In the realm of portable power solutions, having a clear understanding of the component layout is essential for effective maintenance and repair. This section delves into the intricate organization of parts within a compact energy generator, illustrating how each component interacts to deliver reliable performance.

By familiarizing yourself with the configuration of these elements, you can enhance your troubleshooting skills and ensure optimal functionality. This knowledge not only aids in identifying potential issues but also empowers users to undertake necessary adjustments or replacements with confidence.

Detailed insights into the arrangement of the internal mechanisms will facilitate a deeper comprehension of the equipment’s operation, promoting longevity and efficiency. An organized overview of the generator’s structure can serve as a valuable reference for both seasoned technicians and casual users alike.

Engaging with this material equips you with the tools to address common challenges and maintain your equipment in peak condition. A thorough understanding of the generator’s composition fosters a proactive approach to care and utilization.

Understanding Honda EU1000i Components

This section delves into the essential elements that comprise a portable generator, focusing on their functionality and interconnections. Grasping the roles of these components is crucial for optimal performance and maintenance, ensuring reliability during usage. Each part contributes to the overall efficiency and operational capabilities of the device, highlighting the importance of understanding their specific functions.

Key Functional Elements

Among the critical components are the engine, which powers the unit, and the alternator, responsible for converting mechanical energy into electrical energy. Additionally, the fuel system ensures a consistent supply of energy, while the exhaust system manages emissions effectively. Recognizing how these elements interact can aid in troubleshooting and enhancing performance.

Maintenance and Replacement

Routine inspection of these vital components can prevent potential failures and extend the lifespan of the generator. Familiarity with the structure allows users to identify wear and tear, facilitating timely replacements. Regular maintenance ensures that each part functions efficiently, contributing to the overall longevity and reliability of the equipment.

Detailed Parts Breakdown

This section provides an in-depth look at the various components of a portable power generator, focusing on their functions and interrelationships. Understanding the configuration of these elements is essential for effective maintenance and troubleshooting.

Key Components Overview

The primary elements of the generator include:

- Engine Assembly

- Fuel System

- Electrical System

- Cooling Mechanism

- Frame Structure

Component Functions

Each section plays a vital role in the generator’s operation:

- Engine Assembly: Converts fuel into mechanical energy.

- Fuel System: Stores and delivers fuel to the engine.

- Electrical System: Generates and distributes electricity to the output.

- Cooling Mechanism: Maintains optimal operating temperatures.

- Frame Structure: Provides support and protects internal components.

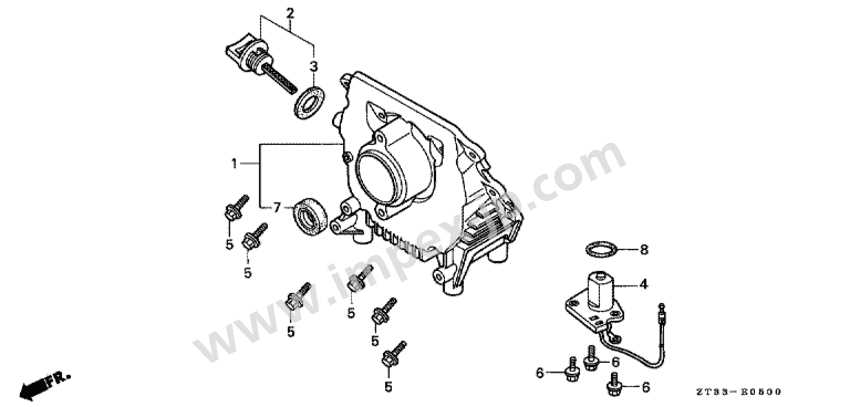

Exploring Engine Assembly Parts

Understanding the components that make up an engine assembly is crucial for maintaining optimal performance. Each element plays a specific role in the overall functionality, contributing to the engine’s efficiency and reliability. By examining these components, one can gain valuable insights into the workings of the engine and how to address potential issues effectively.

Key Components of Engine Assembly

Among the essential components, the crankshaft serves as the backbone, converting linear motion into rotational force. Coupled with the pistons, which move within the cylinders, these elements work harmoniously to generate power. Additionally, the cylinder head houses critical components such as valves and camshafts, playing a vital role in the engine’s breathing process.

Importance of Maintenance

Regular maintenance of these engine elements is paramount for longevity. Components such as gaskets and seals must be inspected to prevent leaks that can lead to significant performance issues. Investing time in understanding these parts can greatly enhance one’s ability to troubleshoot and optimize engine functionality. Knowledge of assembly components not only aids in repair but also promotes a deeper appreciation of engine technology.

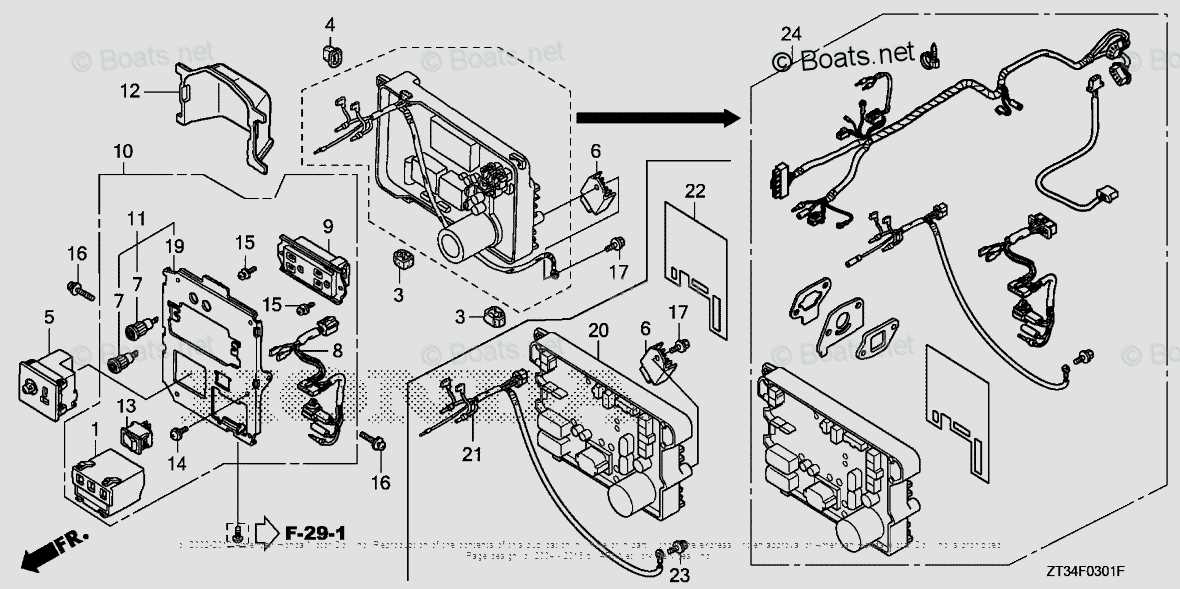

Electrical System Overview

The electrical framework of portable generators plays a crucial role in their functionality and performance. It encompasses various components that ensure efficient power generation and distribution. Understanding this system is vital for troubleshooting and maintenance, as well as for enhancing the overall efficiency of the device.

Key elements of the electrical system include:

- Alternator: Converts mechanical energy into electrical energy.

- Battery: Stores electrical energy and provides starting power.

- Voltage Regulator: Maintains a stable output voltage to protect connected devices.

- Starter Motor: Initiates the engine’s operation by converting electrical energy into mechanical energy.

- Wiring Harness: Connects various electrical components, allowing for efficient energy transfer.

Regular inspection and maintenance of these components can help prevent operational issues and extend the lifespan of the equipment. Additionally, understanding the layout and functions of the electrical system aids in effective troubleshooting, ensuring that any problems can be quickly identified and resolved.

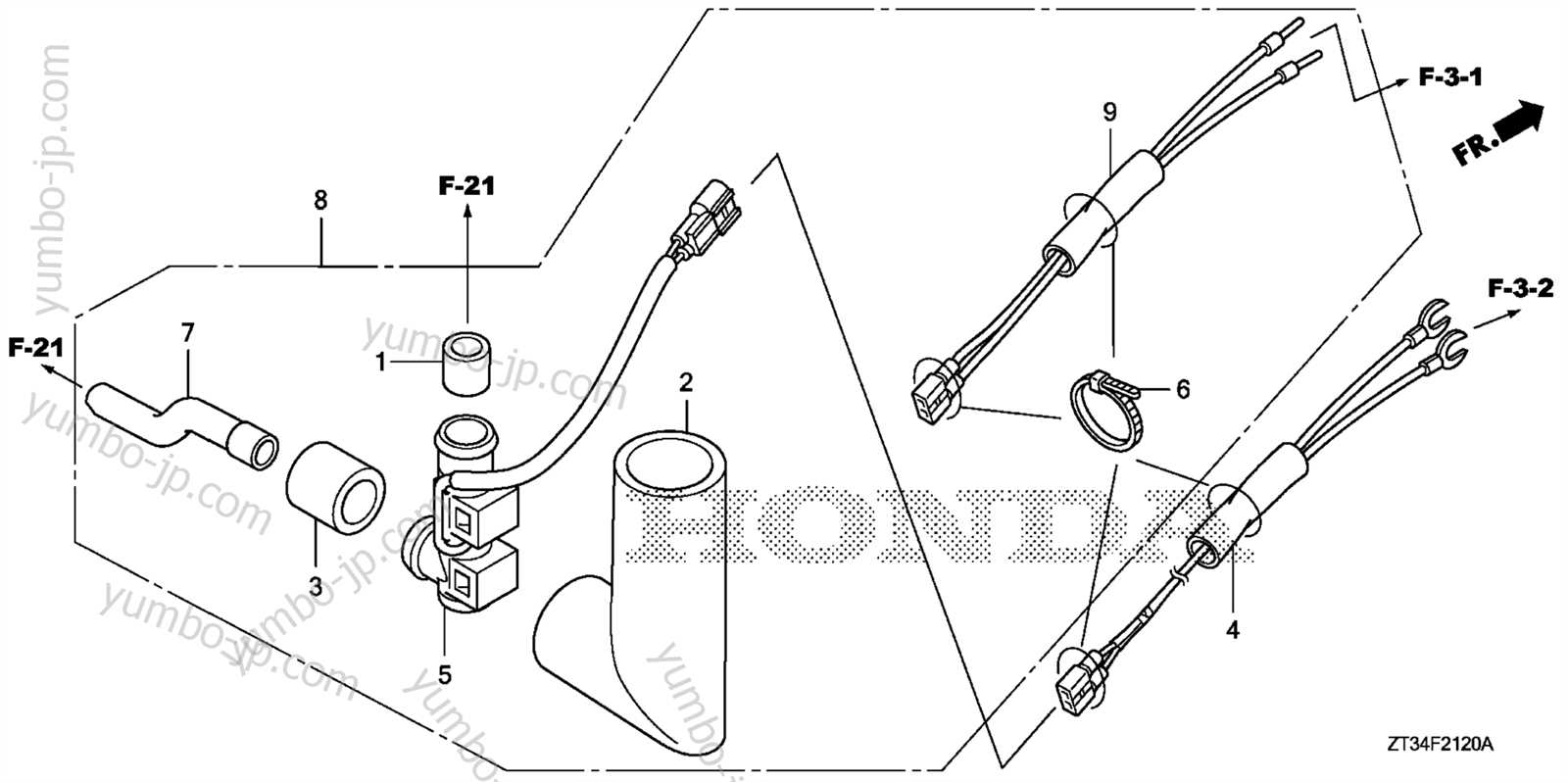

Fuel System Components Explained

The fuel system in a generator is essential for delivering the necessary fuel to the engine for combustion. Understanding its components can help users maintain efficiency and troubleshoot any potential issues. This section provides an overview of the various elements involved in the fuel delivery process.

Key Elements of the Fuel System

The fuel delivery system typically consists of several critical components that work together to ensure smooth operation. These parts include the fuel tank, fuel pump, filters, and carburetor. Each plays a specific role in managing the flow and quality of fuel reaching the engine.

Component Functionality Overview

Below is a table summarizing the primary functions of each component in the fuel system:

| Component | Function |

|---|---|

| Fuel Tank | Stores the fuel until needed by the engine. |

| Fuel Pump | Transfers fuel from the tank to the engine. |

| Fuel Filter | Removes impurities and contaminants from the fuel. |

| Carburetor | Mixes fuel with air for optimal combustion. |

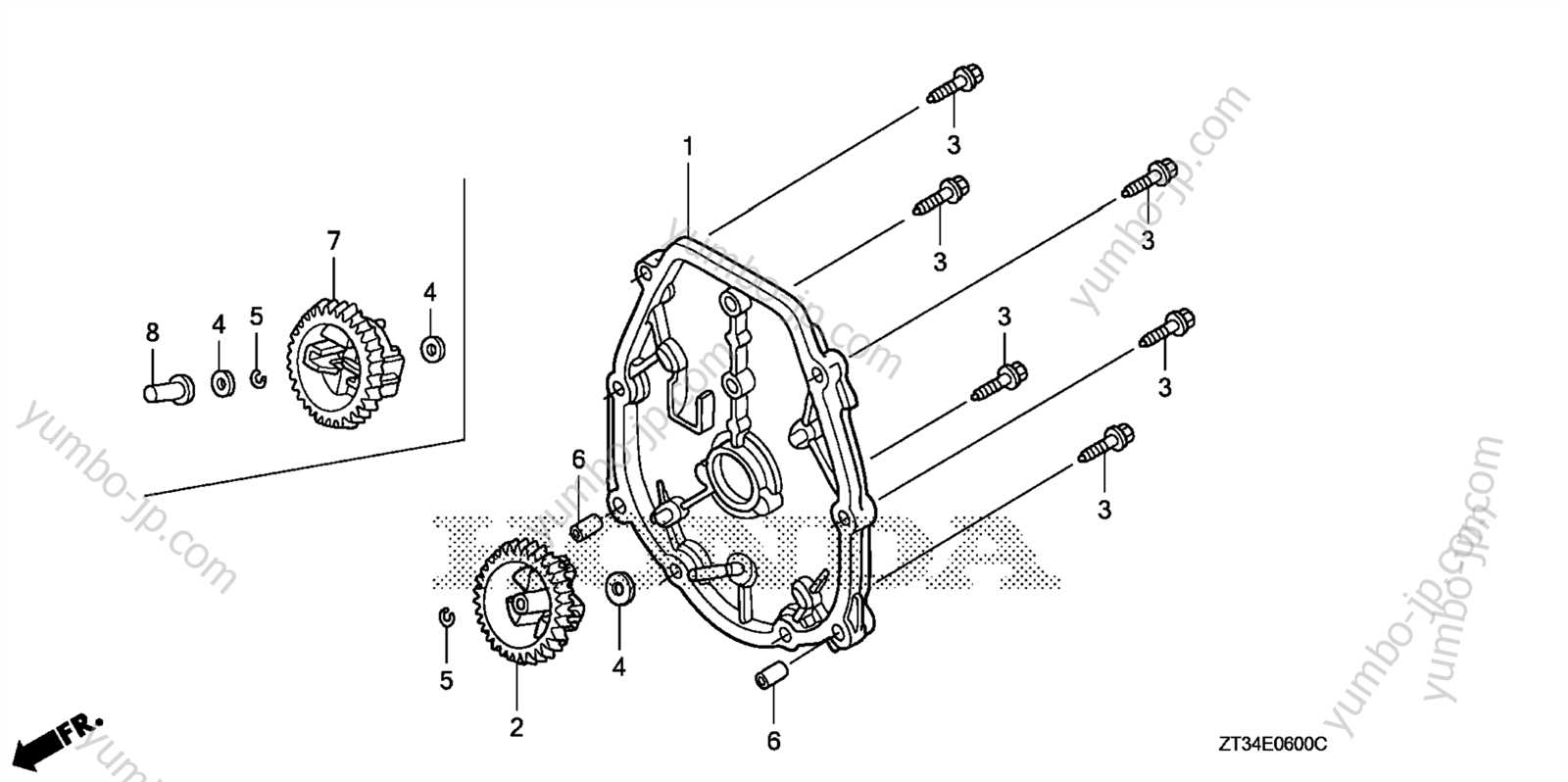

Cooling Mechanism Elements

The cooling system plays a crucial role in maintaining optimal operating temperatures for small engines. Effective management of heat is essential to ensure reliable performance and longevity. Various components work in harmony to dissipate heat generated during operation, preventing overheating and potential damage.

Key Components of the Cooling System

Among the essential elements are the radiator, fan, and coolant passages. The radiator facilitates heat transfer, allowing the engine to release excess warmth into the surrounding air. The fan assists in increasing airflow through the radiator, enhancing the cooling effect. Additionally, coolant passages channel the fluid around critical engine areas, ensuring that heat is effectively absorbed and transported away.

Importance of Maintenance

Regular maintenance of the cooling mechanism is vital for optimal performance. Inspecting components for wear and ensuring proper fluid levels can prevent overheating issues. Neglecting these aspects may lead to severe engine damage, emphasizing the importance of a well-functioning cooling system.

Chassis and Frame Insights

The structure of a portable generator plays a crucial role in its overall performance and durability. This segment delves into the design and functionality of the supporting framework, highlighting its importance in maintaining stability and enhancing mobility. A well-engineered chassis not only protects internal components but also contributes to efficient weight distribution, ensuring that the unit operates smoothly in various environments.

Structural Integrity and Material Selection

Choosing the right materials for the frame is essential for ensuring resilience against wear and tear. High-quality metals and reinforced plastics are often utilized to provide a lightweight yet sturdy foundation. This careful selection helps in minimizing vibrations during operation, thereby prolonging the lifespan of the entire apparatus.

Mobility and Handling Features

Incorporating features such as wheels and handles significantly improves the portability of the unit. Ergonomic designs allow for easier maneuvering, making it convenient for users to transport the generator to different locations. Additionally, the frame’s design can include provisions for secure attachment points, enhancing safety during operation.

Control Panel Functionality

The control panel serves as the primary interface for users to operate and monitor the device’s performance. It is designed to provide essential information and facilitate easy access to various settings, ensuring a seamless experience while managing power output and functionality.

Indicators and Displays

At the forefront of the control panel, indicators and displays present vital information such as operational status, fuel level, and load capacity. These visual cues help users make informed decisions regarding the performance and efficiency of the equipment.

Control Switches and Adjustments

The presence of control switches allows users to modify settings according to their specific needs. These controls enable the adjustment of output voltage, starting procedures, and other operational parameters, ensuring that the equipment runs optimally in diverse conditions.

Starting System Details

The starting mechanism is crucial for the efficient operation of portable generators. This system is designed to initiate the engine’s function, ensuring a reliable power supply for various applications. Understanding the components involved can aid in troubleshooting and maintenance.

Key Components

- Starter Motor: Converts electrical energy into mechanical energy to start the engine.

- Ignition Switch: Controls the flow of electricity to the starter motor.

- Battery: Provides the necessary power to start the engine.

- Solenoid: Acts as a relay to engage the starter motor when the ignition switch is activated.

- Flywheel: Rotates to initiate engine combustion.

Maintenance Tips

- Regularly check battery connections for corrosion and tightness.

- Inspect the starter motor for any signs of wear or damage.

- Ensure the ignition switch operates smoothly without sticking.

- Clean the solenoid terminals to prevent electrical resistance.

- Replace any worn or damaged components promptly to maintain performance.

Maintenance and Replacement Parts

Proper upkeep and timely exchange of components are crucial for ensuring optimal functionality and longevity of your generator. Regular checks and updates of various elements not only enhance performance but also prevent unexpected breakdowns, allowing users to maximize their investment.

Key Components to Monitor

Regular inspection of critical elements such as the air filter, spark plug, and fuel system is essential. Ensuring these parts are clean and functioning properly can significantly improve the efficiency of the device. Additionally, keeping an eye on the oil levels and replacing it as needed is vital for smooth operation.

When to Replace Components

Components should be replaced when signs of wear or malfunction become apparent. For example, if the generator struggles to start or exhibits unusual noises, it may be time to evaluate the state of the ignition system and other related parts. Proactive replacement can prevent more severe damage and costly repairs in the future.

Accessories and Optional Add-ons

When enhancing the functionality and convenience of a portable power generator, numerous accessories and optional enhancements can greatly improve the user experience. These supplementary items are designed to optimize performance, increase versatility, and provide additional features that cater to various needs.

Common Accessories

Investing in specific accessories can significantly enhance the utility of a portable generator. Here are some commonly available options:

- Storage Covers: Protect the unit from dust and moisture when not in use.

- Extension Cords: Facilitate power distribution over longer distances.

- Wheels and Handles: Enhance portability for easier transport.

- Parallel Cables: Allow multiple units to be connected for increased power output.

Optional Enhancements

In addition to basic accessories, several optional enhancements can further improve generator performance and efficiency:

- Fuel Stabilizers: Help maintain fuel quality during storage, preventing engine issues.

- Quiet Operation Kits: Reduce noise levels, making the generator more suitable for residential use.

- Power Management Systems: Monitor and optimize power usage, extending runtime.

- Solar Charging Kits: Enable the use of renewable energy sources for recharging.

Troubleshooting Common Issues

When dealing with a portable generator, it is crucial to identify and resolve frequent problems that may arise during operation. Understanding the common issues can help users maintain optimal performance and enhance the longevity of their equipment. This section highlights typical challenges and provides guidance on how to address them effectively.

Engine Won’t Start

If the engine fails to start, check the fuel levels and ensure that the tank is filled with fresh gasoline. Additionally, inspect the ignition system and make sure the spark plug is in good condition. Replacing a faulty spark plug can often resolve starting issues.

Inconsistent Power Output

For irregular power delivery, examine the connections and ensure that all cables are securely attached. If the generator is overloaded, disconnect some devices and try again. It may also be beneficial to check for any damage to the generator’s internal components, as wear and tear can affect performance.