When it comes to maintaining your machine’s efficiency and performance, having a clear overview of its internal components is essential. Each part plays a critical role in ensuring smooth operation, and understanding how they work together can make a significant difference in upkeep and repairs.

In this section, we will explore the primary elements that contribute to the overall function of the engine, helping you identify which areas may need attention during routine checks. Whether you are an experienced technician or a DIY enthusiast, a clear guide to the engine’s essential components can simplify your maintenance process and enhance the longevity of your equipment.

Exploring individual elements is key to ensuring your machine operates at its best. By breaking down the structure and roles of each component, you’ll be better equipped to handle any issues that arise, ultimately saving time and effort in repairs and replacements.

Overview of the Engine

This internal combustion unit is known for its efficiency and reliability, frequently utilized in various household and professional machinery. It offers a balance between power and fuel economy, making it a popular choice for those requiring steady and long-lasting performance. With advanced features and a streamlined design, this model provides consistent operation, even in demanding conditions.

Key Features of the Engine

The motor integrates modern technology aimed at reducing emissions while maintaining optimal power output. Its compact design contributes to ease of use and transport, while the intuitive control mechanisms ensure straightforward operation. Whether for light or more intensive use, the unit is designed to meet a wide range of demands.

Performance and Durability

One of the primary advantages of this engine is its longevity, with robust materials and engineering that support extended use. Its efficiency allows it to run smoothly with minimal maintenance, and the construction is built to withstand heavy workloads.

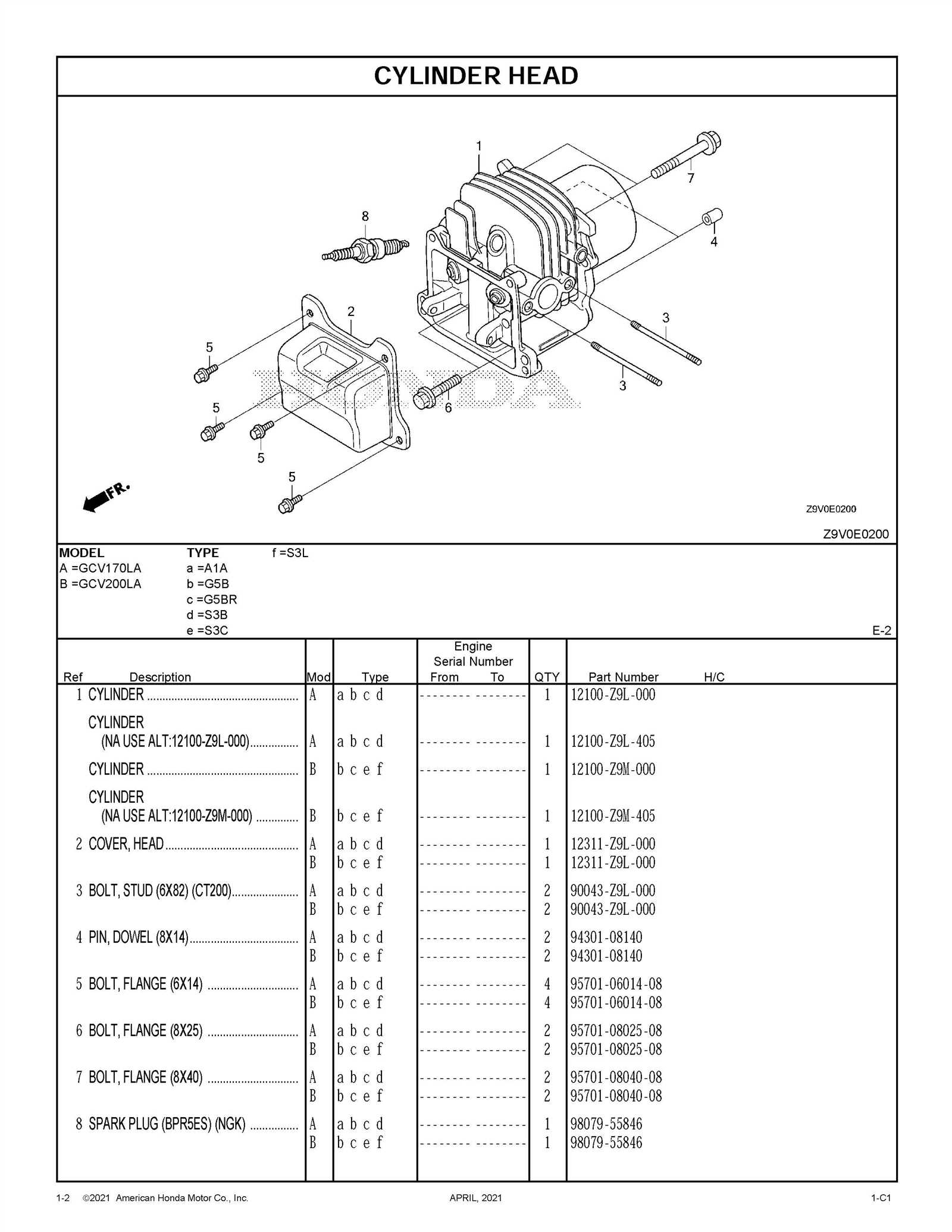

Key Components of the GCV170 Motor

The internal combustion engine relies on a collection of essential elements that ensure its smooth operation. These components work together to deliver efficient performance, regulating fuel intake, air flow, and power distribution. Understanding these crucial parts can help with maintenance, troubleshooting, and overall performance optimization.

Core Engine Elements

Among the most important elements is the cylinder, where the combustion process takes place. This, along with the piston, which moves up and down inside the cylinder, plays a vital role in generating the force needed to drive the machine. The connecting rod transmits this motion to the crankshaft, converting the energy into rotary motion.

Supporting Components

To ensure efficient combustion, the carburetor mixes air and fuel before they enter the cylinder. The air filter prevents debris from entering the system, while the spark plug ignites the mixture to initiate combustion. Additionally, the valve system manages the intake of air-fuel and the release of exhaust gases, keeping the engine cycle in check.

| Component | Function | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cylinder |

| Component | Function |

|---|---|

| Throttle Plate | Regulates airflow into the engine. |

| Spring | Returns the throttle plate to its original position when released. |

| Cable | Connects the throttle control to the throttle plate. |

| Linkage | Transfers motion from the throttle control to the throttle plate. |

Importance of Maintenance

Regular maintenance of the throttle mechanism is essential for ensuring smooth operation and longevity. Checking for wear and tear in components and ensuring proper alignment can prevent performance issues and enhance the efficiency of the engine.

Ignition System Layout and Operation

The ignition system is a crucial component in the engine’s overall functionality, responsible for igniting the air-fuel mixture within the combustion chamber. Its design ensures that the spark occurs at the optimal moment, enabling efficient power generation and smooth operation.

Typically, the ignition assembly includes various elements such as the ignition coil, spark plug, and associated wiring. The coil converts the battery’s low voltage into a high-voltage spark, which is then transmitted to the spark plug. The spark plug ignites the compressed mixture, initiating the combustion process.

Understanding the layout and interaction of these components is vital for troubleshooting and maintenance. Regular checks on the ignition system can help identify potential issues, such as weak sparks or misfiring, leading to improved engine performance and longevity.

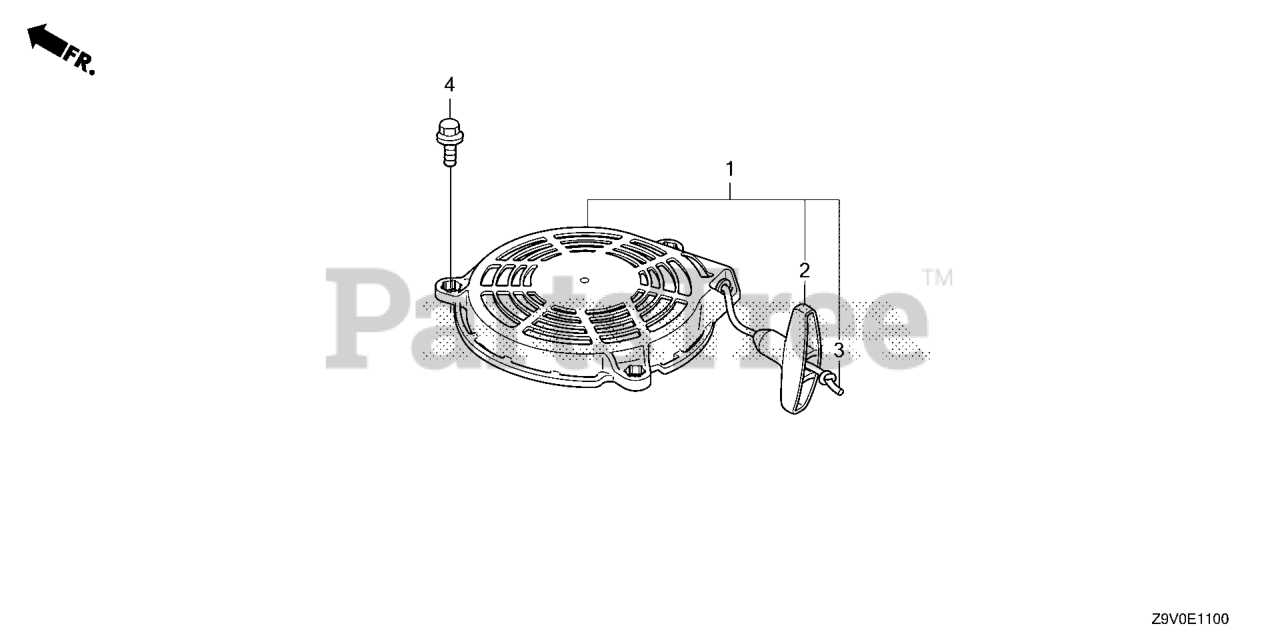

Cooling System Parts Breakdown

The cooling mechanism within a small engine is essential for maintaining optimal operating temperatures. This system consists of various components that work in harmony to dissipate heat and prevent overheating during operation. Understanding the individual elements of this system can help in ensuring efficient performance and longevity of the engine.

The main components of the cooling system include the radiator, cooling fins, and fan assembly. The radiator plays a crucial role in heat exchange, allowing the engine coolant to release excess heat into the atmosphere. Cooling fins are designed to increase the surface area, facilitating better heat dissipation. The fan assembly, typically driven by the engine, helps to enhance airflow through the radiator, especially during low-speed operations when natural airflow is insufficient.

Additionally, various hoses and connections are vital for transporting coolant throughout the system. Maintaining these components in good condition is critical for preventing leaks and ensuring efficient cooling performance. Regular inspection and replacement of worn parts can significantly impact the overall functionality of the engine’s cooling mechanism.

Oil System Components and Diagram

The lubrication system is crucial for ensuring the smooth operation and longevity of an engine. It plays a vital role in minimizing friction between moving parts, preventing wear and tear, and maintaining optimal operating temperatures. Understanding the various components involved in this system helps in efficient maintenance and troubleshooting.

Key Components

- Oil Pump: Responsible for circulating oil throughout the engine.

- Oil Filter: Cleans the oil by removing contaminants and particles.

- Oil Pan: Stores the oil when the engine is not running.

- Oil Dipstick: Allows for checking the oil level and condition.

- Oil Cooler: Regulates oil temperature to prevent overheating.

Functionality Overview

The lubrication system operates by drawing oil from the pan through the pump, which then distributes it to various engine components. As the oil circulates, it absorbs heat and carries debris to the filter, ensuring that the engine remains clean and properly lubricated. Regular maintenance of this system is essential for optimal engine performance.

Internal Engine Parts Overview

This section provides a comprehensive examination of the essential components within an engine. Understanding these elements is crucial for effective maintenance and repair, ensuring optimal performance and longevity. Each part plays a significant role in the overall function, contributing to the seamless operation of the machinery.

Key Components

The internal structure comprises various critical elements that work together harmoniously. Below is a brief description of the primary components commonly found within the engine:

| Component | Description |

|---|---|

| Cylinder Block | The core structure housing the cylinders and providing support for other components. |

| Pistons | Cylindrical components that move up and down within the cylinders, facilitating combustion and power generation. |

| Crankshaft | A rotating shaft that converts linear motion from the pistons into rotational motion. |

| Camshaft | Controls the timing of the opening and closing of the engine valves, essential for the intake and exhaust process. |

| Valves | Components that regulate the flow of air and fuel into the combustion chamber and exhaust gases out. |

Importance of Each Part

Each component has a specific function that directly influences the overall efficiency of the engine. Regular inspection and maintenance of these parts can prevent potential failures and enhance the performance of the machinery.

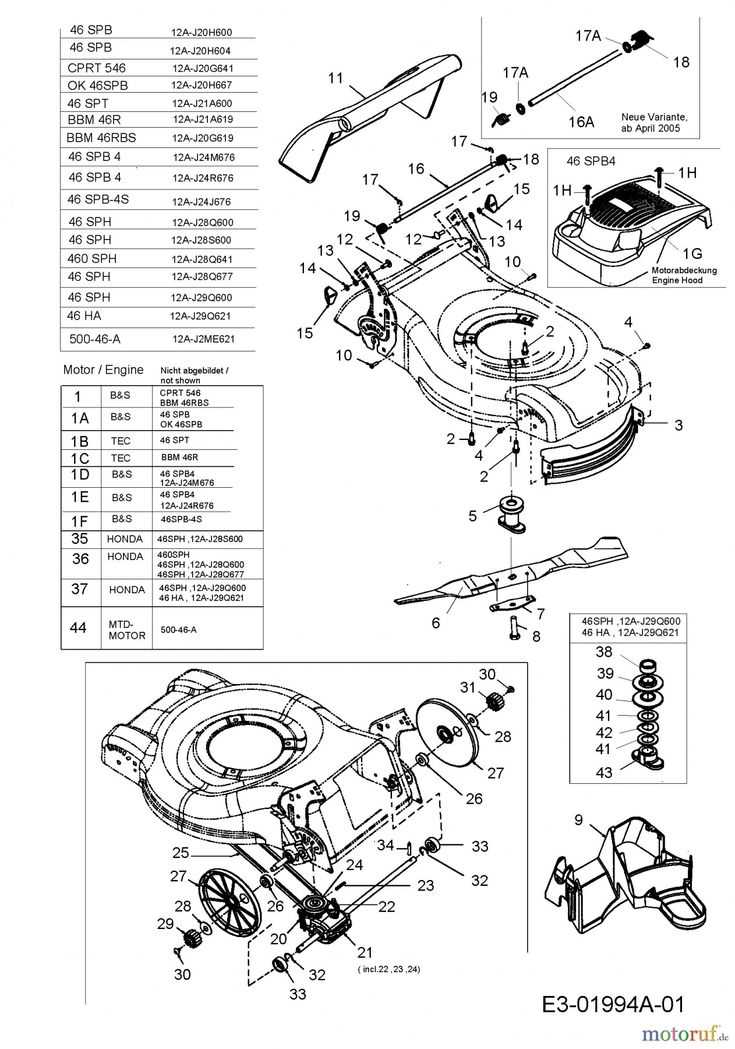

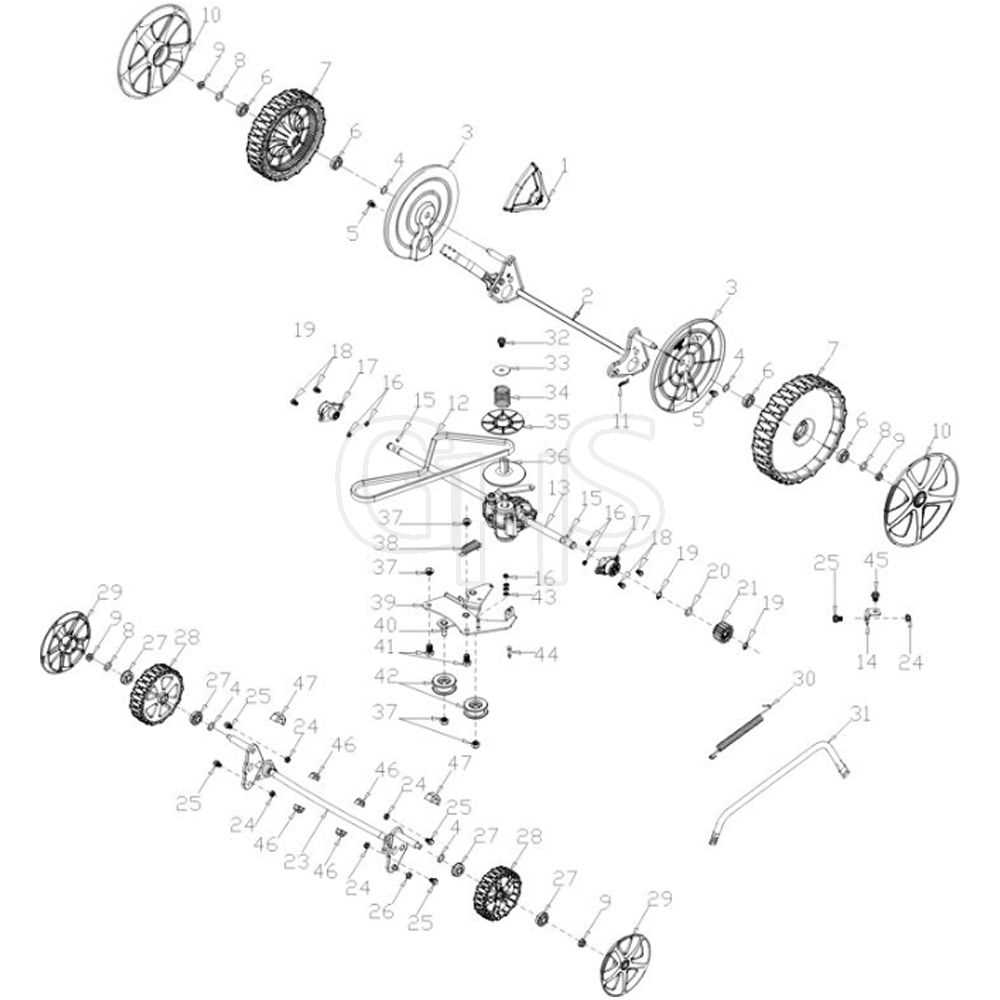

GCV170 Drive and Transmission Components

This section explores the key elements involved in the propulsion and transmission system of a small engine model, emphasizing their roles and interactions within the machinery. Understanding these components is crucial for maintenance and troubleshooting.

Key Elements of the Drive System

- Engine Crankshaft: The primary shaft that converts rotational energy from the engine into motion.

- Pulleys: These components transfer power from the crankshaft to the transmission, enabling efficient movement.

- Belt: A flexible component that connects the engine to the driven pulley, facilitating energy transfer.

Transmission Mechanisms

- Gearbox: A system that adjusts the torque and speed, allowing the machine to operate under varying conditions.

- Drive Axle: Transfers the power generated from the engine through the transmission to the wheels or working parts.

- Clutch Assembly: Engages and disengages the drive system, providing control over the power delivery to the wheels.