In the world of all-terrain vehicles, comprehending the configuration of various elements is crucial for efficient maintenance and repair. A well-structured overview of the essential components aids enthusiasts and mechanics in navigating the intricate machinery that powers these machines. By familiarizing oneself with the arrangement of individual parts, users can enhance their skills and ensure optimal performance.

When delving into the specifics of a particular model, it is vital to explore the relationships between different components. Recognizing how these parts interact not only simplifies troubleshooting but also empowers users to make informed decisions about upgrades and replacements. This knowledge fosters a deeper appreciation for the engineering that underpins the vehicle’s operation.

For those looking to embark on repairs or modifications, having a clear reference guide that outlines the configuration of components is invaluable. Such a resource can serve as a foundation for both novice and experienced individuals, enabling them to tackle projects with confidence and precision. Ultimately, understanding the intricate details of the assembly promotes a more rewarding experience in the realm of off-road exploration.

Understanding Key Components

The functionality of any vehicle relies on a complex system of interconnected elements. Each component plays a critical role in ensuring the smooth operation of the machine. When working with older models, recognizing the purpose of individual elements and how they fit together can help maintain and restore the vehicle to its optimal performance.

Key areas that require attention include:

- Engine Assembly: The powerhouse of the machine, responsible for generating motion through internal processes.

- Transmission Mechanism: Transfers the energy from the motor to the wheels, facilitating movement and control.

- Suspension and Frame: Provides stability, balance, and shock absorption during operation over various terrains.

- Fuel and Air Systems: Ensures the right mixture of air and fuel is supplied to the engine, supporting combustion efficiency.

- Braking System: Allows for effective stopping and control, crucial for both safety and performance.

Each of these sections contains smaller units, all working together to create a reliable and functional system. Maintaining these elements regularly can extend the life of the machine and improve performance over time.

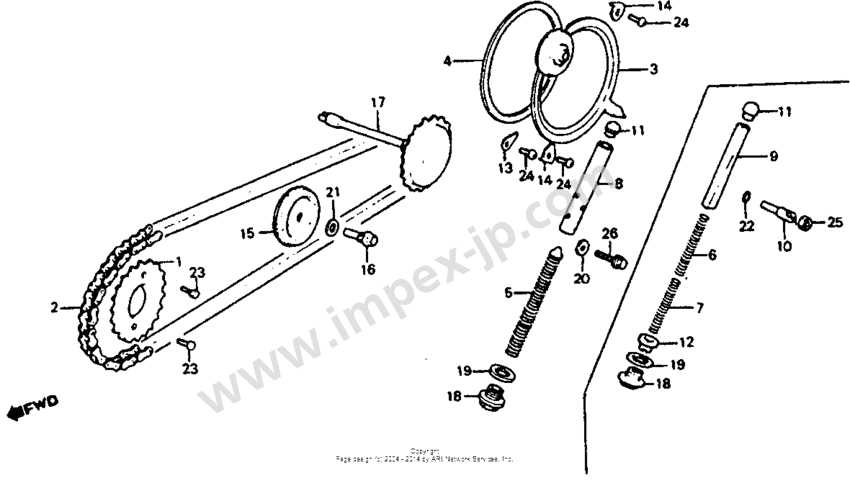

Overview of Parts Diagram Features

Understanding the layout of various mechanical components is essential for anyone looking to maintain or repair equipment. The graphical representation helps to clearly identify each element, ensuring the right pieces are located and understood. This section provides a detailed look at the key elements and layout specifics, designed to assist users in navigation and assembly.

Key Benefits of the Schematic

- Provides a clear visual guide to each component’s position.

- Helps in identifying potential replacement pieces.

- Aids in the proper reassembly during maintenance tasks.

Organized Layout for Easy Reference

- Breaks down the equipment into manageable sections for detailed viewing.

- Each element is labeled for straightforward identification.

- Offers a simplified guide for both professionals and beginners.

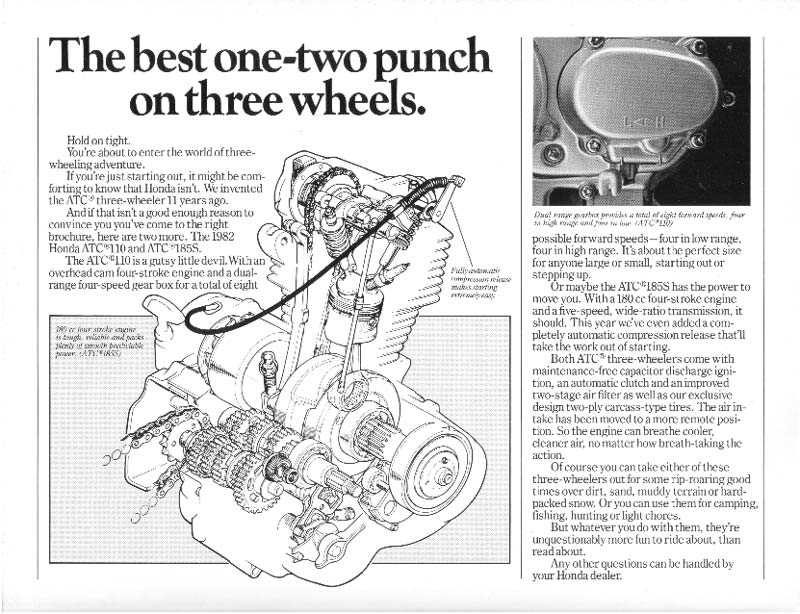

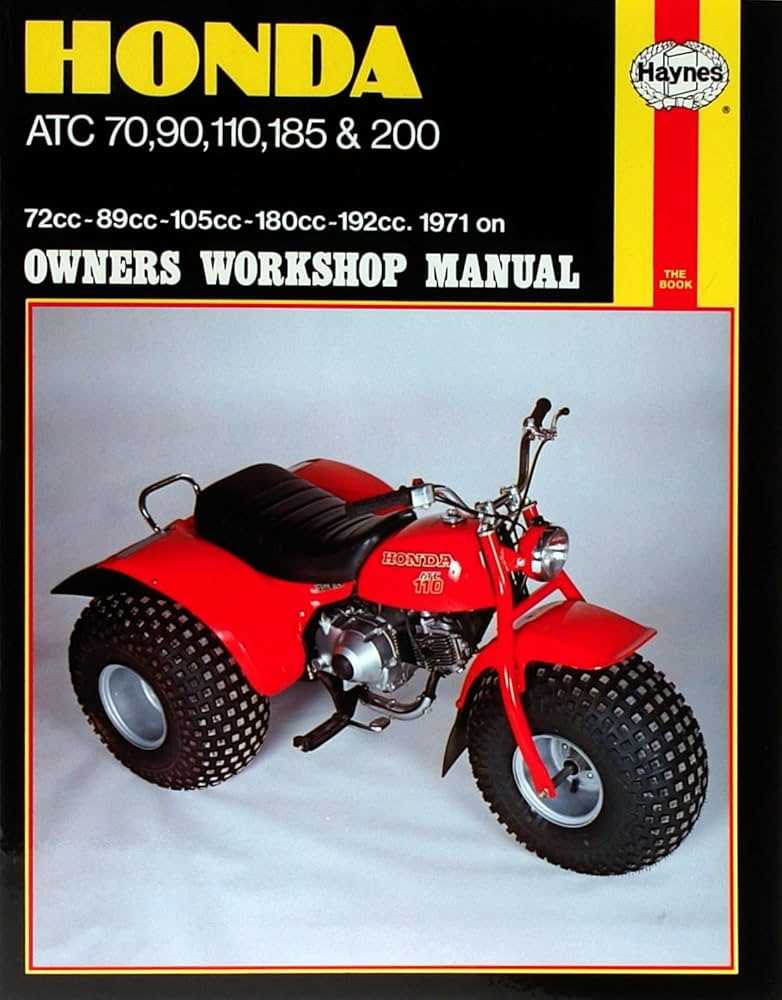

Essential Components of ATC 110

The vehicle’s structure relies on several key elements that work together to ensure smooth performance and durability. Understanding these core parts can provide insight into maintaining and optimizing the machine’s operation. These components, when functioning properly, guarantee a reliable and safe experience on various terrains.

| Component | Function |

|---|---|

| Engine | The power source that drives the entire system, converting fuel into motion. |

| Suspension System | Absorbs shocks and provides a smoother ride over uneven surfaces. |

| Transmission | Controls the vehicle’s speed and power distribution across different gears. |

| Brakes | Ensures controlled stopping by reducing the motion of the wheels when needed. |

| Frame | The foundational structure that holds all components together, offering stability and support. |

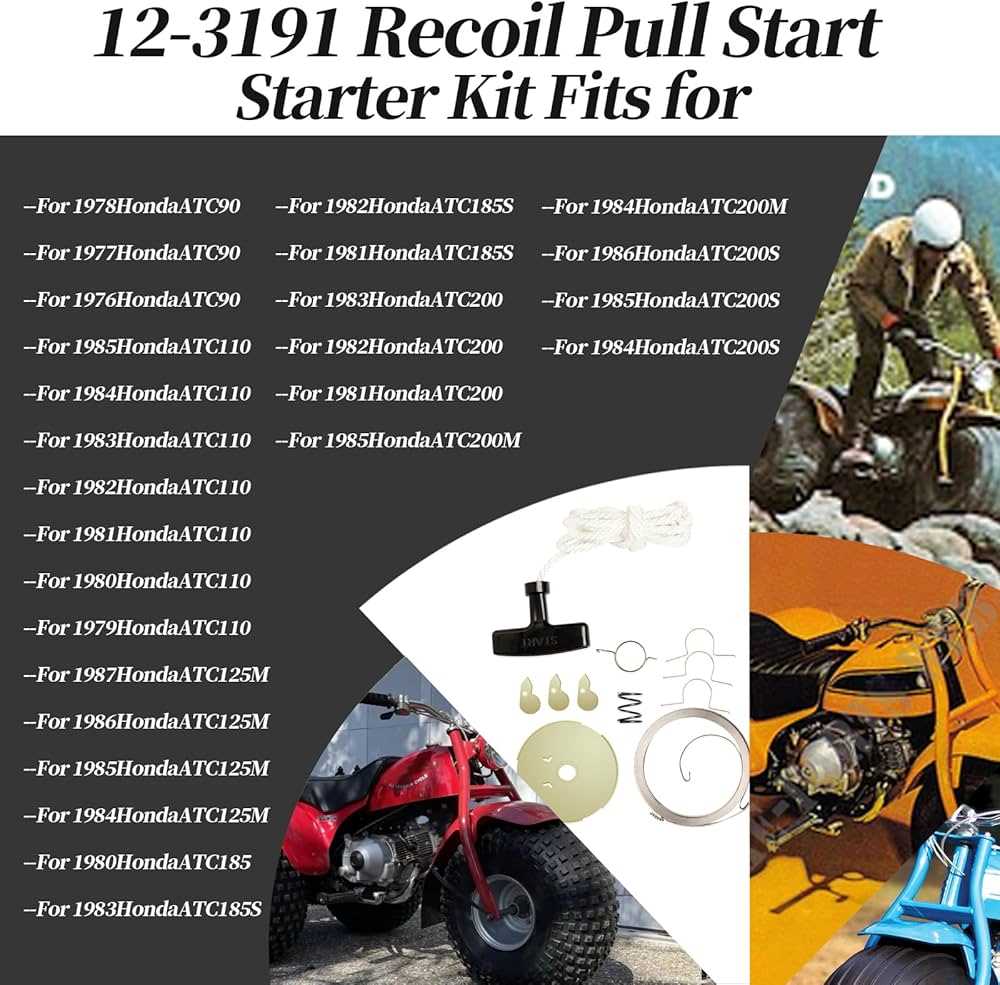

Finding Replacement Parts Easily

Locating the right components for your equipment can be a straightforward process when you know where to look. By focusing on trusted suppliers and platforms, you can quickly find what you need without hassle. Ensuring that the replacements are compatible with your model is essential for smooth performance and longevity.

Start by identifying reliable sources that specialize in your specific machinery. These vendors often provide detailed listings and accurate descriptions, making the selection process simpler. Whether you are looking for mechanical parts or smaller accessories, having access to clear and detailed product information will help you avoid mistakes.

Another useful approach is to seek advice from user communities or forums. Often, experienced users can guide you toward the best options, saving time and ensuring you receive quality replacements. Taking advantage of these resources can greatly improve the efficiency of your search.

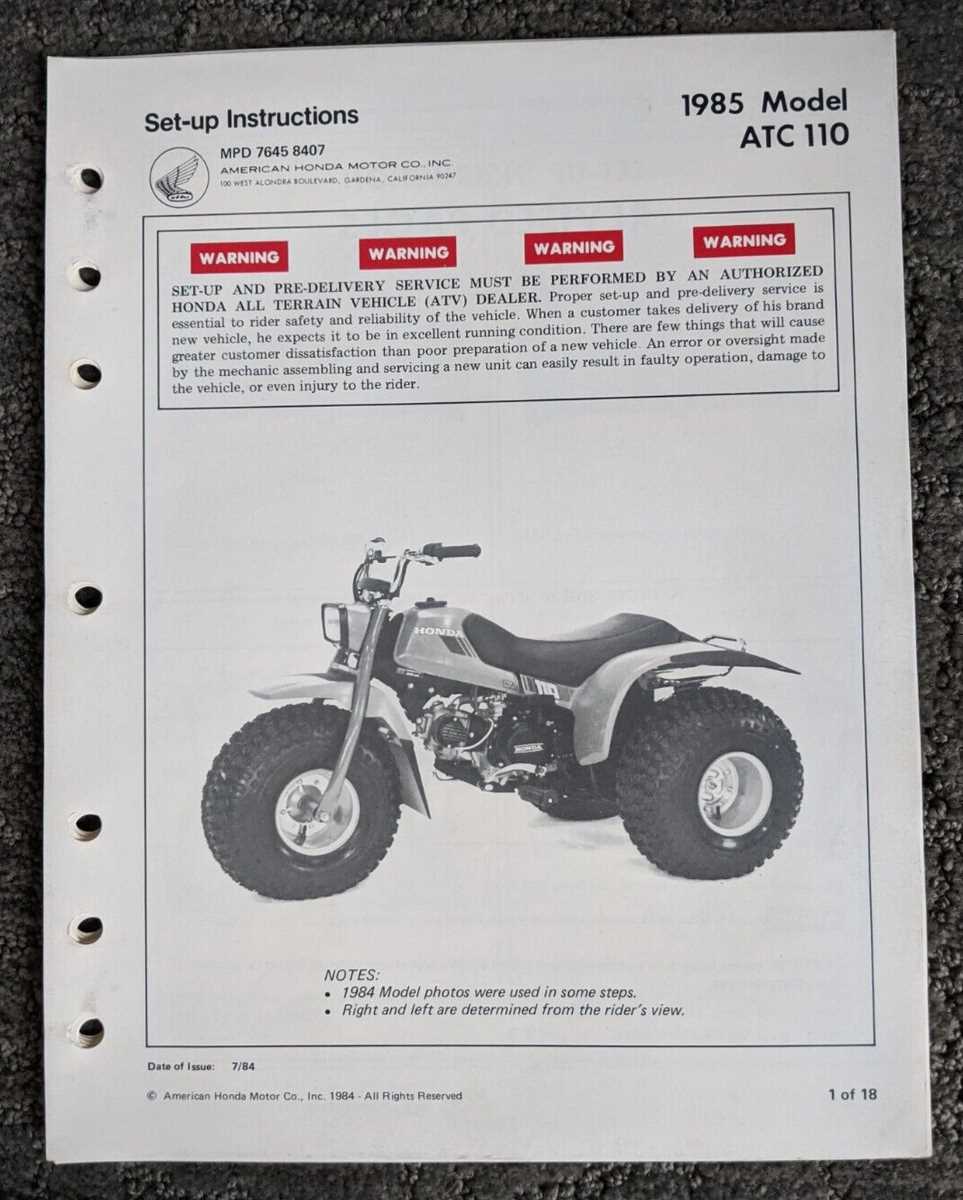

Importance of Accurate Diagrams

Detailed visual guides play a crucial role in understanding how various mechanical components are organized and function together. Without precise representations, it becomes difficult to identify specific items or the correct placement of elements within a complex system. Clear visuals ensure efficiency when conducting repairs or replacements.

Having a reliable illustration is essential for multiple reasons:

- Efficiency: Correct visuals save time by providing a clear understanding of how different parts fit together.

- Prevention of Errors: Mistakes can be costly, and accurate guides help reduce the risk of improper assembly or installation.

- Maintenance: Proper upkeep is easier when you can quickly reference a correct guide for detailed steps.

In summary, precision in visual guides ensures smoother processes

Common Issues with ATC 110 Parts

One of the main concerns with older off-road vehicles is the gradual wear and tear that can affect key mechanical elements. Over time, exposure to rough terrain and heavy use may lead to various functional challenges. Understanding these potential issues helps in maintaining smooth performance and extending the lifespan of critical components.

Frequent Mechanical Failures

Several parts are particularly prone to deterioration due to constant friction and stress. These often involve engine-related elements, suspension systems, and braking mechanisms. Ignoring early signs of malfunction can lead to more severe damage, impacting overall safety and performance.

Wear and Tear Factors

| Component | Common Problem | Cause | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Engine | Overheating | Poor lubrication or debris buildup | ||||||||

| Suspension |

| Label | Description | ||||||

|---|---|---|---|---|---|---|---|

| 1 | Component A – The starting point of the

Recommended Tools for Repairs

When performing maintenance, it’s crucial to have the right set of tools on hand to ensure smooth and efficient work. Using appropriate equipment not only makes the process faster but also helps avoid potential damage to the components. Essential Tools

Some basic tools are indispensable for almost any repair job. These include wrenches, screwdrivers, and pliers, which allow you to handle bolts, screws, and clamps with ease. Specialized EquipmentCertain tasks may require more specific instruments to work on mechanical components accurately. For instance, torque wrenches ensure that fasteners are tightened to precise specifications, while multimeters help diagnose electrical issues effectively.

|