Exploring the intricate layouts of gardening machinery components is essential for effective maintenance and repair. A thorough comprehension of how these elements interact not only enhances performance but also prolongs the life of the equipment.

In this section, we will delve into the various components of a specific cultivator model, providing insights into their arrangement and functionality. This knowledge empowers users to identify and address issues more efficiently.

By mastering the anatomy of such tools, enthusiasts and professionals alike can ensure optimal operation, facilitating a seamless gardening experience. The ultimate goal is to equip users with the confidence to tackle any maintenance challenge that may arise.

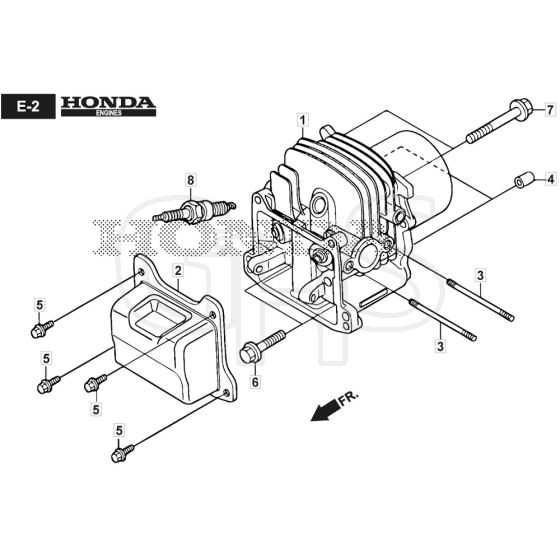

Understanding Honda GX25 Tiller Components

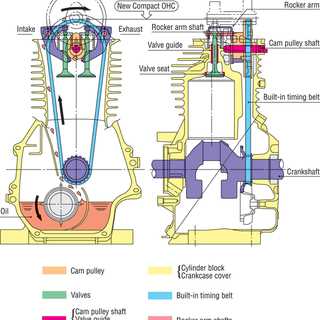

This section aims to explore the essential elements that comprise a small garden implement designed for soil cultivation. Each component plays a vital role in ensuring efficient operation and longevity of the machine, facilitating its overall performance in various gardening tasks.

Key Elements

Familiarity with the individual components allows users to troubleshoot issues and perform maintenance effectively. Understanding how these parts interact enhances the overall user experience.

Component Overview

| Component | Description |

|---|---|

| Engine | Powers the implement, providing necessary torque and speed. |

| Gearbox | Transfers power from the engine to the working parts. |

| Handles | Provide control and maneuverability during operation. |

| Blade Assembly | Engages with the soil, breaking it up for cultivation. |

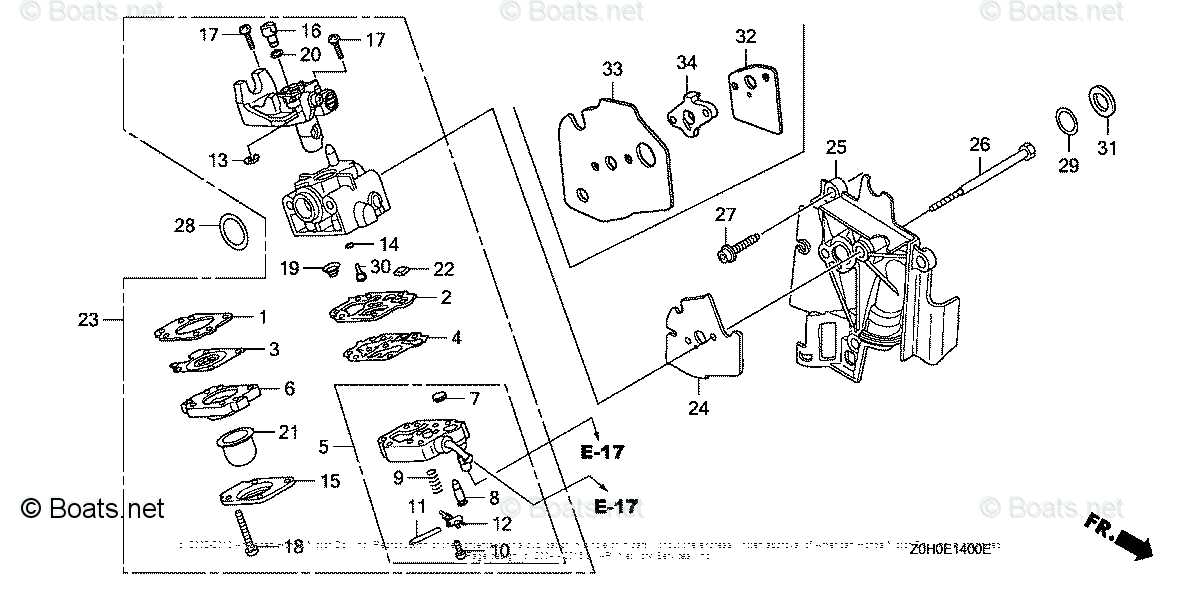

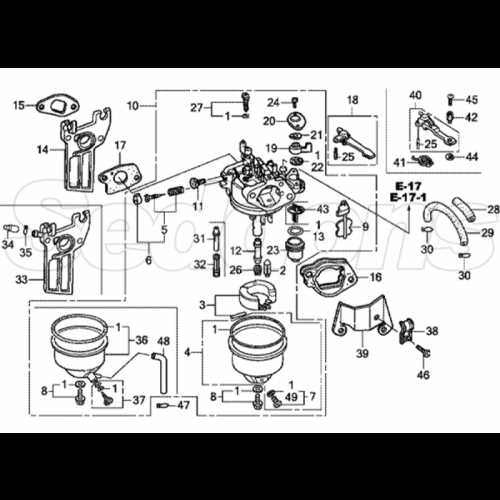

Importance of Accurate Parts Diagrams

Having precise visual representations of components is essential for effective maintenance and repair tasks. These illustrations serve as crucial references, ensuring that users can identify and locate each element needed for assembly or replacement. A well-crafted schematic can significantly reduce the time spent troubleshooting and enhance overall efficiency in the repair process.

Facilitating Repairs and Maintenance

Clear visual guides enable users to understand the assembly and function of various components more easily. By providing a detailed overview, these resources help individuals to tackle issues systematically, minimizing the risk of errors. Accurate representations also ensure that every piece fits correctly, promoting the longevity of the equipment.

Enhancing User Confidence

When individuals have access to high-quality illustrations, they feel more empowered to undertake repairs themselves. This confidence can lead to increased satisfaction with the equipment and a greater willingness to engage in regular maintenance. Ultimately, accurate schematics contribute to a more informed and capable user base, benefiting both individuals and the longevity of their tools.

Key Features of the GX25 Tiller

This section highlights the essential characteristics of a compact and efficient gardening tool designed for easy soil cultivation. Its unique design and functionalities make it an ideal choice for both novice and experienced gardeners.

Compact Design

- Lightweight for easy maneuverability

- Ergonomically designed handles for comfort

- Space-saving dimensions for storage

Powerful Performance

- Robust engine offering reliable power

- Efficient fuel consumption for extended use

- Adjustable settings for different soil types

Common Issues with Tiller Parts

Maintaining a gardening machine involves addressing various frequent challenges that can arise with its components. Understanding these issues can help users ensure optimal performance and longevity of their equipment.

| Issue | Description |

|---|---|

| Worn Blades | Blades can become dull or damaged, reducing efficiency and requiring replacement for effective soil cultivation. |

| Fuel System Problems | Clogged filters or stale fuel can lead to engine performance issues, affecting reliability during operation. |

| Transmission Failure | Wear and tear in the transmission can result in slippage or inability to engage gears, impacting mobility. |

| Electrical Malfunctions | Faulty wiring or issues with the ignition system can prevent the machine from starting or operating properly. |

| Overheating | Poor ventilation or blocked cooling fins can cause overheating, potentially damaging the engine. |

Where to Find Replacement Parts

Locating components for your equipment can seem daunting, yet various avenues simplify the process. From online retailers to local suppliers, there are multiple resources available to ensure you maintain optimal performance.

Online Marketplaces: Websites specializing in machinery often feature extensive inventories, allowing users to compare prices and availability effortlessly.

Local Dealers: Authorized distributors can provide genuine components and expert advice, making them a reliable choice for specific needs.

Community Forums: Engaging in discussions on dedicated platforms can yield recommendations from experienced users, directing you to trusted sources.

Utilizing these options will ultimately enhance your chances of finding the right replacements efficiently.

Benefits of Using Genuine Honda Parts

Utilizing authentic components is crucial for maintaining the longevity and efficiency of your machinery. Genuine items are designed to meet specific performance standards, ensuring optimal functionality and reliability.

- Quality Assurance: Authentic components undergo rigorous testing to meet high standards.

- Perfect Fit: Designed specifically for your equipment, reducing installation issues.

- Enhanced Performance: Genuine items help maintain the original performance levels.

- Warranty Protection: Using original components typically preserves your warranty coverage.

- Increased Longevity: Quality materials contribute to the durability of your machinery.

Investing in authentic components ultimately leads to better performance and peace of mind.

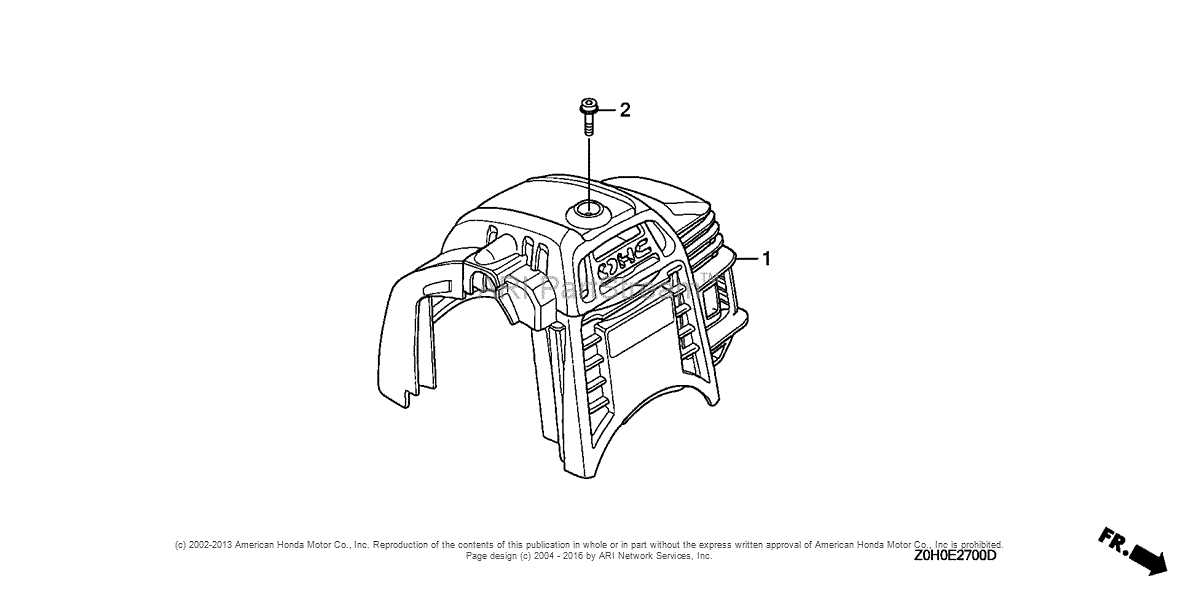

Step-by-Step Assembly Instructions

This section provides a comprehensive guide to assembling your equipment efficiently and accurately. Following these clear steps will ensure that every component fits perfectly, leading to optimal performance and longevity.

Begin by gathering all necessary components and tools. Ensure that you have a clean workspace to prevent any parts from getting lost. Familiarize yourself with each piece and their respective functions to streamline the assembly process.

Start with the main structure, aligning the base and securing it with the appropriate fasteners. Next, attach the handle, ensuring that it is positioned comfortably for operation. Pay close attention to any locking mechanisms that may require adjustment.

Once the primary frame is set, proceed to connect the power unit. Align it carefully and use the designated screws to secure it in place. Double-check all connections to guarantee stability.

Finally, install the operational elements such as the control system and safety features. Test each part to confirm they are functioning correctly. Once completed, review your work and make any necessary adjustments to ensure everything is in proper order.

Maintenance Tips for Optimal Performance

Ensuring your gardening equipment operates efficiently requires regular upkeep and attention. By following a few essential maintenance practices, you can enhance the longevity and effectiveness of your machine.

Here are some key maintenance tips to consider:

- Regular Cleaning: After each use, clean the exterior and remove any soil or debris that may have accumulated. This prevents rust and helps maintain optimal functionality.

- Inspect Components: Frequently check all parts for wear and tear. Look for cracks, corrosion, or loose connections that may affect performance.

- Change Oil: Regular oil changes are crucial. Follow the manufacturer’s recommendations for frequency to ensure smooth operation.

- Sharpen Blades: Keeping blades sharp enhances cutting efficiency. Regularly inspect and sharpen them to ensure they perform well.

- Check Fuel System: Use fresh fuel and check for leaks or blockages in the fuel line. This can prevent starting issues and enhance performance.

By adhering to these practices, you can ensure your equipment remains in peak condition, making your gardening tasks easier and more enjoyable.

Tools Needed for Repairs

When tackling maintenance tasks, having the right equipment is essential for efficiency and effectiveness. A well-organized toolkit can greatly enhance your repair experience, ensuring you have everything at hand to address any issues that may arise.

Essential Tools

Various instruments play a crucial role in executing repairs. The following table outlines the fundamental tools you should consider for your maintenance endeavors:

| Tool | Purpose |

|---|---|

| Wrenches | For loosening or tightening bolts and nuts. |

| Screwdrivers | To drive screws into or out of components. |

| Pliers | For gripping and manipulating small parts. |

| Socket Set | To easily fasten or remove various sized nuts and bolts. |

| Torque Wrench | To apply a specific torque to fasteners. |

Additional Considerations

In addition to these primary tools, consider including safety gear and specialized instruments based on your specific repair needs. This approach will ultimately lead to more successful and safer repair sessions.

Frequently Asked Questions About GX25

This section addresses common inquiries regarding a specific type of gardening equipment, focusing on its functionality, maintenance, and accessories. Understanding these elements can enhance user experience and ensure optimal performance.

What type of fuel should be used?

It is essential to use a high-quality mixture of gasoline and oil as specified in the user manual. This ensures efficient operation and longevity of the machinery.

How often should maintenance be performed?

Regular maintenance is crucial. It is recommended to check the oil levels, clean the air filter, and inspect other components every few uses to maintain peak performance.

What should I do if the equipment won’t start?

If starting issues arise, check the fuel mixture, ensure that the spark plug is clean, and verify that all connections are secure. If problems persist, consulting the manual for troubleshooting tips is advisable.

Are there any compatible accessories available?

Yes, various compatible attachments and accessories can enhance the functionality of the equipment. These include different types of blades and attachments tailored for specific gardening tasks.

How can I ensure safety while using the equipment?

Always wear appropriate protective gear, including gloves and eye protection. Additionally, familiarize yourself with the operational guidelines to minimize the risk of accidents.

Upgrades to Enhance Tiller Efficiency

Improving the performance of gardening equipment can significantly boost productivity and ease of use. By focusing on specific enhancements, users can achieve better results and reduce effort during operation. This section explores various modifications that can elevate functionality and overall effectiveness.

One of the most impactful upgrades involves optimizing the cutting tools. Sharper blades not only penetrate the soil more efficiently but also minimize strain on the engine, resulting in smoother operation. Regular maintenance and timely replacement of worn components can lead to noticeable improvements.

Additionally, upgrading the drive system can enhance power transfer and increase maneuverability. Consider options such as adjustable speed settings, which allow users to adapt their approach based on soil conditions. This flexibility can lead to more consistent results across different gardening tasks.

Another key area for enhancement is the weight distribution of the equipment. Adding or redistributing weight can improve stability and traction, especially in challenging terrains. This adjustment allows for more precise control, making it easier to navigate around obstacles.

Finally, investing in ergonomic handles can significantly reduce operator fatigue. Designs that promote a natural grip and reduce vibration can lead to longer working sessions without discomfort, ultimately improving efficiency and enjoyment during use.