The intricacies of machinery require a thorough understanding of their individual elements. Each component plays a vital role in ensuring optimal performance and reliability. By exploring the layout of these elements, users can gain valuable insights into maintenance and troubleshooting.

Visual representations of machinery structures offer a clear perspective on how various components interact. This understanding not only facilitates easier repairs but also enhances overall functionality. When one can identify each piece’s purpose, it leads to more informed decisions regarding upkeep and enhancements.

For those looking to optimize their equipment’s lifespan, having a comprehensive view of its layout is essential. Such diagrams serve as a crucial reference, enabling users to navigate the complexities of their machinery with confidence. Engaging with this information allows for a deeper appreciation of the engineering that underpins effective operation.

Understanding Husqvarna 340 Components

To optimize the functionality of any equipment, a comprehensive understanding of its individual elements is essential. Each component plays a vital role in the overall performance, contributing to efficiency and durability. By examining these essential pieces, one can better appreciate how they interact and function together.

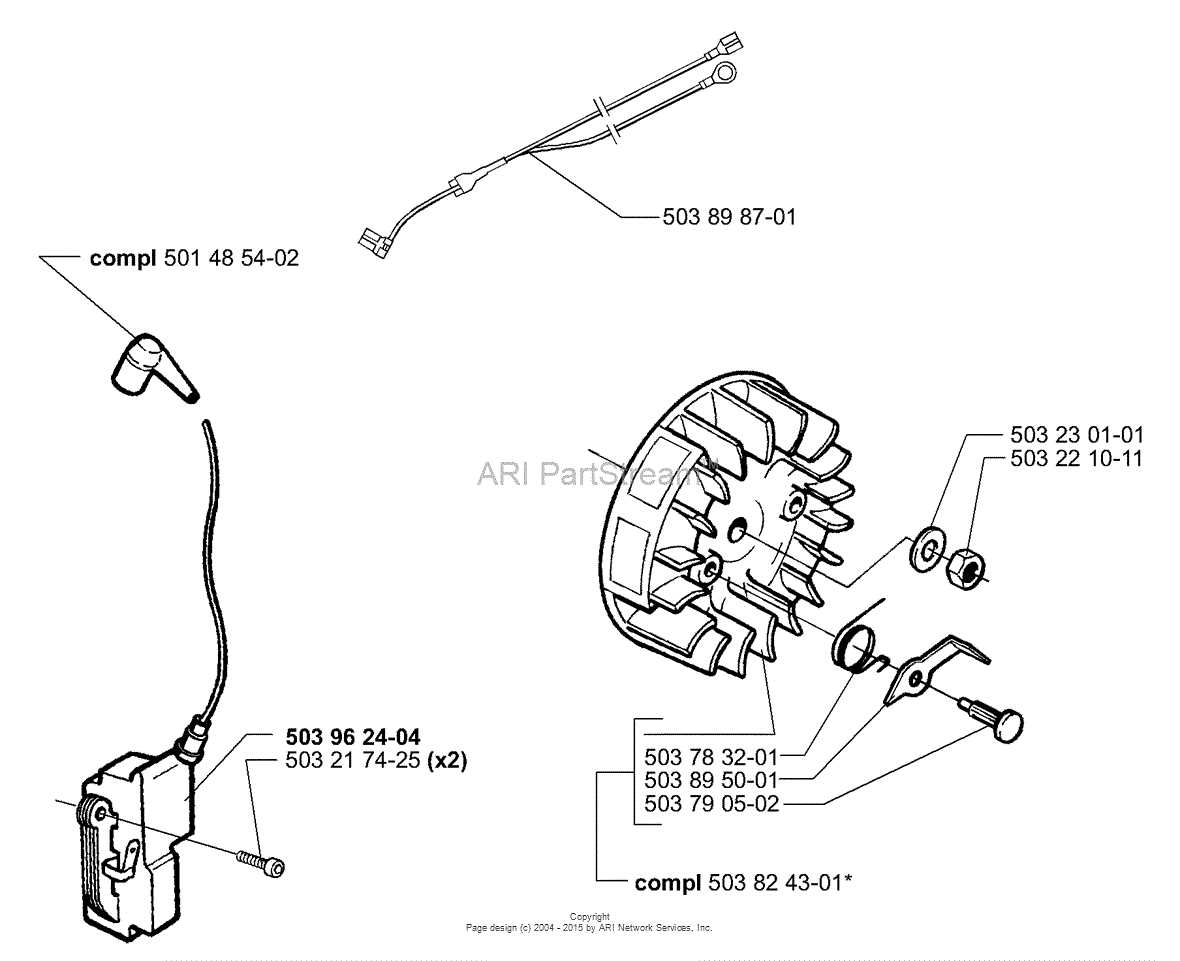

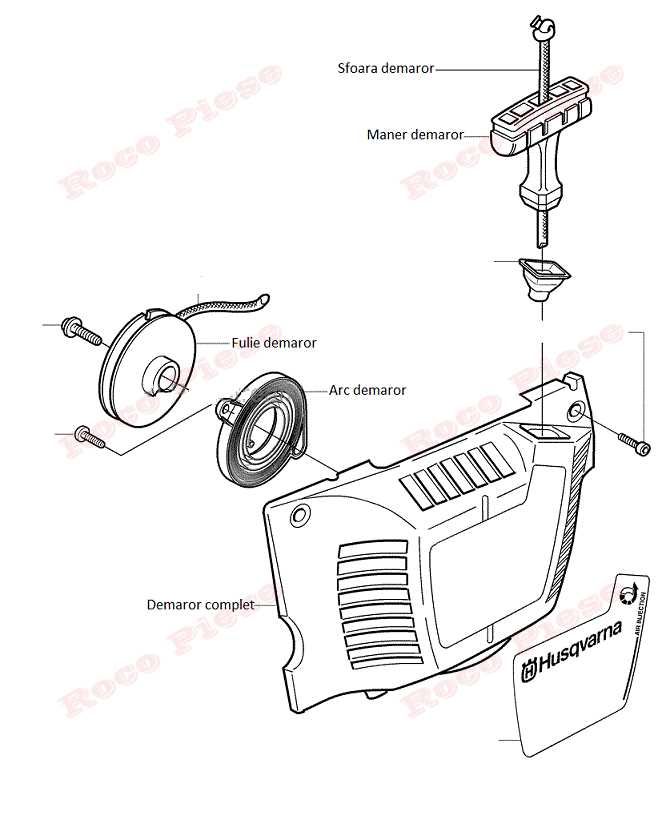

In the case of this specific model, the assembly includes various parts such as the engine, fuel system, and ignition components. Recognizing how these elements work in harmony can lead to more effective maintenance and troubleshooting practices, ensuring longevity and peak performance. Understanding the intricacies of each element allows users to maximize their operational capabilities.

Essential Parts for Optimal Performance

To achieve the best efficiency and longevity in your outdoor power equipment, understanding the critical components is essential. These elements work in harmony to ensure that the machine operates smoothly and effectively, minimizing the risk of breakdowns.

Key elements such as the engine, fuel system, and ignition play vital roles in maintaining optimal functionality. Each component contributes uniquely, ensuring that energy is generated and transmitted efficiently.

Regular maintenance of these integral parts not only enhances performance but also prolongs the lifespan of the machinery, making it a worthwhile investment for users who seek reliability and effectiveness in their tools.

Common Issues with Husqvarna 340

Every mechanical device may encounter challenges that affect its performance. Understanding these frequent problems can help users maintain efficiency and prolong the lifespan of their equipment. Below are some typical concerns associated with this specific model.

- Starting Difficulties: Users may experience trouble initiating the engine, often due to fuel-related issues or spark plug malfunctions.

- Overheating: This can result from inadequate lubrication or blockages in cooling systems, leading to potential damage.

- Vibrations: Excessive shaking may indicate worn components or improper assembly, impacting comfort during use.

- Chain Problems: A dull or misaligned cutting chain can hinder performance and requires regular inspection and adjustment.

Addressing these issues promptly can ensure smoother operation and enhance user satisfaction.

Maintenance Tips for Longevity

To ensure the enduring performance of your equipment, regular upkeep is essential. Implementing effective maintenance practices not only prolongs the life of the machine but also enhances its efficiency. By adhering to a structured maintenance routine, you can prevent unexpected breakdowns and costly repairs.

Regular Cleaning: Keeping your device clean is crucial. Dirt and debris can accumulate and lead to mechanical issues. Periodically inspect and wipe down all surfaces, paying special attention to air filters and exhaust areas. This simple task can significantly improve airflow and overall function.

Lubrication: Adequate lubrication of moving components minimizes friction, reducing wear over time. Use the recommended lubricants for your model and ensure that all parts are well-greased, especially pivot points and joints. This practice will help maintain smooth operation and prevent premature failure.

Check for Wear: Regularly examine your equipment for signs of wear and tear. Look for frayed cables, worn belts, or damaged components. Early detection of these issues allows for timely replacements, preventing further damage and ensuring safe usage.

Follow the Manual: Always refer to the manufacturer’s guidelines for specific maintenance schedules and procedures. Adhering to these recommendations ensures that you are performing the right tasks at the right intervals, keeping your machine in optimal condition.

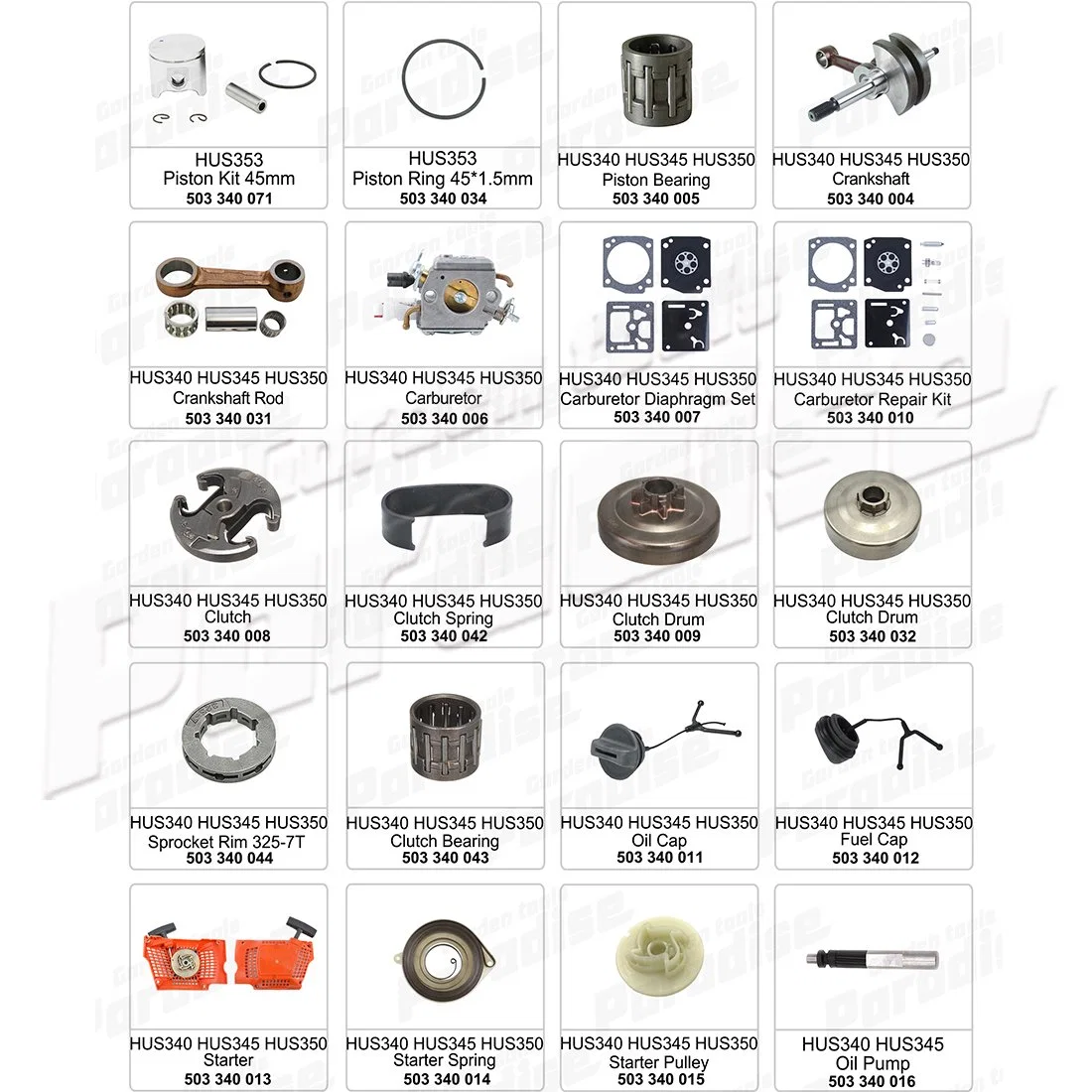

Identifying Genuine Parts and Accessories

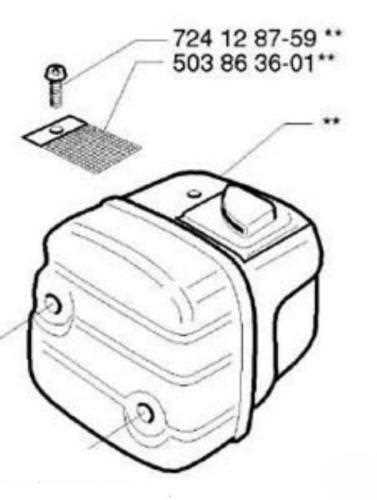

Ensuring the quality and reliability of components is crucial for optimal performance and longevity. Recognizing authentic elements can significantly enhance your equipment’s efficiency and safety. Here are key factors to consider when identifying these essential items.

- Check Packaging: Genuine components often come in branded packaging with clear labels.

- Look for Certification: Authentic items typically have certification marks or holograms.

- Inspect Quality: Genuine items are made with high-quality materials and precise engineering.

- Research Part Numbers: Verify the part numbers against official sources to ensure compatibility.

By following these guidelines, you can confidently choose the right components for your needs, ensuring the best performance of your equipment.

Step-by-Step Repair Guide

This guide provides a comprehensive approach to restoring your equipment efficiently. By following these structured steps, you can ensure that each component is carefully addressed, promoting longevity and optimal performance.

Preparation and Safety

Before starting any repair, it’s essential to prepare your workspace and gather necessary tools. Ensure that you have safety gear, such as gloves and goggles, to protect yourself during the process.

Repair Steps Overview

Follow these sequential stages to complete your repair effectively:

| Step | Description |

|---|---|

| 1 | Disconnect the power source and ensure the unit is safe to work on. |

| 2 | Inspect all components for wear and damage. |

| 3 | Replace any faulty parts using the appropriate tools. |

| 4 | Reassemble the unit carefully, ensuring all fasteners are secure. |

| 5 | Reconnect the power source and perform a functional test. |

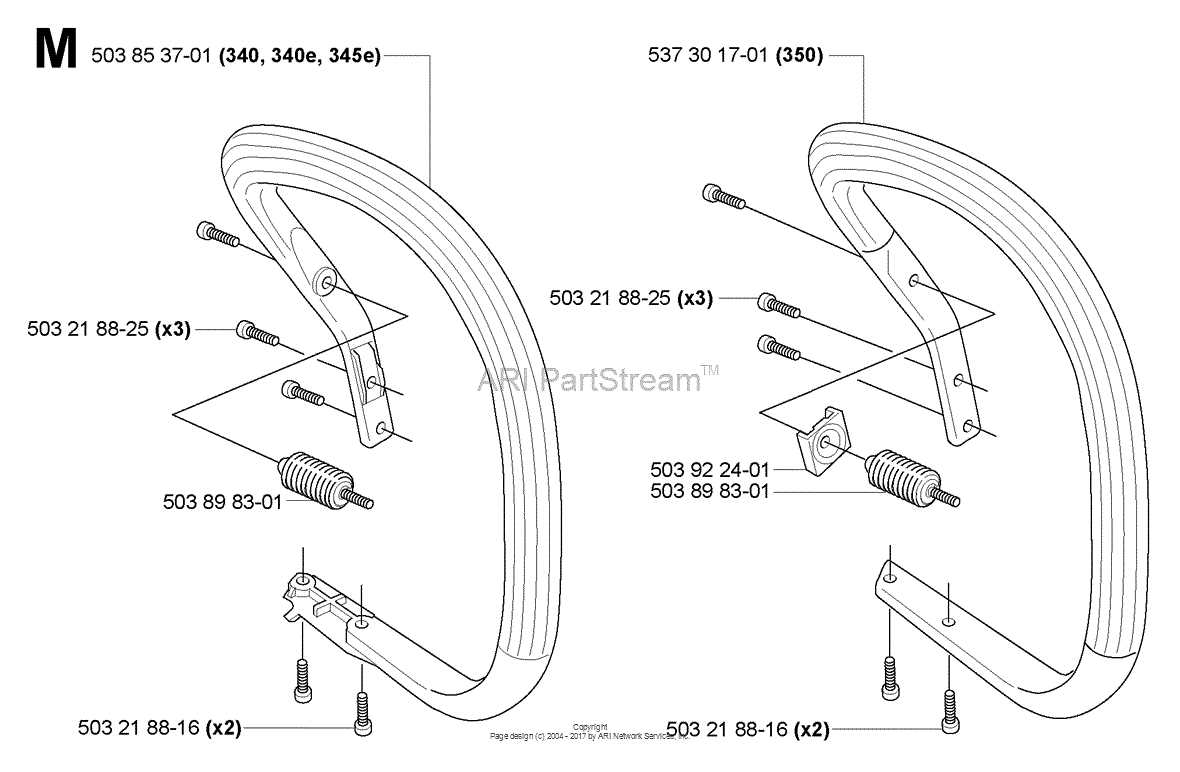

Upgrading Your Husqvarna 340

Enhancing the performance of your equipment can lead to increased efficiency and durability. By selecting high-quality components and making informed modifications, you can significantly improve its capabilities.

Consider the following upgrades:

- Engine Enhancements: Upgrading the engine components can provide more power and better fuel efficiency.

- Filtration System: Installing a superior air filter helps to keep the engine clean and can extend its lifespan.

- Chain Options: Choosing the right chain can improve cutting performance and reduce wear.

- Handlebar Grips: Upgrading to ergonomic grips enhances comfort during prolonged use.

- Safety Features: Adding modern safety features ensures a more secure operation.

Implementing these upgrades can transform your machine into a more efficient and reliable tool, ultimately enhancing your overall experience.

Safety Precautions When Repairing

When undertaking repairs on any machinery, ensuring personal safety is paramount. Adhering to specific guidelines can significantly reduce the risk of accidents and injuries during the maintenance process.

Always wear protective gear such as gloves, goggles, and masks to shield yourself from harmful debris and chemicals. Disconnecting power sources before beginning any work is crucial to prevent unexpected startups that could lead to serious harm.

Maintain a clean workspace to avoid tripping hazards, and make sure tools are in good condition. Understanding the equipment before proceeding with repairs will help you navigate potential risks effectively.

Where to Buy Replacement Parts

When seeking to restore or enhance your equipment, locating the right components is essential. Numerous avenues are available for acquiring these crucial items, each offering distinct advantages and options to suit your needs.

Online Retailers

Online platforms provide a vast selection of components, often at competitive prices. Websites dedicated to tools and machinery frequently feature detailed listings, allowing you to compare specifications and find the perfect fit for your requirements. Additionally, customer reviews can offer insights into quality and performance.

Local Dealers and Stores

Visiting local retailers can be beneficial, as it allows for immediate access to components and the opportunity to consult knowledgeable staff. Many authorized dealers maintain inventories of essential items and can assist with any specific inquiries or recommendations you may need.

Using the Parts Diagram Effectively

Maximizing the utility of an assembly illustration is crucial for efficient maintenance and repair. Understanding how to navigate this visual guide can significantly enhance your ability to identify components, troubleshoot issues, and streamline replacement procedures.

By familiarizing yourself with the layout, you can quickly locate the necessary items and comprehend their relationships within the overall system. This approach minimizes downtime and ensures that tasks are performed accurately.

| Component | Description | Common Issues |

|---|---|---|

| Chain Brake | Prevents chain movement during operation | Failure to engage |

| Fuel Tank | Holds the fuel for the engine | Leaks or cracks |

| Air Filter | Prevents debris from entering the engine | Clogging |

Comparing with Other Chainsaw Models

When evaluating various cutting tools, it’s essential to explore the distinctions between different models. Each design offers unique features that cater to specific needs, enhancing functionality and user experience.

In this section, we will highlight key differences:

- Power Output: Some models deliver greater horsepower, suitable for heavier tasks.

- Weight and Portability: Lighter designs provide easier handling, making them ideal for prolonged use.

- Chain Speed: Higher speeds improve cutting efficiency, especially in thicker materials.

- Fuel Efficiency: Certain chainsaws boast better fuel consumption, reducing operational costs.

- Maintenance Requirements: Variability in maintenance needs can influence long-term ownership satisfaction.

By understanding these differences, users can make informed decisions tailored to their specific cutting requirements.