In the realm of outdoor equipment, having a comprehensive grasp of the various elements that make up your device is essential for effective maintenance and repair. A detailed exploration of these components not only aids in troubleshooting but also enhances the longevity and performance of your tool. Whether you’re a seasoned user or a novice, familiarizing yourself with the inner workings can lead to more informed decisions and successful outcomes.

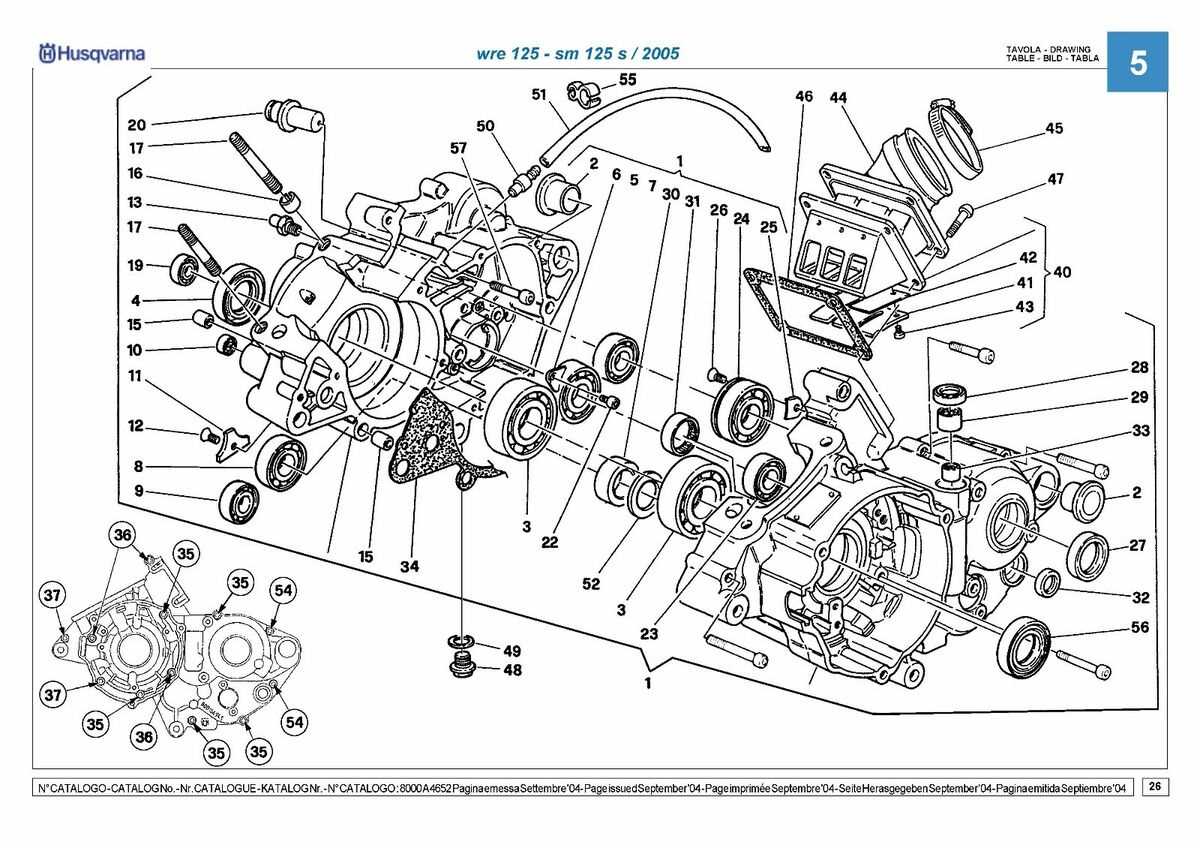

Visual aids play a crucial role in demystifying the assembly and functionality of these machines. By dissecting the intricate relationships between different parts, users can better understand how to operate and care for their equipment. This knowledge empowers users to tackle repairs with confidence, ensuring optimal efficiency in their outdoor tasks.

As we delve deeper into the subject, you will find an organized overview of the essential components, providing an ultimate reference guide for maintenance and assembly. Equipped with this information, you can approach your outdoor endeavors with renewed assurance and skill.

Understanding Husqvarna 125L Components

This section aims to provide an insightful overview of the essential elements that contribute to the functionality and performance of a popular outdoor tool. By exploring each component, users can enhance their knowledge and maintenance skills.

- Engine: The heart of the machine, providing power for operation.

- Fuel System: Responsible for the delivery of fuel to the engine, ensuring efficient combustion.

- Cutting Mechanism: Includes the blade or line, crucial for achieving desired cutting results.

- Handle Assembly: Designed for user comfort and control during operation.

- Starter Mechanism: Facilitates the initial ignition of the engine, often involving a pull cord or electric start.

Each component plays a significant role in the overall effectiveness of the tool, and understanding them can lead to better performance and longevity.

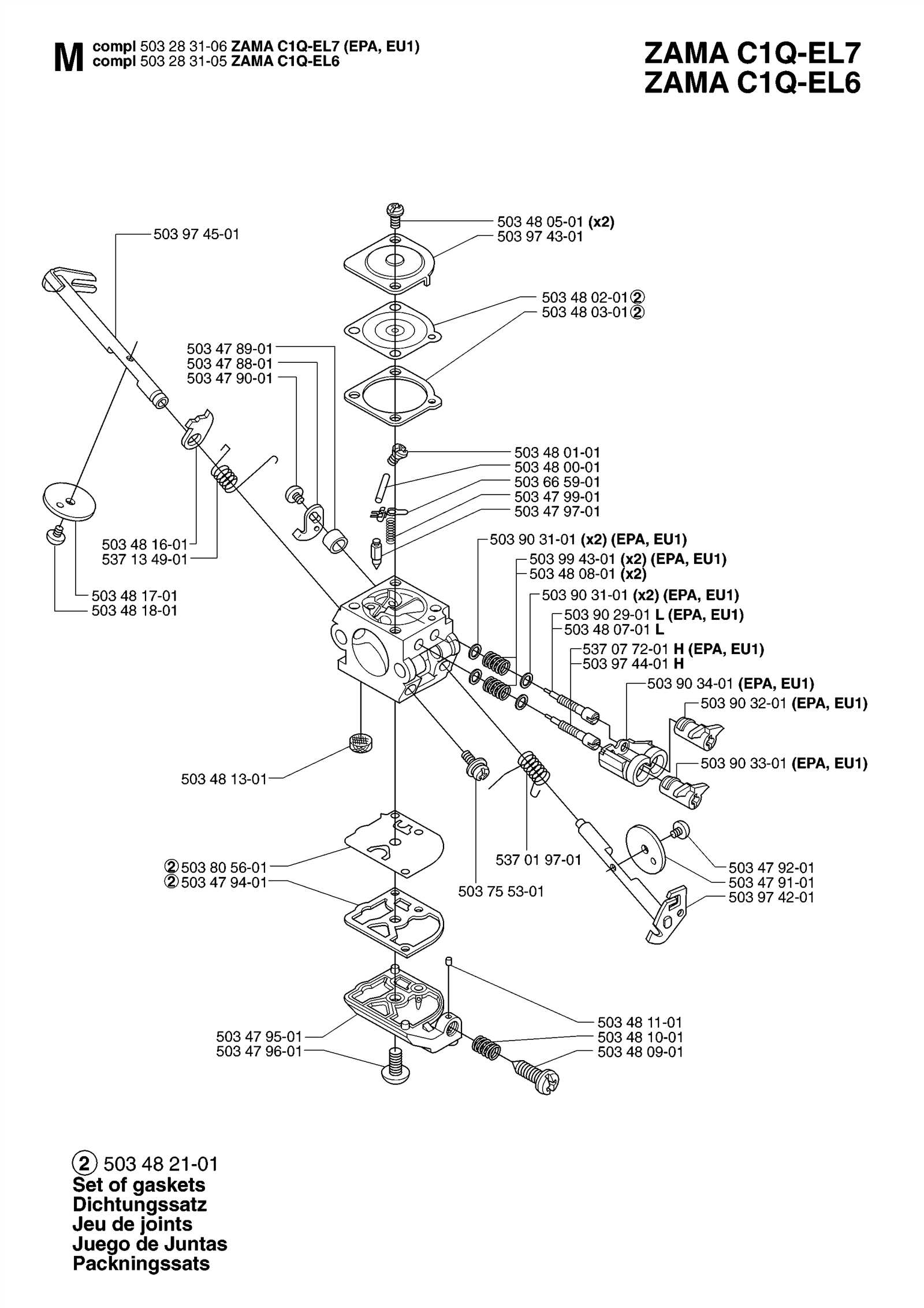

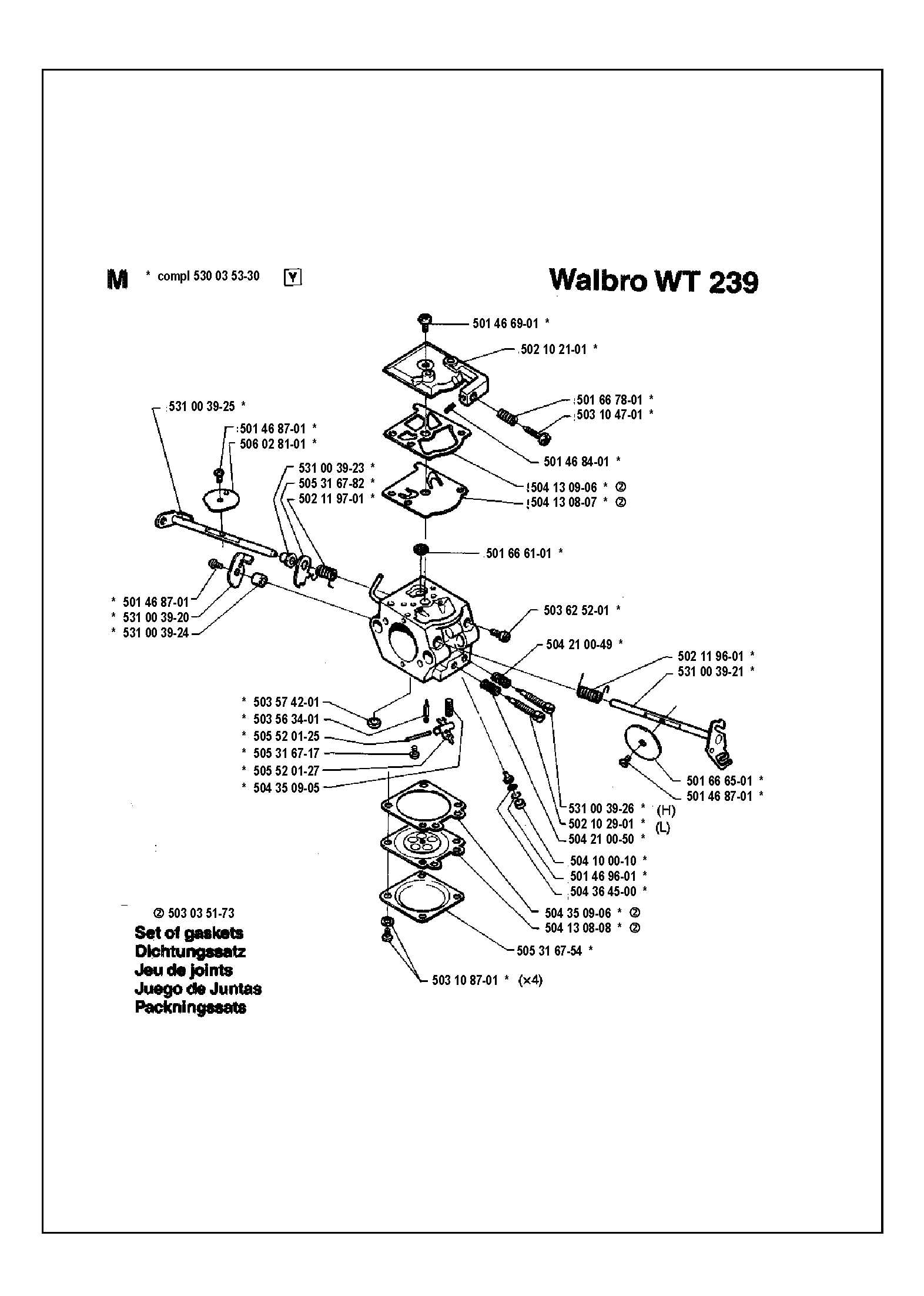

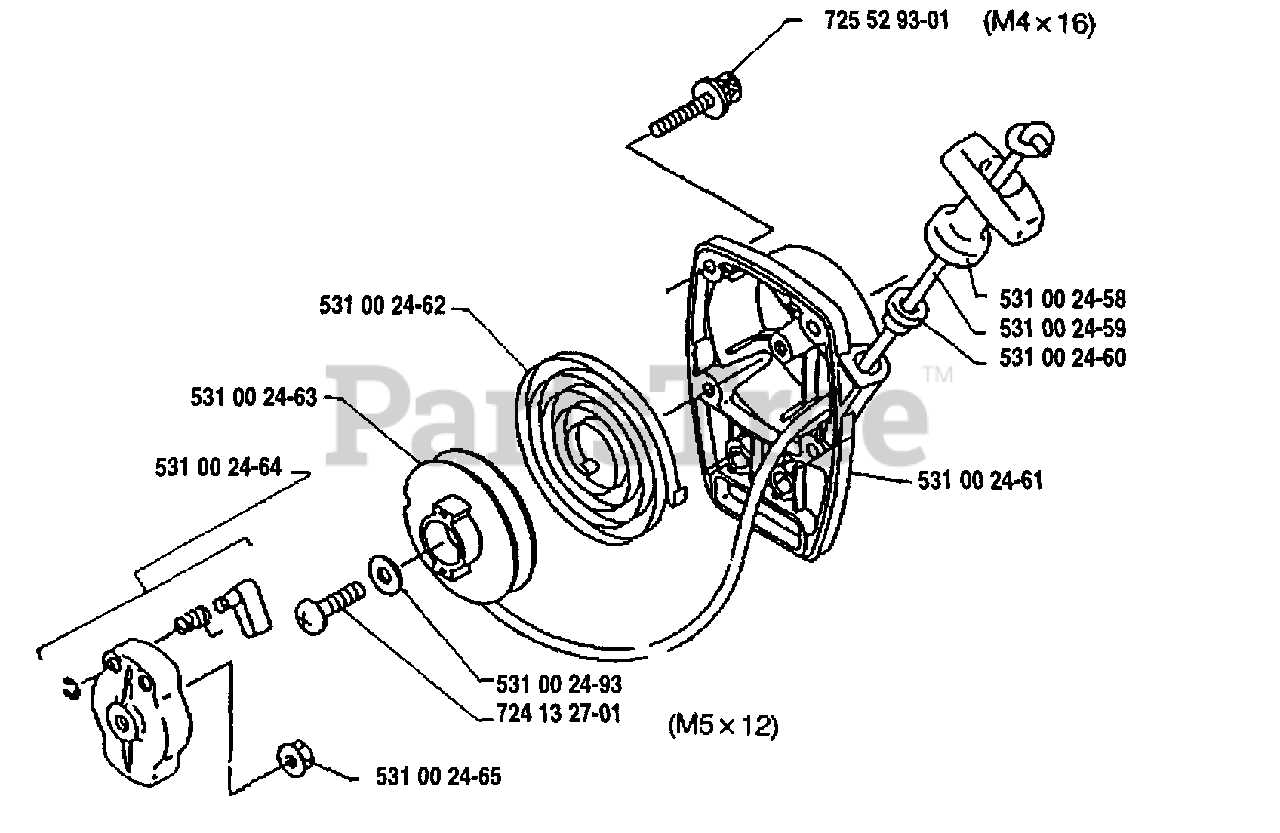

Importance of Parts Diagrams

Understanding the intricate components of machinery is crucial for maintenance and repair. Visual representations serve as essential tools, aiding users in grasping the structure and functionality of various elements.

These illustrations offer several key benefits:

- Enhanced clarity in identifying each component.

- Streamlined troubleshooting processes.

- Facilitation of efficient reassembly after repairs.

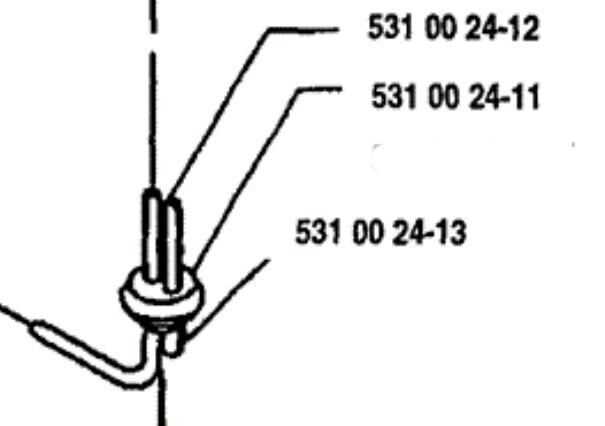

- Assistance in ordering the correct replacements.

Ultimately, having access to these visuals empowers users to delve deeper into the upkeep of their equipment, ensuring longevity and optimal performance.

Common Issues with the 125L

When using outdoor power equipment, users often encounter several recurring problems that can hinder performance and efficiency. Understanding these common challenges is essential for maintaining optimal functionality and ensuring longevity.

One prevalent issue is difficulty in starting the engine, which may stem from fuel delivery problems or spark plug malfunctions. Regular maintenance of fuel lines and filters can mitigate this concern. Another frequent complaint involves overheating, often caused by debris clogging the air intake or improper oil levels. Keeping these areas clean is crucial to prevent engine strain.

Additionally, users might experience vibration or noise, typically indicative of loose components or worn parts. Inspecting and tightening all screws and bolts can alleviate these disturbances. Lastly, fuel mix ratios can lead to performance problems if not properly followed, emphasizing the importance of adhering to manufacturer recommendations.

How to Access the Diagram

Obtaining a visual representation of the components of your equipment can greatly enhance your understanding and maintenance capabilities. This section outlines the steps needed to locate and view these essential illustrations effectively.

- Visit the official website of the manufacturer.

- Navigate to the support or service section.

- Look for links related to documentation or resources.

- Use the search function to enter the model or type of your device.

- Locate the technical documents or schematics available for download.

In addition to the manufacturer’s website, consider these alternative sources:

- Authorized dealers or repair shops may provide hard copies or digital resources.

- Online forums and communities dedicated to equipment maintenance often share valuable insights and visuals.

- Video tutorials on platforms like YouTube may include walkthroughs that highlight parts and assembly.

Ensuring you have the correct visual aids will simplify repairs and enhance your overall experience with your device.

Essential Maintenance Tips

Regular upkeep is crucial for ensuring the longevity and efficiency of your outdoor equipment. By following a few straightforward practices, you can enhance performance, minimize wear, and prevent costly repairs. Consistent attention to maintenance not only keeps your tool in top shape but also contributes to safety during operation.

Routine Inspections

Conducting periodic checks of your machine is vital. Look for any signs of wear and tear, including frayed cables, loose screws, or damaged components. Early detection of issues can save you from more extensive repairs later. Always ensure that the equipment is clean, as debris can hinder its functionality.

Proper Lubrication and Storage

Keeping moving parts well-lubricated is essential for smooth operation. Use the appropriate lubricants as specified in the user manual. Additionally, proper storage is key to maintaining the integrity of your tool. Store it in a dry, sheltered place to protect it from moisture and extreme temperatures. This practice will prolong the lifespan of various components and ensure reliable performance.

Replacing Worn Out Parts

Maintaining equipment in optimal condition is crucial for performance and longevity. Over time, components can wear out, leading to decreased efficiency and potential breakdowns. Regularly assessing these elements ensures smooth operation and minimizes costly repairs.

Identifying Worn Components

Start by examining each section of the machine for signs of wear, such as unusual noises, reduced power, or visible damage. Key indicators often include fraying, discoloration, or any form of physical degradation.

Replacement Process

Once worn components are identified, the replacement process involves several steps. Ensure you have the correct replacements on hand and follow a systematic approach for installation to guarantee proper functionality.

| Component | Signs of Wear | Recommended Action |

|---|---|---|

| Blade | Chipping, dullness | Replace with new blade |

| Filter | Clogging, discoloration | Install a fresh filter |

| Fuel Line | Cracking, leaks | Replace with new line |

Tools Required for Repairs

When it comes to performing maintenance or fixing equipment, having the right instruments is essential for achieving optimal results. The right tools not only facilitate the repair process but also ensure safety and efficiency. Below is a list of necessary tools that will aid in troubleshooting and repairing various components.

Essential Tools

- Wrenches: Adjustable and socket wrenches are vital for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips types are necessary for different screw types.

- Pliers: Useful for gripping, twisting, and cutting wires or small components.

- Torque Wrench: Ensures that fasteners are tightened to the correct specifications.

- Utility Knife: Handy for cutting through packaging or materials.

Additional Equipment

- Safety Gear: Always wear gloves and goggles to protect yourself during repairs.

- Cleaning Supplies: Rags and brushes help maintain cleanliness while working.

- Multimeter: Useful for checking electrical components and diagnosing issues.

- Workbench: A sturdy surface to organize tools and complete repairs effectively.

Comparing 125L to Other Models

When evaluating various trimmers, it’s essential to explore the differences and similarities between different models to find the right fit for your needs. Each design offers unique features and performance levels that can influence your choice.

Key factors to consider include:

- Engine power and efficiency

- Weight and maneuverability

- Cutting width and capability

- Ease of use and maintenance

- Durability and build quality

For example, while some models may excel in power, others might prioritize lightweight designs for better handling. By delving into these aspects, you can determine which option provides the ultimate balance for your specific tasks.

Additionally, consider user feedback and expert reviews, which can offer valuable insights into performance across different environments. This comprehensive approach will guide you toward the best selection for your landscaping needs.

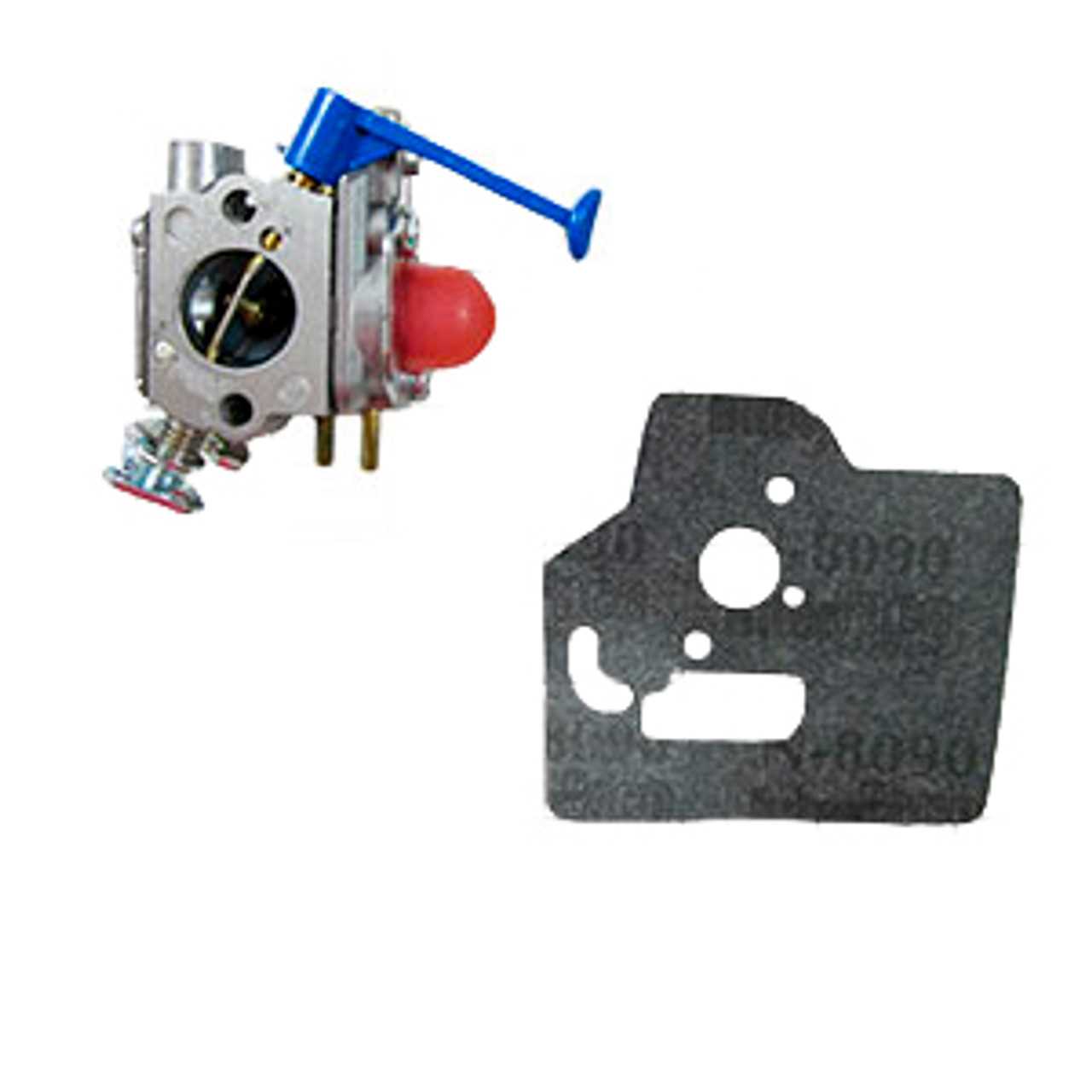

Finding Genuine Replacement Parts

When maintaining or restoring equipment, sourcing high-quality replacement components ensures optimal performance and extends the lifespan of the tool. It is essential to focus on authenticity and compatibility to avoid potential issues caused by inferior substitutes.

Where to Look for Reliable Components

- Official retailers and authorized service centers offer original replacements with guaranteed compatibility.

- Online platforms provide an extensive selection, but it is important to verify seller credibility and product authenticity through reviews and ratings.

- Second-hand markets can be a budget-friendly option, though careful inspection is crucial to ensure the component is in working condition.

Key Considerations When Selecting Replacements

- Ensure the model or serial number matches the required specifications for a seamless fit.

- Check for product warranties or return policies to safeguard against defects or incorrect orders.

- Consult user manuals or professional technicians to avoid compatibility risks with essential components.

By focusing on these guidelines, you can keep your equipment running smoothly and avoid the downtime associated with faulty or mismatched replacements.

Assembly Instructions for 125L

In this section, we provide a step-by-step guide to properly assembling your equipment, ensuring optimal performance and safety. The focus is on correctly aligning and securing the components to avoid operational issues and extend the system’s lifespan.

Required Tools and Preparation

Before starting, gather essential tools such as a wrench set, screwdriver, and lubricant. Make sure all individual parts are accounted for and arranged for easy access during the process. A clean, flat workspace is recommended to avoid misplacements.

Step-by-Step Assembly Process

Follow the instructions below carefully, checking off each step as you go. This will ensure that all components are correctly connected and aligned, reducing the risk of malfunctions.

| Step | Description | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Attach the primary shaft to the engine mount, ensuring it locks into place securely. | |||||||||||

| 2 | Install the handle assembly by aligning the grip with the support bracket and fastening it with bolts. | |||||||||||

| 3 | Insert the guard beneath the cutting head, tightening it with the screws provided. | |||||||||||

| 4 |

| Platform | Type of Information | Accessibility |

|---|---|---|

| Manufacturer’s Website | Official Documents, Updates | Free |

| Community Forums | User Advice, Practical Solutions | Free / Registration Required |

| Online Marketplaces | Replacement Components, Reviews | Paid Access |