Having a clear understanding of the assembly layout of outdoor power equipment is essential for maintenance and repair tasks. Knowing how the various components fit together not only aids in troubleshooting but also enhances the overall efficiency of the machine. A well-organized layout can help users identify the necessary components and ensure proper functionality.

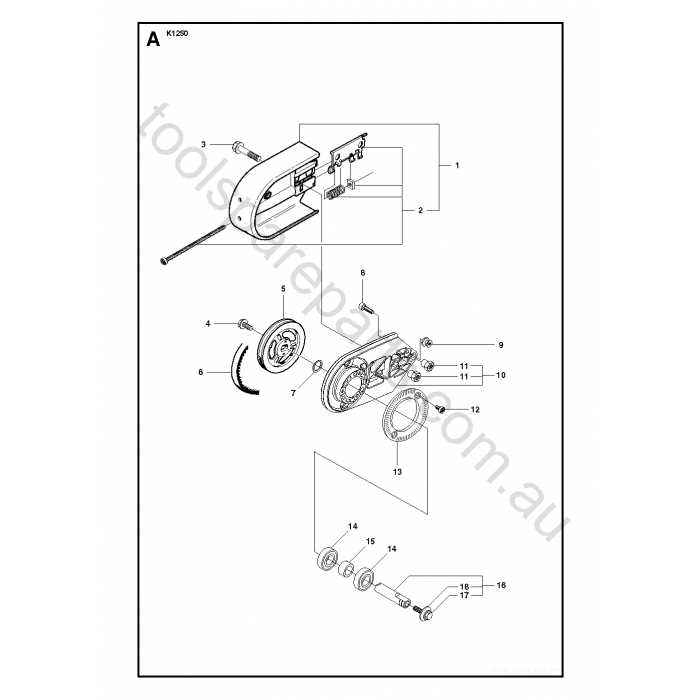

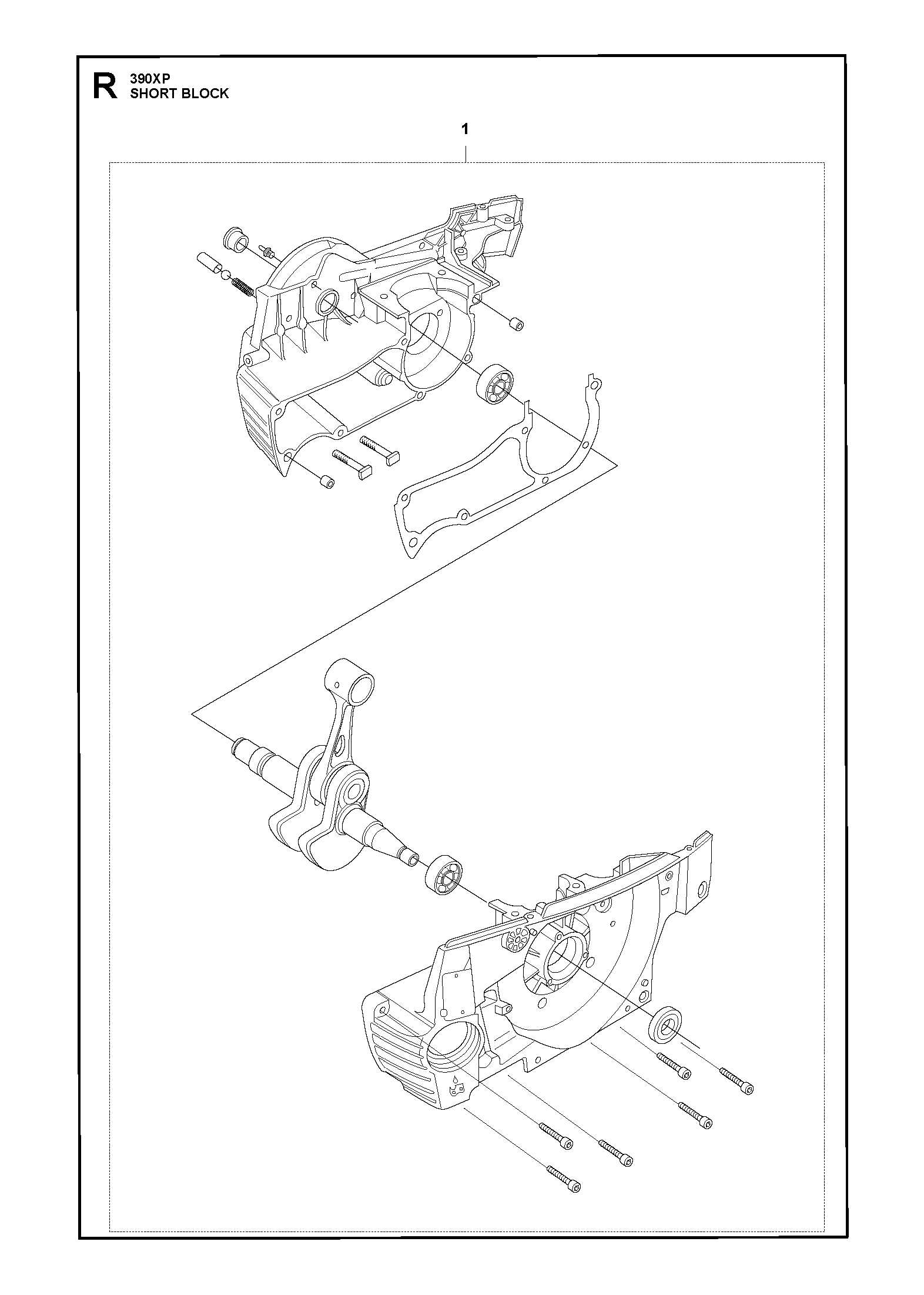

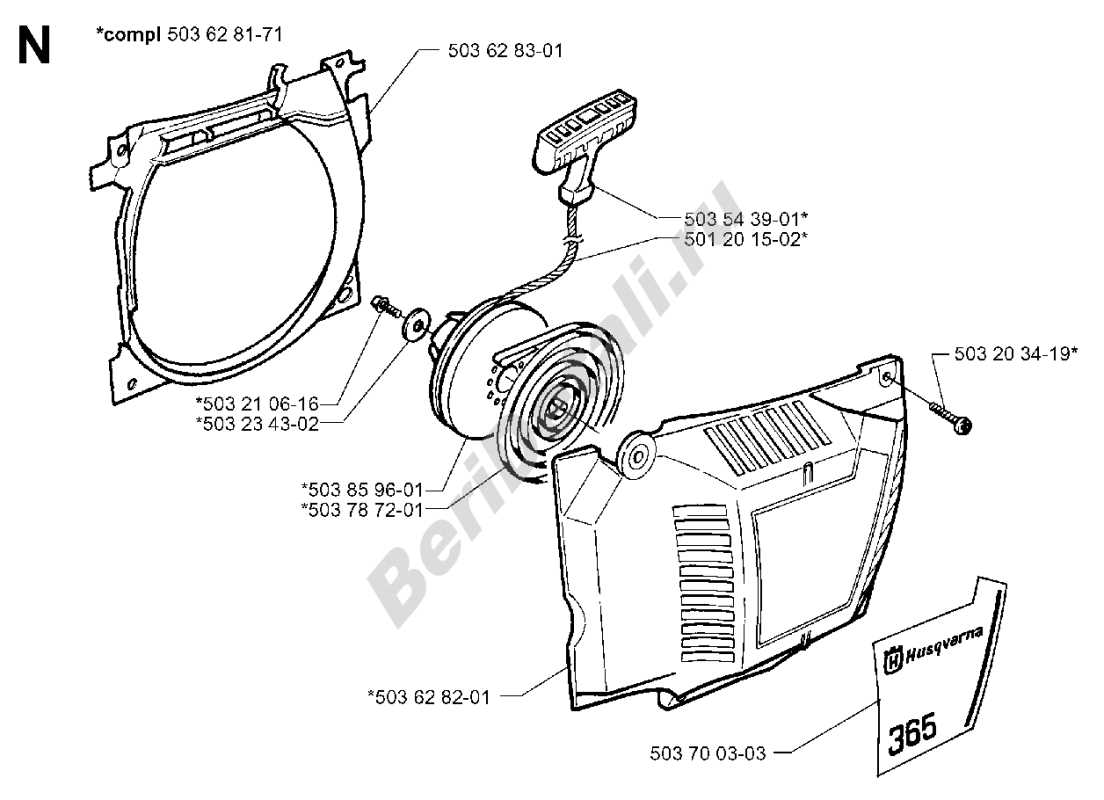

When working on any equipment, referencing an assembly schematic can be incredibly beneficial. These visual representations provide insights into how different elements interact with one another, enabling users to make informed decisions during repairs or modifications. By familiarizing oneself with these layouts, operators can enhance their skills and tackle issues more effectively.

In this section, we will delve into the specifics of the assembly layout for a particular model, offering detailed information that can assist both novice and experienced users alike. By understanding the key components and their arrangement, individuals will be better equipped to manage their equipment’s upkeep and address potential problems proactively.

Understanding the Parts Layout

Having a clear comprehension of the assembly structure is essential for effective maintenance and repair. Each component plays a vital role in the overall functionality of the machine. Recognizing how these elements interact can lead to improved performance and longevity.

Typically, the layout is organized in a way that illustrates the relationships between different sections. For instance, the engine, cutting mechanism, and power transmission are often highlighted separately, making it easier to identify their specific roles. This arrangement not only aids in troubleshooting but also facilitates the replacement of individual elements when necessary.

Moreover, visual representations often include labels and references that simplify the identification process. Understanding these annotations can empower users to perform maintenance tasks with confidence. Familiarity with the layout ultimately enhances the ability to diagnose issues and implement solutions efficiently.

Essential Accessories for Husqvarna 390xp

When operating a high-performance outdoor power tool, equipping it with the right supplementary items can significantly enhance its functionality and safety. Various add-ons contribute to improved efficiency, making tasks smoother and more enjoyable.

Here are some crucial accessories to consider:

- Chain Lubricant: Proper lubrication is vital for maintaining optimal performance and extending the life of the cutting chain.

- Protective Gear: Safety should always come first. Investing in gloves, goggles, and ear protection ensures a secure working environment.

- Carrying Case: A sturdy case protects the equipment during transport and storage, preventing damage from external elements.

- Replacement Chains: Having extra cutting chains on hand allows for quick changes during work, minimizing downtime.

- Fuel Mixing Container: An efficient fuel mixing container makes it easy to prepare the right fuel mixture, ensuring smooth operation.

Utilizing these essential accessories can enhance the overall experience and efficiency of any outdoor cutting tool, ensuring it operates at peak performance.

Maintenance Tips for Engine Parts

Proper upkeep of engine components is essential for optimal performance and longevity. Regular maintenance can prevent potential issues and ensure smooth operation, enhancing overall efficiency. Here are some essential tips to keep your engine running effectively.

- Regular Cleaning: Keep engine parts clean from dirt and debris. Use appropriate cleaning agents and tools to avoid damage.

- Frequent Inspections: Conduct periodic checks for wear and tear. Look for any signs of corrosion, cracks, or loose connections.

- Lubrication: Ensure that all moving parts are adequately lubricated to minimize friction and prevent overheating. Use the recommended lubricant types.

- Replace Worn Components: Identify and replace any damaged or worn parts promptly. This helps to maintain efficiency and prevents further damage.

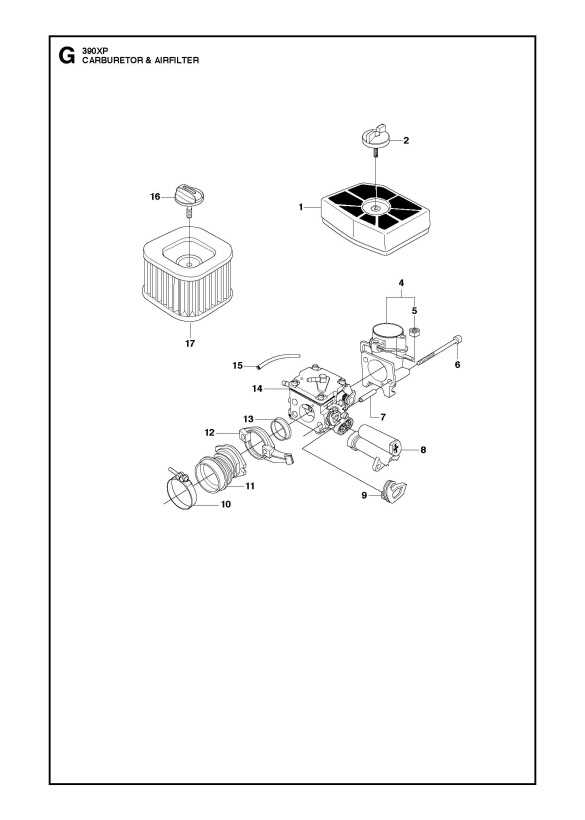

- Check Filters: Inspect and replace air and fuel filters as needed. Clogged filters can hinder performance and lead to engine strain.

By following these maintenance tips, you can significantly extend the lifespan of your engine components and enhance their functionality.

Common Replacement Parts for Efficiency

Regular maintenance and timely replacement of components are crucial for the optimal performance of any outdoor equipment. By understanding which components require periodic attention, users can enhance the longevity and functionality of their machines. This section highlights some of the essential elements that contribute to maintaining efficiency and performance.

Essential Components to Consider

Several key elements play a significant role in ensuring smooth operation. Chains and bars should be inspected regularly, as wear and tear can lead to decreased performance. Replacing these items when they show signs of damage can prevent further complications.

Maintenance Tips for Optimal Performance

To achieve the best results, it’s advisable to replace filters and spark plugs periodically. Clean air filters ensure proper airflow, while new spark plugs promote efficient ignition. Regularly checking and updating these components can significantly enhance the overall effectiveness of your equipment.

Identifying Wear and Tear in Components

Recognizing the signs of degradation in machinery elements is crucial for maintaining optimal performance and extending the lifespan of equipment. By understanding the common indicators of wear, operators can take timely actions to prevent further damage and ensure efficient operation.

Here are some common signs to look out for:

- Visual Inspection: Regularly check components for cracks, dents, or any visible damage.

- Unusual Noises: Listen for any strange sounds during operation that may indicate a malfunction.

- Performance Changes: Noticeable drops in performance can signal that parts are no longer functioning effectively.

- Heat Emission: Excessive heat generation can be a sign of friction or improper lubrication.

- Leaks: Fluid leaks around components can indicate worn seals or gaskets.

In addition to these signs, regular maintenance schedules should include detailed inspections of all critical parts. By staying proactive, operators can address issues before they escalate into costly repairs.

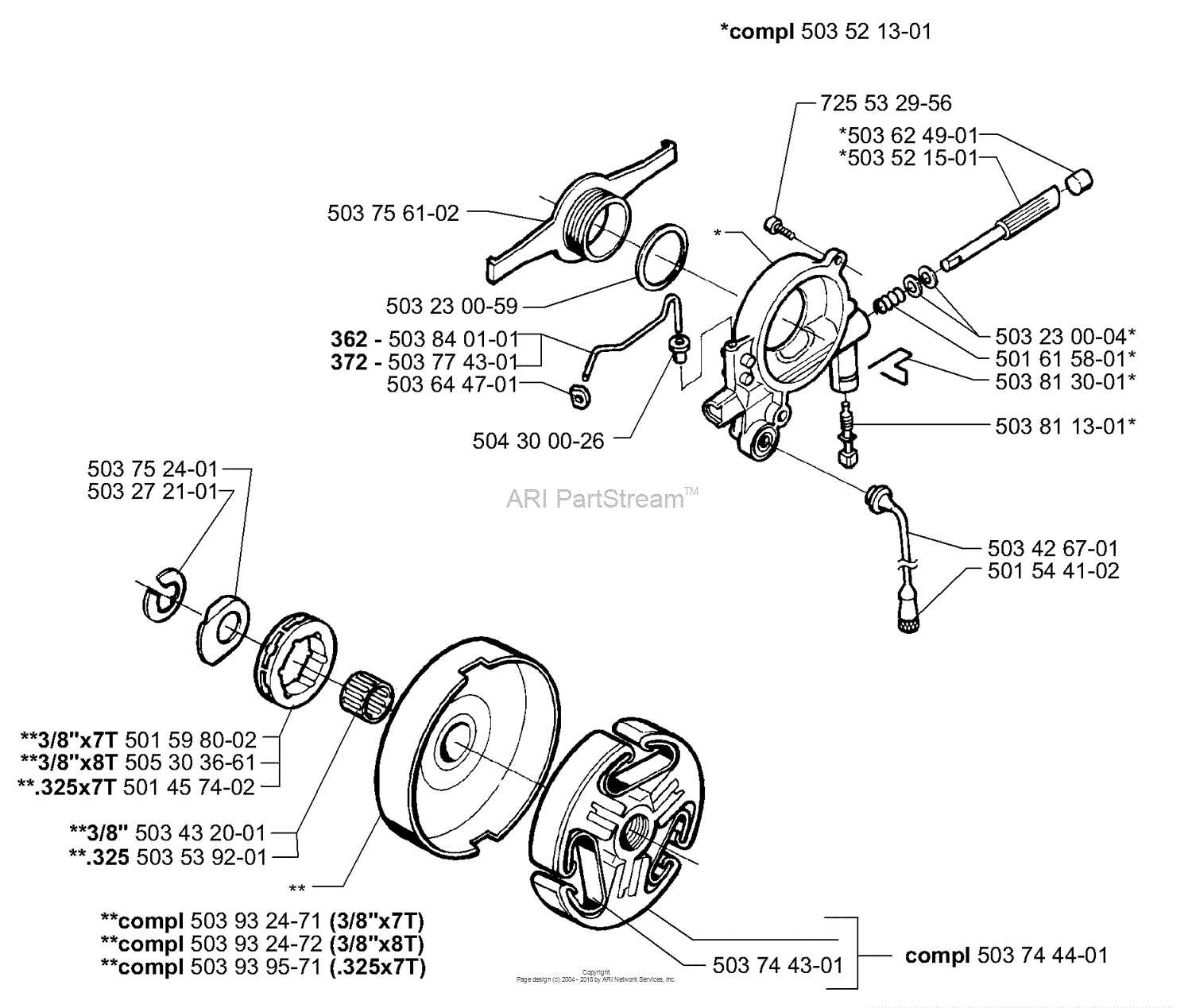

Parts Compatibility with Other Models

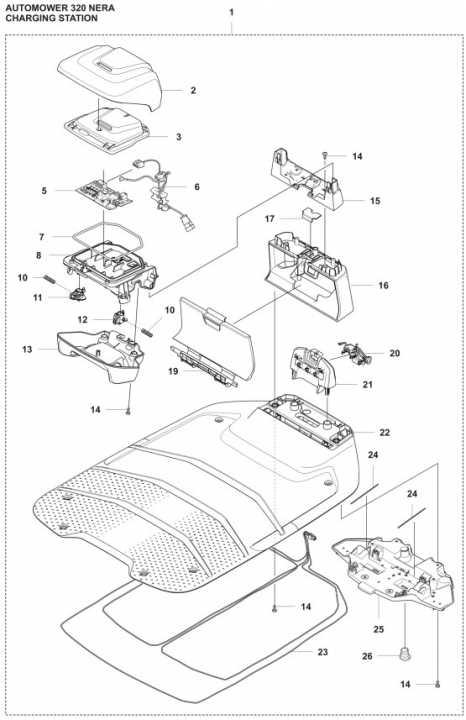

Understanding the interchangeability of components between various machine models is crucial for maintenance and repair efficiency. Knowing which elements can be used across different versions can save time and reduce costs for users. This section delves into the similarities and differences in components that can be shared among a range of equipment.

Shared Components Across Models

Several machines utilize comparable elements, allowing for easier sourcing of replacements. Key components such as filters, ignition systems, and certain casings may often be compatible between different models. When seeking replacements, it is advisable to consult the manufacturer’s specifications to ensure that the selected parts will function correctly within the intended machine.

Importance of Verification

While many components may appear similar, it is vital to verify compatibility before making any purchases. Minor variations in design or specifications can lead to inefficiencies or even damage to the machinery. Always cross-reference with reliable sources or consult experts to confirm that the chosen items meet the required standards.

How to Order Replacement Parts

Ordering new components for your equipment can be a straightforward process if you follow the right steps. Ensuring you have the correct information and resources will help you acquire the necessary items efficiently. This guide outlines the essential actions to take when seeking to replace specific elements of your machinery.

Identify the Required Components

Before placing an order, it is crucial to determine which elements need replacement. This involves checking your device for any visible wear or damage. Refer to your user manual or consult online resources to understand the specific items compatible with your model. Taking note of the serial number can also assist in ensuring you order the correct replacements.

Find a Reputable Supplier

Once you have identified the needed components, the next step is to locate a reliable supplier. This can be achieved through official retailers, authorized dealers, or trusted online platforms. Always verify the credibility of the source before making a purchase to avoid counterfeit products that may not function correctly. It is also beneficial to compare prices and availability from multiple vendors to ensure you get the best deal.

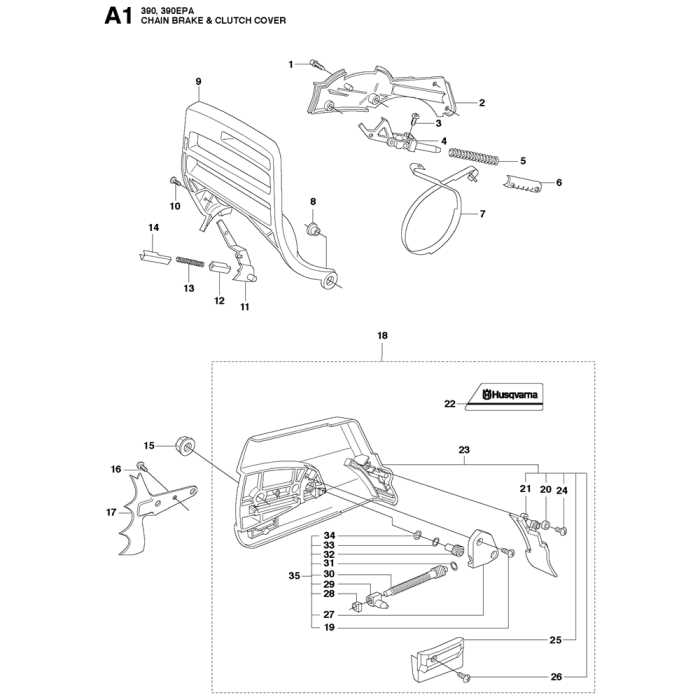

Visual Guide to Parts Identification

This section provides an overview of how to recognize and differentiate various components of outdoor power equipment. Understanding these elements is crucial for maintenance and repair tasks, ensuring optimal performance and longevity.

Here’s a systematic approach to identifying key components:

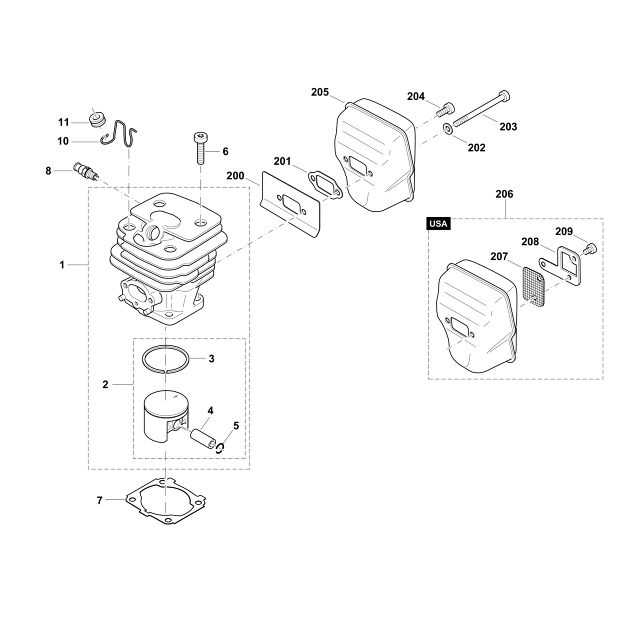

- Engine Components

- Cylinders: The primary unit where combustion occurs.

- Pistons: Responsible for transferring force generated during combustion.

- Crankshaft: Converts linear motion into rotational motion.

- Fuel System

- Carburetor: Mixes air and fuel for combustion.

- Fuel Lines: Transport fuel from the tank to the engine.

- Filters: Cleanse fuel to prevent contamination.

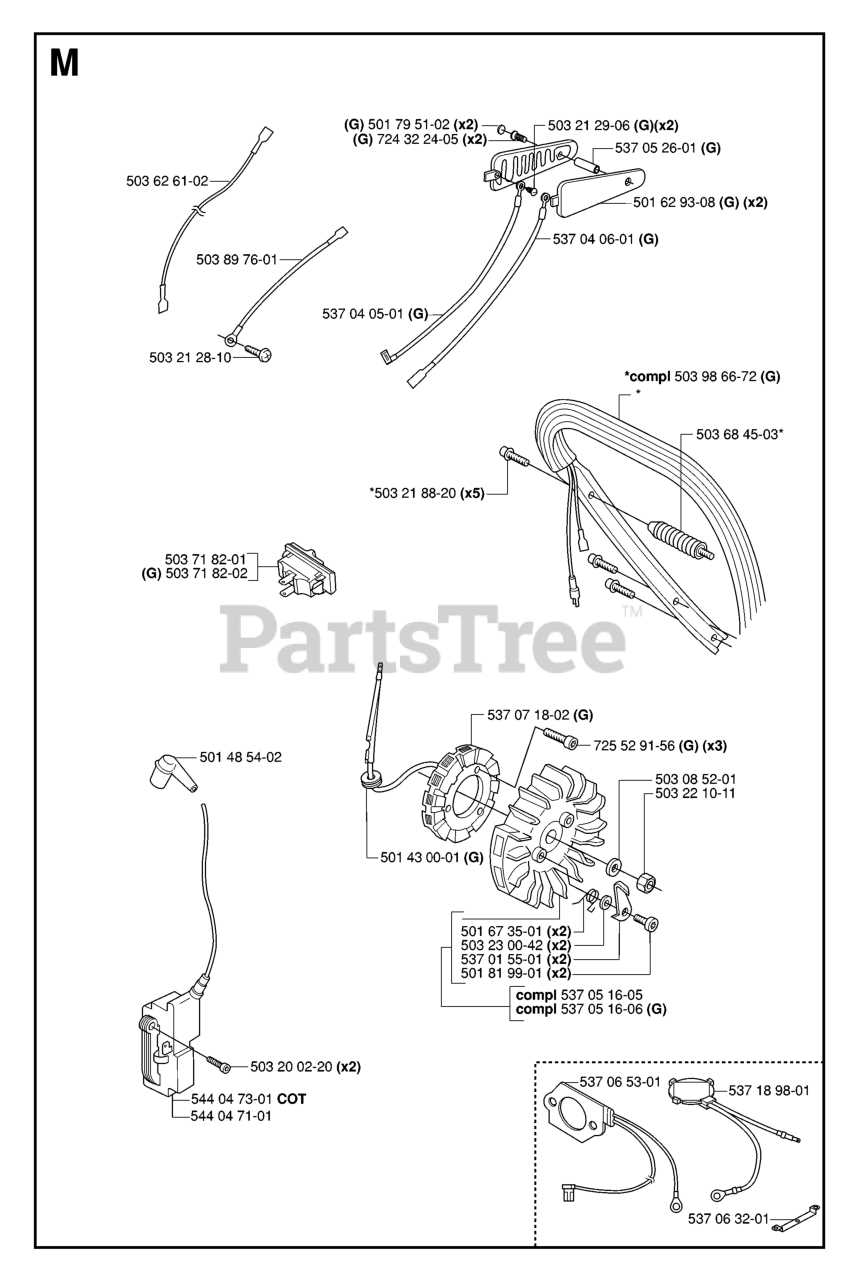

- Ignition System

- Spark Plug: Ignites the air-fuel mixture.

- Coil: Generates the electrical spark needed for ignition.

- Wiring: Connects various ignition components.

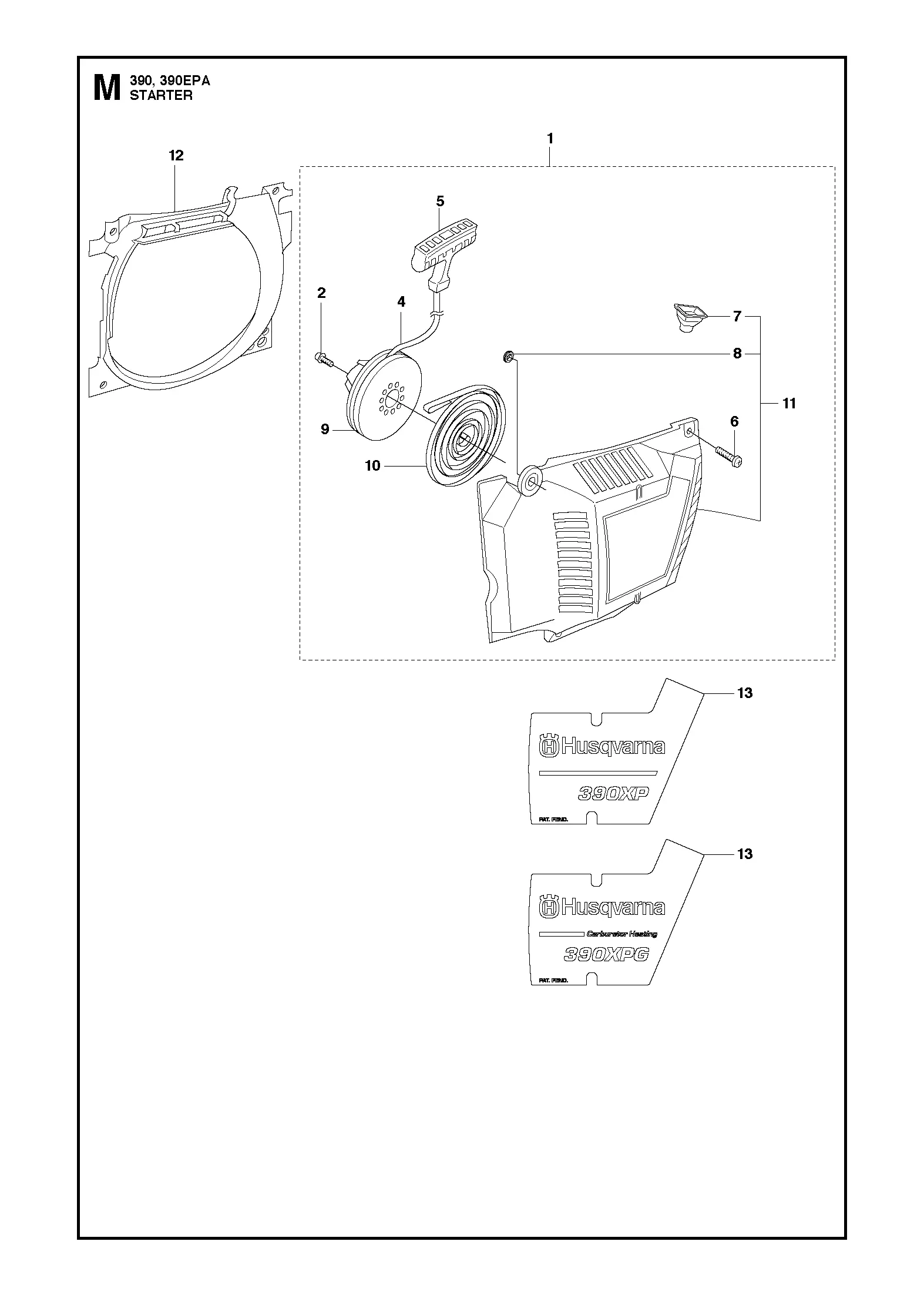

- Cooling Mechanism

- Fan: Circulates air to cool the engine.

- Shrouds: Direct airflow over the engine.

- Cooling Fins: Dissipate heat from the engine surface.

Utilizing a reference guide or visual aids can significantly enhance your ability to identify and work with these essential elements effectively.

Installation Process for New Components

The installation of new elements in machinery is crucial for ensuring optimal performance and longevity. This process requires careful attention to detail and adherence to specific steps to achieve a successful outcome. Proper installation not only enhances functionality but also prevents potential issues that may arise from incorrect assembly.

Preparation for Installation

Before commencing the installation, it is essential to gather all necessary tools and components. Ensure that the workspace is clean and organized to facilitate a smooth operation. Review the manufacturer’s guidelines for detailed instructions specific to the components being installed. This preparation phase sets the foundation for an efficient and effective installation.

Step-by-Step Installation

Begin by removing any existing parts that may obstruct access to the new components. Follow the outlined steps in the guidelines to secure the new elements properly. It is important to double-check connections and ensure that all fasteners are tightened according to specifications. Finally, perform a thorough inspection to confirm that everything is assembled correctly before operating the machinery.

Troubleshooting Common Parts Issues

When operating outdoor power equipment, various components may encounter issues that affect performance. Identifying and resolving these problems promptly is crucial for maintaining efficiency and longevity. This section provides insights into common malfunctions and their potential solutions.

Worn Components: Over time, certain elements can experience wear and tear. Regular inspections are essential to detect signs of deterioration. Look for cracks, fraying, or discoloration, which may indicate that a replacement is necessary.

Improper Assembly: If equipment fails to function correctly, it may result from incorrect assembly of components. Ensure that all parts are fitted properly, and consult the manual for guidance on correct installation. Tighten any loose fittings to avoid operational failures.

Fuel Issues: Fuel quality can significantly impact performance. Stale or contaminated fuel may cause starting difficulties or erratic behavior. Always use fresh fuel and consider adding a fuel stabilizer to prolong its life.

Cleaning and Maintenance: Regular maintenance, including cleaning filters and checking spark plugs, is vital for optimal performance. Neglecting these tasks can lead to buildup that impairs function. Establish a routine maintenance schedule to ensure longevity.

Seek Professional Help: If troubleshooting does not resolve the issues, it may be necessary to consult a professional technician. They can diagnose complex problems that may not be evident during a basic inspection.