The intricate workings of a beloved all-terrain vehicle reveal a world of precision engineering and thoughtful design. Enthusiasts often seek to delve deeper into the components that contribute to the performance and reliability of these machines. A clear visual representation can significantly enhance one’s understanding of how each element functions together to create a seamless driving experience.

Exploring the assembly of these vehicles is essential for anyone interested in maintenance or restoration. By familiarizing oneself with the layout and functions of various elements, riders can ensure their vehicle remains in peak condition. Moreover, gaining insights into the mechanical structure aids in troubleshooting issues that may arise over time.

In this section, we will provide a comprehensive overview of the key components, illustrating how they interconnect. Whether you are a seasoned mechanic or a novice owner, having access to a detailed breakdown will empower you to make informed decisions regarding repairs and upgrades. Embrace the journey of discovery as we uncover the vital pieces that make up this iconic machine.

Understanding the Honda ATC 200

This section explores the essential components and structure of a specific three-wheeled vehicle, focusing on its functionality and design. A thorough comprehension of its elements is vital for maintenance and performance enhancement.

Key Components

Each element plays a crucial role in the overall operation. Familiarity with these components can significantly impact the user experience and reliability of the vehicle.

| Component | Description |

|---|---|

| Engine | Power source that drives the vehicle. |

| Transmission | System that transfers power from the engine to the wheels. |

| Suspension | Absorbs shocks and provides stability. |

| Brakes | Essential for safety, allowing the operator to slow down or stop. |

Maintenance Tips

Regular upkeep is necessary to ensure longevity and peak performance. Simple checks and servicing can prevent larger issues and enhance the overall experience.

Overview of ATC 200 Features

This section explores the key characteristics of a popular three-wheeled vehicle designed for versatility and ease of use. Its robust design and user-friendly features make it suitable for various terrains and activities.

Key Attributes

- Powerful engine for efficient performance

- Durable frame ensuring stability

- Responsive steering for enhanced maneuverability

- Comfortable seating for long rides

Additional Highlights

- Adaptable suspension system for rough surfaces

- Easy maintenance and accessibility of components

- Wide tires for improved traction

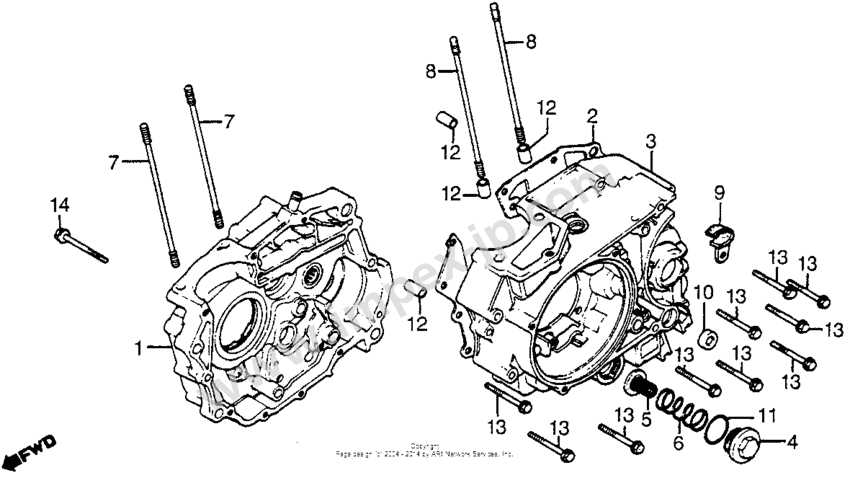

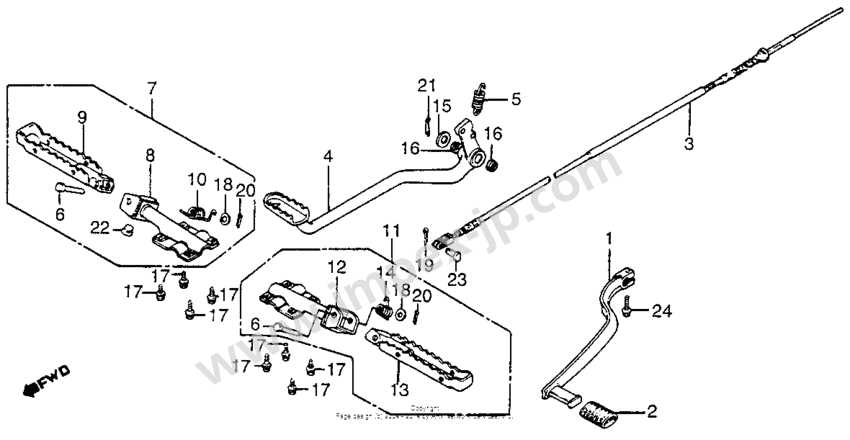

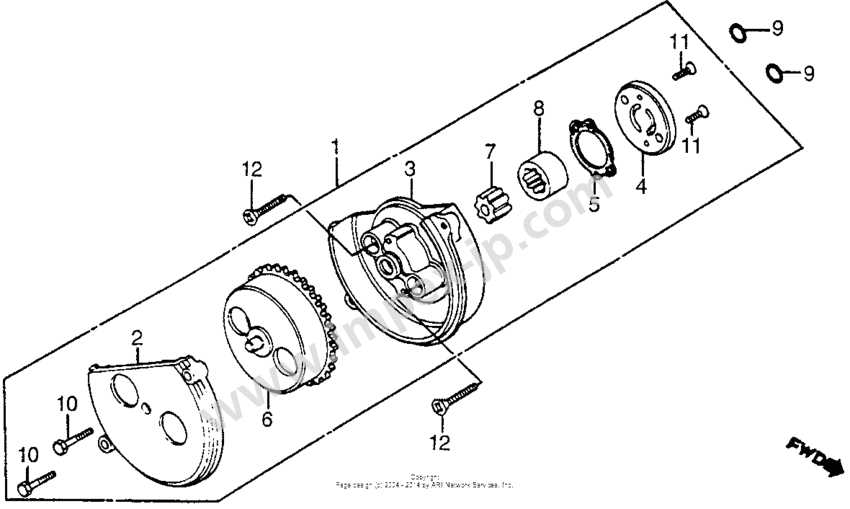

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding assembly and repair processes. They provide clarity and help identify individual elements, facilitating smoother maintenance and replacement tasks.

Enhanced Understanding

Having access to visual guides allows users to grasp the structure and organization of machinery easily. This understanding leads to more effective troubleshooting and a reduction in errors during repairs.

Efficiency in Repairs

With clear depictions of each element, mechanics can quickly locate necessary items, speeding up the repair process and minimizing downtime. This ultimately results in a more efficient workflow.

| Benefit | Description |

|---|---|

| Clarity | Helps identify specific components easily. |

| Accuracy | Reduces chances of mistakes during repairs. |

| Time-saving | Speeds up the identification of needed parts. |

Key Components of the ATC 200

This section delves into the essential elements that comprise the vehicle’s design, highlighting their functions and significance. Understanding these components is crucial for effective maintenance and performance enhancement.

- Engine: The heart of the machine, responsible for generating power and propulsion.

- Transmission: Facilitates the transfer of power from the engine to the wheels, allowing for smooth acceleration and deceleration.

- Chassis: The framework that supports all other parts, providing stability and structure.

- Suspension: Enhances ride comfort and handling by absorbing shocks from uneven terrain.

- Braking System: Ensures safety by enabling effective stopping power through hydraulic or mechanical means.

- Electrical System: Powers various components, including lighting and ignition, ensuring operational efficiency.

Each of these elements plays a vital role in the overall functionality and reliability of the machine, making knowledge of them essential for any enthusiast or technician.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide a clear overview of various elements and their connections, enabling users to identify what is needed for replacement or repair tasks.

To effectively interpret these visual guides, follow these steps:

| Step | Description |

|---|---|

| 1 | Familiarize yourself with the layout, noting sections and labels. |

| 2 | Identify numbered items, which typically correspond to a list of components. |

| 3 | Refer to accompanying documentation for detailed descriptions and specifications. |

| 4 | Cross-check parts with your inventory to ensure accuracy. |

By mastering these techniques, you can enhance your ability to tackle repairs efficiently and confidently.

Common Maintenance Practices

Regular upkeep is essential for ensuring the longevity and optimal performance of your all-terrain vehicle. Adopting a routine maintenance schedule can prevent minor issues from developing into major problems, enhancing both safety and reliability. Here are some widely recommended practices that every owner should consider.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 100 hours or 6 months | Replace old oil to ensure smooth engine operation and prevent wear. |

| Air Filter Inspection | Every 50 hours | Check and clean the air filter to maintain optimal airflow and engine performance. |

| Tire Pressure Check | Monthly | Ensure tires are properly inflated to improve handling and reduce wear. |

| Brake System Inspection | Every 100 hours | Check brake pads and fluid levels to maintain stopping power and safety. |

| Battery Maintenance | Monthly | Inspect battery terminals for corrosion and ensure proper charge levels. |

By following these guidelines, operators can significantly enhance the performance and safety of their vehicle, ensuring enjoyable rides for years to come.

Finding Replacement Parts

Locating suitable components for your vehicle can be a straightforward process when you know where to look. Understanding the various sources available to you is crucial for ensuring the longevity and performance of your machine.

Online Retailers: Numerous websites specialize in offering an extensive selection of replacement components. They provide detailed descriptions and often include images to assist you in making the right choice.

Local Dealerships: Visiting a nearby dealership can be beneficial, as they may carry specific components and can offer professional advice. Establishing a relationship with local experts can simplify future maintenance.

Forums and Community Groups: Engaging with fellow enthusiasts through online forums or local clubs can yield valuable insights. Members often share their experiences and recommendations for reliable suppliers.

Salvage Yards: Don’t overlook the potential of salvage yards, where you can find used components at a fraction of the cost. This option requires a bit of digging but can lead to significant savings.

By exploring these avenues, you can effectively find the necessary components to keep your vehicle in top shape, ensuring a smooth and enjoyable ride.

Aftermarket vs. OEM Parts

When it comes to maintaining and enhancing your vehicle, choosing the right components is crucial. Two primary options often arise: original equipment manufacturer (OEM) components and aftermarket alternatives. Each choice presents its own set of advantages and considerations, making it essential to understand their differences and implications for your vehicle’s performance and longevity.

OEM Components

OEM components are manufactured by the same company that produced the original items installed in your vehicle. These items are designed to match the exact specifications of the original parts, ensuring a perfect fit and reliable performance. One key advantage of opting for OEM is the assurance of quality and compatibility, which often translates to longer-lasting results and fewer maintenance issues down the line.

Aftermarket Alternatives

Aftermarket alternatives, on the other hand, are produced by third-party manufacturers and can vary widely in quality and price. While some of these options offer significant savings and enhanced features, it is essential to exercise caution when selecting them. Thorough research and reviews can help identify reputable brands that provide reliable components. Additionally, the diverse range of aftermarket offerings can allow for greater customization and potential performance improvements.

Tools Needed for Repairs

When undertaking maintenance or restoration tasks, having the right equipment is essential for ensuring efficiency and effectiveness. Proper tools not only streamline the process but also enhance safety and precision during repairs. This section outlines the essential items that every mechanic should have on hand to tackle various challenges.

Basic Hand Tools

A solid set of hand tools is the foundation of any repair job. Wrenches, pliers, screwdrivers, and sockets are crucial for loosening or tightening components. Additionally, having a torque wrench ensures that parts are fastened to the correct specifications, preventing future issues.

Specialized Equipment

Beyond the basics, specialized tools can make certain tasks significantly easier. A service manual is invaluable for understanding the intricacies of the equipment. Furthermore, items like a compression tester, multimeter, or alignment tools can help diagnose and resolve specific problems effectively.

Typical Repair Procedures Explained

Understanding the essential processes involved in maintenance and restoration can significantly enhance the lifespan and performance of your vehicle. This section will guide you through common methods, ensuring you are well-equipped to tackle repairs effectively.

Assessment and Diagnosis

Before any repairs begin, it’s crucial to conduct a thorough evaluation. This involves identifying symptoms and isolating issues, allowing for an accurate diagnosis. Utilizing a systematic approach ensures that all problems are addressed efficiently.

Parts Replacement

Once the issues are identified, the next step is to replace the faulty components. This process may involve removing old parts and installing new ones, often requiring specialized tools. Following the manufacturer’s specifications is vital for optimal results, ensuring a seamless fit and functionality.

Safety Tips for ATC Maintenance

Ensuring the safe upkeep of your three-wheeled vehicle is essential for both performance and rider safety. Proper maintenance not only extends the lifespan of the machine but also minimizes the risk of accidents. Following a set of safety guidelines can make a significant difference in your maintenance routine.

Wear Appropriate Gear

Always use protective equipment such as gloves, goggles, and sturdy footwear when working on your vehicle. This reduces the likelihood of injury from sharp components or hazardous materials.

Follow Manufacturer Guidelines

Refer to the manufacturer’s instructions for maintenance tasks. Adhering to these recommendations ensures that you are using the correct procedures and tools, ultimately enhancing safety and efficiency during service.

Where to Source Quality Parts

Finding reliable components for your off-road vehicle can be a challenge. Whether you’re looking to replace a worn-out element or enhance performance, it’s crucial to source high-quality materials. This guide will explore various avenues to ensure you get the best options available.

Online Marketplaces

The internet offers a plethora of platforms where enthusiasts can find components. Websites like eBay and specialized forums provide a wide selection, often featuring new and used items. When browsing, make sure to check seller ratings and reviews to gauge reliability. Additionally, consider joining online communities; they can provide recommendations and insights on trustworthy sellers.

Local Retailers and Salvage Yards

Don’t overlook local shops and salvage yards. Visiting these places can yield surprising finds, as they often carry rare or discontinued items. Engaging with local mechanics can also lead to useful tips and potential sources for high-quality materials. Building relationships in your community can enhance your search for durable components, saving time and money in the long run.