Understanding the structure and positioning of mechanical elements is crucial for anyone involved in maintenance or repairs. When it comes to off-road vehicles, knowing how each component fits together ensures smooth operation and helps prevent issues before they arise. A clear visualization of all the individual sections and their connections can make a significant difference in the overall performance and longevity of the machine.

Each mechanism relies on the seamless interaction of its various parts. Recognizing the placement of crucial elements is essential for diagnosing potential problems and ensuring that repairs are done correctly. Whether you’re performing routine upkeep or addressing a specific issue, having a clear outline of the machinery’s internal configuration is invaluable for efficient and accurate work.

Vehicle Component Overview

The overall structure and design of this off-road machine highlight its durability and ease of maintenance. Its assembly includes essential mechanical systems, each serving a distinct function to ensure optimal performance. Whether you’re navigating rough terrains or conducting routine checks, understanding the composition of key elements is vital for smooth operation.

Engine system is the powerhouse that delivers the necessary force, working in tandem with the transmission to convert energy into movement. Attention to these components ensures longevity and efficiency.

The chassis framework supports the entire structure, providing stability and withstanding stress during intensive use. Coupled with the suspension system, it offers a balanced and comfortable ride even in challenging environments.

Lastly, the braking mechanism is crucial for safety, offering precise control and stopping power. Regular inspections and proper upkeep of this system are imperative for ensuring reliable performance.

Engine Components Breakdown

In this section, we will explore the key elements that make up a standard off-road vehicle’s power unit. Understanding how these components function and work together is crucial for anyone looking to maintain or repair their vehicle. The engine is a complex system, with each part playing an essential role in ensuring optimal performance.

Main Sections of the Power Unit

- Cylinder block:

Chassis and Frame Structure

The structure of the vehicle’s chassis plays a crucial role in providing both support and stability. The overall frame design ensures that all essential components are securely attached, contributing to smooth operation even in demanding conditions. Built with durability in mind, the framework also helps distribute weight evenly, reducing stress on individual parts during use.

Materials and Construction

The framework is typically made from robust materials designed to withstand harsh environments. The construction process involves precise engineering to enhance strength while minimizing unnecessary bulk. This results in a lightweight yet sturdy structure that enhances performance and longevity.

Frame Durability and Maintenance

To ensure long-lasting use, regular inspections and maintenance of the chassis are essential. Paying attention to signs of wear, especially in joints and connections, helps prevent more significant issues. Proper care not

Suspension System and Key Parts

The suspension system plays a crucial role in ensuring a smooth and stable ride, effectively absorbing shocks and maintaining balance across uneven terrains. It consists of various components that work together to enhance comfort and control during operation. Each element contributes to the overall functionality, ensuring the vehicle remains stable even in challenging conditions.

One of the most essential components is the shock absorber, which dampens vibrations and reduces the impact of bumps. Additionally, the control arms provide flexibility and allow the wheels to move up and down independently. Springs are responsible for cushioning the weight, offering both support and flexibility. Together, these parts create a seamless interaction that enhances performance and stability during use.

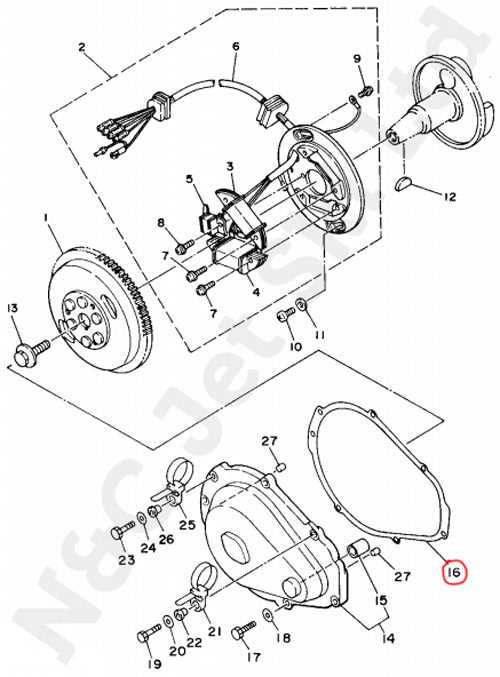

Electrical Wiring and Connections

The proper arrangement of electrical circuits and their connections plays a critical role in ensuring the smooth operation of any vehicle. Wiring serves as the backbone for the distribution of power, while connections ensure that each component receives the correct amount of energy. Maintaining these systems in optimal condition prevents malfunctions and ensures reliability in all driving conditions.

Every wire, switch, and connection must be inspected regularly to avoid issues like shorts, corrosion, or poor conductivity. Quality materials and secure fittings are key to sustaining a well-functioning electrical system. Ensuring clean and tight connections can also prevent energy loss, prolonging the lifespan of the entire setup.

Fuel System Layout

The fuel system is a critical component of any all-terrain vehicle, ensuring optimal performance and efficiency. This section outlines the essential elements of the fuel delivery network, highlighting its configuration and function within the machine.

Key Components

- Fuel Tank: Stores the gasoline required for operation.

- Fuel Pump: Delivers fuel from the tank to the engine.

- Fuel Filter: Removes impurities from the fuel before it reaches the engine.

- Fuel Lines: Transport fuel between the tank, pump, and engine.

- Carburetor or Fuel Injector: Mixes air and fuel in the correct ratio for combustion.

Operational Overview

The system functions by drawing fuel from the tank through the pump, which then sends it through the filter to eliminate any contaminants. This ensures that only clean fuel enters the carburetor or injector, where it is prepared for combustion. Proper maintenance of each component is essential for reliable operation and longevity of the vehicle.

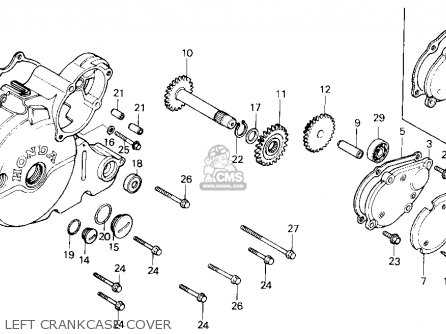

Transmission Assembly Details

The transmission assembly plays a crucial role in the overall performance of a vehicle, ensuring smooth power delivery from the engine to the wheels. Understanding its components and their functions can help in diagnosing issues and performing maintenance effectively.

Key components of the transmission assembly include:

- Gearbox: Houses various gears that enable the vehicle to operate at different speeds.

- Clutch: Engages and disengages the power flow between the engine and transmission.

- Output Shaft: Transfers power from the transmission to the drive system.

- Input Shaft: Connects the engine to the gearbox, allowing power to enter the transmission.

Regular inspection of these components is essential for maintaining optimal functionality. Common issues that may arise include:

- Wear and tear on gears, leading to grinding noises.

- Clutch slippage, causing difficulty in shifting.

- Fluid leaks, which can result in overheating and damage.

By keeping a close eye on the transmission assembly and addressing any problems promptly, vehicle owners can ensure longevity and reliability in their machine’s performance.

Brake System Components

The braking system is a vital part of any vehicle, ensuring safety and control during operation. It comprises several elements that work together to provide reliable stopping power. Understanding these components is essential for maintaining and troubleshooting any issues that may arise.

Key Elements of the Braking Mechanism

The braking mechanism includes various parts, such as the brake pads, rotors, and calipers. The brake pads create friction against the rotors, allowing the vehicle to slow down or stop effectively. Calipers house the brake pads and play a crucial role in applying pressure to the pads, enhancing braking efficiency.

Hydraulic System Features

A hydraulic system is often integrated into the braking assembly, using fluid to transmit force from the brake pedal to the calipers. This system ensures smooth and effective braking action. Key components include the master cylinder, brake lines, and fluid reservoir, all of which must be regularly inspected for leaks or wear.

Handlebars and Control Mechanisms

The handlebars and associated control systems play a crucial role in ensuring the operator’s comfort and safety while navigating various terrains. These components are designed to provide optimal maneuverability and responsiveness, allowing for precise handling of the vehicle. The integration of ergonomic design elements enhances the user experience, making it easier to operate the machine efficiently.

At the forefront of the control setup, the handlebars are equipped with various levers and switches that facilitate essential functions, such as throttle control and braking. These mechanisms are strategically positioned to ensure that the operator can easily access them without diverting attention from the trail. Proper maintenance of these elements is vital, as any wear or malfunction can significantly affect the vehicle’s performance and safety.

Additionally, the linkage between the handlebars and the steering system is engineered for optimal responsiveness. This connection ensures that even slight movements are translated accurately, enhancing the rider’s ability to navigate tight turns and challenging obstacles. Understanding the intricacies of these components can lead to improved handling and a more enjoyable riding experience.

Exhaust System Diagram

The exhaust mechanism is a crucial component of any vehicle, responsible for directing gases away from the engine while minimizing noise and emissions. Understanding its layout and function can greatly aid in troubleshooting and maintenance tasks, ensuring optimal performance and longevity.

Components of the Exhaust System

This assembly typically includes parts such as the manifold, catalytic converter, muffler, and exhaust pipes. Each element plays a distinct role, from filtering harmful substances to reducing sound output, contributing to a more efficient and environmentally friendly operation.

Maintenance Considerations

Regular inspection of the exhaust assembly is essential for identifying issues like leaks or corrosion. Proper upkeep not only enhances engine efficiency but also ensures compliance with environmental regulations, making it imperative for any operator to familiarize themselves with the system’s configuration and health.

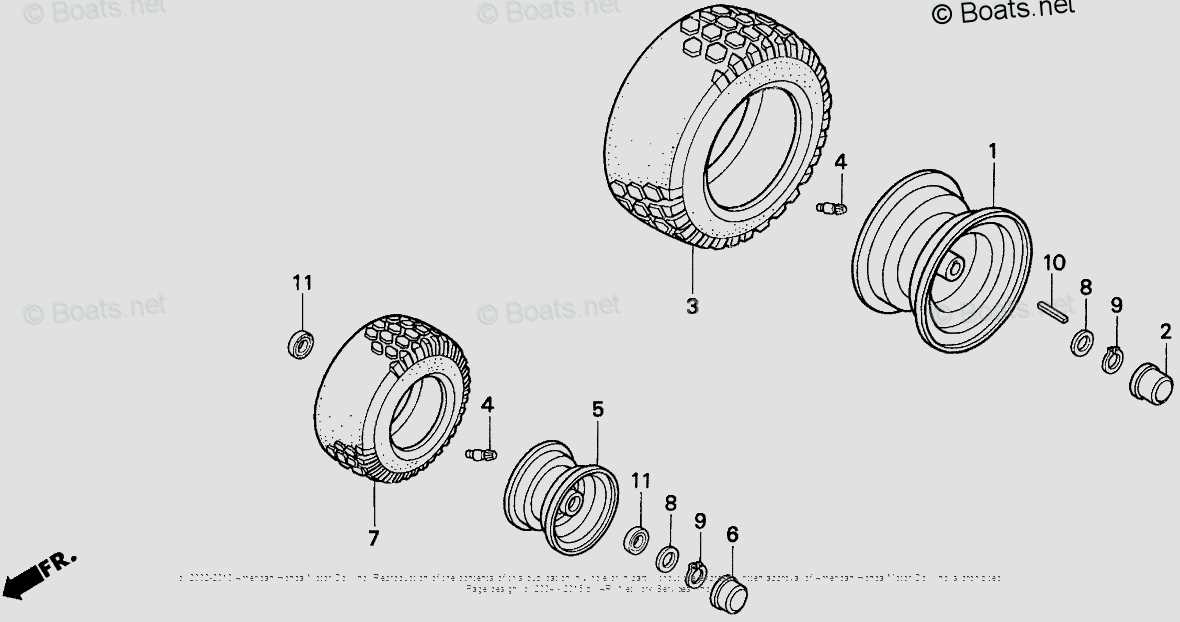

Wheel and Tire Configuration

The arrangement of wheels and tires plays a crucial role in the overall performance and handling of any all-terrain vehicle. A well-thought-out configuration ensures optimal traction, stability, and ride comfort, allowing for enhanced maneuverability on various terrains.

When selecting the appropriate wheel and tire combination, factors such as size, tread pattern, and material should be considered. Below is a summary of essential elements involved in the configuration:

Aspect Description Size Choosing the correct diameter and width affects handling and ground clearance. Tread Pattern The design influences grip on different surfaces, including mud, sand, and gravel. Material Lightweight alloys enhance performance, while steel offers durability for rugged use. Inflation Pressure Proper tire pressure maximizes traction and extends the lifespan of tires. Understanding these factors will aid in making informed choices to achieve the best performance in diverse environments.