The intricate makeup of a powerful device reveals the engineering behind its functionality and efficiency. Understanding how each component interacts contributes to a greater appreciation of its performance capabilities. This exploration delves into the various elements that form the backbone of a reliable and effective tool.

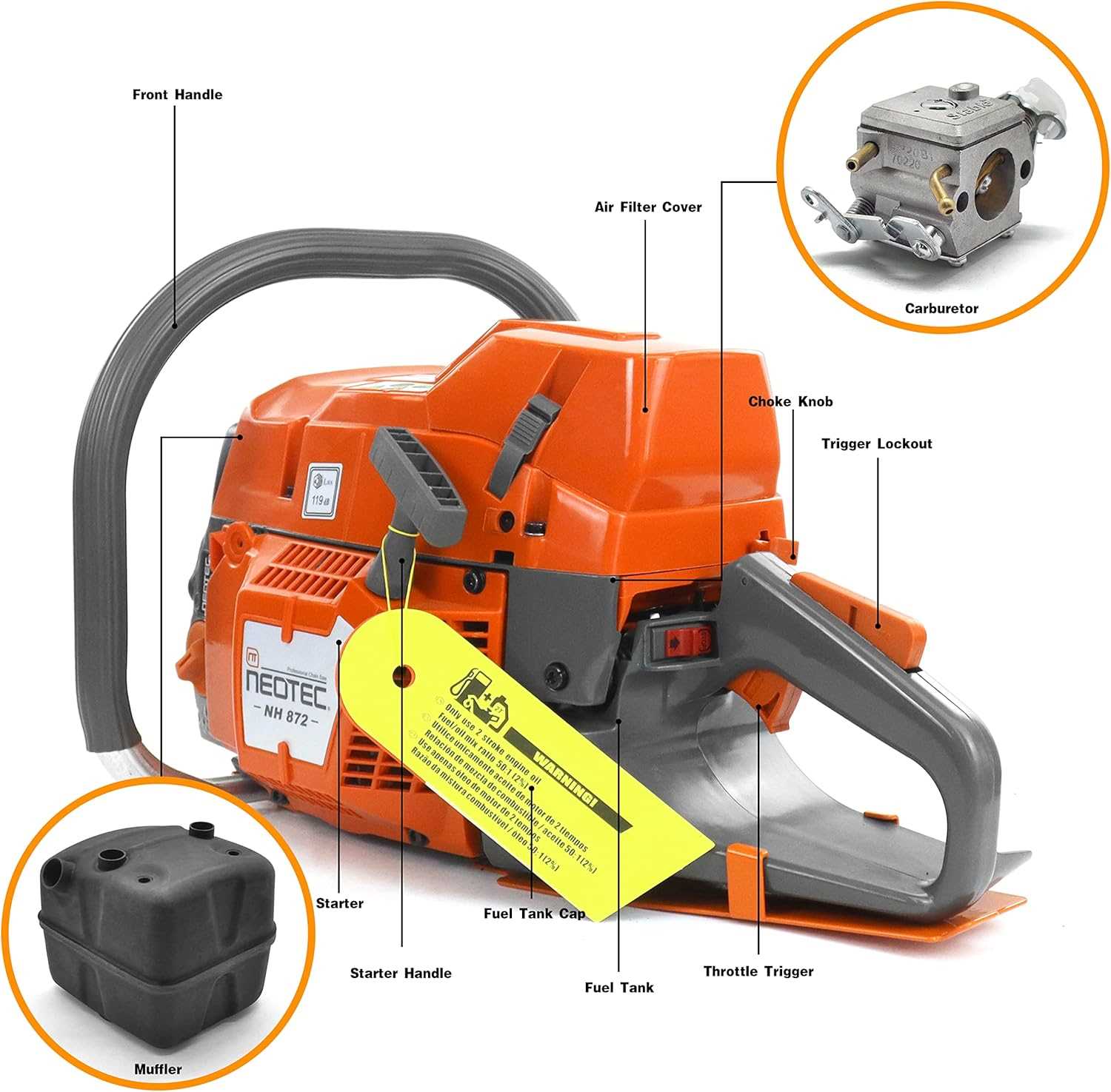

Visual representations of these components provide valuable insights into their arrangement and functionality. By examining the layout, users can identify essential parts and their respective roles, aiding in both maintenance and troubleshooting. Such clarity enhances the overall experience, ensuring that the machine operates smoothly and effectively.

Knowledge of the internal structure not only aids in repairs but also empowers users to make informed decisions about upgrades and replacements. Recognizing how specific pieces contribute to the overall mechanism is crucial for maximizing performance and longevity. This guide aims to illuminate these aspects, enhancing the user’s understanding of their essential equipment.

Key Components of the 372xp Chainsaw

Understanding the essential elements of a chainsaw is crucial for effective operation and maintenance. Each component plays a significant role in the overall functionality, ensuring that the tool performs efficiently and reliably during use.

One of the primary parts is the engine, which powers the device and enables it to cut through various materials. Additionally, the guide bar is vital, providing the path for the chain to follow while cutting. The chain itself is another key element, featuring sharp teeth designed to facilitate quick and clean cuts.

Moreover, the fuel system is essential for supplying the necessary energy to the engine, while the ignition system ensures that the engine starts smoothly. Another critical component is the clutch, which engages and disengages the chain, allowing for safer operation.

Lastly, the handling system, including grips and safety features, enhances user comfort and control, making the chainsaw easier to manage during various tasks. Together, these elements contribute to the overall effectiveness and safety of the equipment.

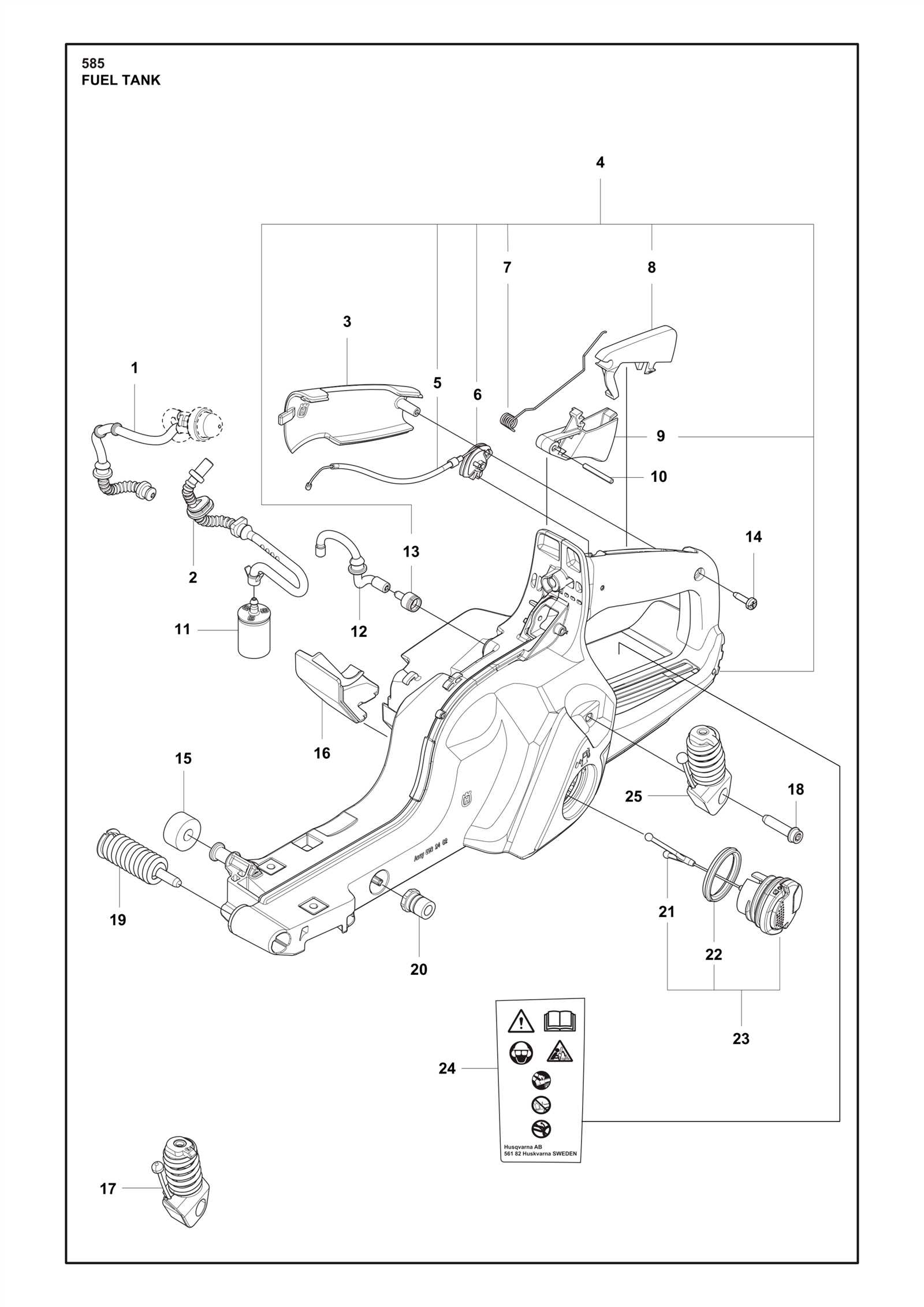

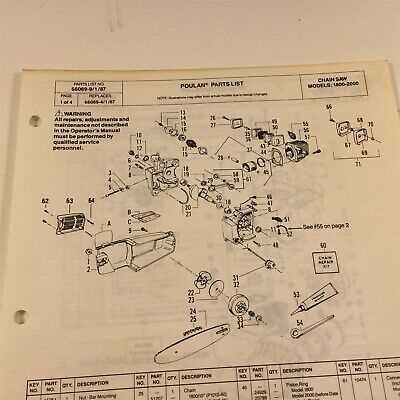

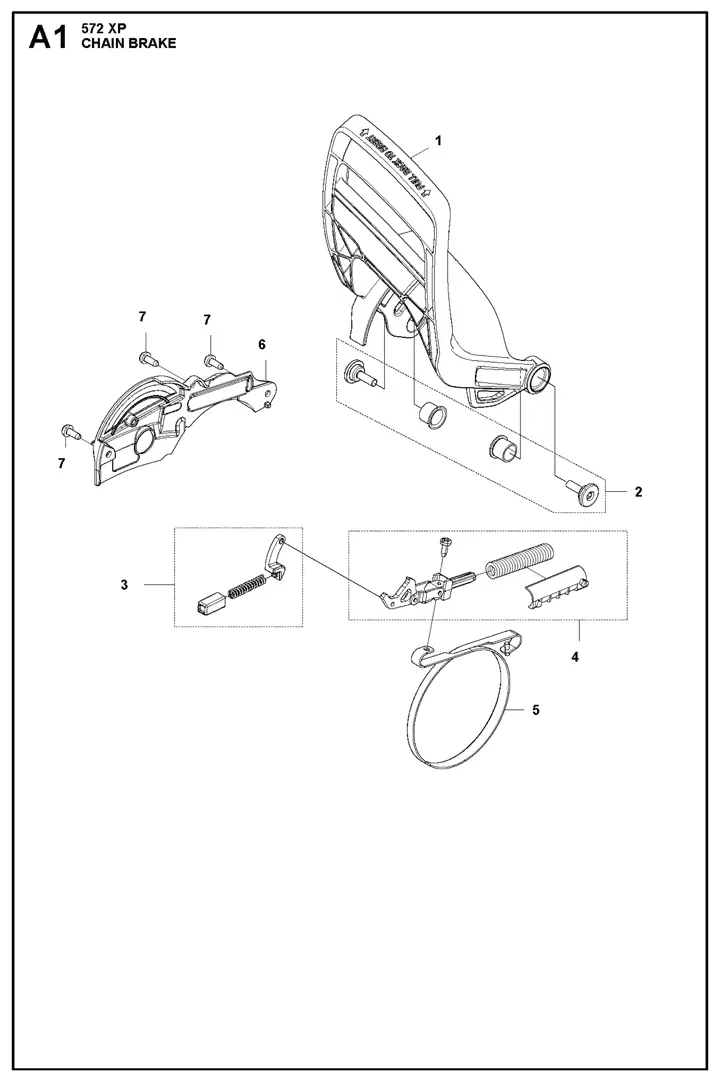

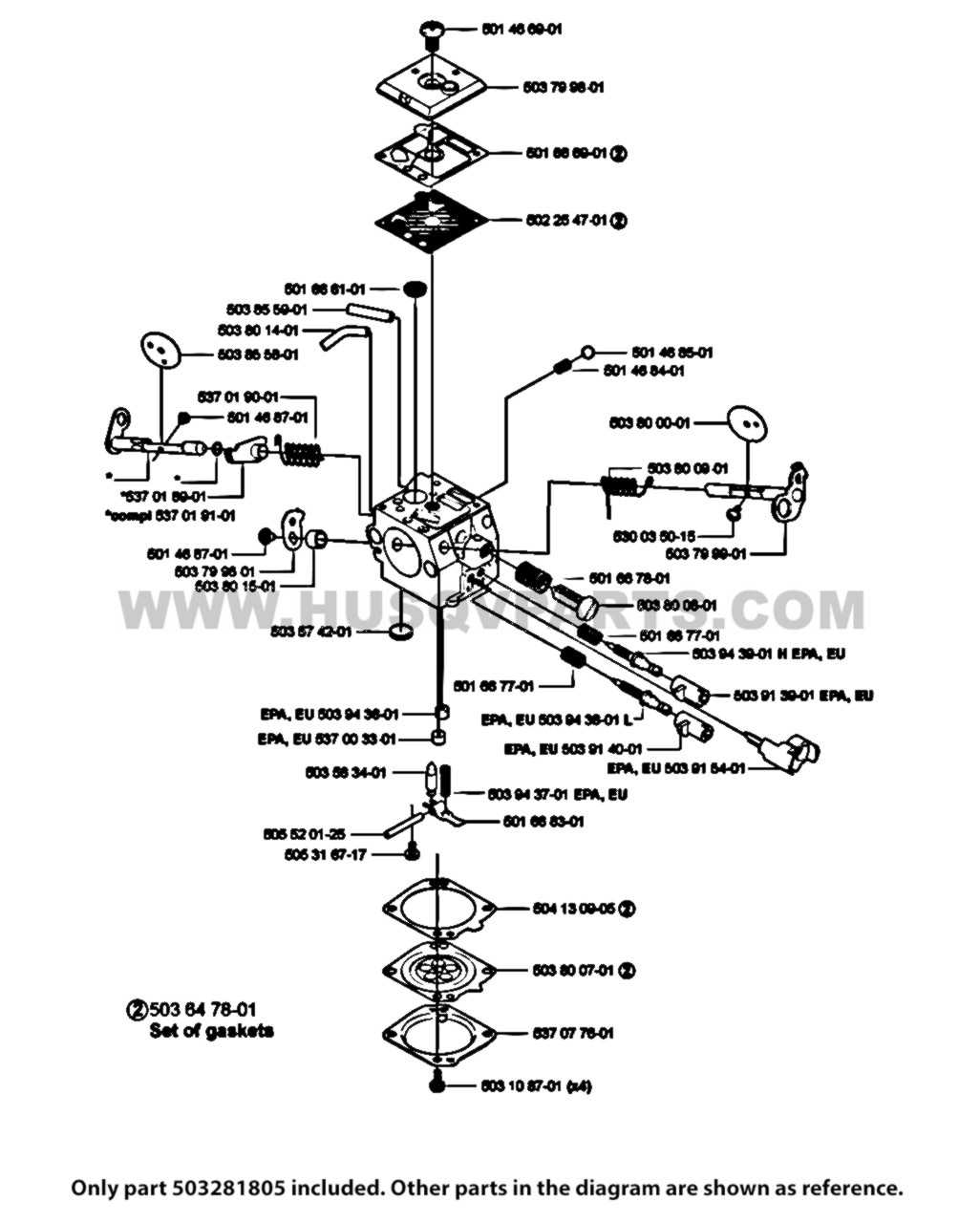

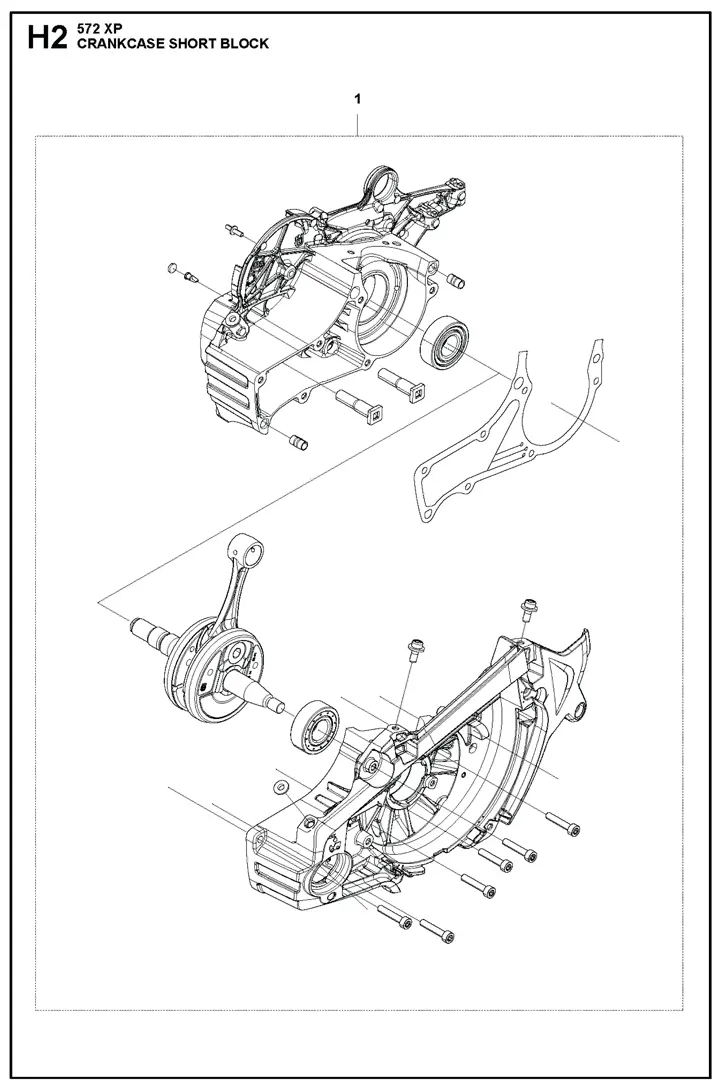

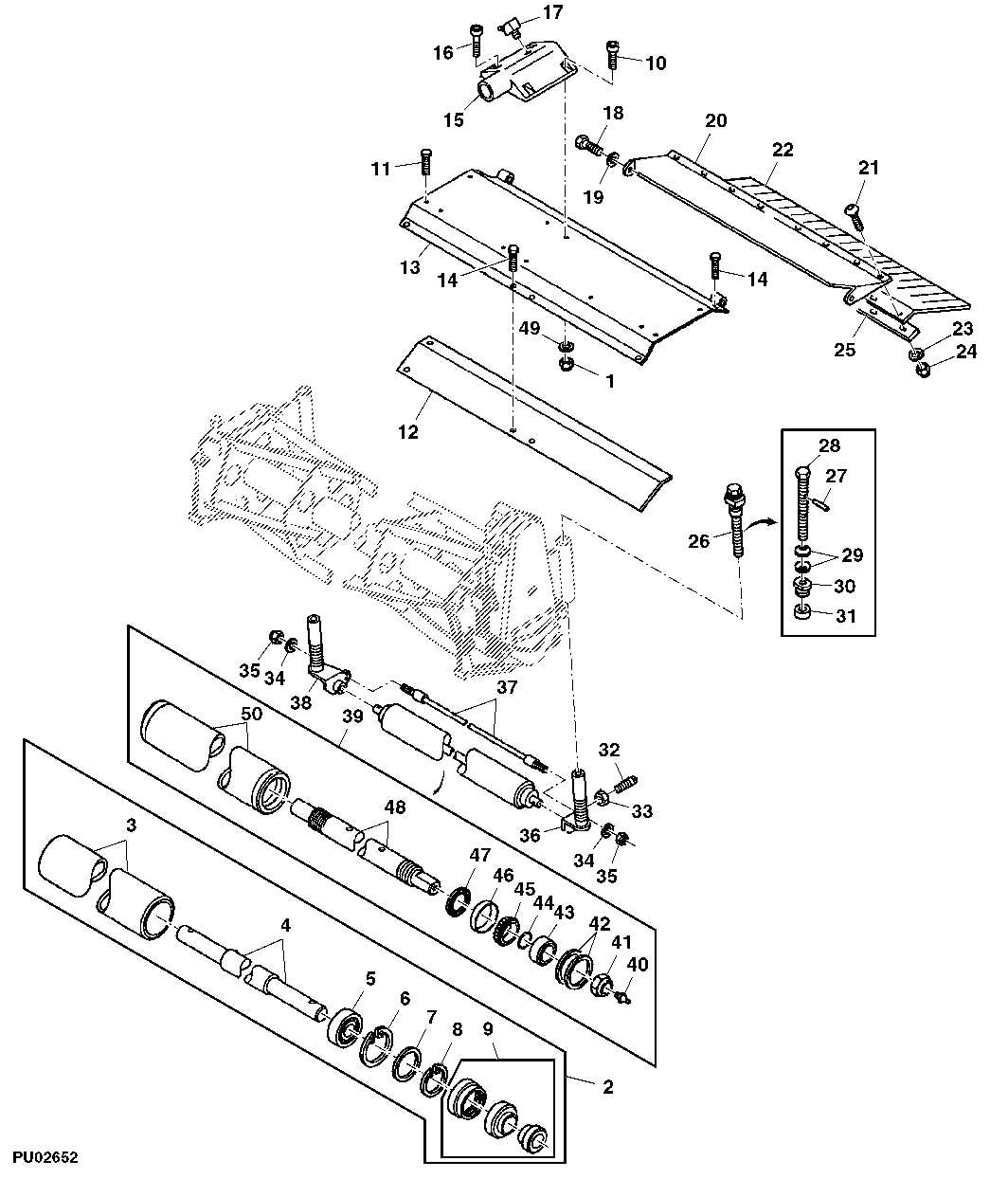

Exploring the Parts Diagram Overview

This section provides an insightful look into the visual representation of component layouts for a specific type of equipment. Understanding this overview is essential for anyone looking to grasp the intricate details of assembly and maintenance.

Importance of Understanding Component Layouts

Comprehending how various elements are interconnected enhances one’s ability to perform repairs effectively. Each illustration serves as a valuable reference for identifying and locating specific components, ensuring that any tasks are carried out with precision.

Key Features of Component Representations

These visual guides typically include labels and numbers that correspond to each part, making it easier for users to follow along during maintenance or assembly. Below is a simplified table illustrating some of the common features found in such representations:

| Feature | Description |

|---|---|

| Labeling | Each element is clearly marked for easy identification. |

| Numbering | Sequential numbers assist in locating parts in manuals or catalogs. |

| Connection Lines | Lines indicating how components interact or fit together. |

Essential Tools for Disassembly

To effectively dismantle mechanical devices, having the right tools is crucial. The appropriate instruments not only facilitate a smoother process but also ensure the integrity of components during disassembly. Below is a list of necessary tools that will assist in achieving an efficient and organized breakdown.

- Screwdrivers: A variety of sizes and types, including flathead and Phillips, are essential for removing screws.

- Wrenches: Adjustable wrenches and socket sets are useful for loosening bolts and nuts of different sizes.

- Pliers: Needle-nose and standard pliers help in gripping and maneuvering small parts.

- Hammer: A rubber mallet is ideal for gently tapping parts apart without causing damage.

- Pick Set: These tools are useful for removing O-rings and seals that may be hard to reach.

- Safety Goggles: Protecting your eyes during disassembly is paramount, especially when working with springs or fragile components.

Utilizing the correct tools will make the disassembly process more efficient and safe, allowing for a thorough inspection and maintenance of the device.

How to Identify Each Part

Recognizing the various components of a machine is crucial for effective maintenance and repairs. By understanding the distinct features and functions of each element, users can ensure proper operation and longevity of their equipment. This section will guide you through the process of identifying essential components, making it easier to troubleshoot issues and perform necessary replacements.

Common Components and Their Functions

Each section of the equipment serves a specific role, contributing to its overall performance. Familiarity with these roles aids in quick identification and problem-solving.

| Component Name | Description |

|---|---|

| Engine | The core unit that powers the device, responsible for converting fuel into mechanical energy. |

| Fuel Tank | Holds the fuel required for operation, usually designed for easy filling and monitoring. |

| Chain Brake | A safety feature that stops the chain quickly, preventing accidents during use. |

| Guide Bar | The metal strip that supports the cutting chain, influencing cutting performance. |

Visual Identification Tips

To accurately identify each element, examine their shapes, sizes, and positions within the machinery. Utilizing images or diagrams can greatly enhance understanding, providing a visual reference to complement written descriptions.

Common Issues and Solutions

When operating machinery, encountering difficulties is not uncommon. Understanding the typical problems that may arise, along with their corresponding solutions, can significantly enhance performance and longevity. This section aims to highlight frequent challenges users face and provide effective remedies.

Engine Fails to Start

If the engine does not start, the issue might stem from various factors. Common causes include an empty fuel tank, a faulty spark plug, or a clogged air filter. Ensure the fuel tank is filled, check the spark plug for wear, and clean or replace the air filter to restore functionality.

Excessive Vibration

Unusual vibrations during operation can indicate loose components or imbalanced parts. Inspect all fasteners to ensure they are securely tightened. Additionally, examine the blades or cutting components for any signs of damage or misalignment, as these may contribute to the problem.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan of any equipment. By implementing regular care routines and addressing issues promptly, users can significantly enhance performance and durability.

Regular Cleaning: Keeping the exterior and interior components clean prevents the buildup of debris that can affect functionality. Ensure to remove dirt, dust, and any other particles after each use.

Routine Inspections: Conduct frequent assessments of critical parts to identify wear and tear. Checking for signs of damage or excessive wear can help in making timely repairs and replacements.

Lubrication: Applying appropriate lubricants to moving parts minimizes friction and reduces the risk of overheating. Ensure to use the recommended products for optimal performance.

Storage Practices: Properly storing the equipment in a dry, sheltered area protects it from environmental factors. Consider covering it with a protective cover to prevent dust accumulation.

Timely Repairs: Addressing issues as soon as they arise can prevent minor problems from escalating into major failures. Keep a lookout for unusual sounds or performance issues and resolve them immediately.

By following these maintenance practices, users can ensure that their equipment remains reliable and efficient for years to come.

Replacement Parts and Compatibility

When maintaining and repairing equipment, understanding the options for replacement components is essential for optimal performance. Ensuring that each part is compatible with the specific model can enhance functionality and longevity, preventing potential issues during operation.

Key Considerations for Compatibility

- Model specifications: Always refer to the manufacturer’s guidelines for the correct specifications.

- Component quality: Choose high-quality substitutes to maintain efficiency and safety.

- Compatibility verification: Double-check if the new parts are designed for your specific equipment model.

Common Replacement Options

- Air filters: Regularly replacing air filters ensures optimal airflow and engine performance.

- Chains and bars: Select chains and bars that match the required length and pitch for efficient cutting.

- Spark plugs: Replacing spark plugs can improve ignition and overall engine responsiveness.

Where to Purchase Original Parts

Acquiring authentic components for your equipment is essential for maintaining its performance and longevity. There are various avenues available to ensure that you obtain high-quality items that meet the manufacturer’s standards.

One effective option is to visit authorized dealers who specialize in selling genuine replacements. These establishments often provide a wide selection of items that are specifically designed for optimal compatibility. Additionally, they can offer expert advice on the right components for your needs.

Online platforms dedicated to tool accessories can also be valuable resources. These websites frequently stock a comprehensive range of original replacements, allowing you to compare prices and availability from the comfort of your home. Be sure to verify the credibility of the online store to ensure you are purchasing reliable products.

Another practical approach is to connect with local repair shops that focus on similar equipment. These businesses typically have access to authentic replacements and can assist in sourcing the necessary items for your repair projects.

In summary, whether you opt for physical retailers or online marketplaces, prioritizing original components is vital for ensuring the efficiency and durability of your machinery.

Visual Guide to Parts Locations

This section provides an illustrative overview of component placements within the equipment. Understanding the arrangement of various elements can greatly enhance maintenance and repair processes. By familiarizing oneself with the layout, users can efficiently identify and access the necessary sections for troubleshooting or replacement.

| Component | Location | Description |

|---|---|---|

| Air Filter | Rear compartment | Essential for maintaining airflow and engine performance. |

| Fuel Tank | Top section | Holds the necessary fuel for operation. |

| Spark Plug | Side access panel | Ignites the fuel-air mixture for combustion. |

| Chain Brake | Front handle area | Increases safety by stopping the chain in emergencies. |

| Oil Reservoir | Bottom compartment | Stores oil for chain lubrication. |

DIY Repairs: A Step-by-Step Guide

Engaging in do-it-yourself repairs can be a rewarding experience, empowering individuals to address issues with their equipment independently. This guide will walk you through essential steps to effectively troubleshoot and repair common problems, ensuring your machinery remains in optimal condition.

Before beginning any repair process, it is crucial to gather the necessary tools and familiarize yourself with the components involved. Proper preparation will facilitate a smoother repair experience.

Preparation Steps

- Identify the symptoms of the malfunction.

- Gather the appropriate tools, such as wrenches, screwdrivers, and safety gear.

- Consult the user manual or online resources for guidance.

Repair Process

- Start by disassembling the relevant sections of the equipment carefully.

- Inspect the components for wear, damage, or any obstructions.

- Replace any faulty parts with suitable replacements.

- Reassemble the equipment, ensuring all connections are secure.

- Test the equipment to confirm that it operates as expected.

By following these steps, you can tackle repairs effectively and extend the life of your machinery. Remember, practice makes perfect, and with time, your skills will improve, making you more confident in your DIY endeavors.

Frequently Asked Questions

This section addresses common inquiries related to maintenance and components of various equipment. Understanding the essentials can enhance the performance and longevity of your tools.

General Inquiries

- What are the key components I should regularly check?

- How often should I perform maintenance on my equipment?

- What signs indicate that a replacement part is needed?

Specific Concerns

- Where can I find reliable information about spare parts?

- What is the best way to troubleshoot common issues?

- Are there any recommended upgrades for better efficiency?

Resources for Husqvarna Owners

For individuals who own outdoor power equipment, having access to reliable resources is essential for maintaining optimal performance and longevity. Various guides, manuals, and online communities provide valuable information and support, ensuring that users can address issues effectively and make informed decisions regarding repairs and upgrades.

Online Forums and Communities

Engaging with fellow enthusiasts through online forums can be an excellent way to gain insights and share experiences. These platforms often feature discussions about troubleshooting, maintenance tips, and modifications, allowing users to learn from one another’s expertise.

Manufacturer’s Resources

Utilizing the official resources offered by manufacturers can provide crucial information on maintenance schedules and replacement components. Official manuals and instructional videos often detail procedures and specifications, ensuring that users have the guidance needed for proper upkeep.