When it comes to maintaining and optimizing watercraft engines, a comprehensive understanding of their individual components is crucial. Each element plays a significant role in ensuring smooth operation and enhancing performance. By exploring these vital parts, one can effectively troubleshoot and execute necessary repairs or upgrades.

In the realm of marine machinery, recognizing the intricate relationships between various elements can lead to improved functionality and longevity. A detailed overview not only aids in the assembly and disassembly processes but also enhances overall user experience. For enthusiasts and professionals alike, diving into this subject opens doors to deeper knowledge and informed decision-making.

Ultimately, grasping the layout and function of each component empowers owners to take charge of their equipment. Whether for routine maintenance or major repairs, having a clear visual reference can simplify complex tasks. Engage with the specifics, and unlock the potential for enhanced performance and reliability on the water.

Understanding Honda BF15 Engine Components

The intricate machinery of a small outboard motor is comprised of various essential elements that work together to ensure optimal performance. A thorough comprehension of these components is vital for effective maintenance and troubleshooting. Each part plays a specific role, contributing to the overall functionality and efficiency of the engine.

Key components include the powerhead, lower unit, and fuel system, each responsible for crucial tasks. The powerhead generates thrust, while the lower unit facilitates propulsion. The fuel system ensures that the engine receives the right mixture of air and fuel for combustion. Understanding how these parts interact can significantly enhance the longevity and reliability of the motor.

| Component | Function |

|---|---|

| Powerhead | Generates power through combustion. |

| Lower Unit | Transmits power to the propeller. |

| Fuel System | Mixes fuel and air for efficient combustion. |

| Cooling System | Regulates temperature to prevent overheating. |

| Ignition System | Initiates combustion process. |

In conclusion, familiarizing oneself with the various components of this engine type not only aids in effective repairs but also enhances the overall user experience. Proper knowledge enables better decision-making regarding maintenance and upgrades, ultimately leading to improved performance on the water.

Key Features of BF15 Outboard Motor

This versatile marine engine offers remarkable performance and efficiency, making it an ideal choice for various watercraft. Designed with user convenience in mind, it combines advanced technology with reliable construction to ensure a smooth sailing experience.

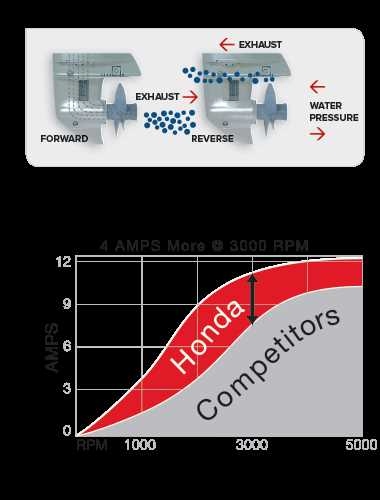

Performance and Efficiency

Equipped with a powerful yet fuel-efficient engine, this model provides excellent thrust while minimizing fuel consumption. The innovative design allows for easy maneuverability and responsiveness, ensuring that users can navigate with confidence.

Durability and Maintenance

Built to withstand harsh marine environments, this engine features corrosion-resistant materials that extend its lifespan. Regular maintenance is simplified thanks to accessible components, allowing for effortless upkeep and optimal performance.

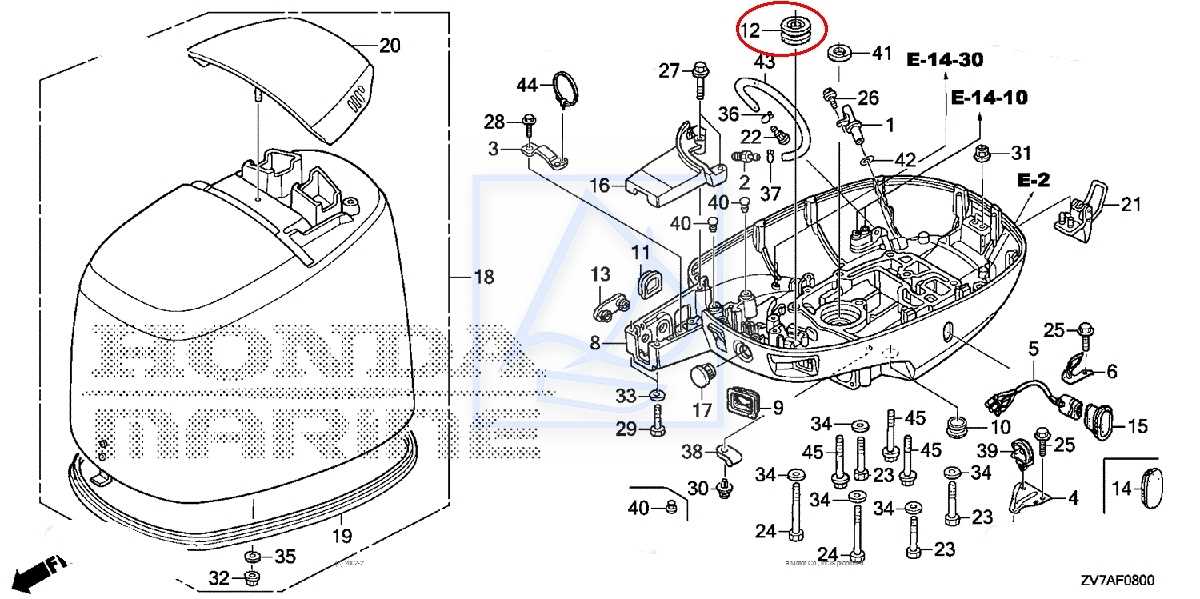

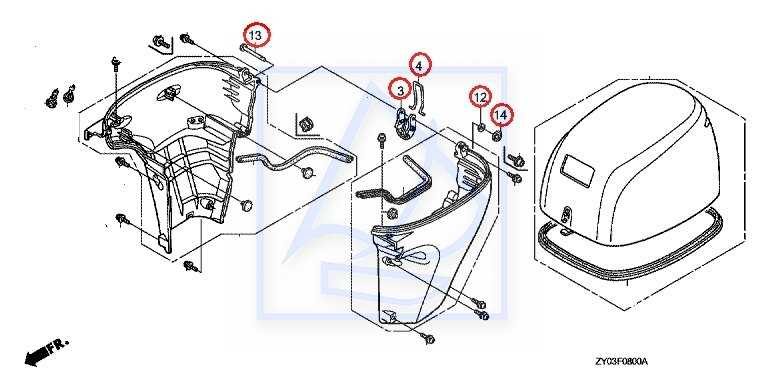

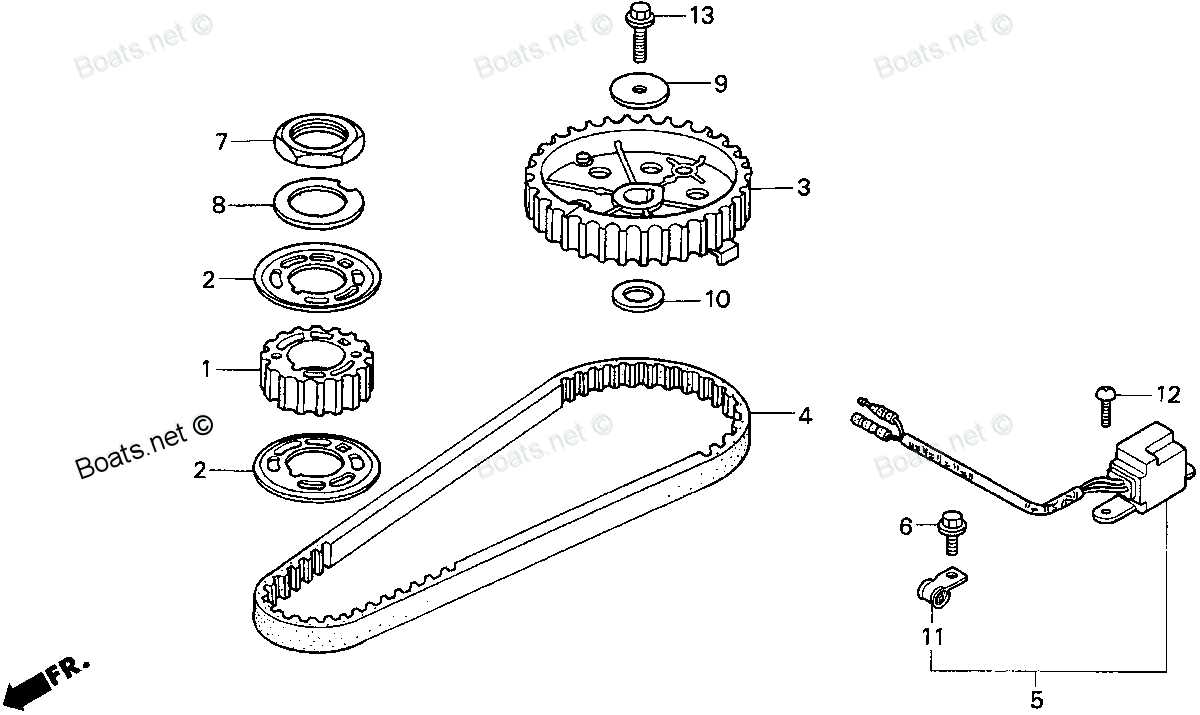

Importance of Accurate Parts Diagrams

Precise illustrations of components are crucial for effective maintenance and repair tasks. These visual representations provide essential guidance, helping technicians and enthusiasts alike identify the necessary elements for their projects. An accurate blueprint simplifies the assembly process and minimizes the risk of errors, ultimately leading to a more efficient workflow.

Moreover, having a detailed reference can save both time and resources. When individuals can easily locate and understand each segment, they are less likely to encounter complications during installation or replacement. This not only enhances the overall experience but also ensures that machinery operates at its optimal capacity.

In conclusion, investing in quality illustrations pays off by fostering a deeper understanding of how individual components interact. This knowledge is invaluable, enabling users to delve into repairs with confidence and achieve the ultimate functionality of their equipment.

Common Issues with BF15 Parts

When dealing with small marine engines, it’s essential to be aware of typical complications that may arise with various components. Understanding these issues can help ensure optimal performance and longevity, ultimately making maintenance easier for boat owners and technicians alike.

Frequent Problems

- Fuel delivery issues, often caused by clogged filters or damaged lines.

- Overheating, which can result from insufficient cooling or coolant leaks.

- Electrical failures, typically linked to corroded connections or faulty wiring.

- Wear and tear on moving parts, leading to decreased efficiency and increased noise levels.

Maintenance Tips

- Regularly inspect and replace fuel filters to maintain optimal flow.

- Check the cooling system for blockages and leaks to prevent overheating.

- Inspect electrical connections and clean any corrosion to ensure reliable operation.

- Monitor moving parts for signs of wear and replace them as necessary.

Maintenance Tips for Honda BF15

Regular upkeep is essential for ensuring the longevity and performance of your outboard motor. By following a few key practices, you can enhance efficiency and prevent potential issues, keeping your equipment running smoothly throughout its lifespan.

Routine Inspections

Perform frequent checks on the motor’s components, including the fuel system, electrical connections, and cooling mechanisms. This proactive approach helps identify wear or damage early, allowing for timely repairs and adjustments.

Fluid Changes

Consistently change the oil and coolant as recommended by the manufacturer. Clean fluids are vital for optimal function, as they reduce friction and prevent overheating, ultimately extending the life of your engine.

Where to Find Genuine Parts

Locating authentic components for your marine engine is crucial for optimal performance and longevity. Utilizing trusted sources ensures reliability and compatibility with your equipment.

- Official Dealerships: These are the most reliable sources, providing components that meet manufacturer standards.

- Authorized Retailers: Look for stores recognized by the manufacturer, offering a range of genuine items.

- Online Marketplaces: Websites specializing in marine supplies often feature sections for original components.

- Forums and Community Groups: Engaging with fellow enthusiasts can lead to recommendations for reputable sources.

Always verify the authenticity of components to avoid potential issues in the future.

Step-by-Step Repair Guide

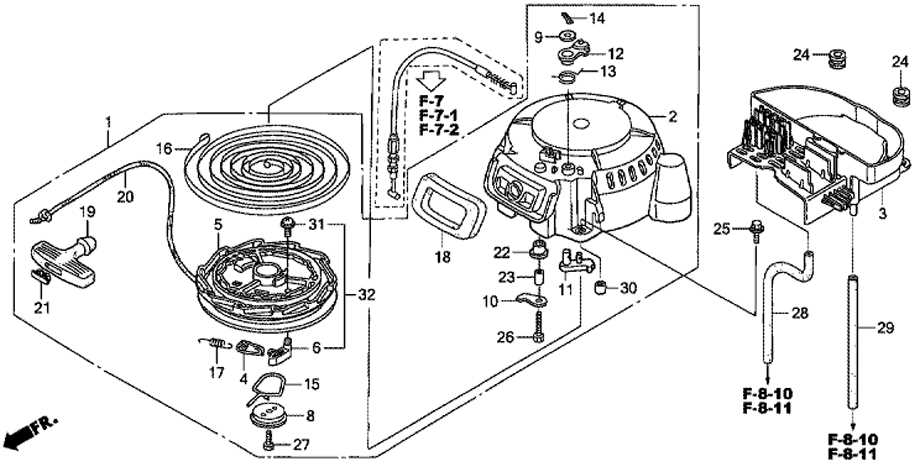

When it comes to maintaining and restoring your marine engine, having a systematic approach is essential. This guide will walk you through a series of methodical steps to ensure efficient troubleshooting and repairs, enhancing the overall performance of your equipment.

1. Preparation: Begin by gathering all necessary tools and replacement components. Make sure you have a clean, organized workspace to avoid losing any small parts during the process.

2. Disassembly: Carefully remove the outer casing and any components that obstruct access to the internal parts. Take note of the order in which you disassemble to simplify reassembly later.

3. Inspection: Examine each part for signs of wear, damage, or corrosion. This step is crucial for identifying which components need replacement or repair.

4. Cleaning: Thoroughly clean all parts using appropriate solvents. Removing dirt and grime will help you assess the condition of the components more accurately.

5. Replacement: Install new parts as needed, ensuring that each component fits securely. Refer to the manufacturer’s specifications for torque settings and alignment.

6. Reassembly: Reassemble the unit in reverse order of disassembly. Double-check all connections and fasteners to ensure they are tightened properly.

7. Testing: After reassembly, conduct a thorough test to confirm that everything operates smoothly. Listen for unusual sounds and check for leaks.

8. Maintenance: Implement a regular maintenance schedule to prolong the life of your engine. This includes routine inspections and timely replacements of worn components.

Benefits of Regular Inspections

Routine evaluations of equipment play a crucial role in maintaining optimal performance and longevity. These assessments help identify potential issues before they escalate, ensuring reliability and efficiency in operation.

Enhanced Safety

Regular inspections significantly contribute to the overall safety of machinery. By uncovering hidden defects or wear and tear, they prevent accidents and ensure a safer working environment.

Cost Savings

Proactive maintenance can lead to substantial financial savings. Addressing minor problems early on often prevents costly repairs or replacements down the line, optimizing budget management for users.

Upgrading BF15 Performance Parts

Enhancing the capabilities of your marine engine can lead to improved speed and efficiency. By focusing on various components, enthusiasts can unlock the full potential of their vessel, ensuring a more enjoyable and powerful experience on the water.

| Component | Description | Benefits |

|---|---|---|

| Exhaust System | Upgraded exhaust systems improve airflow. | Increased horsepower and torque. |

| Intake Manifold | Enhanced manifolds allow better air intake. | Improved throttle response and efficiency. |

| Propeller | High-performance propellers optimize water flow. | Better acceleration and speed. |

| Fuel System | Refined fuel delivery systems enhance combustion. | Greater power output and fuel efficiency. |

By considering these upgrades, boat owners can significantly enhance their engine’s performance, leading to a more thrilling maritime experience.

Comparing BF15 to Other Models

This section explores the differences and similarities between the featured model and its counterparts, focusing on performance, efficiency, and design aspects. By examining these variations, users can make informed decisions based on their specific needs and preferences.

Performance Comparison

The performance metrics highlight key distinctions that influence user experience. When considering power output, fuel efficiency, and overall reliability, it’s essential to assess how each model stacks up against one another.

| Model | Power Output (HP) | Fuel Efficiency (MPG) | Weight (lbs) |

|---|---|---|---|

| Model A | 15 | 25 | 100 |

| Model B | 20 | 22 | 120 |

| Model C | 15 | 30 | 95 |

Design Features

Examining the design elements reveals both aesthetic and functional differences. Users may find variations in weight distribution, overall dimensions, and material quality that affect usability and maintenance.

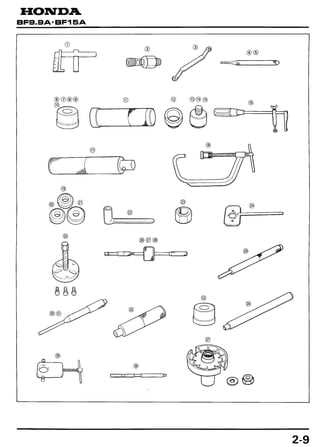

Tools Needed for Maintenance

Proper upkeep of any engine requires a specific set of instruments to ensure efficiency and longevity. Having the right tools on hand not only simplifies the process but also enhances safety during maintenance tasks.

Essential Instruments

- Wrenches (various sizes)

- Screwdrivers (flathead and Phillips)

- Plier set

- Socket set

- Torque wrench

Additional Gear

- Oil change pump

- Fuel system cleaner

- Cleaning rags

- Safety goggles

- Gloves

Understanding BF15 Wiring Schematics

Comprehending the electrical configurations of small engines is crucial for effective maintenance and troubleshooting. A wiring schematic serves as a visual guide that illustrates the interconnections and relationships between various electrical components. By familiarizing oneself with these diagrams, users can gain insights into how electrical signals flow, enabling efficient diagnosis of potential issues.

Typically, these schematics will include elements such as ignition systems, fuel pumps, and battery connections. Understanding how these parts work together can enhance overall performance and reliability. Below is a simplified representation of common electrical components and their functions:

| Component | Function |

|---|---|

| Ignition Coil | Generates high voltage to ignite the fuel-air mixture |

| Starter Motor | Engages the engine to initiate operation |

| Battery | Supplies electrical energy to various components |

| Regulator | Maintains consistent voltage levels for electrical systems |

By closely analyzing these connections, operators can effectively troubleshoot issues and ensure that all electrical systems are functioning as intended. This foundational understanding empowers users to perform maintenance with confidence and precision.

Community Resources and Forums

Engaging with fellow enthusiasts can greatly enhance your understanding and maintenance of marine engines. Online communities and discussion boards provide invaluable support, allowing users to share insights, troubleshoot issues, and exchange experiences. These platforms foster collaboration and knowledge sharing among members, making them essential resources for anyone involved in marine activities.

Here are some key benefits of participating in these communities:

- Access to Expertise: Members often include seasoned professionals who can offer advice and solutions.

- Shared Experiences: Learning from others’ successes and challenges can help prevent common pitfalls.

- Parts and Maintenance Tips: Discussions often cover sourcing components and effective maintenance techniques.

- Networking Opportunities: Connect with other users for potential collaborations or local meetups.

Some popular online platforms to consider include:

- Dedicated Marine Forums: Look for forums specifically focused on engine discussions.

- Social Media Groups: Platforms like Facebook host groups for enthusiasts to share insights and questions.

- Video Channels: YouTube offers tutorials and troubleshooting videos that can be beneficial.

- Local Clubs: Seek out community organizations that hold regular meetings or events.

By actively participating in these resources, you can gain a wealth of knowledge and build connections that will enhance your experience and skills in marine engine maintenance.