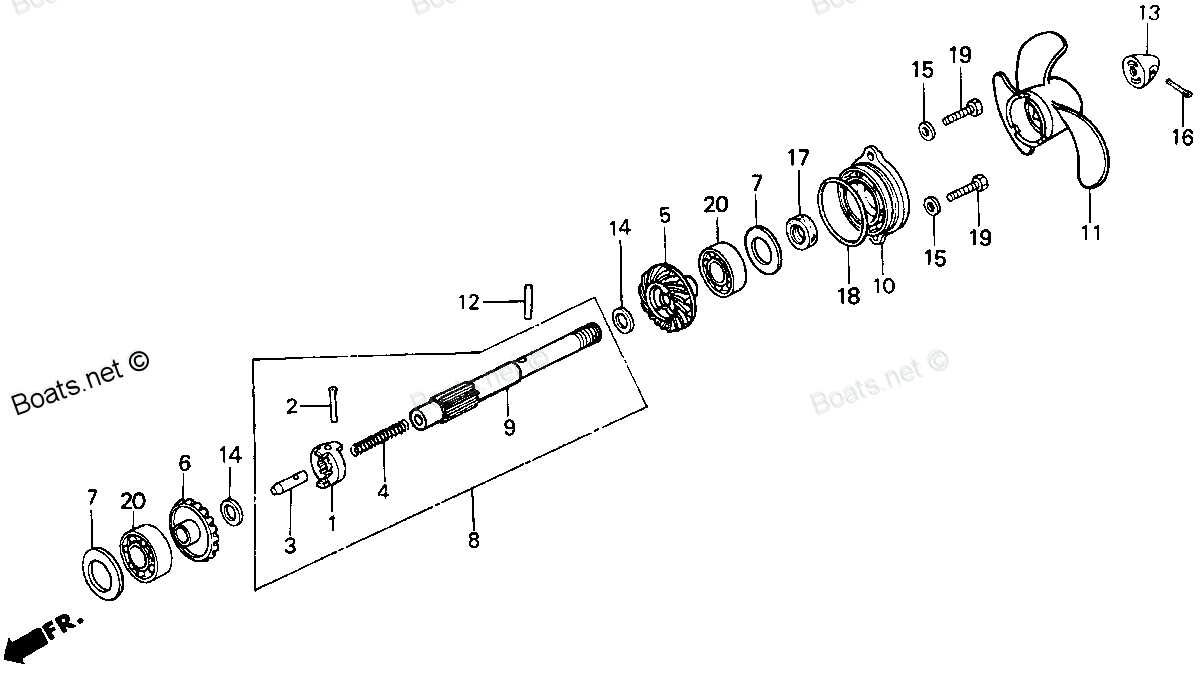

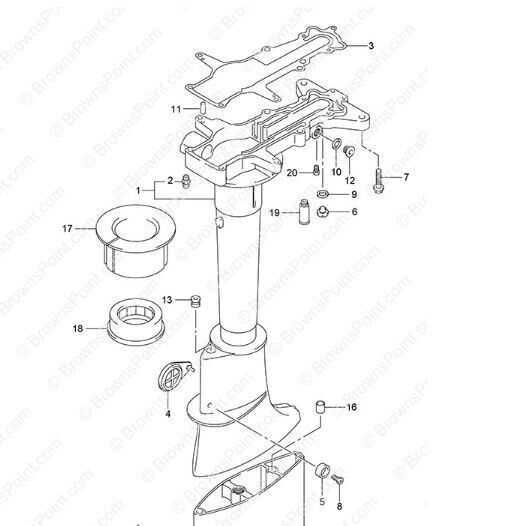

Propeller and Shaft Connection Explained

The link between the propeller and the drive shaft plays a crucial role in the overall functionality of a marine propulsion system. This connection ensures the effective transfer of rotational force, allowing the vessel to move efficiently through the water.

Understanding the components involved in this connection is essential for maintenance and troubleshooting. Here are the key elements:

- Propeller: This component generates thrust by converting rotational motion into forward movement.

- Shaft: The shaft transmits power from the engine to the propeller, providing the necessary force for propulsion.

- Coupling: This part connects the shaft to the propeller, allowing for flexibility and movement while maintaining a secure attachment.

Proper alignment and secure fastening of these components are vital to prevent mechanical failures. Regular inspection can help identify wear and tear, ensuring optimal performance of the propulsion system.

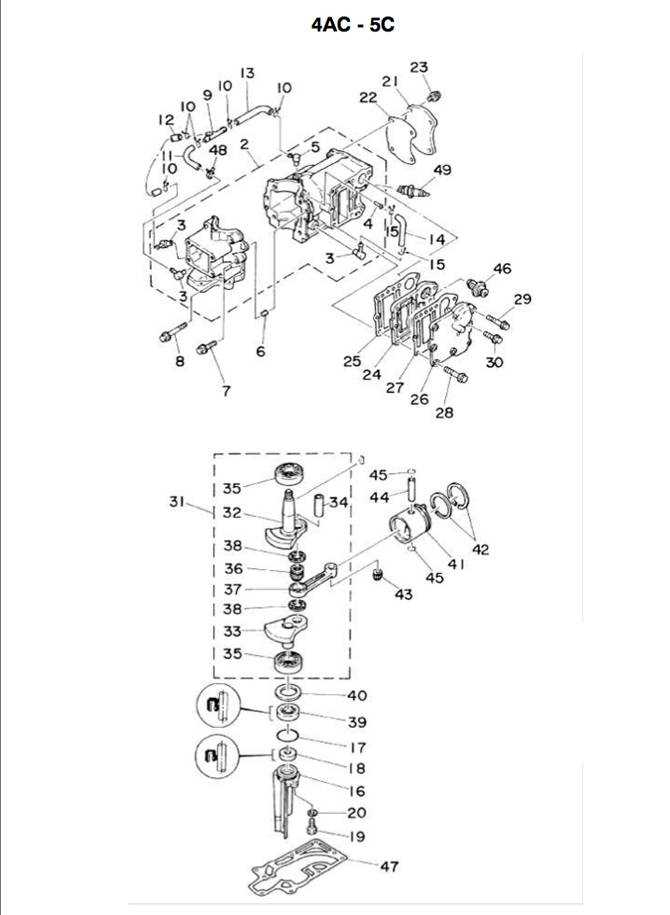

Understanding Gearbox Mechanism

The gearbox mechanism plays a crucial role in the overall functionality of marine propulsion systems. It serves to transfer power from the engine to the propeller, ensuring that the vessel operates efficiently and effectively. Understanding this mechanism involves examining its components and their interactions, which ultimately influence the performance and reliability of the entire system.

Key Components of the Gearbox

At the heart of the gearbox are several essential components, including gears, shafts, and bearings. Gears are responsible for changing the torque and speed of the power generated by the engine, allowing for optimal propulsion in various conditions. Shafts connect these gears, transmitting the rotational force, while bearings support the moving parts and reduce friction, enhancing overall performance.

Functionality and Maintenance

The efficiency of the gearbox depends on proper maintenance and understanding its operational principles. Regular inspections and servicing are vital to prevent wear and tear that could lead to mechanical failures. Understanding the functionality of each component will empower users to perform necessary checks and replacements, ensuring the longevity and reliability of the mechanism.

Exhaust System Components and Maintenance

The exhaust assembly plays a crucial role in the overall performance of marine engines by directing exhaust gases away from the engine while minimizing noise and emissions. Understanding its components and ensuring regular upkeep is vital for optimal functionality and longevity.

Key elements of the exhaust setup include the manifold, which channels gases from the engine; the riser, responsible for elevating exhaust flow; and the silencer, which helps reduce sound levels. Each of these parts must be regularly inspected for wear, corrosion, and blockages to maintain efficient operation.

Routine maintenance tasks involve checking for leaks, cleaning components to remove buildup, and ensuring all connections are secure. Seasonal checks, especially before extended use, can prevent potential issues and enhance performance. Keeping the exhaust system in top condition contributes significantly to the overall health of the marine engine.

How the Muffler Manages Noise and Emissions

The functionality of the silencing component is crucial in reducing the disturbances produced by combustion engines while also minimizing harmful substances released into the atmosphere. By effectively controlling both sound and emissions, this element plays a vital role in ensuring compliance with environmental standards and enhancing the overall user experience.

Mechanisms of Noise Reduction

The silencing device employs several strategies to dampen sound levels:

- Sound Absorption: Utilizing materials that absorb sound waves, reducing noise intensity.

- Chamber Design: Implementing various chambers to disrupt sound wave propagation.

- Path Length Modification: Extending the exhaust path to diffuse sound before it exits.

Emission Control Techniques

In addition to noise reduction, this component aids in managing emissions through:

- Filtration: Removing particulates and contaminants from exhaust gases.

- Temperature Regulation: Maintaining optimal temperatures to promote efficient combustion.

- Gas Expansion: Allowing gases to expand and cool, thereby reducing toxicity.

By integrating these methods, the silencing unit significantly enhances the performance of combustion engines, contributing to a quieter and cleaner environment.

Throttle and Steering Controls Overview

The operation of a small marine engine involves various components that ensure smooth navigation and speed regulation. Among these, the control mechanisms play a crucial role in delivering a seamless experience for the operator. Understanding the functions and interactions of these controls is essential for optimal performance and maneuverability.

Typically, two primary controls are involved:

- Throttle Control: This component regulates the engine’s power output, allowing the operator to adjust speed efficiently.

- Steering Mechanism: This system directs the vessel, enabling it to turn and navigate through water with precision.

Each control is designed to enhance the usability and responsiveness of the engine. Here are some key aspects:

- Throttle Lever: Usually located on the side, it provides a straightforward means to increase or decrease speed.

- Steering Wheel or Handle: This allows the user to guide the craft in the desired direction, with variations depending on the specific model.

- Control Cables: These connect the throttle and steering controls to the engine, ensuring effective communication and response.

Proper maintenance of these components is vital for reliable performance. Regular checks can prevent issues and ensure that the controls function smoothly, contributing to a safer boating experience.