Carburetor: Balances air and fuel intake, ensuring proper combustion. Regular tuning and cleaning are necessary to

Transmission Parts and Maintenance

The transmission system is a crucial component that ensures smooth operation and effective power transfer in machinery. Proper care and regular inspection of this system can significantly enhance overall performance and prolong the lifespan of the equipment. By focusing on maintenance, you can prevent potential malfunctions and improve the machine’s reliability.

Key Components of the System

The system consists of various mechanisms that work together to transfer energy efficiently. These include gears, shafts, and bearings, all of which require routine checks and servicing. Ensuring these elements are well-lubricated and free from excessive wear can help avoid costly repairs.

Regular Maintenance Tips

It is essential to perform periodic assessments to identify any signs of wear or damage. Cleaning, tightening, and replacing worn-out elements is necessary to maintain the system’s functionality. Routine adjustments and lubrication are simple but effective ways to keep the system running smoothly.

Handle and Control Assembly Features

The handle and control assembly plays a vital role in the functionality and user experience of outdoor power equipment. This component ensures that the operator can easily manage and navigate the machine while maintaining comfort and safety during operation.

Ergonomic Design

One of the standout aspects of the handle and control assembly is its ergonomic design. This feature provides a comfortable grip, reducing strain on the hands and wrists during prolonged use. The shape and material used are specifically chosen to enhance user comfort, allowing for extended operation without fatigue.

Control Mechanisms

The assembly incorporates various control mechanisms that enable the user to easily manage the equipment’s functions. These controls are strategically positioned for quick access, ensuring the operator can adjust settings without taking their attention away from the task at hand. Intuitive layout and responsive feedback are key elements that enhance the overall efficiency of the operation.

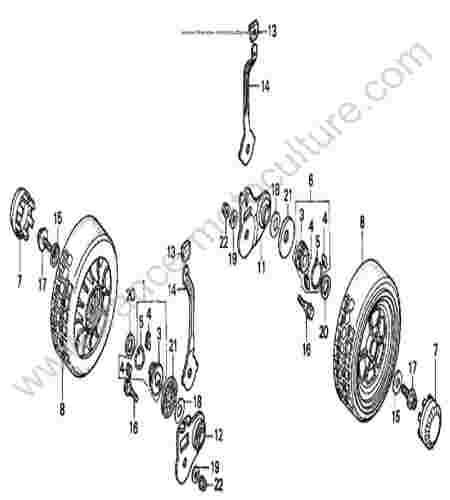

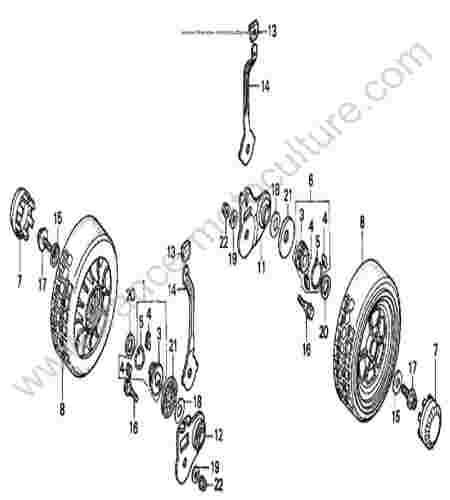

Wheels and Axle Structure

The foundation of mobility in many machines relies on the intricate arrangement of wheels and axles. This assembly plays a vital role in ensuring smooth movement and stability during operation. Understanding the components involved is crucial for effective maintenance and optimal performance.

- Wheels: The circular elements that facilitate movement by rolling over surfaces. Their design influences traction and maneuverability.

- Axles: The shafts that connect and support the wheels, allowing them to rotate freely. They are essential for transmitting power from the engine to the wheels.

- Bearings: These components reduce friction between the wheel and axle, ensuring efficient rotation and longevity of the assembly.

Each element within this structure is interdependent, contributing to the overall functionality. Regular inspection and maintenance of wheels and axles can enhance performance and extend the lifespan of the equipment.

Air Filter and Exhaust System

The air filtration and exhaust mechanisms play crucial roles in maintaining the performance and efficiency of outdoor power equipment. Proper airflow and effective expulsion of gases are essential for optimal operation. Understanding these systems can significantly enhance maintenance practices and prolong the lifespan of the machinery.

Importance of Clean Air Filtration

A clean air filter is vital for preventing debris and contaminants from entering the engine. When air quality is compromised, it can lead to reduced performance, increased wear, and potential mechanical failure. Regular inspection and timely replacement of the air filter are recommended to ensure the engine operates smoothly and efficiently.

Efficient Exhaust Management

The exhaust system is responsible for directing harmful gases away from the engine and operator. An unobstructed exhaust pathway is essential for maintaining engine efficiency and reducing emissions. Regular checks for blockages and leaks in this system help in sustaining optimal functionality and compliance with environmental standards.

Ignition and Electrical Parts Breakdown

This section delves into the components responsible for starting mechanisms and electrical functions within the machine. Understanding the intricacies of these elements is crucial for ensuring optimal performance and reliability.

Ignition System: The ignition system comprises several key components that work in unison to initiate the combustion process. These include the spark plug, ignition coil, and various wiring harnesses that facilitate the transfer of electrical energy. Each element plays a vital role in generating the necessary spark to ignite the fuel-air mixture.

Electrical Components: Essential electrical parts include the battery, fuses, and starter motor. The battery provides the necessary voltage for the ignition process, while fuses protect the circuit from overloads. The starter motor, activated by the ignition switch, is crucial for cranking the engine and initiating operation.

Maintenance Tips: Regular checks and replacements of these components can prevent potential issues. Ensure connections are clean and secure, inspect wiring for wear, and replace any damaged parts promptly. By maintaining these systems, one can enhance the longevity and reliability of the equipment.

Fuel Tank and Line Assembly

The fuel tank and line assembly plays a crucial role in the efficient functioning of outdoor power equipment. This component is designed to store and supply fuel to the engine, ensuring that it operates smoothly and effectively. Understanding the structure and features of this assembly is essential for maintenance and troubleshooting.

Components of the Assembly

This assembly typically consists of several key elements, including the tank itself, fuel lines, and connectors. The tank is constructed from durable materials to withstand various environmental conditions while securely holding the fuel. The fuel lines are designed to transport the fuel from the tank to the engine, ensuring a consistent flow for optimal performance.

Maintenance Tips

Regular maintenance of the fuel tank and line assembly is vital for longevity and performance. It is important to check for any leaks or cracks in the tank and ensure that the fuel lines are free of obstructions. Additionally, keeping the assembly clean and free from debris can prevent potential issues and enhance the overall efficiency of the equipment.

Clutch and Brake System Components

The clutch and brake system is vital for the effective operation of machinery, providing control over speed and stopping power. Understanding the various elements involved can enhance maintenance practices and improve performance.

Key Elements of the System

- Clutch Assembly: This component facilitates the engagement and disengagement of power transmission, allowing for smooth operation.

- Brake Mechanism: A crucial part that provides the necessary force to slow down or stop movement, ensuring safety and control.

- Levers and Cables: These components enable manual operation, allowing the user to effectively manage the clutch and brake functions.

- Springs: Essential for returning the clutch and brake components to their resting position, contributing to the overall efficiency of the system.

Maintenance Tips

- Regularly inspect all components for wear and tear.

- Lubricate moving parts to ensure smooth operation.

- Replace damaged or worn components promptly to maintain optimal performance.

- Keep the area around the system clean to prevent debris from interfering with operation.

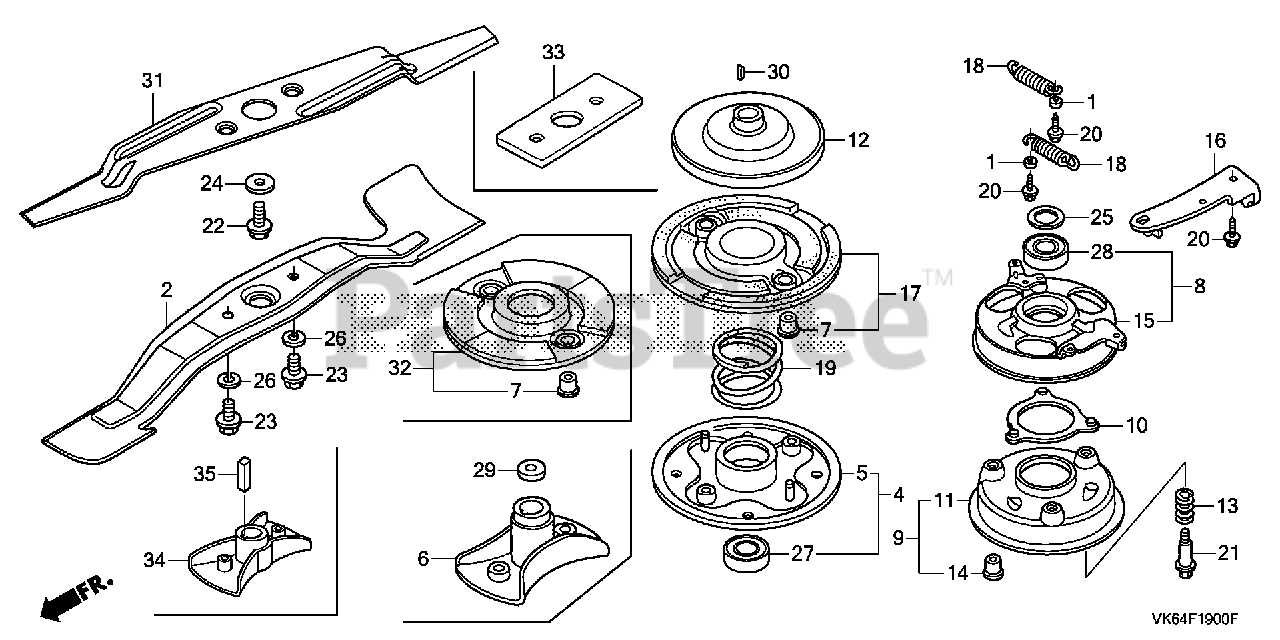

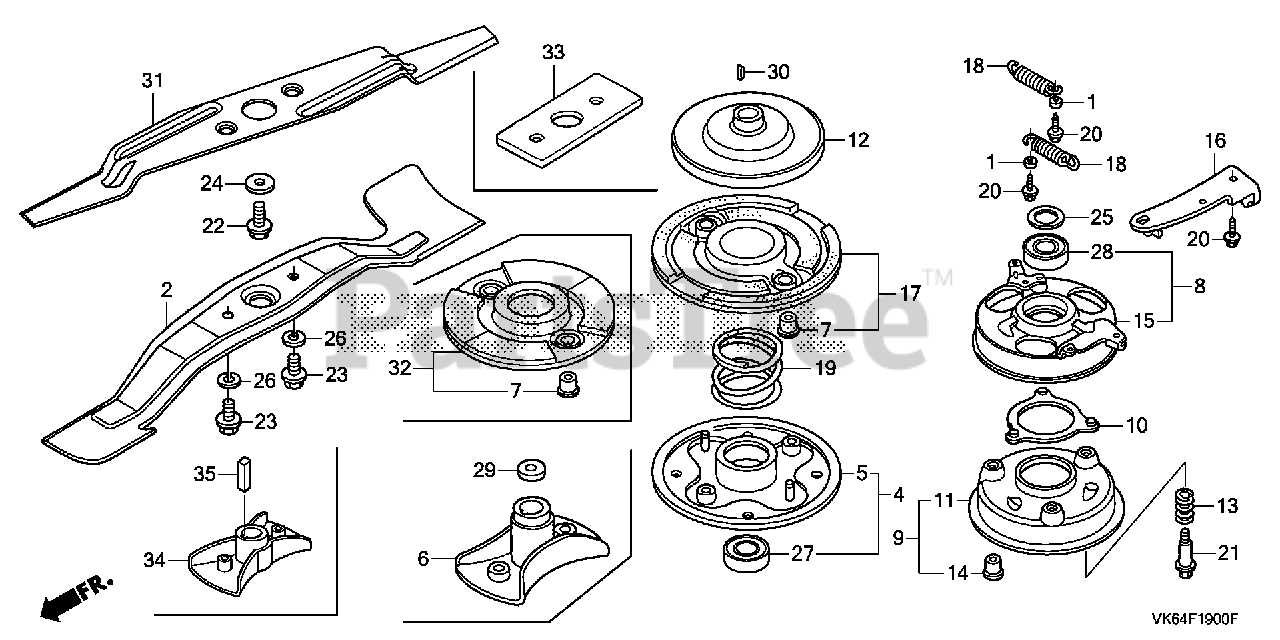

Belt and Pulley Setup

The belt and pulley configuration is essential for the efficient operation of a lawn care machine. This assembly transmits power from the engine to the cutting mechanism, ensuring optimal performance. Understanding the layout and function of each component is crucial for maintenance and troubleshooting.

Proper alignment and tension of the belt are vital for preventing wear and ensuring longevity. Regular inspections can help identify any issues that may arise, such as slippage or fraying.

| Component |

Description |

| Belt |

Transfers power from the engine to the pulleys. |

| Drive Pulley |

Connected to the engine, it drives the belt. |

| Driven Pulley |

Engages with the belt to operate the cutting mechanism. |

| Tensioner |

Maintains proper tension in the belt to prevent slippage. |

Replacement Guidelines for Honda Parts

Ensuring optimal performance of your equipment requires timely updates and replacements of essential components. By following systematic procedures, one can effectively maintain functionality and longevity of the machinery.

Identification of Required Components

Before initiating any replacement process, it’s vital to accurately determine which elements need to be exchanged. The following steps can assist in this identification:

- Consult the manufacturer’s manual for detailed information.

- Inspect the unit thoroughly to spot any signs of wear or damage.

- Make a checklist of items that require replacement.

Procurement and Installation Tips

Once the necessary components have been identified, the next phase involves sourcing and installing them correctly. Consider these tips:

- Opt for high-quality replacements to ensure durability.

- Purchase from reputable suppliers to guarantee authenticity.

- Follow installation instructions meticulously to avoid errors.

Proper maintenance routines contribute significantly to the efficiency and reliability of your machinery, making adherence to these guidelines essential.