The functionality of marine machinery relies heavily on the intricate interplay of various elements that make up its design. Each component plays a crucial role in ensuring optimal performance and reliability in demanding aquatic environments. Gaining a clear understanding of these elements is essential for both maintenance and repair tasks.

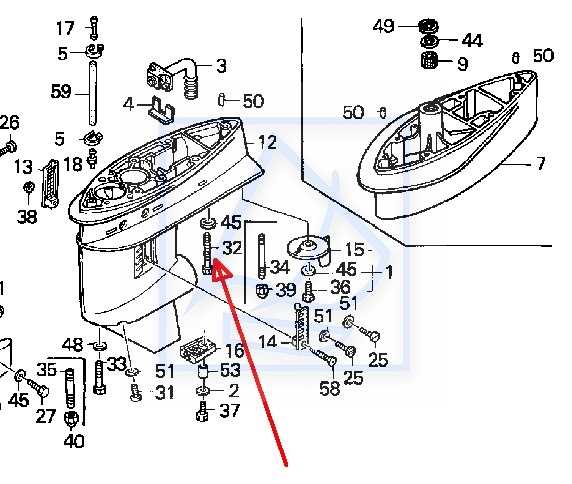

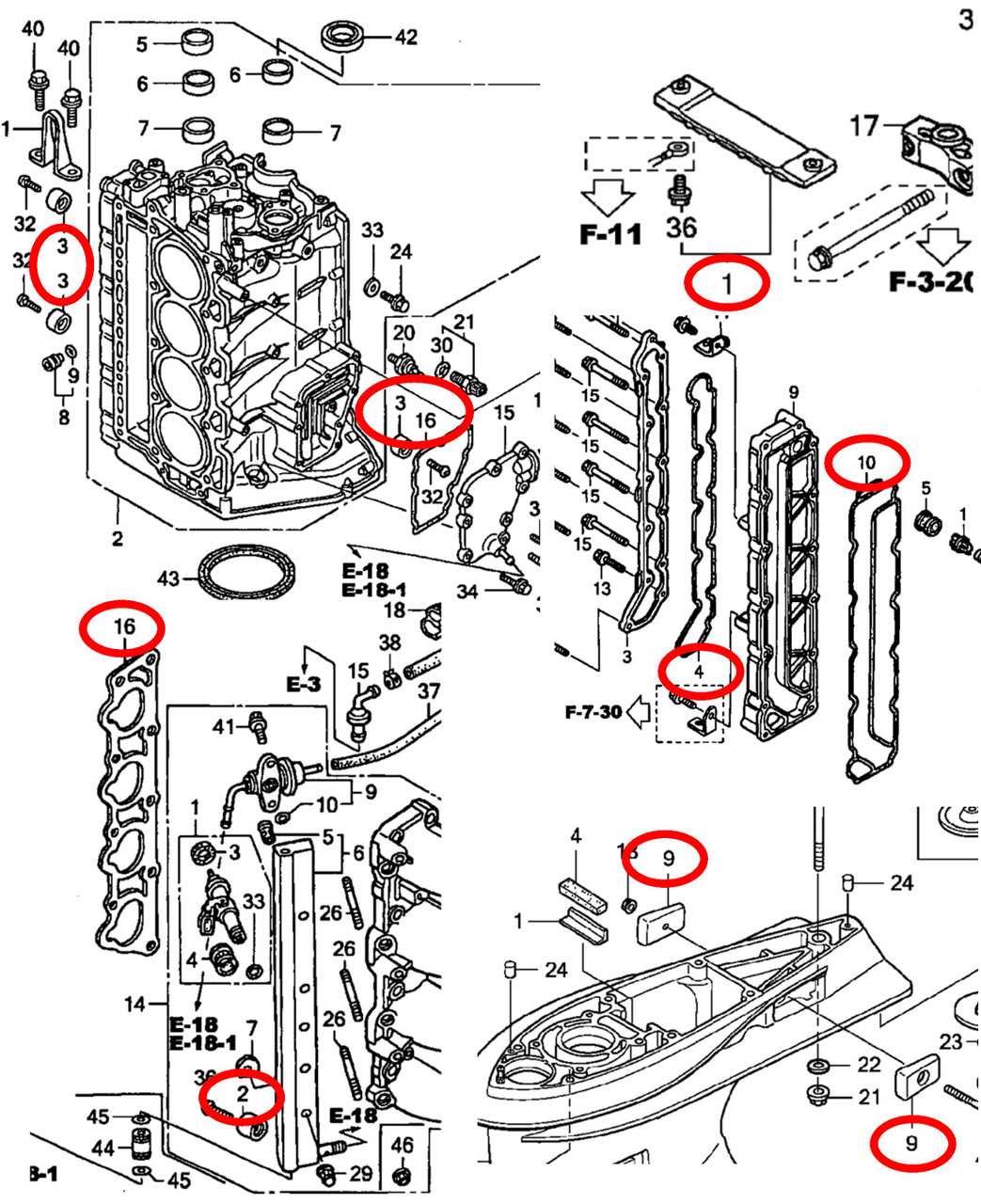

Visual representations of these components can significantly aid in identifying their placement and relationships within the overall assembly. Such representations serve as valuable references, enabling enthusiasts and technicians alike to navigate the complexities of machinery with greater confidence.

Furthermore, knowing the specifics of each component can enhance troubleshooting capabilities and facilitate more effective repairs. This knowledge empowers individuals to make informed decisions when sourcing replacements or upgrades, ultimately contributing to the longevity and efficiency of their equipment.

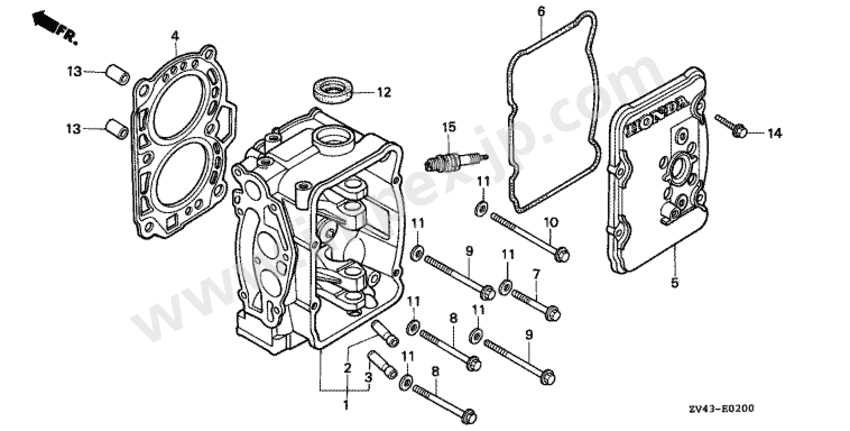

This section will delve into the intricacies of a specific marine engine, providing a comprehensive overview of its components and functionality. By understanding the essential elements that make up this power unit, readers will gain valuable insights into maintenance, troubleshooting, and enhancement options.

- Engine Components Overview:

- Block: The core structure housing essential internal mechanisms.

- Piston: A key element that converts fuel energy into mechanical movement.

- Crankshaft: Responsible for transforming linear motion into rotational force.

- Cylinder Head: The upper part of the engine that contains valves and combustion chambers.

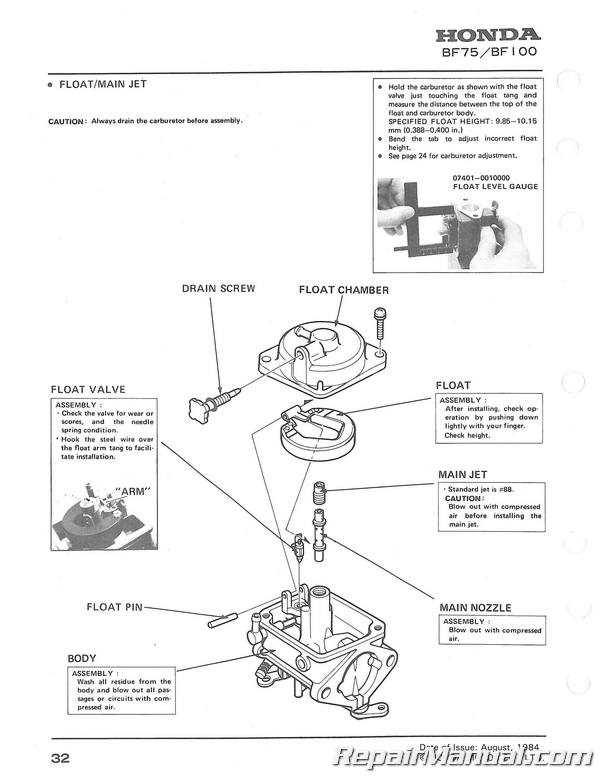

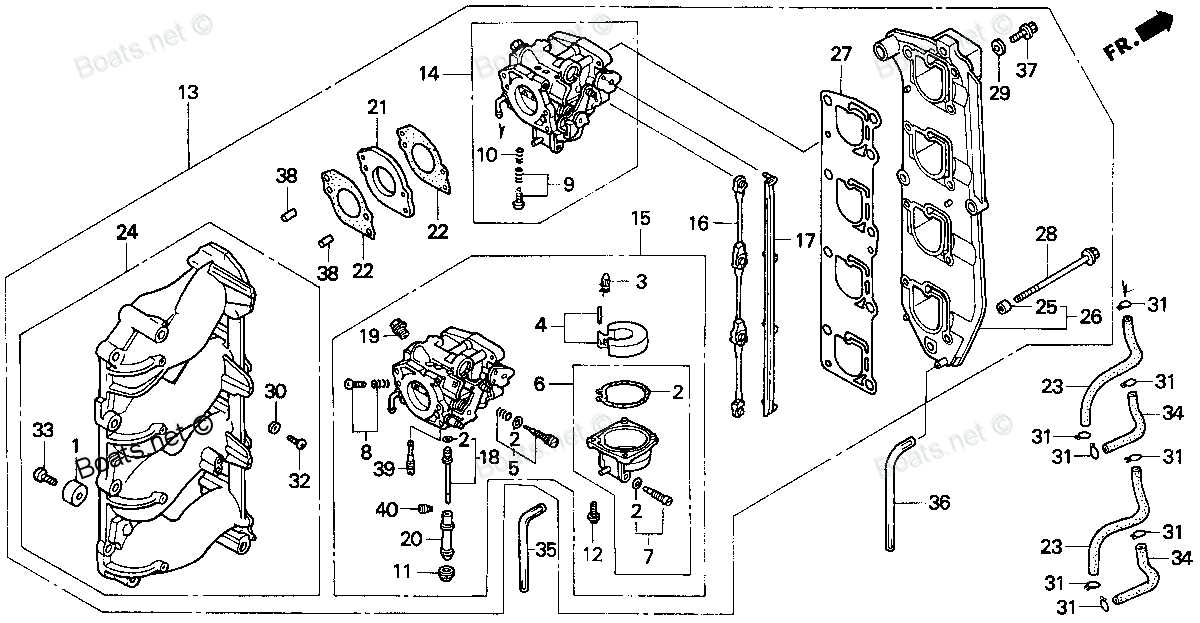

- Fuel System:

- Fuel Pump: Delivers fuel from the tank to the engine.

- Injectors: Atomize fuel for optimal combustion.

- Carburetor: Mixture of air and fuel for efficient engine performance.

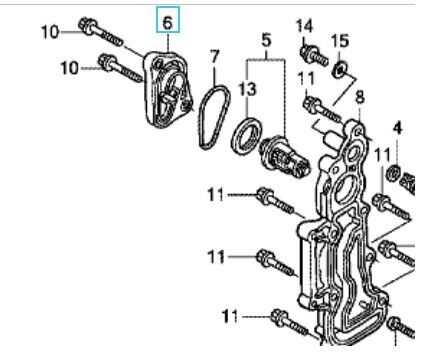

- Cooling System:

- Water Pump: Circulates coolant to regulate temperature.

- Thermostat: Monitors and controls engine temperature.

- Heat Exchanger: Facilitates cooling by transferring heat to a coolant.

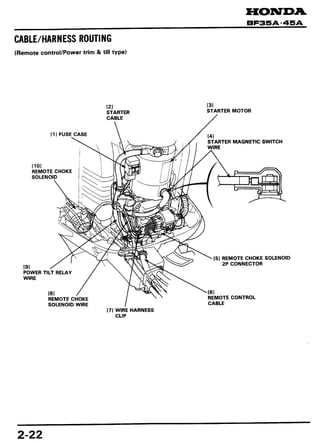

- Electrical Components:

- Battery: Provides the necessary power for ignition and accessories.

- Alternator: Generates electricity to recharge the battery during operation.

- Ignition System: Ensures proper engine starting and operation through spark generation.

By exploring these critical aspects, readers will be better equipped to comprehend the operational principles of the engine, enabling them to make informed decisions regarding maintenance and upgrades.

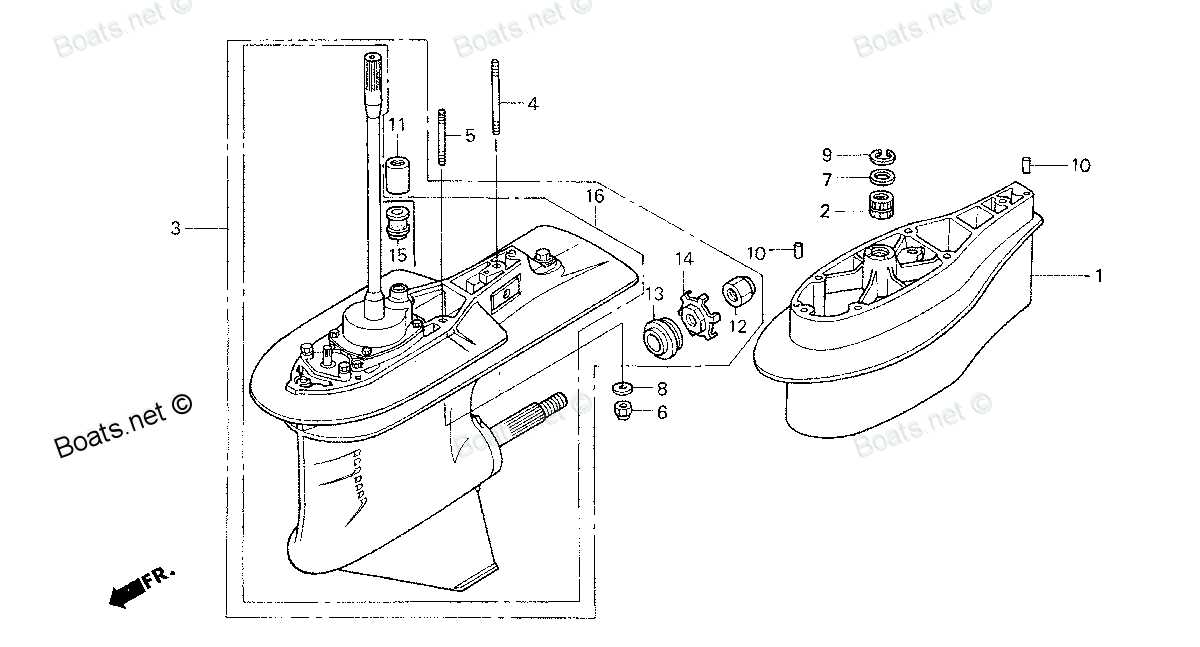

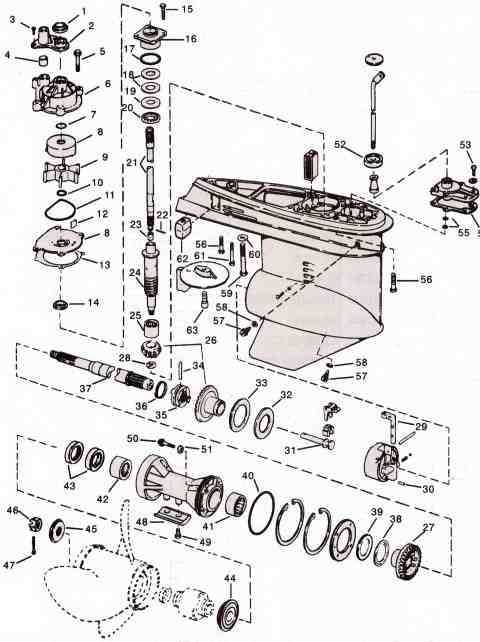

Key Components of the Honda BF90

This section delves into the essential elements of a popular outboard motor, highlighting their significance in ensuring optimal performance and reliability. Understanding these critical components can aid users in maintenance and troubleshooting, ultimately enhancing their boating experience.

Major Parts

- Engine: The heart of the system, responsible for generating power.

- Propeller: A crucial component that converts engine power into thrust, propelling the vessel forward.

- Gear Case: Houses the drive mechanism, facilitating smooth power transfer from the engine to the propeller.

- Fuel System: Comprises elements that store and supply fuel to the engine, ensuring efficient combustion.

- Cooling System: Maintains optimal operating temperatures, preventing overheating and damage.

Additional Features

- Electrical System: Powers various components, including ignition and navigation lights.

- Steering Mechanism: Allows for directional control and maneuverability on the water.

- Trim and Tilt System: Adjusts the motor’s angle for improved performance and fuel efficiency.

- Control Box: Interfaces for operating the motor, including throttle and gear shifting.

Familiarity with these fundamental elements contributes to better management and upkeep of the engine, ensuring prolonged service life and reliable operation.

Benefits of a Parts Diagram

Understanding the layout and organization of components within a machine is crucial for effective maintenance and repair. A visual representation of the assembly not only aids in identifying individual elements but also enhances the overall comprehension of how these elements work together. This can significantly reduce the time and effort spent on troubleshooting and repairs.

Enhanced Clarity

Clarity is one of the primary advantages of such visual aids. By providing a clear illustration, users can quickly locate specific components, ensuring that they can perform their tasks efficiently. This visual guidance minimizes confusion, especially for those who may not be familiar with the intricate details of the machinery.

Improved Efficiency

Utilizing a visual reference can lead to greater efficiency in repair processes. Technicians can easily pinpoint the necessary components, which streamlines the replacement or adjustment process. Moreover, having a comprehensive visual guide helps in preparing for any necessary repairs, thus reducing downtime and enhancing productivity.

How to Read Parts Diagrams

Understanding technical illustrations is crucial for effective maintenance and repair of machinery. These visual guides serve as essential tools that provide insight into the various components of equipment, facilitating easier identification and troubleshooting. By mastering the art of interpreting these images, users can enhance their familiarity with the structure and functionality of their machines.

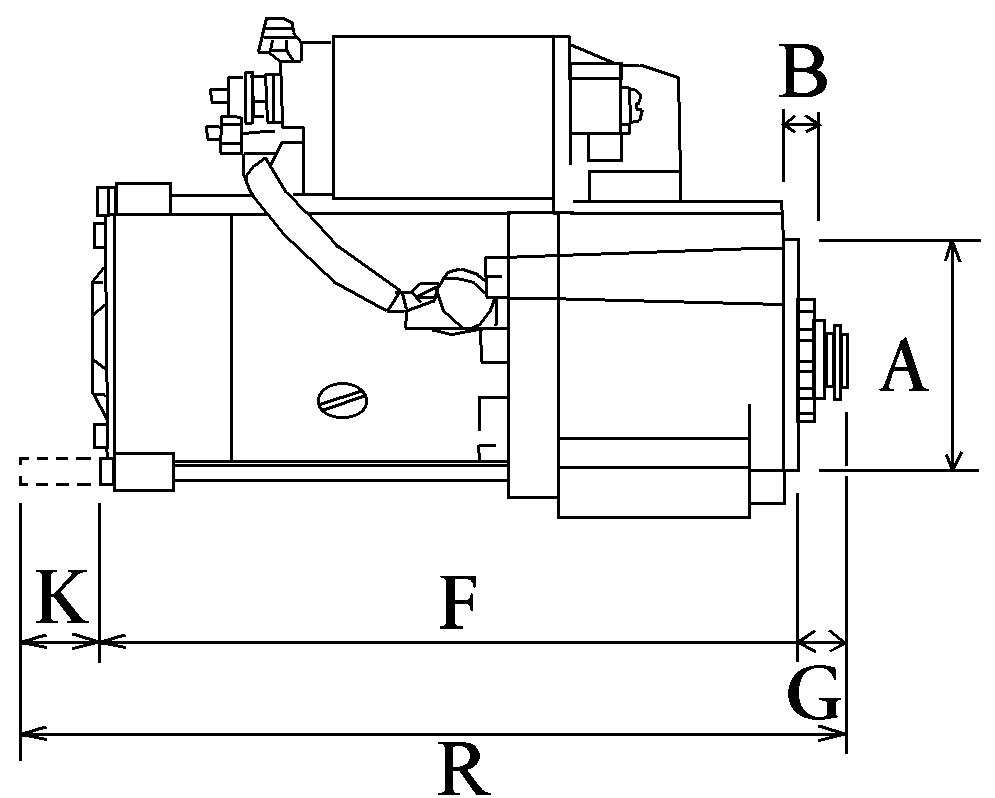

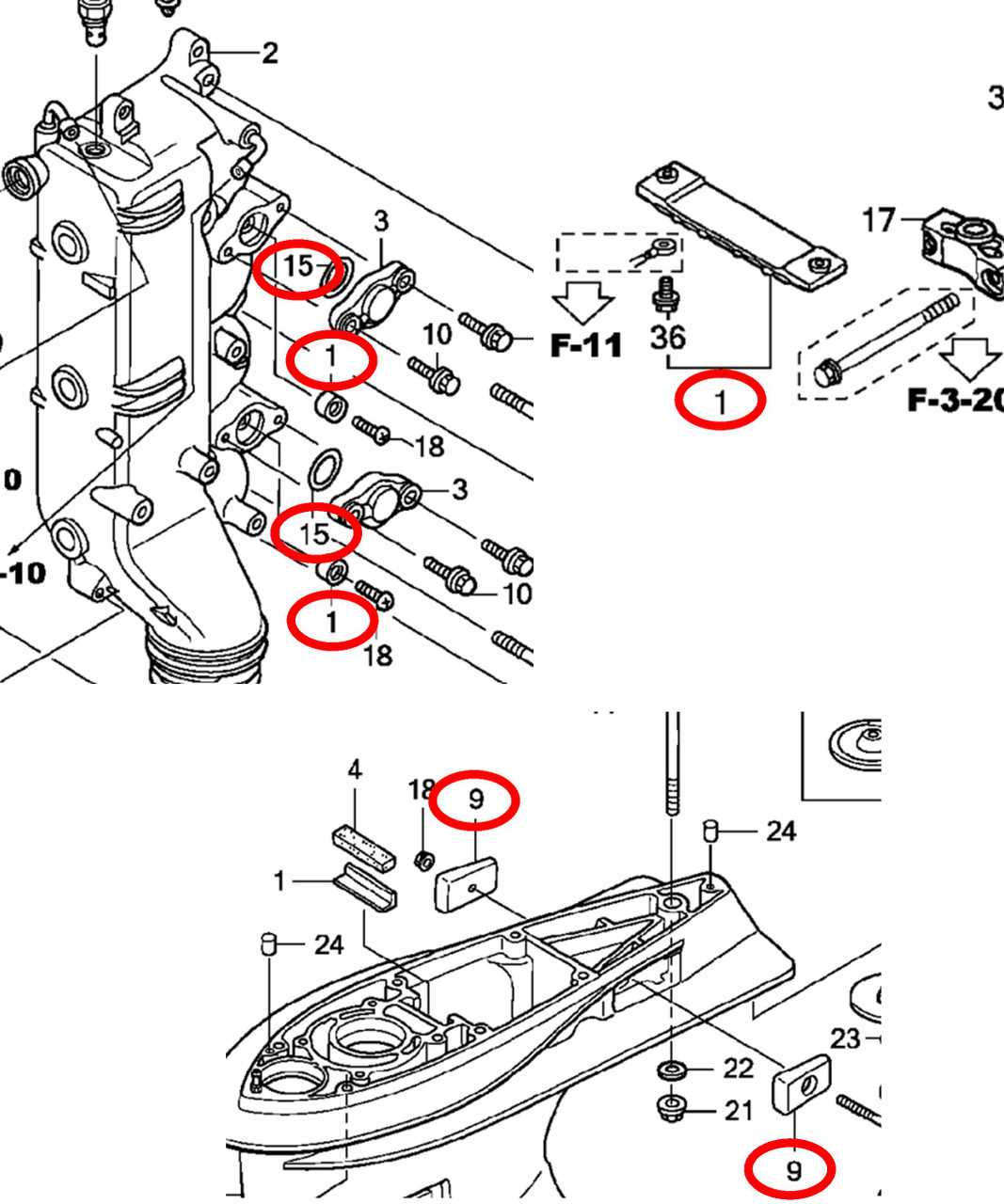

Key Elements to Look For

- Labels: Each section typically features annotations that clarify the purpose and designation of different elements.

- Numbers: Components are often numbered, corresponding to a list that provides further details about each item.

- Sections: Diagrams are usually divided into parts, making it easier to focus on specific areas without overwhelming information.

Steps to Effectively Interpret Visual Guides

- Begin by familiarizing yourself with the overall layout, noting how the various components are organized.

- Check the accompanying list for detailed descriptions and specifications of each numbered item.

- Identify common symbols used within the illustrations to understand the relationships between different elements.

- Refer to additional documentation if available, as it may offer further clarification on complex parts.

Common Issues with BF90 Parts

When it comes to marine machinery, various components may encounter problems that can affect performance and reliability. Understanding these common issues is crucial for maintenance and can prevent costly repairs. In this section, we will explore frequent concerns associated with the critical components of this outboard engine.

Frequent Malfunctions

Several malfunctions can arise due to wear and tear, environmental factors, or improper maintenance. Some of the most common issues include:

| Component | Common Issue | Symptoms | Recommended Action |

|---|---|---|---|

| Fuel System | Clogged Filters | Poor acceleration, stalling | Regularly inspect and replace filters |

| Cooling System | Overheating | High temperature gauge reading | Check for obstructions and pump functionality |

| Ignition System | Weak Spark | Difficulty starting, rough idling | Test ignition components and replace as needed |

Preventive Measures

To minimize these issues, regular maintenance is essential. This includes scheduled inspections, timely replacements of worn components, and adhering to operational guidelines. By taking proactive steps, you can ensure the longevity and efficiency of the engine.

Where to Find Genuine Parts

Locating authentic components for your machinery is crucial for ensuring optimal performance and longevity. Utilizing reliable sources not only guarantees quality but also provides peace of mind regarding compatibility and reliability.

Authorized Dealers: One of the best options is to visit authorized dealers. They often have a comprehensive inventory of original components and can offer expert guidance on your specific model’s requirements.

Online Retailers: Numerous reputable online platforms specialize in offering genuine items. Be sure to verify the seller’s credibility by checking customer reviews and ratings to ensure you are purchasing from a trusted source.

Manufacturer’s Website: Another reliable avenue is to check the official website of the manufacturer. Many manufacturers provide an online store or a list of authorized retailers, allowing you to purchase directly or find nearby suppliers.

Local Workshops: Local repair shops often have connections with suppliers of authentic components. Engaging with professionals can lead you to quality options while also potentially saving on shipping costs.

Forums and Community Groups: Online forums and community groups dedicated to your machinery can be valuable resources. Members frequently share their experiences and can recommend trustworthy places to acquire genuine items.

Aftermarket vs. OEM Parts

The choice between alternative and original equipment components can significantly impact the performance and longevity of your vehicle. Understanding the differences between these two categories is essential for making informed decisions during maintenance and repairs.

Alternative components are often produced by third-party manufacturers and can provide a cost-effective solution for those seeking budget-friendly options. While they may not always match the quality or specifications of the original items, many reputable brands offer reliable substitutes that can perform adequately in various conditions.

On the other hand, original equipment items are designed specifically for your vehicle by the manufacturer, ensuring compatibility and optimal performance. They typically come with a warranty and adhere to strict quality control standards, making them a preferred choice for those who prioritize reliability and longevity.

When deciding between alternative and original components, consider factors such as budget, performance requirements, and the importance of warranty coverage. Each option has its advantages and disadvantages, and your specific needs will ultimately guide your choice.

Maintenance Tips for BF90

Regular upkeep is essential for ensuring the longevity and efficient performance of your outboard motor. By adhering to a structured maintenance routine, you can prevent issues and enhance the overall functionality of your equipment.

Check Fluid Levels: Always monitor the oil and coolant levels, topping them off as needed. Low fluid levels can lead to overheating and engine damage.

Inspect the Propeller: Examine the propeller for any signs of wear or damage. A damaged propeller can affect performance and fuel efficiency. Ensure it is securely attached and free of debris.

Clean Fuel System: Regularly clean the fuel filter and ensure that fuel lines are clear. Contaminated fuel can lead to engine failure and reduced performance.

Battery Care: Check the battery connections for corrosion and ensure a strong connection. Keep the battery charged to avoid starting issues.

Visual Inspections: Conduct routine visual inspections of hoses, belts, and electrical connections. Look for any signs of wear or fraying, which can lead to more significant problems down the line.

Follow Manufacturer’s Schedule: Adhere to the recommended maintenance schedule outlined in the user manual. Regular professional servicing can identify potential issues before they escalate.

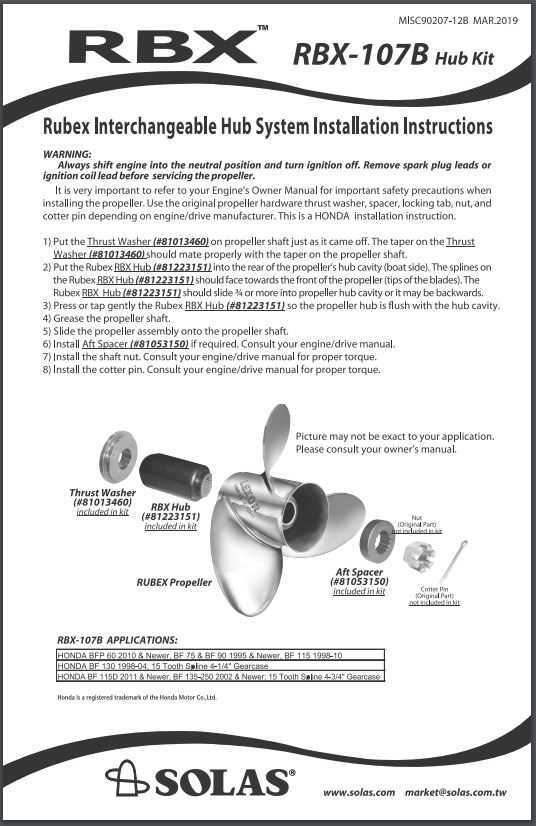

Installation of New Components

Replacing outdated or damaged elements is essential for maintaining optimal performance in any mechanical system. This process involves careful selection and proper fitting of new items to ensure seamless integration and functionality.

Before commencing the installation, it is crucial to prepare adequately. Here are the steps to follow:

- Gather the necessary tools and replacement items.

- Review the installation manual for specific guidance related to your model.

- Ensure that the working area is clean and well-lit.

During the installation process, consider the following best practices:

- Begin by removing the old components carefully to avoid causing damage.

- Inspect surrounding areas for any wear or necessary repairs.

- Follow the manufacturer’s instructions closely for each new component.

- Double-check all connections and fittings before securing them in place.

- Test the system thoroughly after the installation to confirm proper operation.

Regular maintenance and timely replacement of components can significantly enhance the longevity and reliability of your equipment.

Replacing Worn-out Parts

Maintaining the efficiency of your watercraft often involves replacing components that have experienced wear over time. Identifying these areas and addressing them promptly can enhance performance and prolong the lifespan of your equipment. Regular inspections and timely replacements are essential for ensuring optimal functionality.

Identifying Worn Components

Recognizing when components need to be replaced is crucial. Here are some common signs of wear:

- Unusual noises during operation

- Decreased performance or power loss

- Visible signs of corrosion or damage

- Fluid leaks

Replacement Process

Once you have identified the components that need replacing, follow these steps to ensure a smooth process:

- Gather necessary tools and replacement items.

- Carefully remove the worn components, taking note of their placement.

- Install the new components, ensuring they fit securely.

- Conduct a thorough check to confirm everything is in proper order.

Frequently Asked Questions

This section addresses common inquiries regarding the components and assembly of a specific outboard engine model. Understanding the various elements involved can enhance your experience and aid in maintenance and repairs.

- What is included in the assembly manual?

The manual typically provides detailed illustrations, a list of components, and step-by-step instructions for assembly and disassembly.

- How can I identify the components?

Each component is usually marked with a specific code or number, making it easier to locate and reference them in the documentation.

- Where can I find replacement items?

Replacement components can be sourced from authorized dealers, online retailers, or specialized marine supply stores.

- What maintenance tasks should I regularly perform?

Regular maintenance tasks may include checking fluid levels, inspecting for wear and tear, and ensuring that all components are securely fastened.

- How often should I consult the manual?

It is advisable to refer to the manual whenever performing maintenance, repairs, or when unfamiliar issues arise.

Resources for Further Information

Accessing reliable sources can greatly enhance your understanding of various components and their functionalities. Whether you are seeking technical documentation, instructional guides, or user forums, a plethora of resources is available to aid in your exploration.

For in-depth technical insights, consider visiting specialized websites that focus on marine engines and their assemblies. These platforms often provide comprehensive manuals and troubleshooting advice. Additionally, engaging with online communities or forums dedicated to boating enthusiasts can offer invaluable peer support and shared experiences.

Lastly, don’t overlook the value of local retailers and service centers. They can provide not only parts but also expert knowledge about maintenance and best practices, ensuring you are well-informed for your projects.

Community Forums and Support

Engaging with fellow enthusiasts can provide invaluable insights and assistance. Online communities serve as a hub for sharing knowledge, troubleshooting issues, and exchanging tips related to marine engines. By participating in these discussions, users can access a wealth of information and benefit from the collective experience of others.

Many forums are dedicated to specific brands or types of equipment, allowing members to delve deeper into specialized topics. Here are some key benefits of joining such communities:

- Access to expert advice from seasoned users.

- Opportunities to share personal experiences and solutions.

- Updates on the latest trends and innovations in the industry.

- A platform for asking questions and receiving prompt responses.

- Networking opportunities with like-minded individuals.

When looking for support, consider the following popular online resources:

- Dedicated forums focused on boating and marine mechanics.

- Social media groups where users share experiences and advice.

- Video platforms with tutorials and demonstrations.

- Blogs and websites that offer in-depth articles and troubleshooting guides.

Joining these communities not only enhances your understanding but also fosters a sense of camaraderie among fellow enthusiasts. Whether you are a novice or an experienced user, these platforms can greatly enhance your ownership experience.