When maintaining any outdoor machinery, a clear understanding of its individual elements is crucial for optimal performance. Each piece plays a specific role, contributing to the overall functionality and efficiency of the device. Familiarizing oneself with these components not only enhances repair skills but also prolongs the lifespan of the equipment.

By examining the intricate relationships between various parts, users can ensure that their tools operate smoothly and effectively. A detailed visual representation can serve as an invaluable resource, enabling users to identify, replace, or upgrade specific components with confidence. Knowledge in this area ultimately empowers users to tackle maintenance tasks more effectively.

In the pursuit of mastery over one’s machinery, exploring the unique assembly of parts is essential. This exploration not only aids in troubleshooting issues but also fosters a deeper appreciation for the engineering behind the tools. Delve into the specifics to unlock the full potential of your equipment.

Understanding Honda HS520 Components

Gaining insight into the various elements of a snow-clearing machine is essential for effective operation and maintenance. Each component plays a critical role in the overall performance, ensuring that the equipment functions smoothly and efficiently. Familiarity with these elements not only aids in troubleshooting but also enhances the user experience.

Key Elements of the Snow Remover

Among the vital components, the engine serves as the powerhouse, delivering the necessary energy to operate the device. Coupled with the auger assembly, which is responsible for gathering and expelling snow, these elements work in harmony to achieve optimal results. Belts and cables are equally important, transmitting power and controlling various functions, thus ensuring a seamless operation.

Maintenance and Care

Regular inspection of the components is crucial for longevity. Users should pay close attention to the condition of the shoes and blades, as these wear down over time and can significantly impact performance. By understanding the intricacies of each part, operators can make informed decisions regarding repairs and replacements, ultimately enhancing the durability and effectiveness of their machine.

Importance of Parts Diagrams

Understanding the layout and components of machinery is essential for effective maintenance and repair. Visual representations serve as vital tools for identifying individual elements, ensuring that users can accurately troubleshoot and replace necessary components. This clarity can significantly enhance efficiency and reduce the risk of errors during the servicing process.

Enhanced Efficiency

Utilizing visual guides allows for quicker identification of specific elements, streamlining the repair process. When users can readily locate each component, they save valuable time and can focus on resolving issues swiftly.

Minimized Errors

Clear visual aids reduce the likelihood of mistakes during assembly or disassembly. By providing a comprehensive view, these representations ensure that every part is correctly identified and handled, ultimately leading to more successful repairs.

Key Features of the HS520 Model

This section explores the standout characteristics of a popular snow-clearing machine, emphasizing its functionality, efficiency, and user-friendly design. Understanding these features helps users appreciate the advantages offered by this model, making it an essential tool for winter maintenance.

| Feature | Description |

|---|---|

| Powerful Engine | Equipped with a robust engine, it delivers excellent performance in heavy snow conditions. |

| Compact Design | Its compact build allows for easy maneuverability in tight spaces. |

| Ergonomic Controls | User-friendly controls provide ease of operation, enhancing comfort during use. |

| Efficient Clearing Width | The effective clearing width ensures quick and thorough snow removal. |

| Durable Construction | Built with high-quality materials, it offers longevity and reliability in challenging conditions. |

Common Replacement Parts for HS520

When maintaining your outdoor equipment, understanding the essential components that may require replacement is crucial for optimal performance. Regular wear and tear can lead to various issues, making it important to identify which elements are commonly replaced. By focusing on these components, you can ensure your machinery operates smoothly and efficiently.

One frequently replaced item is the cutting blade, which can dull over time and affect performance. Additionally, air filters are vital for maintaining engine efficiency and should be changed regularly to prevent blockages. Spark plugs are another key component; replacing them can significantly enhance starting and overall functionality. Lastly, belts that drive various mechanisms may wear out, leading to reduced power transfer and should be inspected regularly.

Where to Find OEM Parts

For those seeking high-quality replacement components for their machinery, finding the right source is crucial. Authentic items ensure reliability and compatibility, ultimately enhancing performance and longevity. Various channels offer these essential components, making the search more accessible.

Authorized Dealers: One of the most reliable options is to visit authorized distributors. These retailers specialize in genuine products and often provide expert advice on selection.

Online Retailers: Numerous online platforms cater to consumers looking for original components. Websites dedicated to equipment supplies typically feature extensive catalogs, allowing users to search by model or part number.

Manufacturer Websites: Official websites often include sections for replacements, offering direct access to the latest products. This can be the ultimate destination for those wanting assurance of authenticity.

Local Repair Shops: Many repair shops stock genuine items or can order them upon request. Engaging with local professionals can also yield valuable insights into the best options available.

By exploring these avenues, users can delve into the world of genuine components, ensuring their equipment operates at peak efficiency.

Benefits of Using Genuine Components

Opting for original replacement parts is crucial for maintaining the efficiency and longevity of your equipment. Genuine components are designed specifically to fit and function seamlessly, ensuring optimal performance and reliability. Here are some key advantages of choosing authentic materials over generic alternatives.

Quality Assurance

One of the primary benefits of using original components is the assurance of quality. Genuine items undergo rigorous testing and adhere to strict manufacturing standards. This ensures:

- Enhanced durability

- Consistent performance

- Reduced risk of malfunctions

Compatibility and Fit

Original components are engineered to perfectly match the specifications of your machinery. This compatibility leads to:

- Smoother operation

- Easier installation

- Minimized wear and tear

Choosing genuine components ultimately results in a more reliable and efficient performance, safeguarding your investment over time.

Maintenance Tips for Honda HS520

Regular upkeep is essential for ensuring the longevity and efficiency of your snow-clearing equipment. By following a few key practices, you can keep your machine in optimal condition and ready to tackle winter challenges. Proper maintenance not only enhances performance but also reduces the likelihood of costly repairs.

1. Check and Change Fluids: Regularly inspect the oil and fuel levels. Replace the oil according to the manufacturer’s recommendations to ensure smooth operation and prevent engine wear. Clean or replace the fuel filter as needed to maintain fuel efficiency.

2. Inspect Belts and Cables: Examine drive belts and cables for signs of wear or damage. Replace any frayed or broken components to avoid mechanical failures. Keeping these parts in good condition is crucial for reliable performance.

3. Clean the Chassis: After each use, remove snow and debris from the exterior. A clean chassis not only improves aesthetics but also prevents rust and corrosion, which can impact functionality over time.

4. Sharpen Blades: Dull blades can reduce efficiency and increase fuel consumption. Regularly check and sharpen the blades to ensure they cut effectively. This practice also prolongs the life of the cutting components.

5. Store Properly: During off-seasons, store your equipment in a dry, sheltered area. Use a protective cover to shield it from dust and moisture. Proper storage helps prevent deterioration and keeps it ready for use when the snow falls.

By adhering to these maintenance guidelines, you can enjoy reliable performance and extend the life of your snow-clearing machine, ensuring it serves you well through the cold months.

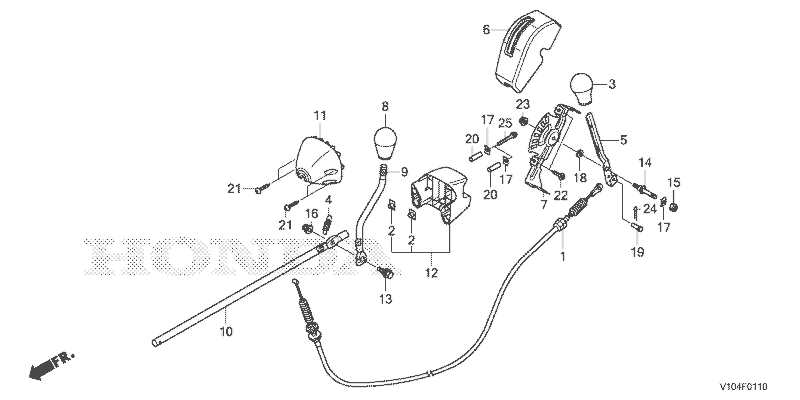

How to Read Parts Diagrams

Understanding visual representations of components can significantly enhance your ability to identify and source the necessary elements for maintenance or repair tasks. These illustrations serve as guides, showcasing the relationship between various pieces and how they fit together within a machine.

Breaking Down the Visuals

When examining these visuals, start by familiarizing yourself with the layout. Each component is typically numbered or labeled, which corresponds to a key or legend. This key provides descriptions or specifications, helping you understand what each part does. Pay attention to any grouped sections, as they often indicate assemblies that work together.

Utilizing the Information

After identifying the elements, you can efficiently locate them in catalogs or stores. Make a list of the specific parts you need based on the illustration. This approach not only saves time but also ensures accuracy in ordering. Remember to verify compatibility with your equipment, as small variations can lead to functional issues.

Troubleshooting Common Issues

When operating outdoor machinery, encountering problems can be frustrating. Identifying and resolving common challenges can enhance performance and prolong the lifespan of your equipment. This section provides guidance on diagnosing frequent issues and offers potential solutions to restore functionality.

-

Engine Won’t Start:

- Check the fuel level and ensure it is fresh.

- Inspect the spark plug for damage or wear.

- Examine the battery connections and charge level.

-

Poor Performance:

- Clean or replace the air filter to ensure proper airflow.

- Verify that the blades are sharp and free of debris.

- Adjust the throttle settings if necessary.

-

Unusual Noises:

- Listen for loose parts or components that may need tightening.

- Inspect for foreign objects lodged in moving parts.

- Check for worn bearings or belts that might require replacement.

-

Excessive Vibration:

- Ensure all bolts and screws are properly secured.

- Examine the cutting deck for damage or misalignment.

- Look for uneven tire pressure that could affect stability.

By systematically addressing these common issues, operators can often restore equipment functionality and ensure smoother operation. Regular maintenance and prompt attention to problems can prevent more serious complications down the line.

Online Resources for Parts Information

Finding reliable information about components and their specifications is essential for maintenance and repairs. The internet offers a wealth of resources that can assist users in locating necessary items, understanding their functionalities, and ensuring compatibility with various models.

Key Online Platforms

- Manufacturer Websites: Directly visiting the official sites often provides the most accurate and comprehensive data. Users can access catalogs, user manuals, and installation guides.

- Retailer Sites: Numerous online stores specialize in selling components. They typically offer searchable databases where users can input model numbers to find suitable replacements.

- Forums and Communities: Enthusiast forums can be invaluable for gaining insights from experienced users. Members often share tips on sourcing items and troubleshooting common issues.

Additional Resources

- Video Tutorials: Platforms like YouTube host countless instructional videos that cover installation and repair processes, providing visual aids that enhance understanding.

- Repair Manuals: Websites that specialize in repair manuals can be helpful for in-depth guidance, often detailing step-by-step processes for various tasks.

- Online Marketplaces: Sites like eBay and Amazon often have listings for both new and used components, giving users a range of options at different price points.

Upgrading Your Honda HS520

Enhancing your snow clearing machine can significantly improve its efficiency and performance. By integrating advanced components and making strategic modifications, you can elevate its capabilities to meet your specific needs. This section will explore effective ways to upgrade your equipment, ensuring it operates at its ultimate potential.

Key Enhancements

Consider focusing on the following areas for improvements:

| Component | Upgrade Options | Benefits |

|---|---|---|

| Engine | High-performance carburetor | Increased power and efficiency |

| Auger | Heavy-duty steel blades | Better snow management |

| Transmission | Enhanced drive belts | Smoother operation |

Installation Tips

When installing new components, ensure proper alignment and secure fittings. Regular maintenance post-upgrade will maximize longevity and performance. Delve into each aspect carefully to achieve the best results.