Snow blowers are essential machines designed to tackle heavy snowfall, ensuring clear paths and driveways during winter. Each unit consists of various key elements that work together to achieve efficient snow removal. Proper maintenance of these components ensures the equipment remains reliable for many seasons.

In this section, we will delve into the breakdown of the essential elements that make up these machines. Learning about the internal mechanisms and their functions will help users maintain and repair their equipment effectively, ensuring smooth operation and longevity.

By understanding how each section contributes to the overall function, users can perform more efficient repairs, source compatible replacements, and maintain their machines with greater confidence. Familiarity with these technical details is crucial for ensuring optimal performance in harsh winter conditions.

Overview of Honda HS928 Components

Understanding the various elements of this machinery is crucial for its maintenance and repair. Each section of the equipment plays a specific role, ensuring optimal performance during operation. By familiarizing yourself with the key mechanical units, you can better assess functionality and address any issues that may arise.

Core mechanical components include systems responsible for propulsion, control, and the clearing mechanism. These elements are designed to work in harmony, contributing to the overall efficiency and effectiveness of the equipment. Regular inspection of these units is essential for long-term durability and reliability.

Additionally, the design incorporates auxiliary systems such as safety mechanisms, ensuring smooth operation under various conditions. Recognizing how these pieces fit together can significantly improve troubleshooting and maintenance efforts.

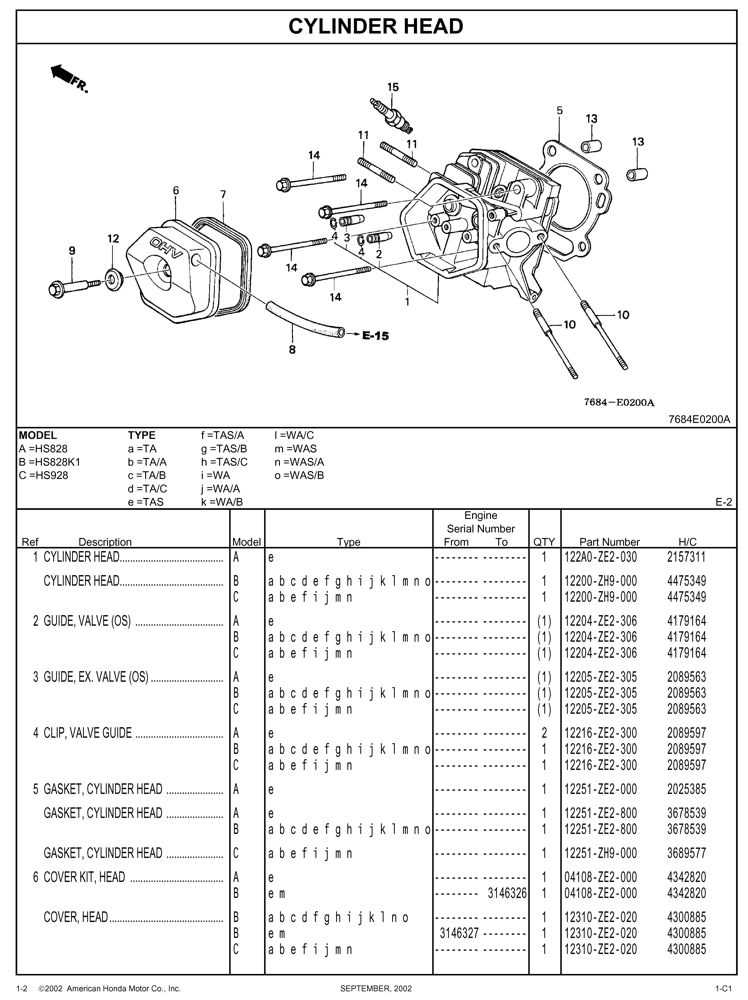

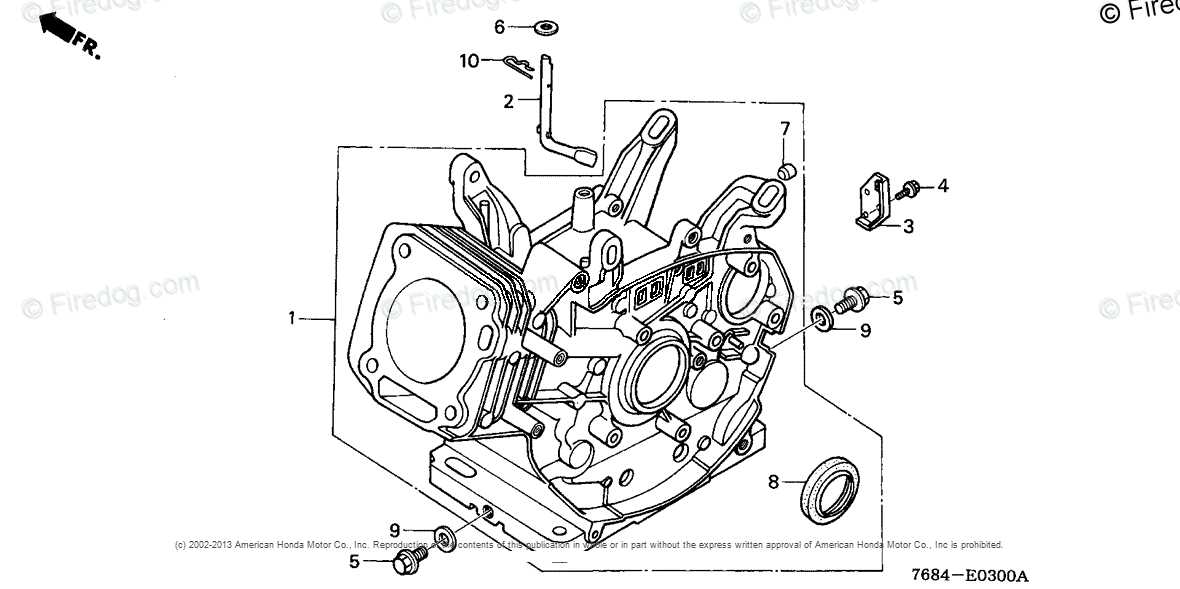

Engine System and Key Features

The engine system is designed to deliver high efficiency and consistent performance in various conditions. Its structure is optimized to handle different workloads, ensuring smooth operation and longevity. Understanding the key elements of this system allows for better maintenance and enhanced durability.

- Fuel Efficiency: The system maximizes fuel usage, offering better output while consuming less.

- Durability: The engine components are built to withstand prolonged use, reducing the need for frequent repairs.

- Power Output: Designed to deliver consistent power, making it suitable for handling heavy-duty tasks with ease.

- Cooling Mechanism: An advanced cooling system

Chassis Design and Structure

The framework of the machine serves as the foundation for all its components, providing both support and stability. This essential structure is designed to ensure durability, balance, and efficient weight distribution, which are crucial for optimal performance. Its layout and materials directly influence the overall resilience and adaptability to varying conditions.

Structural Integrity

Built with a focus on robustness, the chassis is engineered to withstand extensive use and challenging environments. The emphasis on rigidity ensures that the machine remains operational under heavy loads and stress, maintaining long-term reliability without compromising flexibility in movement.

Material Composition

The choice of materials plays a key role in the structure’s efficiency. A blend of lightweight yet durable metals contributes to enhanced maneuverability while maintaining structural strength. This composition allows for an improved balance between agility

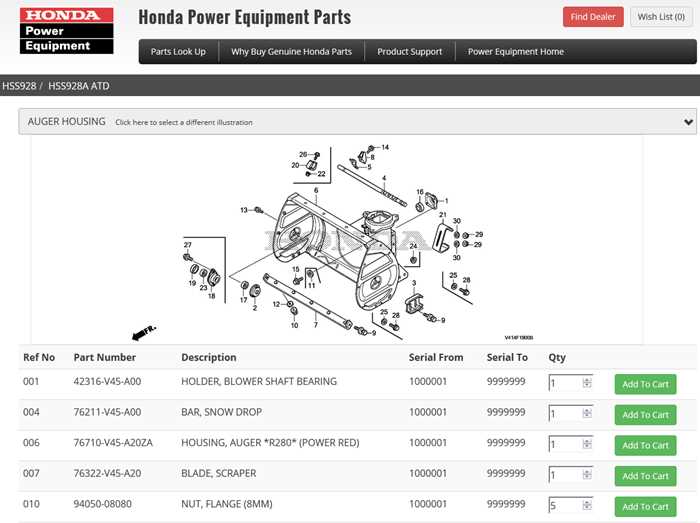

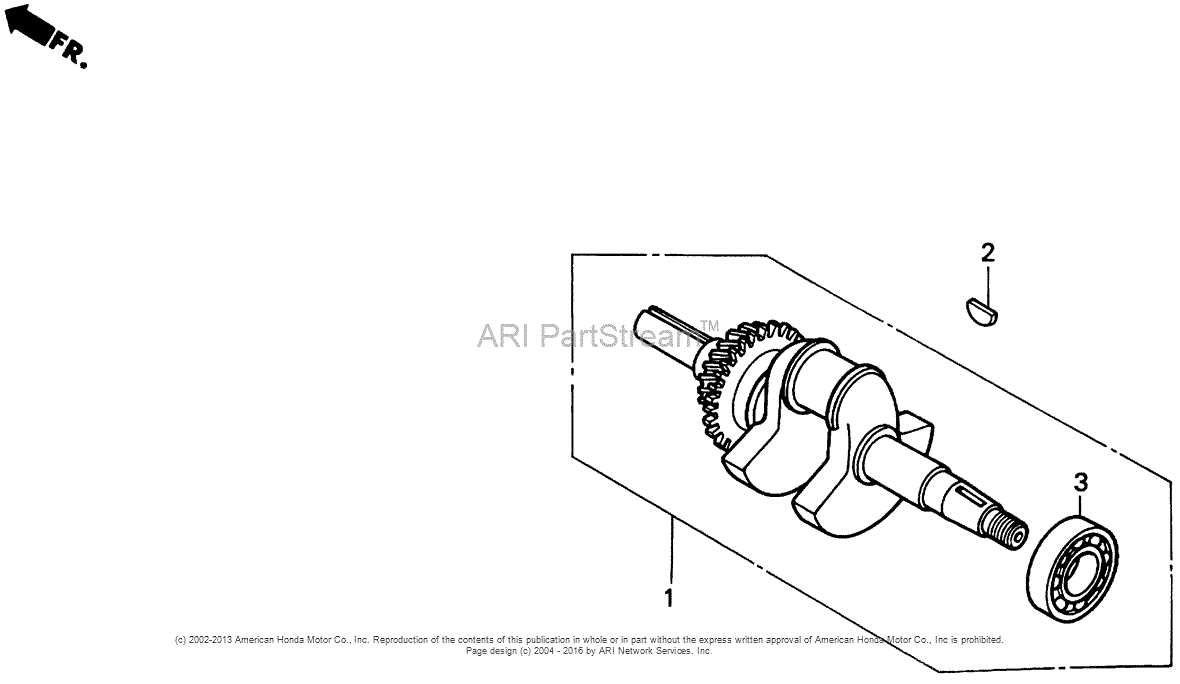

Auger Assembly and Functionality

The auger assembly plays a crucial role in moving snow efficiently from the surface to the discharge chute. Its rotating blades break down compacted layers and ensure smooth clearing, which is vital for maintaining consistent performance. The mechanism behind the auger’s operation is designed to maximize efficiency and minimize the effort required during operation.

Main Components of the Auger

The core elements of the auger system include a set of blades, a central shaft, and a housing that supports the entire assembly. These components work in unison to gather snow and guide it toward the chute. Each part has a specific role, ensuring the smooth and continuous flow of snow removal.

How the Auger Operates

When activated, the blades rotate at high speed, slicing through snow and ice. The auger’s rotation direction and speed are precisely controlled to adapt to varying snow conditions, ensuring optimal performance. The system is built to withsta

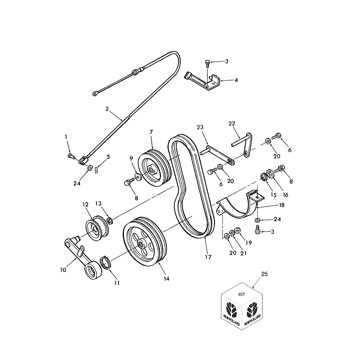

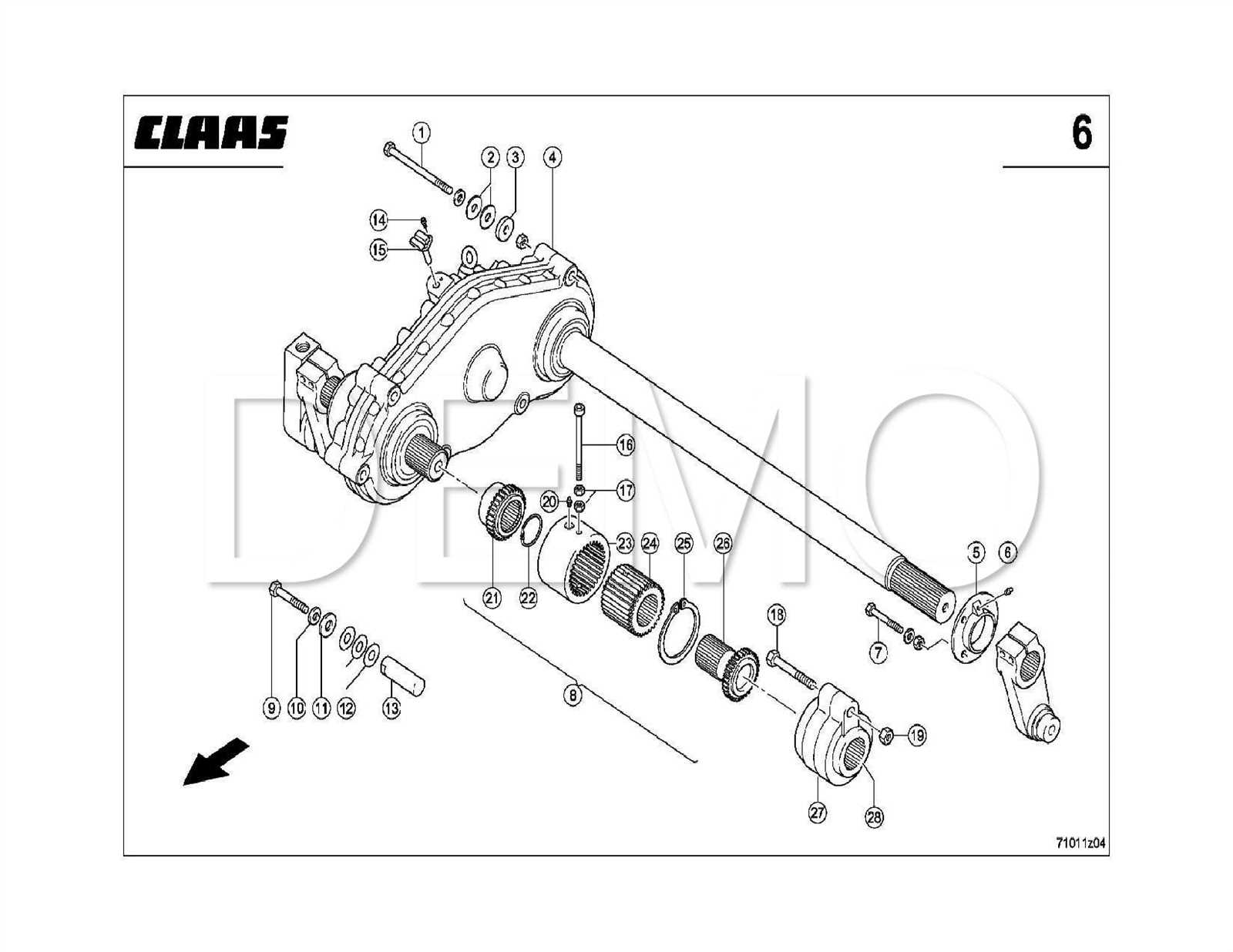

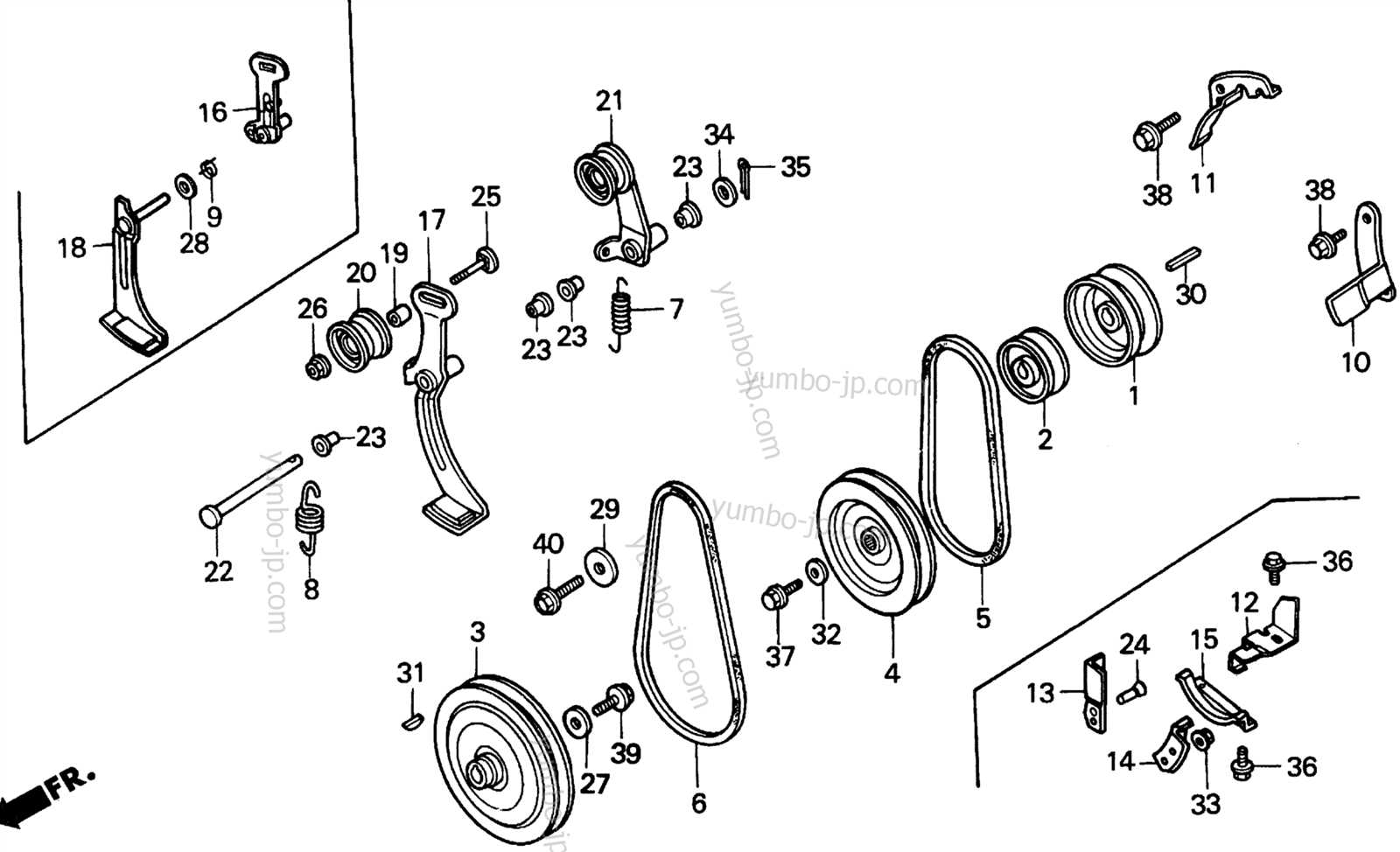

Transmission and Drive Mechanism

The transmission and drive mechanism are crucial components in ensuring smooth operation and efficient power delivery in machinery. These systems work together to convert the engine’s output into usable motion, allowing the equipment to function across varying terrains and conditions.

Main Drive System

The main drive system is responsible for transferring energy from the engine to the wheels or tracks, ensuring optimal traction. This system typically includes gears, belts, or chains, which help regulate speed and torque, adapting to the needs of the machine’s performance.

Transmission System

The transmission system plays a vital role in controlling the speed and direction of the machine. It usually consists of a series of gears that adjust the power output to match the operator’s requirements, whether it’s to increase speed or provide more force for demanding tasks.

Component Function Gears Regulate speed and torque Fuel System Layout and Parts

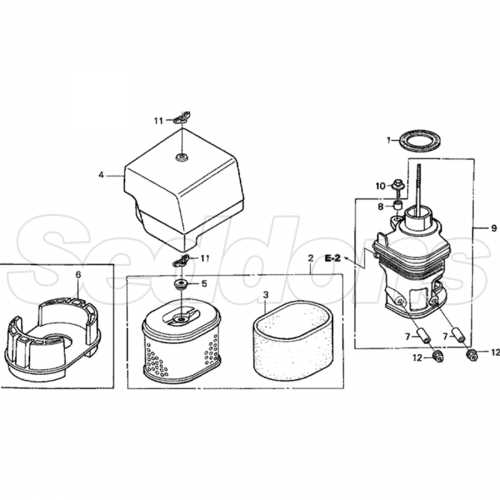

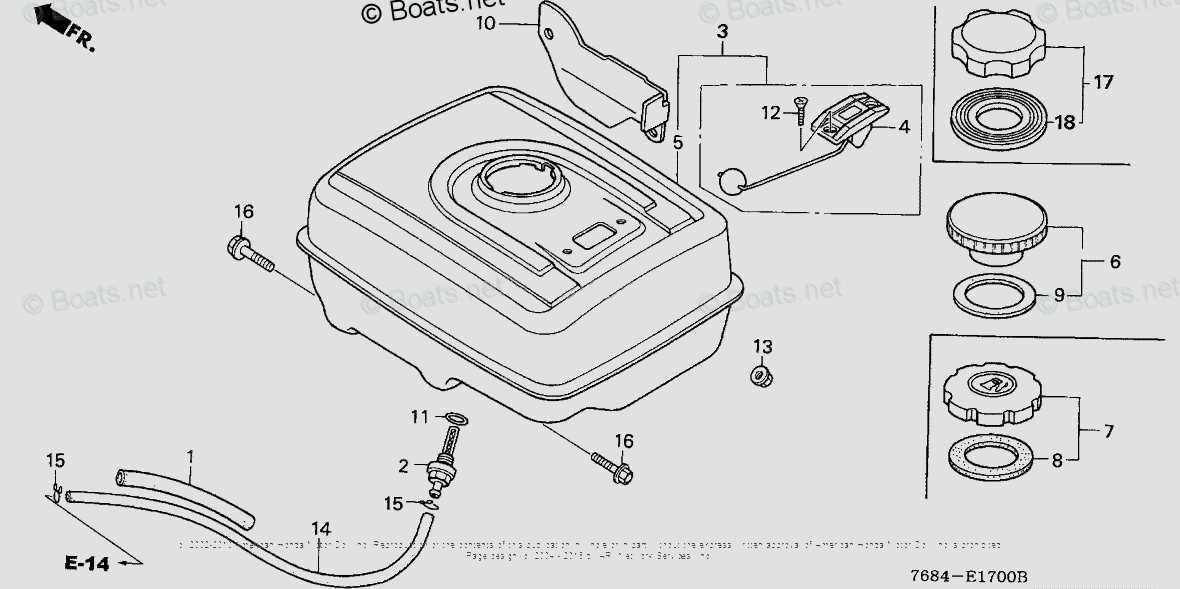

The fuel system in a small engine is crucial for its performance and efficiency. It consists of various components that work together to ensure the proper delivery of fuel to the combustion chamber. Understanding the arrangement and function of these elements is essential for effective maintenance and troubleshooting.

Key Components of the Fuel System

Central to the fuel delivery process is the fuel tank, which stores

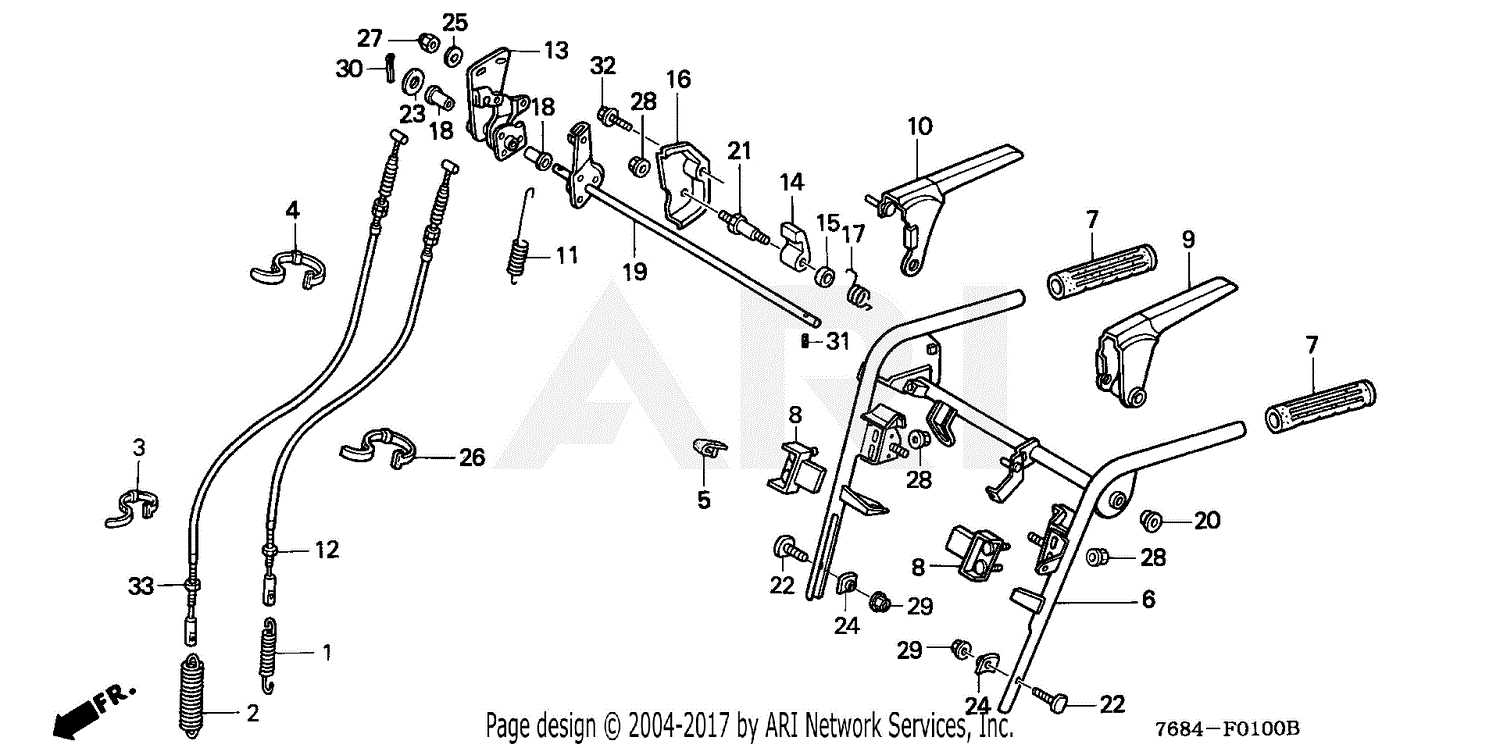

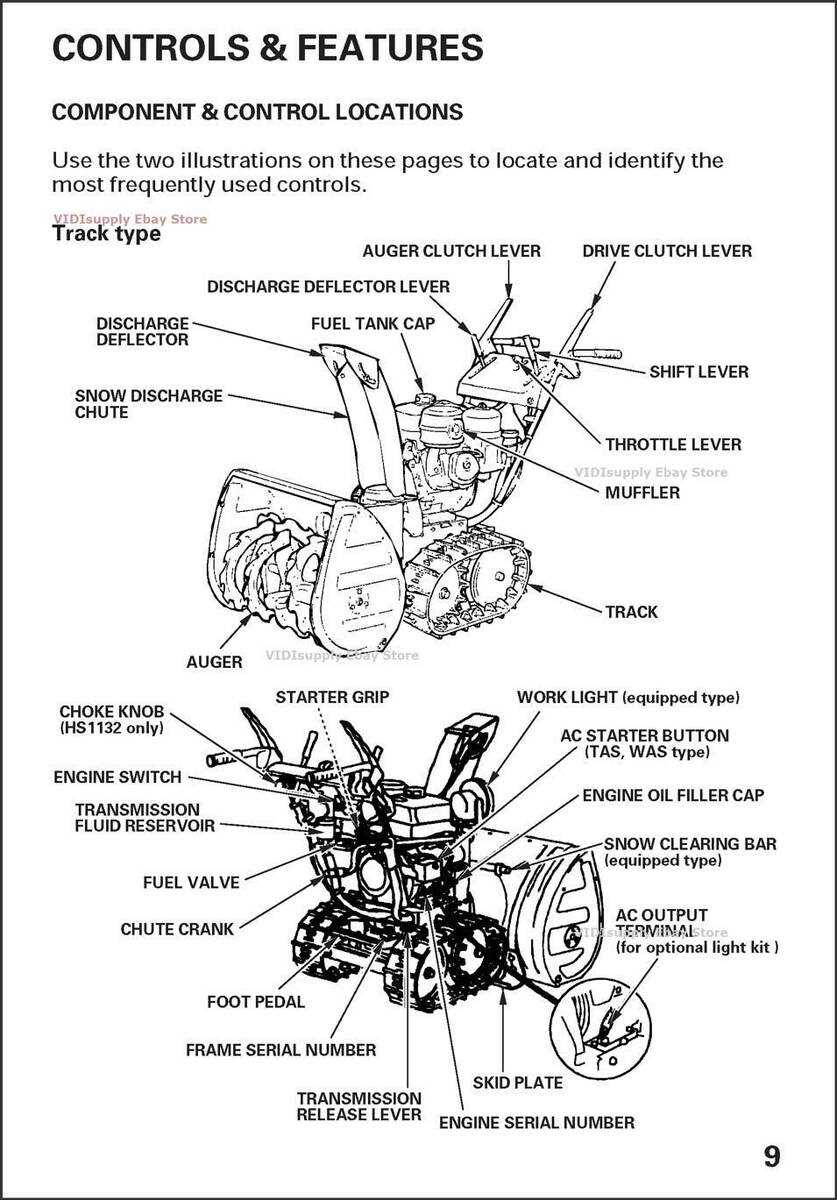

Controls and User Interface

The interface and operational controls of this snow-clearing machine are designed to enhance user experience, ensuring ease of operation and efficient functionality. Each component plays a vital role in the seamless interaction between the operator and the equipment.

Key Control Features

- Throttle Control: Adjusts the engine speed for optimal performance based on varying conditions.

- Auger Control: Engages and disengages the auger for effective snow removal.

- Chute Direction: Allows for precise adjustment of snow discharge direction.

- Wheel Lock: Provides stability during operation on uneven surfaces.

User Interface Elements

- Control Panel: Centralized display that provides essential information about machine status.

- Indicator Lights: Visual alerts for maintenance needs and operational conditions.

- Ergonomic Handles: Designed for comfortable grip and maneuverability during use.

- Foot Pedals: Simplifies control of movement and auger activation.

Blower Housing and Shielding

The blower housing and its protective components play a crucial role in the overall functionality of the equipment. These elements are designed to effectively contain and direct the airflow generated by the motor, ensuring optimal performance during operation.

Proper shielding is essential to prevent debris and other particles from entering the internal mechanisms, which could lead to potential damage or reduced efficiency. The materials used in the construction of the housing are typically durable and resistant to wear, providing longevity and reliability.

Additionally, the design of the housing allows for easy access to internal components for maintenance and repair, ensuring that users can keep the equipment running smoothly. Regular inspection of the housing and shielding is recommended to identify any signs of wear or damage that could affect performance.

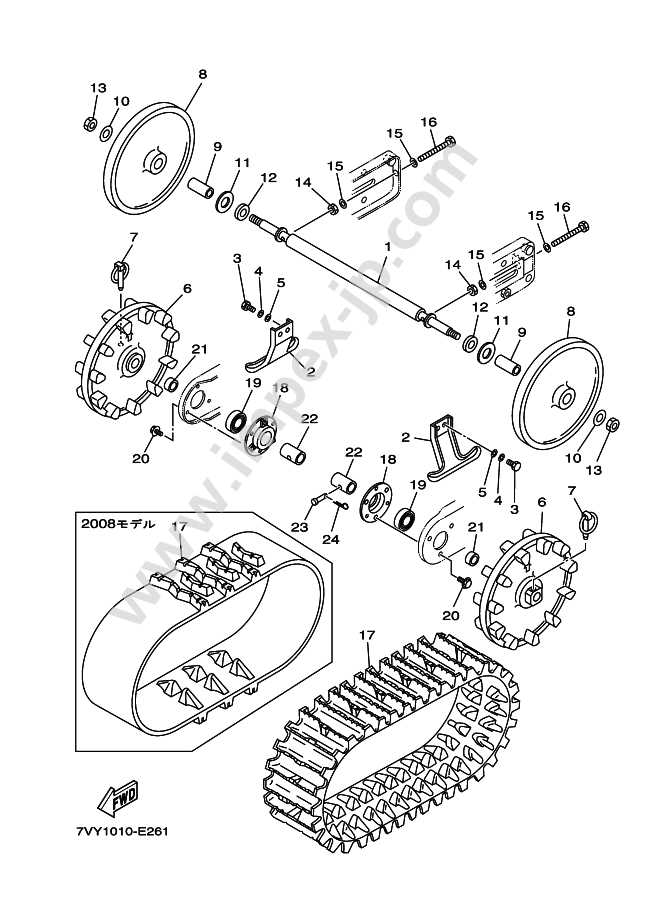

Track and Wheel Assembly Breakdown

The assembly responsible for mobility is crucial for the overall performance of snow removal equipment. Understanding its components and their functions can enhance maintenance and repair efforts, ensuring optimal functionality in various conditions.

Here is an overview of the key elements involved in the assembly:

- Tracks: These components provide traction and stability, designed to navigate through snow and uneven surfaces effectively.

- Wheels: Supporting the structure, they enable movement and assist in steering the unit, playing a vital role in maneuverability.

- Drive Mechanism: This system connects the engine to the tracks, transferring power efficiently to ensure smooth operation.

- Track Tensioner: This device maintains the appropriate tension on the tracks, preventing slippage and enhancing performance.

- Bearings: Essential for reducing friction, these components allow smooth rotation of wheels and facilitate effortless movement.

Regular inspection and servicing of these parts can significantly extend the lifespan of the assembly, ensuring reliable performance during operation.

Electrical System and Wiring Diagram

This section provides an overview of the electrical components and their connections within the machine. Understanding the layout and functionality of these elements is crucial for effective maintenance and troubleshooting.

The electrical system comprises various parts that work together to ensure optimal performance. Familiarity with the wiring layout helps in identifying issues and making necessary repairs.

Component Description Function Battery Storage unit for electrical energy Powers the ignition system and other electrical components Starter Motor Device that initiates engine operation Engages the engine to begin operation Ignition Coil Transformer that generates high voltage Provides spark for fuel ignition Wiring Harness Group of wires connecting components Facilitates electrical flow between parts Fuse Safety device protecting the circuit Prevents overload by breaking the circuit Exhaust System and Muffler Assembly

The exhaust system plays a crucial role in directing gases away from the engine, ensuring optimal performance and reducing noise. This assembly is designed to effectively manage emissions while providing a quieter operation, enhancing the overall efficiency of the equipment.

The key components of the exhaust system include:

- Exhaust Pipe: Facilitates the flow of exhaust gases from the engine to the muffler.

- Muffler: Reduces noise produced by the engine’s exhaust process, helping to create a more pleasant operating environment.

- Gaskets: Provide a seal between components, preventing leaks and ensuring proper functionality.

- Mounting Brackets: Secure the exhaust system in place, reducing vibration and wear.

Maintaining the integrity of the exhaust assembly is vital for peak performance. Regular inspections can help identify any issues, such as corrosion or damage, that may affect efficiency. Proper care ensures longevity and optimal operation.

Maintenance Parts and Service Tips

Ensuring optimal performance and longevity of your outdoor equipment requires regular attention to specific components and best practices. A proactive approach to upkeep not only enhances functionality but also prevents potential breakdowns and costly repairs. This section provides essential insights into necessary elements and effective servicing strategies to maintain your machinery in peak condition.

Essential Components for Regular Maintenance

Identifying and utilizing the right components for maintenance is crucial. Regularly inspecting and replacing wear items can significantly improve the performance and reliability of your equipment. Below is a table outlining key elements to focus on during routine checks:

Component Function Replacement Frequency Belts Transmit power to various systems Every 50 hours of use Filters Clean air and fuel for optimal combustion Every 100 hours of use Blades Cutting and shredding materials effectively As needed, check for wear Fluids Lubrication and cooling Check and replace seasonally Service Techniques for Longevity

Adopting specific techniques during servicing can prolong the lifespan of your equipment. Cleaning and lubricating moving parts, checking for loose connections, and adjusting tension on belts can prevent issues before they arise. Regularly scheduled maintenance checks, combined with a keen eye for detail, will keep your machinery running smoothly.

Replacement Parts and Ordering Guide

When it comes to maintaining and repairing your outdoor equipment, understanding how to acquire suitable components is crucial. This section provides insights into sourcing essential elements that ensure the longevity and efficiency of your machinery.

Identifying Essential Components

Before placing an order, it’s vital to identify the specific elements needed for your equipment. Utilize manufacturer resources or consult your local supplier to ascertain the correct specifications and ensure compatibility with your device.

Ordering Process

Once you’ve identified the required components, you can proceed with the ordering process. It’s advisable to compare prices from various suppliers to obtain the best deals. When placing an order, provide accurate details, including part numbers and descriptions, to avoid delays and ensure you receive the correct items promptly.

Note: Always verify the credibility of the supplier and consider purchasing from authorized dealers to guarantee the quality and authenticity of the components.