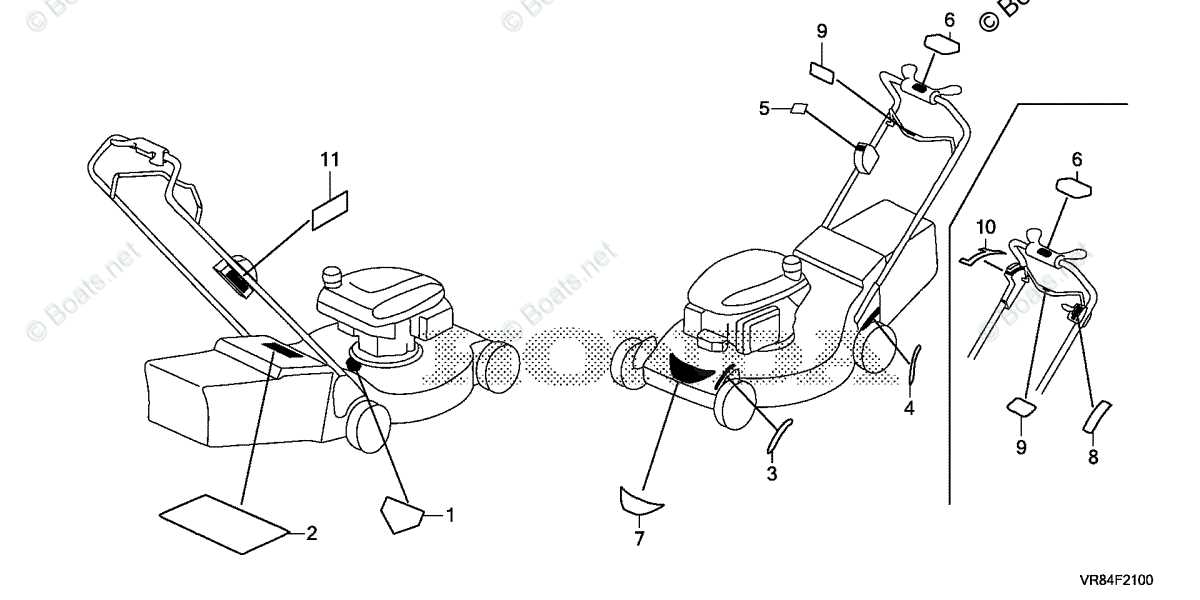

Maintaining a well-functioning lawn mower is crucial for efficient yard work. Each component plays a specific role in ensuring the smooth operation of the machine, contributing to its overall performance. Understanding the various elements involved can help in identifying and replacing necessary items when needed, ensuring the longevity and reliability of your equipment.

Exploring the structure of the machine’s mechanics provides valuable insight into how these components work together. By recognizing the key areas that require regular upkeep or replacement, you can keep your equipment in top condition, allowing it to perform at its best for years to come.

Whether you’re dealing with simple wear or preparing for more significant repairs, it’s helpful to familiarize yourself with the names and functions of each component. This knowledge empowers you to address any issues promptly and efficiently, avoiding disruptions in your regular maintenance routine.

Understanding the Honda HRN216 Mower Parts

Every lawn mower consists of several key elements that work together to ensure efficient operation. These components are designed for durability and ease of use, making regular maintenance an important aspect of keeping the machine in optimal condition. By familiarizing yourself with the essential elements, you can easily identify the right piece when maintenance or replacement is needed.

Key Components

- Blade System – The sharp cutting edge responsible for trimming grass evenly across the yard.

- Engine – Provides the power needed to operate the machine and ensure smooth functioning.

- Wheels – Sturdy supports that allow for easy maneuverability on various terrains.

- Deck – The protective casing that houses the cutting mechanism, helping to guide grass into the right path

Key Components of the HRN216 Mower

This versatile lawn maintenance tool features a variety of essential elements designed to ensure efficient performance and durability. Each component plays a critical role in the overall functionality, making it reliable for long-term use in different outdoor conditions.

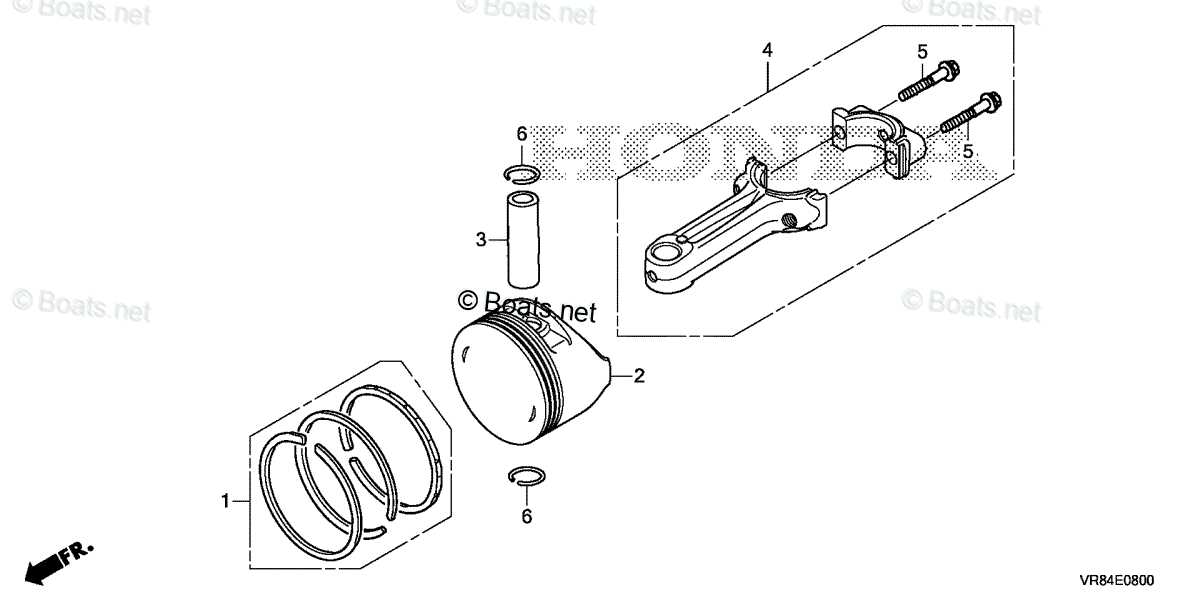

Engine and Cutting System

The power source and cutting mechanism form the core of this mower’s design. The engine drives the cutting blades, providing the necessary force to trim grass effectively. The cutting system consists of durable, high-quality blades, which are positioned to deliver a clean, even cut.

Wheels and Drive System

The sturdy wheels and drive mechanism allow for smooth movement across various terrains. The wheels are designed to handle different surfaces, while the drive system ensures controlled speed and maneuverability, reducing the physical effort required during operation.

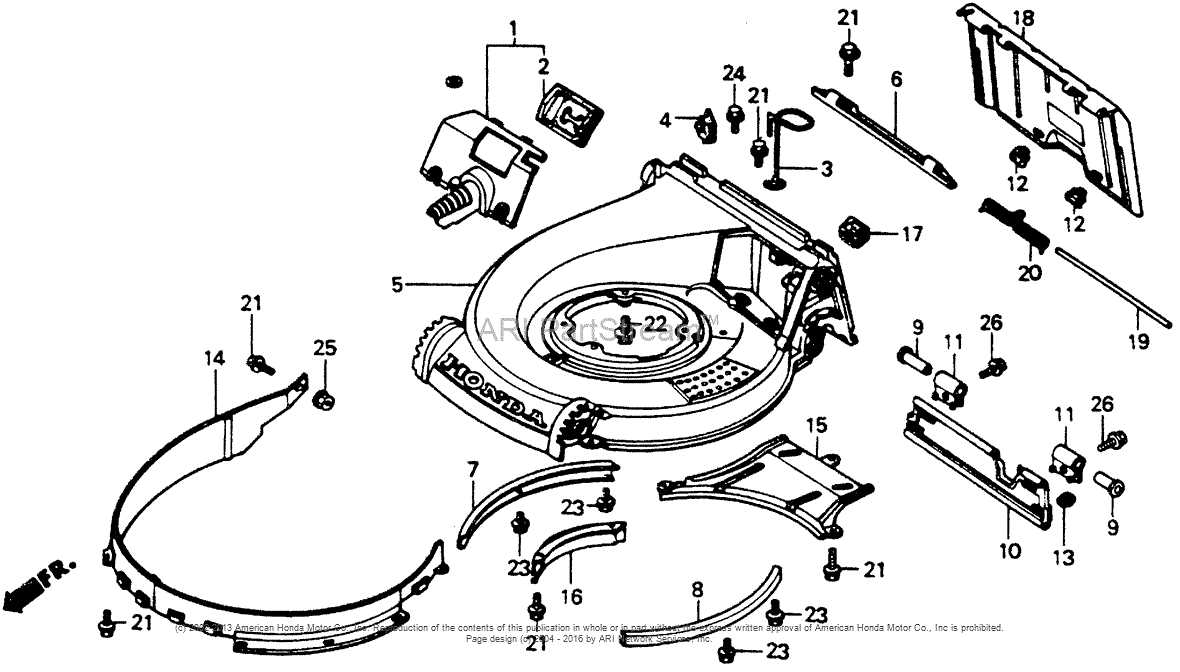

Component Blade System and Its Maintenance

The blade mechanism plays a crucial role in ensuring efficient cutting and overall machine performance. Proper upkeep of the system is essential for maintaining consistent results and extending the machine’s lifespan. Regular attention to this component can prevent unexpected issues during operation.

Inspection of the blade mechanism should be a routine task. Check for any signs of wear, such as nicks or dull edges, which can affect the quality of the cut. It’s important to sharpen or replace blades when necessary to maintain precision.

Additionally, balancing the blades is a critical step to avoid vibrations that could impact both the cutting efficiency and the machine’s overall functionality. An unbalanced system can lead to excessive strain on the motor and reduce performance over time.

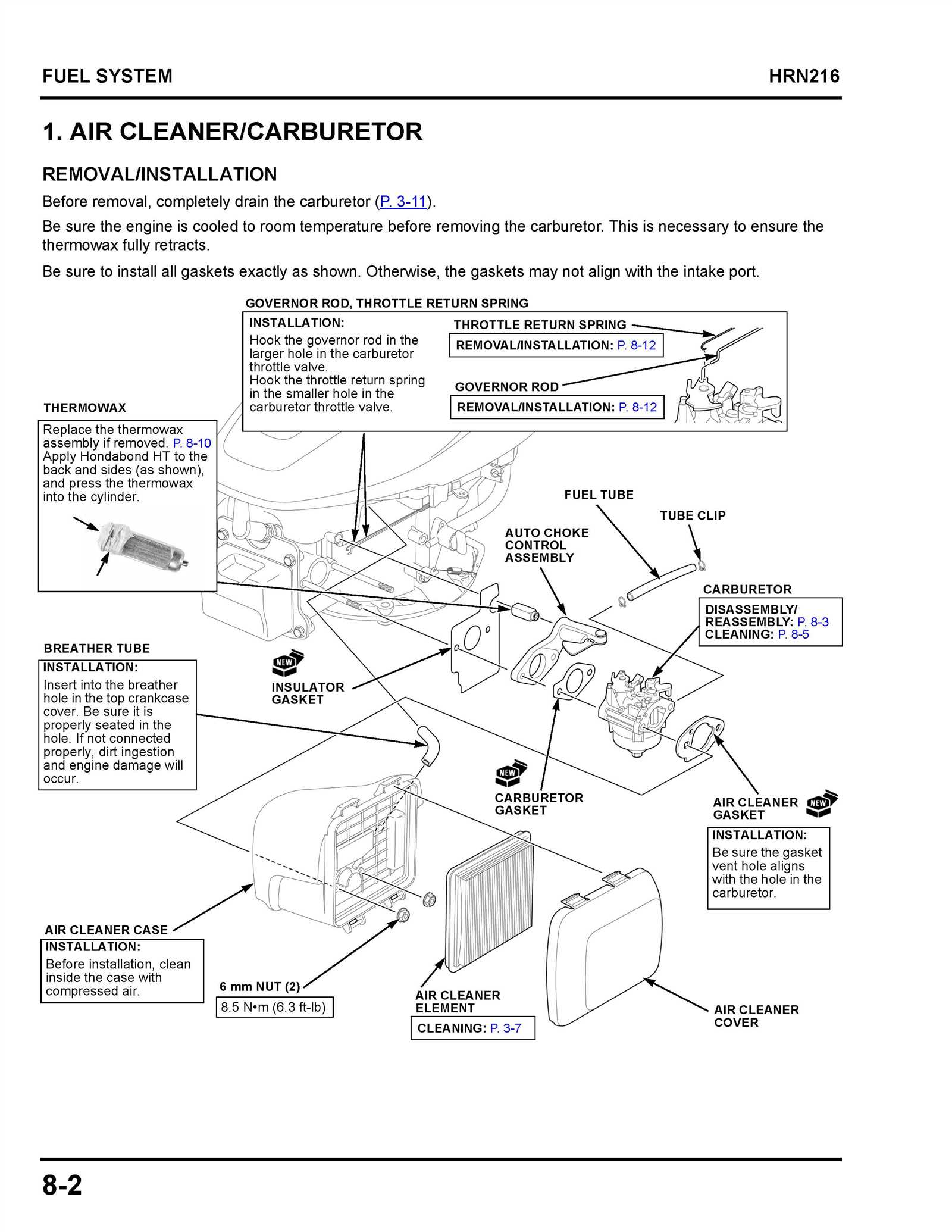

Air Filter Replacement Guide

The air filter plays a vital role in ensuring that your equipment functions efficiently by keeping harmful debris out of the engine. Regular maintenance and timely replacement of this component are essential for optimal performance and longevity.

To begin the replacement process, first ensure that the device is completely powered off and in a safe, stable position. Locate the housing that covers the filter. Typically, this cover is secured with either clips or screws, which you will need to remove carefully to access the filter.

Once the cover is removed, take out the old filter and inspect it for excessive dirt or damage. Compare the new filter to the old one to ensure it’s the correct fit before placing it into the housing. After positioning the new filter, securely fasten the cover back in place.

Regularly checking and replacing the filter as needed will help maintain the equipment’s efficiency and prolong its overall lifespan.

Fuel System Overview for Honda HRN216

The fuel system is responsible for delivering the necessary energy to the engine. Its components ensure that fuel is properly mixed with air and directed into the combustion chamber. A well-maintained system guarantees smooth operation and efficient performance.

- Fuel Tank: Stores the gasoline that powers the engine.

- Fuel Line: Transports fuel from the tank to other parts of the system.

- Carburetor: Mixes fuel with air in the correct proportion for combustion.

- Fuel Filter: Prevents debris and impurities from entering the engine, protecting internal components.

- Choke Lever:

Drive Belt Function and Replacement Tips

The drive belt is a crucial component that plays a significant role in transferring power from the engine to various moving parts of the equipment. Its efficiency directly affects the overall performance, ensuring smooth operation and effective power transmission. Over time, wear and tear may lead to a decline in its functionality, necessitating timely maintenance and replacement to keep the equipment running optimally.

Understanding Drive Belt Functionality

The primary purpose of the drive belt is to connect the engine’s crankshaft to the pulley systems that drive various attachments. This linkage facilitates the conversion of rotational energy into the necessary mechanical motion required for effective operation. When in good condition, the belt maintains proper tension and alignment, ensuring efficient energy transfer and preventing slippage.

Replacement Guidelines

To maintain optimal performance, regular inspection of the drive belt is essential. Look for signs of wear, such as fraying, cracking, or glazing. If any of these indicators are present, it is advisable to replace the belt promptly. Here are some tips for the replacement process:

Step Description 1 Disconnect the power source to prevent any accidents. 2 Remove any covers or shields that may obstruct access to the belt. 3 Loosen the tensioner to relieve pressure on the belt. 4 Carefully remove the old belt from the pulleys. 5 Install the new belt, ensuring it is aligned properly on the pulleys. 6 Reapply tension to the belt and check for proper fit. 7 Replace any covers and reconnect the power source. Carburetor Cleaning and Adjustment Process

The process of maintaining the carburetor is essential for ensuring optimal performance of small engines. Regular cleaning and proper adjustments can prevent fuel-related issues, enhance efficiency, and prolong the lifespan of the equipment. This section outlines the steps involved in effectively cleaning and fine-tuning the carburetor for best results.

Preparation for Cleaning

Before beginning the cleaning process, gather the necessary tools and materials, including a cleaning solution, soft brushes, and screwdrivers. Ensure the engine is turned off and cooled down to prevent accidents. Remove the carburetor from the engine, taking care to note the position of any components for reassembly.

Cleaning and Adjustment Steps

Using a suitable cleaning solution, thoroughly clean all parts of the carburetor, paying close attention to jets and passages. Soft brushes can help remove stubborn deposits. After cleaning, dry all components completely. Once dry, reassemble the carburetor, making any necessary adjustments to the fuel and air mixture according to the manufacturer’s specifications. Reinstall the carburetor and check for proper operation before using the engine.

Wheel Assembly and Maintenance Tips

Ensuring optimal performance and longevity of your equipment requires proper wheel assembly and routine care. This section provides essential guidelines and practical advice to help you maintain the wheel components effectively.

Assembly Guidelines

When assembling the wheels, begin by verifying that all necessary components are present. Carefully align the wheel with the axle, ensuring that it fits snugly without excessive force. Utilize appropriate tools to secure fasteners, maintaining even tension across all parts. Regularly inspect the alignment and functionality to prevent premature wear and damage.

Maintenance Practices

Routine maintenance is crucial for keeping wheels in peak condition. Regularly check for any signs of wear, such as cracks or unusual noises. Clean the wheel surfaces to remove debris and dirt, which can hinder performance. Lubricate moving parts according to manufacturer recommendations to ensure smooth operation. Adopting these practices will enhance the durability and efficiency of your equipment.

Ignition System Components Explained

The ignition system is a crucial part of any engine, responsible for generating the spark necessary to ignite the fuel-air mixture. Understanding its components helps in diagnosing issues and performing maintenance effectively.

Key Components of the Ignition System

- Ignition Coil: This device transforms low battery voltage into the high voltage needed to create a spark.

- Spark Plug: Positioned in the combustion chamber, it receives the spark and ignites the fuel-air mixture.

- Distributor: This component directs the electrical current from the ignition coil to the correct spark plug at the right time.

- Ignition Wires: These cables transmit the electrical current from the coil to the spark plugs, ensuring a reliable connection.

Functionality Overview

Each element works in harmony to ensure optimal engine performance. The ignition coil generates the necessary voltage, which travels through ignition wires to the distributor. The distributor then sends this voltage to the appropriate spark plug, leading to combustion. Regular maintenance of these components can prevent engine misfires and improve overall efficiency.

Deck Design and Maintenance Instructions

The design and upkeep of a lawnmower deck are crucial for ensuring optimal performance and longevity. A well-constructed deck not only enhances the efficiency of the machine but also contributes to a cleaner cut and healthier lawn. Regular maintenance practices help in identifying potential issues before they escalate, thereby preserving the integrity of the equipment.

To begin with, it’s important to regularly inspect the deck for any signs of wear or damage. Look for cracks, dents, or rust that may compromise the structure. Cleaning the deck after each use is essential; grass clippings and debris can accumulate, leading to corrosion and hindering performance. Using a stiff brush and water can effectively remove these materials.

Additionally, lubrication of moving parts within the deck should not be overlooked. Applying a suitable lubricant to joints and bearings helps reduce friction and prevent premature wear. It is also advisable to check the blades regularly, ensuring they are sharp and free from nicks. Dull blades not only produce an uneven cut but can also stress the engine, leading to further complications.

Finally, consider covering the deck during storage to protect it from the elements. A simple cover can shield it from moisture and debris, extending its lifespan. By following these maintenance instructions, users can ensure that their lawnmower deck remains in optimal condition, resulting in a more efficient and effective mowing experience.

Throttle and Control Cable Adjustments

Proper adjustments to the throttle and control cables are essential for ensuring optimal performance and responsiveness of your equipment. These components play a crucial role in regulating the engine speed and controlling various functions. Regular maintenance and precise tuning can enhance the efficiency and longevity of the machine.

Importance of Proper Adjustments

Ensuring that the cables are correctly adjusted offers several benefits:

- Improved engine responsiveness.

- Enhanced safety during operation.

- Minimized wear on engine components.

Steps for Adjustment

Follow these steps to achieve accurate adjustments:

- Start by locating the throttle and control cables.

- Check for any signs of fraying or damage.

- Loosen the adjusting screws to allow for movement.

- Pull the cables to remove any slack.

- Retighten the screws once the desired tension is achieved.

- Test the operation to ensure proper function.

Spark Plug Inspection and Replacement Guide

The spark plug plays a crucial role in the proper functioning of an engine by igniting the air-fuel mixture. Regular inspection and timely replacement are essential to maintain optimal performance and efficiency. This guide outlines the steps to effectively check and change spark plugs, ensuring your equipment operates smoothly.

Inspection Process

To determine the condition of the spark plug, follow these steps:

- Ensure the engine is turned off and cooled down.

- Locate the spark plug using the owner’s manual as a reference.

- Remove the spark plug wire carefully to avoid damage.

- Use a spark plug socket to extract the plug from the cylinder head.

Evaluating Spark Plug Condition

Once the spark plug is removed, inspect it for the following:

- Wear and Tear: Check for any signs of erosion or damage on the electrodes.

- Carbon Deposits: Look for excessive buildup, which may indicate rich fuel mixture or other issues.

- Color: A healthy spark plug typically shows a tan or light brown color. Dark or oily deposits may suggest engine problems.

If the spark plug exhibits significant wear or damage, it is advisable to replace it with a new one to ensure reliable ignition and efficient operation.

How to Troubleshoot Common Issues

Addressing frequent problems with lawn maintenance equipment requires a systematic approach. By understanding the common challenges that may arise, users can effectively diagnose and resolve issues, ensuring optimal performance and longevity of their machines.

Issue Possible Causes Solutions Engine won’t start Empty fuel tank, clogged filter, dead battery Refill fuel, replace filter, charge or replace battery Uneven cutting Worn blades, uneven tire pressure Sharpen or replace blades, check and adjust tire pressure Excessive vibration Loose components, damaged blades Tighten screws, inspect and replace damaged blades Stalling during operation Dirty spark plug, fuel line blockage Clean or replace spark plug, check and clear fuel line