When maintaining or repairing your outdoor power equipment, a clear understanding of its individual elements is essential. This knowledge allows for better performance and longevity of the machine, ensuring it operates at peak efficiency. Identifying each section can help users tackle common issues with ease.

In this guide, we will explore the intricate layout of a popular chainsaw model, highlighting the key components and their functions. By examining these critical parts, you can gain insights into how they work together to create a powerful tool for your cutting tasks.

Whether you’re a seasoned professional or a weekend warrior, delving into the specifics of your equipment’s structure can be the ultimate key to successful maintenance. We aim to provide you with a comprehensive overview that will enhance your understanding and proficiency in handling your chainsaw.

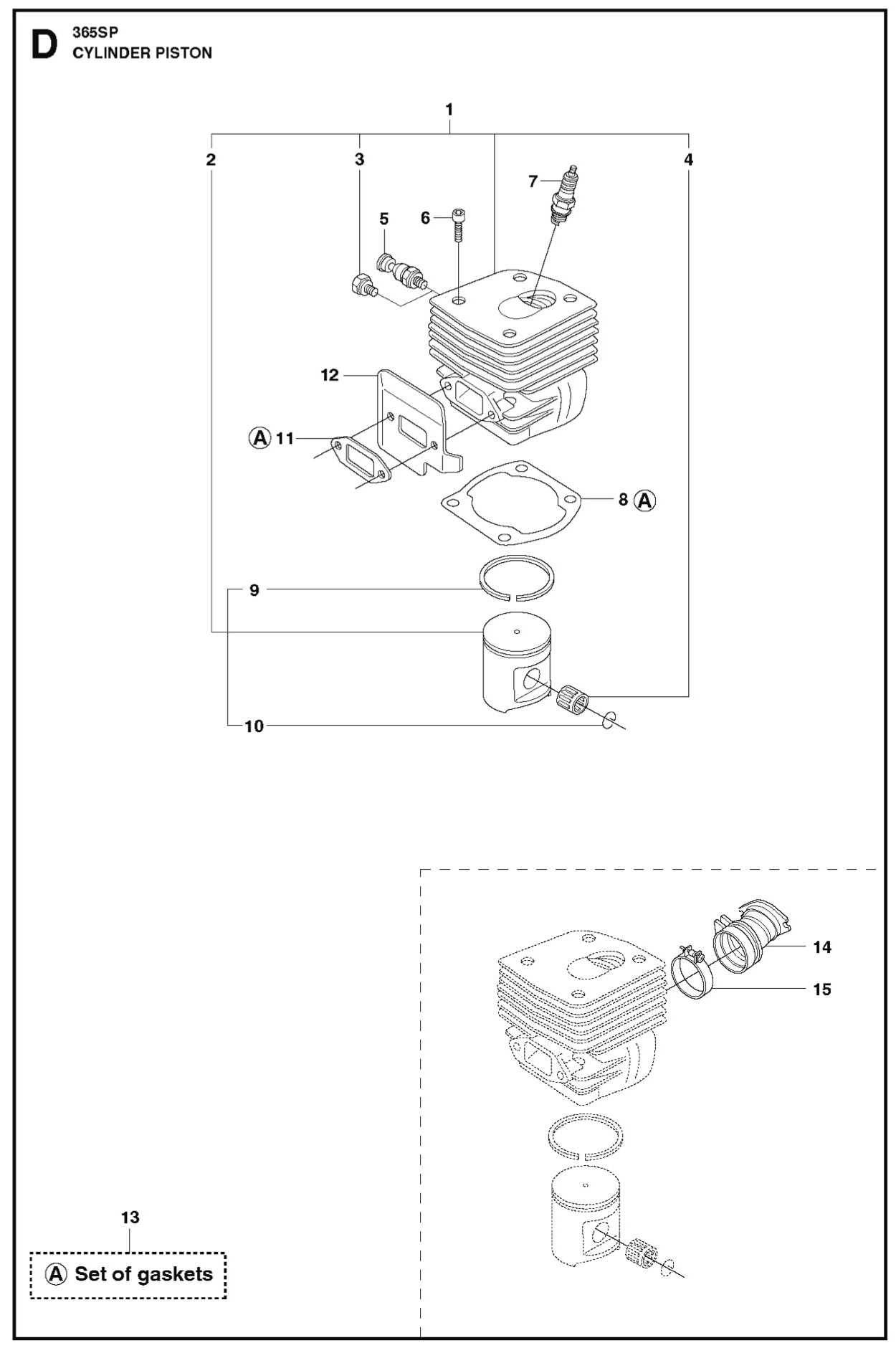

Exploring the Chainsaw Assembly Parts

Understanding the components of a cutting tool is essential for effective maintenance and operation. Each element plays a critical role in ensuring the machine runs smoothly, providing both performance and safety. This section delves into the various sections of the tool, highlighting their functions and interrelations.

| Component | Description |

|---|---|

| Engine | The heart of the machine, responsible for generating power. |

| Guide Bar | A metal strip that supports the cutting chain, guiding it during operation. |

| Cutting Chain | The sharpened loop of metal links that performs the actual cutting. |

| Clutch | Engages and disengages the chain from the engine to control operation. |

| Air Filter | Prevents debris from entering the engine, ensuring optimal performance. |

| Fuel Tank | Holds the fuel necessary for powering the engine. |

| Handle | Provides grip and control, allowing for precise maneuvering. |

By familiarizing yourself with these essential components, you can enhance both your understanding and efficiency when working with the cutting tool. Proper knowledge allows for better troubleshooting and maintenance, ultimately extending the lifespan of the equipment.

Key Features of the 365 Model

This particular model stands out for its combination of power, efficiency, and user-friendly design. It is engineered to meet the demands of both professionals and enthusiasts, making it a versatile choice for a variety of tasks.

Performance: The machine is equipped with a robust engine that delivers high output while maintaining fuel efficiency. This ensures that users can accomplish more in less time without compromising on quality.

Durability: Crafted from high-quality materials, this unit is built to withstand the rigors of frequent use. Its sturdy construction not only enhances longevity but also reduces maintenance needs.

Comfort: The ergonomic design focuses on user comfort, featuring a lightweight body and well-placed controls. This reduces fatigue during extended use, allowing for better handling and maneuverability.

Safety Features: Safety is prioritized with integrated mechanisms that minimize risks during operation. These features provide peace of mind, allowing users to focus on their tasks without distraction.

Versatility: This model is compatible with various attachments and accessories, making it adaptable for different projects. Whether for cutting, trimming, or more specialized tasks, it offers flexibility to meet diverse needs.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of your outdoor power equipment. By following a consistent maintenance routine, you can enhance performance and reduce the likelihood of breakdowns. Here are some key strategies to keep your machinery running smoothly.

Routine Inspections

- Check the air filter regularly. A clean filter ensures optimal airflow and engine performance.

- Inspect the fuel system for leaks or blockages. This prevents potential operational issues.

- Examine the spark plug for wear and carbon buildup. Replacing it as needed can improve ignition efficiency.

Cleaning and Lubrication

- Clean the exterior surfaces to prevent dirt buildup, which can lead to overheating.

- Lubricate moving parts according to the manufacturer’s recommendations to minimize friction and wear.

- Regularly check and clean the cutting mechanism to ensure precise operation.

By implementing these maintenance practices, you can maximize the effectiveness of your equipment and extend its operational lifespan.

Common Replacement Parts for Durability

Ensuring the longevity of outdoor equipment often involves replacing worn-out components. Regular maintenance and timely substitutions can significantly enhance performance and extend the life of your machinery. Understanding which elements are prone to wear can help you prepare and keep your tools in optimal condition.

Key Components to Monitor

Several critical elements should be on your radar when considering replacements. Chains, for instance, are vital for cutting efficiency; frequent use can lead to stretching or damage. Similarly, air filters play an essential role in maintaining engine health by preventing debris from causing blockages. Regular inspection and timely replacement of these parts can prevent more extensive damage down the line.

Benefits of Using Quality Replacements

Opting for high-quality replacements can make a noticeable difference in durability and performance. Authentic or premium components are designed to meet the original specifications, ensuring compatibility and reliability. Investing in superior materials may initially seem costlier, but it often leads to fewer breakdowns and lower overall maintenance costs, ultimately saving you time and effort.

Tools Required for Disassembly

When it comes to taking apart machinery for maintenance or repair, having the right tools is essential. A well-equipped toolkit ensures that the process is efficient and minimizes the risk of damage to components. Below is a list of necessary instruments that will facilitate a smooth disassembly process.

Wrenches and Sockets: A variety of wrenches, including adjustable and socket types, are vital for loosening and tightening bolts. Ensure that you have both metric and standard sizes to accommodate different fasteners.

Screwdrivers: A set of screwdrivers with both flathead and Phillips head options will be necessary for removing screws that hold various parts in place. Magnetic screwdrivers can also be beneficial for retaining screws during the process.

Pliers: Needle-nose pliers and slip-joint pliers can help grip and manipulate small components or wires, especially in tight spaces where other tools may not fit.

Torque Wrench: To ensure proper assembly after disassembly, a torque wrench is crucial for applying the correct amount of force to bolts and screws, preventing damage from over-tightening.

Safety Gear: Don’t forget protective eyewear and gloves. Safety should always be a priority when working with machinery, as it helps prevent injuries from sharp edges and flying debris.

Equipping yourself with these essential tools will pave the way for an efficient and effective disassembly, allowing for thorough inspection and maintenance of your equipment.

Identifying Worn-Out Components

Recognizing deteriorated elements is crucial for maintaining optimal performance and ensuring longevity of your equipment. Regular inspection can prevent breakdowns and enhance efficiency.

Common indicators of wear include:

- Unusual noises during operation

- Decreased performance or power

- Visible signs of damage, such as cracks or fraying

- Increased vibrations

To assess the condition effectively, consider the following steps:

- Conduct a visual inspection for obvious damage.

- Test functionality to gauge performance levels.

- Check for looseness in moving parts.

- Consult the manual for specific maintenance recommendations.

Timely identification of these issues can lead to better maintenance strategies and ultimately extend the life of your machinery.

Understanding the Fuel System Layout

The fuel delivery mechanism plays a crucial role in the overall performance of outdoor power equipment. A well-designed layout ensures that the engine receives a consistent flow of fuel, optimizing combustion and enhancing efficiency. Understanding the components and their arrangement is essential for maintenance and troubleshooting.

Key Components of the Fuel Delivery System

- Fuel Tank: The primary reservoir that stores the fuel before it enters the system.

- Fuel Filter: Prevents contaminants from entering the engine, protecting sensitive components.

- Fuel Pump: Delivers fuel from the tank to the carburetor or injector at the required pressure.

- Carburetor: Mixes fuel with air in the correct ratio for efficient combustion.

- Fuel Lines: Tubing that connects the various components, ensuring a smooth flow of fuel.

Importance of Layout in Performance

The arrangement of these elements impacts the reliability and efficiency of the system. A proper layout minimizes fuel leaks and ensures optimal pressure is maintained throughout the process. Regular checks and maintenance of these components are vital to avoid performance issues.

By familiarizing yourself with the fuel delivery architecture, you can better appreciate how each part contributes to the overall functionality and longevity of your equipment.

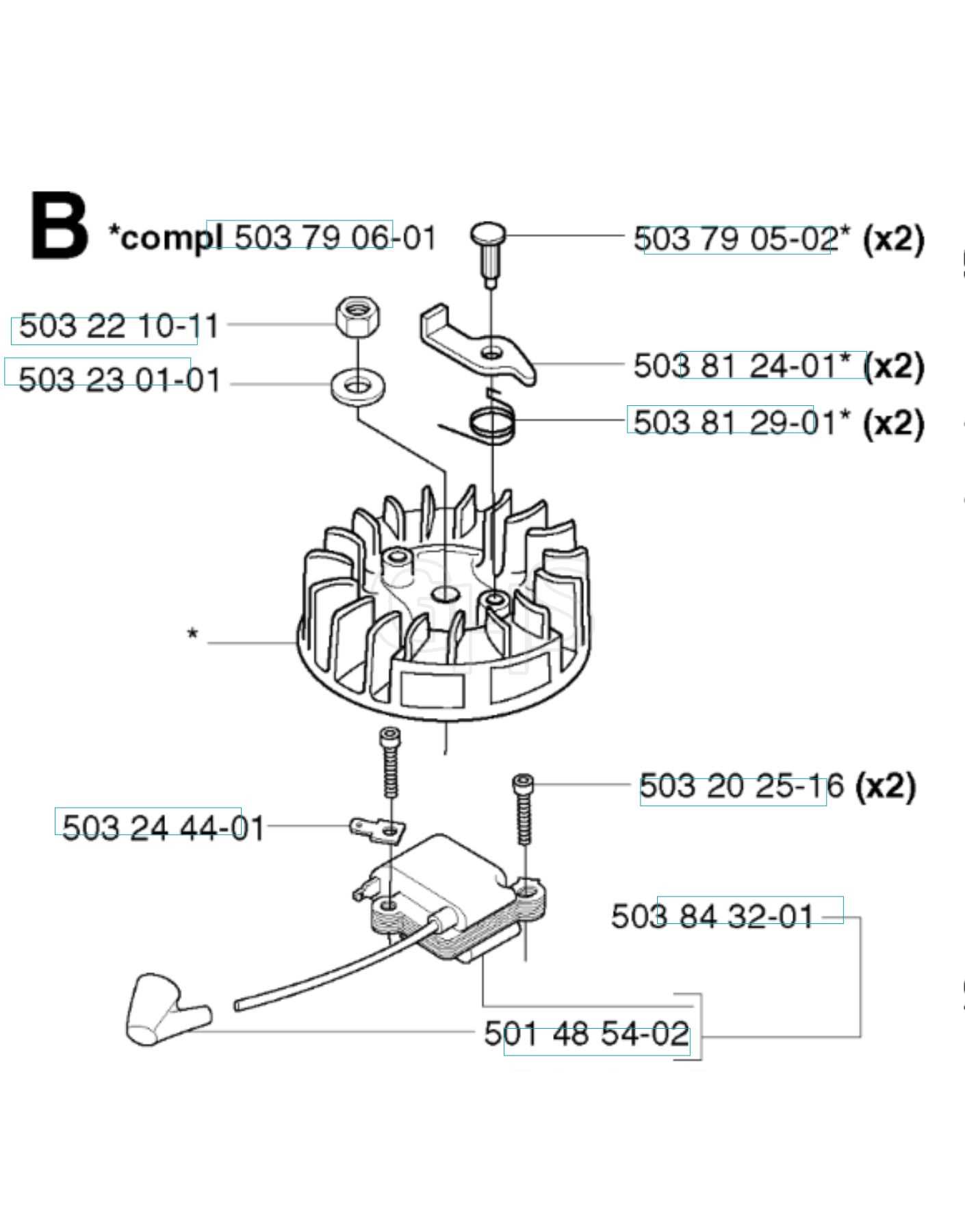

Electrical System Overview and Diagrams

The electrical system of a chainsaw plays a critical role in its functionality, ensuring smooth operation and efficiency. Understanding its components and how they interact is essential for maintenance and troubleshooting. This section provides an overview of the electrical components and their configurations, offering insights into their roles within the machinery.

Key Components of the Electrical System

- Ignition Coil: Responsible for generating the spark needed to ignite the fuel mixture.

- Starter Motor: Engages to start the engine, providing the necessary torque.

- Battery: Supplies power to various electrical components and systems.

- Wiring Harness: Connects all electrical parts, facilitating communication and power distribution.

- Switches: Control the operation of different electrical components, enhancing user convenience.

Basic Wiring Configuration

The wiring configuration in a chainsaw is designed to ensure that electrical signals flow smoothly between components. A simplified overview of the typical layout includes:

- The ignition coil is linked to the spark plug, allowing for combustion.

- The starter motor is connected to the battery, enabling engine initiation.

- Wiring routes connect switches to various components, allowing for control over the system.

- Ground connections ensure safety by preventing electrical faults.

Understanding this layout can assist in diagnosing issues and performing repairs effectively, ensuring optimal performance of the equipment.

Finding OEM Parts and Accessories

When it comes to maintaining outdoor equipment, sourcing original components and add-ons is crucial for ensuring optimal performance and longevity. Utilizing genuine items not only guarantees compatibility but also enhances the overall reliability of the machine. This section explores effective strategies for locating authentic replacements and enhancements.

Online Retailers: Numerous online platforms specialize in offering original components. By visiting these websites, you can easily browse through a wide selection, often accompanied by detailed descriptions and specifications.

Authorized Dealers: Connecting with certified dealers is another excellent approach. These establishments often provide expert guidance and can assist in locating the exact item you need, ensuring it meets the manufacturer’s standards.

Manufacturer’s Website: Many manufacturers maintain comprehensive online resources where you can search for authentic items. These sites typically include catalogs and support tools to help you find the right match for your equipment.

Forums and Community Groups: Engaging with fellow enthusiasts in online forums or local community groups can be beneficial. Members often share valuable insights about where to find original items, along with recommendations based on their own experiences.

Maintenance and Repair Shops: Local service centers may stock genuine components or be able to order them for you. Their expertise can also provide guidance on which items will best suit your needs.

By leveraging these resources, you can confidently procure authentic components and accessories, ensuring your equipment remains in top condition for years to come.

Step-by-Step Assembly Instructions

Assembling your outdoor equipment can seem daunting, but with the right guidance, it becomes a straightforward task. This section provides a detailed, step-by-step approach to ensure that each component is correctly fitted, enhancing both functionality and safety. Follow these instructions carefully for optimal results.

Preparation and Tools

Before starting, gather all necessary tools, including a screwdriver, wrench, and any specific items indicated in the assembly guide. Ensure that you have all components laid out in an organized manner. This preparation will streamline the process and reduce the chances of misplacing parts.

Assembly Steps

Begin with the base assembly, securing it firmly as the foundation of your unit. Next, attach the main body, ensuring all connections are tight. Follow by integrating additional components, such as the handle and guard, in the order specified. Double-check each connection to ensure they are secure before proceeding to the next step. Finally, inspect the entire assembly for any loose parts or misalignments, making adjustments as necessary.