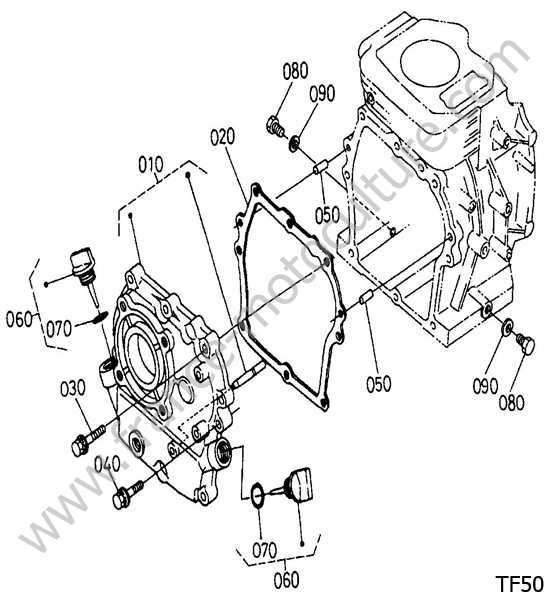

When it comes to maintaining outdoor machinery, having a clear understanding of its various components is essential. This knowledge not only aids in effective repairs but also enhances the overall performance of the equipment. With a visual representation of the assembly, users can navigate through the intricate parts more efficiently.

Every machine has unique elements that work in harmony to ensure optimal functionality. Identifying these elements allows for targeted troubleshooting and can extend the lifespan of the equipment. By breaking down the assembly into understandable segments, operators can approach maintenance tasks with confidence and precision.

In this section, we will explore a detailed representation of the essential components involved in small engine machinery. With an emphasis on clarity, this guide aims to simplify the process of recognizing each part’s role, ultimately leading to more effective upkeep and repair strategies.

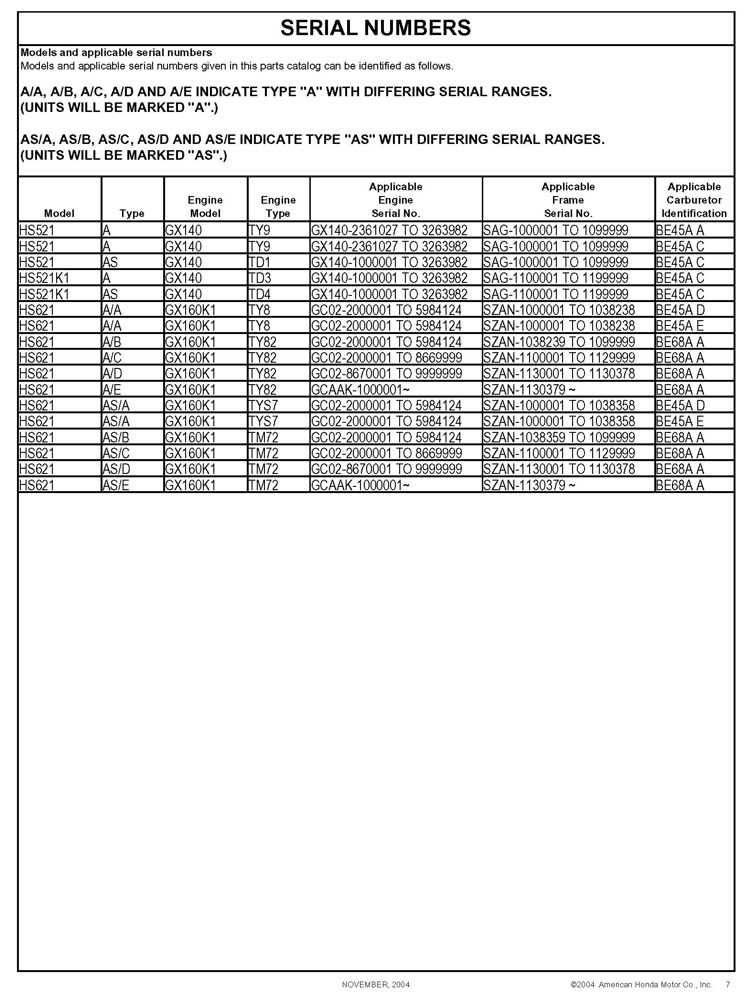

Understanding Honda HS621 Parts Diagram

Grasping the intricacies of a machine’s component layout is essential for effective maintenance and repair. Such layouts provide a visual representation that simplifies the identification of each element, enabling users to comprehend the functionality and interconnectivity of the various parts.

A comprehensive understanding of these schematics can significantly enhance troubleshooting efficiency and facilitate smoother repairs. This knowledge empowers users to pinpoint issues swiftly and accurately, ensuring optimal performance of the equipment.

| Component | Description | Function |

|---|---|---|

| Engine | Primary power source | Drives the entire system |

| Auger | Snow-throwing mechanism | Collects and expels snow |

| Chassis | Main frame structure | Supports all components |

| Control Panel | User interface | Operates various functions |

| Wheels | Mobility elements | Facilitates movement |

Recognizing the role of each element within the layout can streamline the process of repair and maintenance, ultimately leading to prolonged longevity and reliability of the machine.

Overview of Honda HS621 Features

This section provides a comprehensive look at the key attributes of a popular snow-clearing machine designed for efficiency and ease of use. With its robust construction and thoughtful engineering, this equipment is tailored to tackle winter conditions effectively.

Powerful Engine: The machine is equipped with a reliable engine that ensures consistent performance, making it capable of handling various snow depths.

Efficient Auger System: An advanced auger system enhances the ability to break through compacted snow, allowing for quicker clearing operations.

Adjustable Chute: The adjustable discharge chute provides the ultimate flexibility in directing snow away from pathways and driveways, minimizing the need for additional clean-up.

Ergonomic Design: Its user-friendly design incorporates comfortable controls, making operation straightforward even during prolonged use.

These features collectively contribute to an effective solution for maintaining clear and safe outdoor spaces during winter months.

Importance of Accurate Parts Identification

Proper identification of components is crucial for maintaining the efficiency and longevity of machinery. When every element is correctly recognized, it ensures that replacements are not only compatible but also optimized for performance. This attention to detail minimizes the risk of errors that could lead to costly repairs or operational downtimes.

Precision in identification allows for streamlined maintenance processes, where technicians can swiftly locate and procure the necessary items. This efficiency can significantly reduce the time required for repairs, leading to increased productivity. Furthermore, understanding each component’s specifications helps in selecting high-quality alternatives, thereby enhancing the overall functionality of the equipment.

Additionally, correct identification plays a vital role in safety. Using mismatched or incorrect components can pose serious risks, potentially resulting in accidents or damage to the machine. Ensuring that every part is accurately determined fosters a safer working environment and promotes reliability in performance.

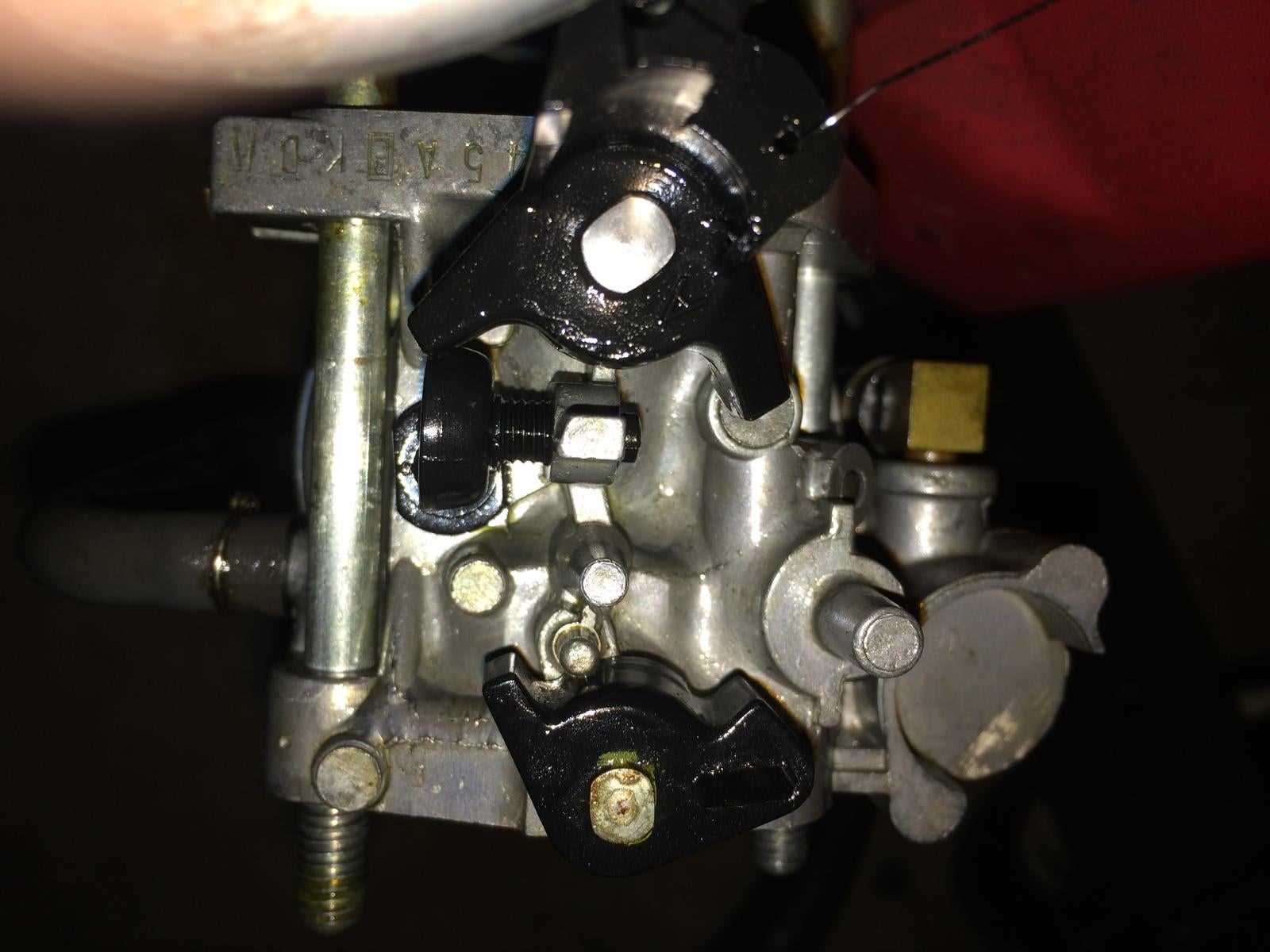

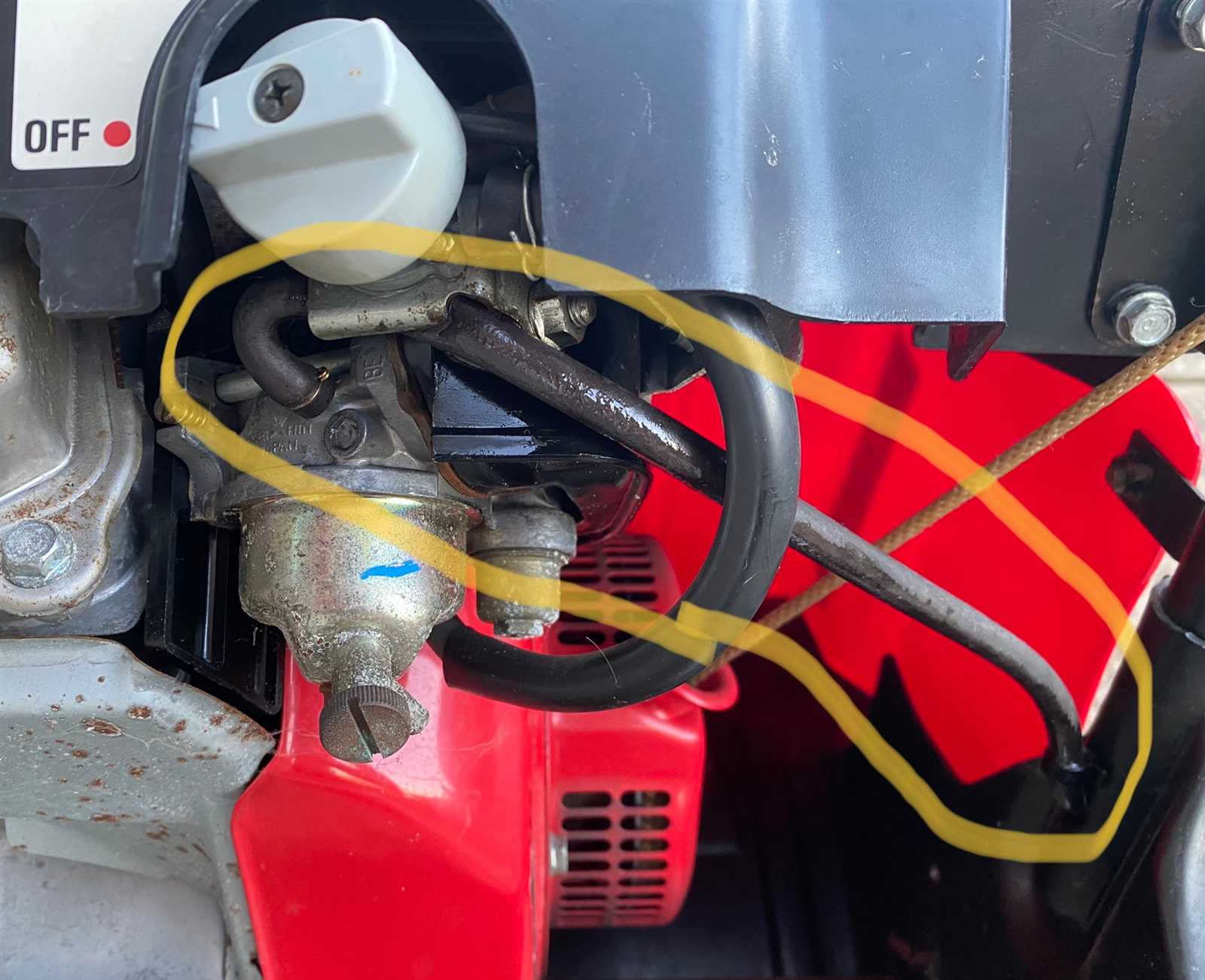

Common Problems with HS621 Components

Various components in outdoor machinery can face issues over time, affecting performance and reliability. Identifying common malfunctions can help in maintaining the equipment effectively and ensuring its longevity.

- Engine Starting Difficulties:

Often, machinery may struggle to start due to:

- Fuel system blockages

- Weak spark plugs

- Battery issues

- Unusual Noises:

Strange sounds can indicate problems such as:

- Loose or damaged components

- Worn-out bearings

- Improper lubrication

- Power Loss:

A decrease in power can stem from:

- Air filter clogs

- Fuel quality issues

- Malfunctioning carburetors

- Excessive Vibration:

Increased vibration can be caused by:

- Imbalanced parts

- Worn-out mounts

- Improperly aligned components

Regular maintenance and timely inspections can mitigate these issues, ensuring optimal operation and reducing the likelihood of significant repairs.

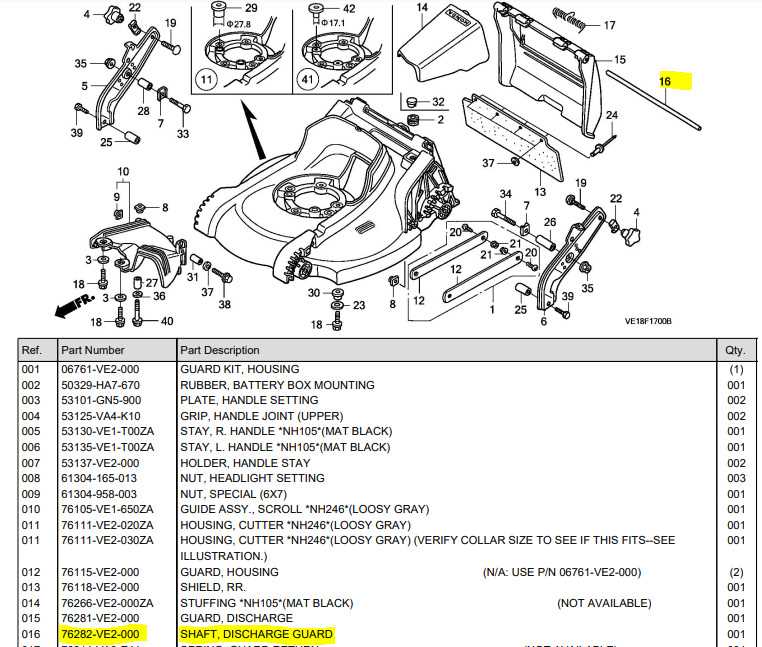

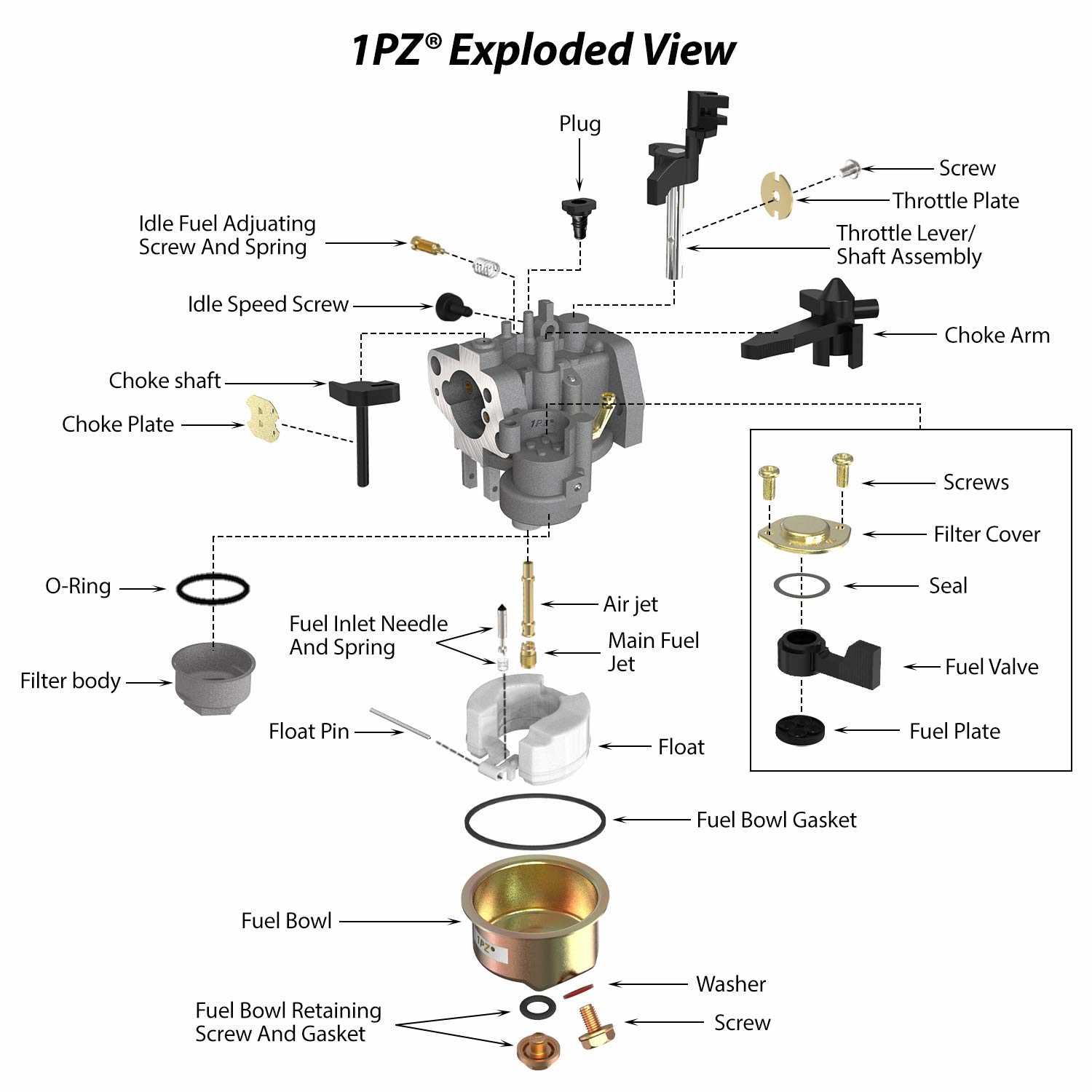

How to Read Parts Diagrams Effectively

Understanding visual representations of components can significantly enhance your ability to identify and source necessary items for maintenance or repair tasks. These illustrations serve as a guide, allowing users to visualize the relationship between different elements and how they fit together in a system. By familiarizing yourself with the conventions used in these representations, you can streamline your repair process and ensure accuracy in your work.

Familiarize Yourself with Symbols: Each illustration employs specific icons and notations that denote various types of components. Taking the time to learn what each symbol represents will help you quickly locate the parts you need. Look for a legend or key that explains these symbols; this will be invaluable as you study the visual materials.

Follow the Flow of Assembly: Components are often organized in a way that reflects their assembly order. Pay attention to how elements are grouped and connected. This organization can give you insight into how parts interact and may highlight potential issues that arise from wear or damage.

Utilize Reference Numbers: Most illustrations include reference numbers next to each component, linking them to detailed descriptions. These numbers are crucial for ordering replacements or consulting manuals. Ensure you keep a list of these references handy for quick access during your maintenance activities.

Take Notes and Highlight Key Areas: As you study the visual guide, make notes on specific areas that require attention or seem particularly complex. Highlighting these sections can aid in quick retrieval of information when you’re deep into a project, preventing confusion and saving time.

Cross-Reference with Manuals: For a deeper understanding, cross-reference the visual representations with any accompanying manuals or documentation. This approach provides context and clarifies any ambiguities, helping you grasp the operational aspects of each component.

By mastering these techniques, you’ll be able to navigate component illustrations with confidence, leading to more efficient repairs and maintenance practices.

Essential Tools for Maintenance Tasks

Proper upkeep of machinery requires a range of essential instruments to ensure efficiency and longevity. Having the right tools not only simplifies the process but also enhances safety and performance. Below are some critical implements every technician should consider.

- Wrenches: Adjustable and socket wrenches are vital for loosening and tightening bolts.

- Screwdrivers: A set of various sizes and types, including flathead and Phillips, is necessary for multiple applications.

- Torque Wrench: This tool ensures that fasteners are tightened to the manufacturer’s specifications.

- Pliers: Useful for gripping, twisting, and cutting wires or components.

- Oil Can: Essential for lubrication to maintain optimal operation.

Investing in quality tools can significantly improve maintenance tasks, enabling a smoother workflow and prolonging the lifespan of the equipment.

Locating Genuine Honda Parts

Finding authentic components for your machinery is essential for ensuring optimal performance and longevity. Using original items enhances reliability and preserves the integrity of the equipment. This section explores effective methods for sourcing high-quality replacements.

Online Resources

Several platforms specialize in offering original components. Utilizing these resources can save time and guarantee that you receive genuine products.

- Official Manufacturer Websites

- Authorized Dealers

- Reputable E-commerce Sites

Local Options

In addition to online avenues, local shops and dealerships can provide authentic replacements. Visiting these locations can offer the advantage of immediate access.

- Authorized Retail Outlets

- Local Repair Shops

- Trade Shows and Expos

By exploring these avenues, you can ensure that you find the best-quality items for your equipment, maintaining its performance and reliability over time.

Aftermarket Options for HS621 Users

For enthusiasts seeking to enhance their equipment, exploring alternatives can yield significant benefits. These options often provide improved performance, durability, and cost-effectiveness compared to original components. Users can find a variety of enhancements tailored to their specific needs, ensuring a more customized experience.

Aftermarket suppliers frequently offer a wide range of upgrades, from more robust blades to advanced engine components. These enhancements not only optimize functionality but can also extend the lifespan of the machine. Additionally, the competitive pricing of these alternatives makes them an appealing choice for many operators.

When selecting aftermarket components, it’s crucial to research reputable vendors and ensure compatibility with your model. Investing time in comparing features and user reviews can lead to informed decisions that elevate the overall efficiency and effectiveness of your equipment.

Step-by-Step Repair Guide

This guide aims to provide a comprehensive approach to troubleshooting and restoring outdoor power equipment. By following these organized steps, users can efficiently identify issues, replace faulty components, and ensure optimal performance.

Preparation and Tools

Before beginning any maintenance, gather necessary tools such as wrenches, screwdrivers, and safety gear. Ensure you have access to a well-lit workspace to enhance visibility during the process. Familiarize yourself with the equipment’s manual for reference on specific components and their functions.

Identifying and Fixing Issues

Start by conducting a thorough inspection of the equipment. Look for signs of wear, leaks, or unusual noises. Once the problem is identified, consult the manual to locate the specific parts involved. Replacing damaged elements is crucial for restoring functionality. Always double-check that new components are compatible before installation. After replacing, conduct a test run to confirm that the repair was successful.

Tips for Regular Maintenance Practices

Regularly inspect key components for wear and tear. Pay attention to any unusual sounds or vibrations during operation, as these may indicate potential issues. Clean or replace filters as necessary to maintain airflow and efficiency.

Ensure that all moving parts are adequately lubricated to reduce friction and wear. Refer to the manufacturer’s guidelines for the appropriate intervals and types of lubricants to use.

Keep the equipment free from debris and dirt. A clean machine not only operates better but also has a reduced risk of overheating and damage. Regularly wash the exterior and check for blockages.

Lastly, maintain a log of all maintenance activities. This record can be invaluable for tracking performance trends and identifying recurring issues, helping you to delve deeper into any necessary repairs or upgrades.

Upgrading Components for Better Performance

Enhancing the efficiency and output of your equipment can significantly improve its overall functionality. By focusing on specific elements within the system, users can achieve greater reliability and extended lifespan. This section explores various upgrades that can lead to superior performance and enhanced user experience.

| Component | Upgrade Options | Benefits |

|---|---|---|

| Engine | High-performance carburetor | Improved fuel efficiency and power delivery |

| Blades | Enhanced cutting blades | Finer cuts and reduced effort |

| Transmission | Heavy-duty belt | Increased durability and smoother operation |

| Air Filter | High-flow air filter | Better airflow and performance |

Resources for Honda HS621 Owners

For enthusiasts and operators of specific outdoor machinery, having access to reliable information and resources is essential. This section aims to provide valuable tools, guides, and support that can enhance the ownership experience, ensuring optimal performance and maintenance of your equipment.

Online Communities and Forums

Joining dedicated online forums and communities can be incredibly beneficial. These platforms allow owners to share experiences, ask questions, and find solutions to common issues. Engaging with fellow users fosters a sense of camaraderie and can lead to invaluable tips and tricks that improve overall functionality.

Maintenance Manuals and Guides

Obtaining detailed maintenance manuals is crucial for proper care. These documents often contain step-by-step instructions for troubleshooting and servicing. Additionally, online resources provide video tutorials that visually guide users through complex repairs, ensuring that even novices can tackle maintenance tasks with confidence.

By leveraging these resources, you can enhance your understanding and keep your equipment running smoothly for years to come.

Frequently Asked Questions About HS621

This section addresses common inquiries related to a popular snow removal machine. Users often seek clarity on functionality, maintenance, and replacement components.

What type of fuel is recommended for optimal performance?

It is best to use clean, unleaded gasoline with an octane rating of 87 or higher for efficient operation.

How often should I perform maintenance on my equipment?

Regular maintenance is crucial; it’s advisable to check the machine after every use and conduct a thorough inspection at the beginning of each season.

Where can I find replacement components?

Replacement parts are available at authorized dealers, online marketplaces, or specialized retailers that focus on outdoor power equipment.

What should I do if the machine won’t start?

If starting issues arise, check the fuel level, ensure the ignition is functioning, and inspect the spark plug for any signs of wear or damage.

Is there a warranty on new purchases?

Most new machines come with a warranty, which typically covers parts and labor for a specified period; always review the documentation provided upon purchase.