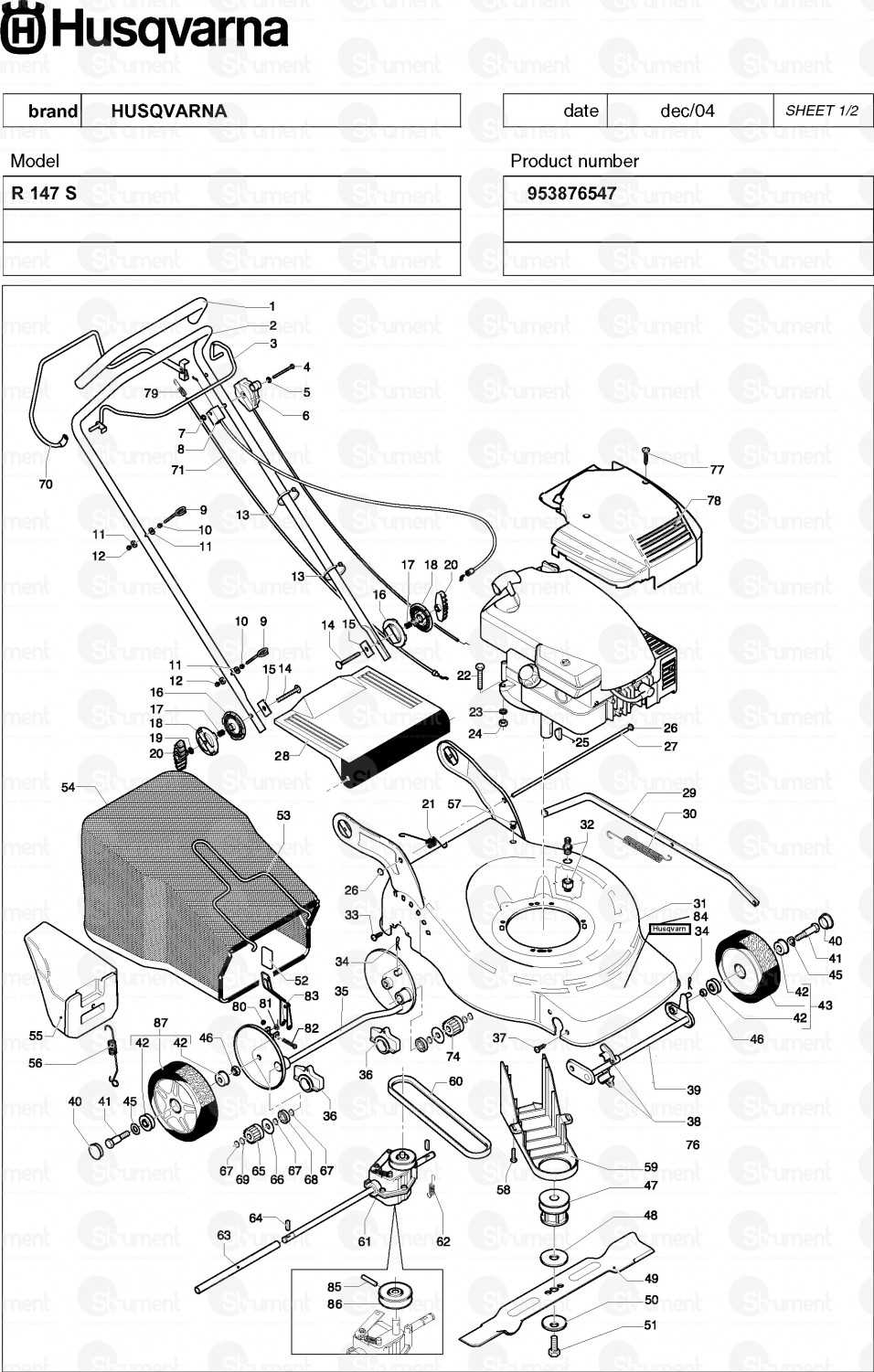

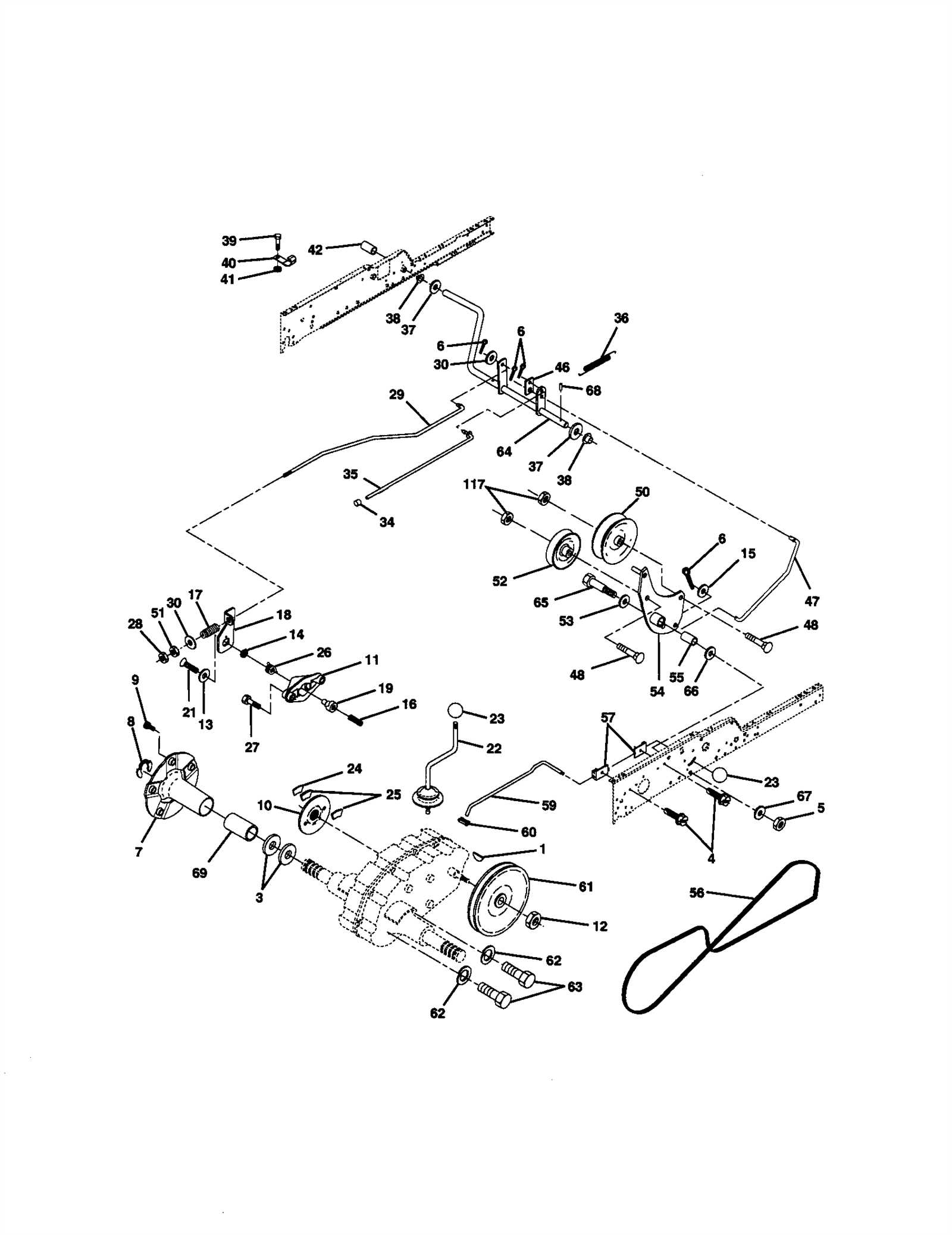

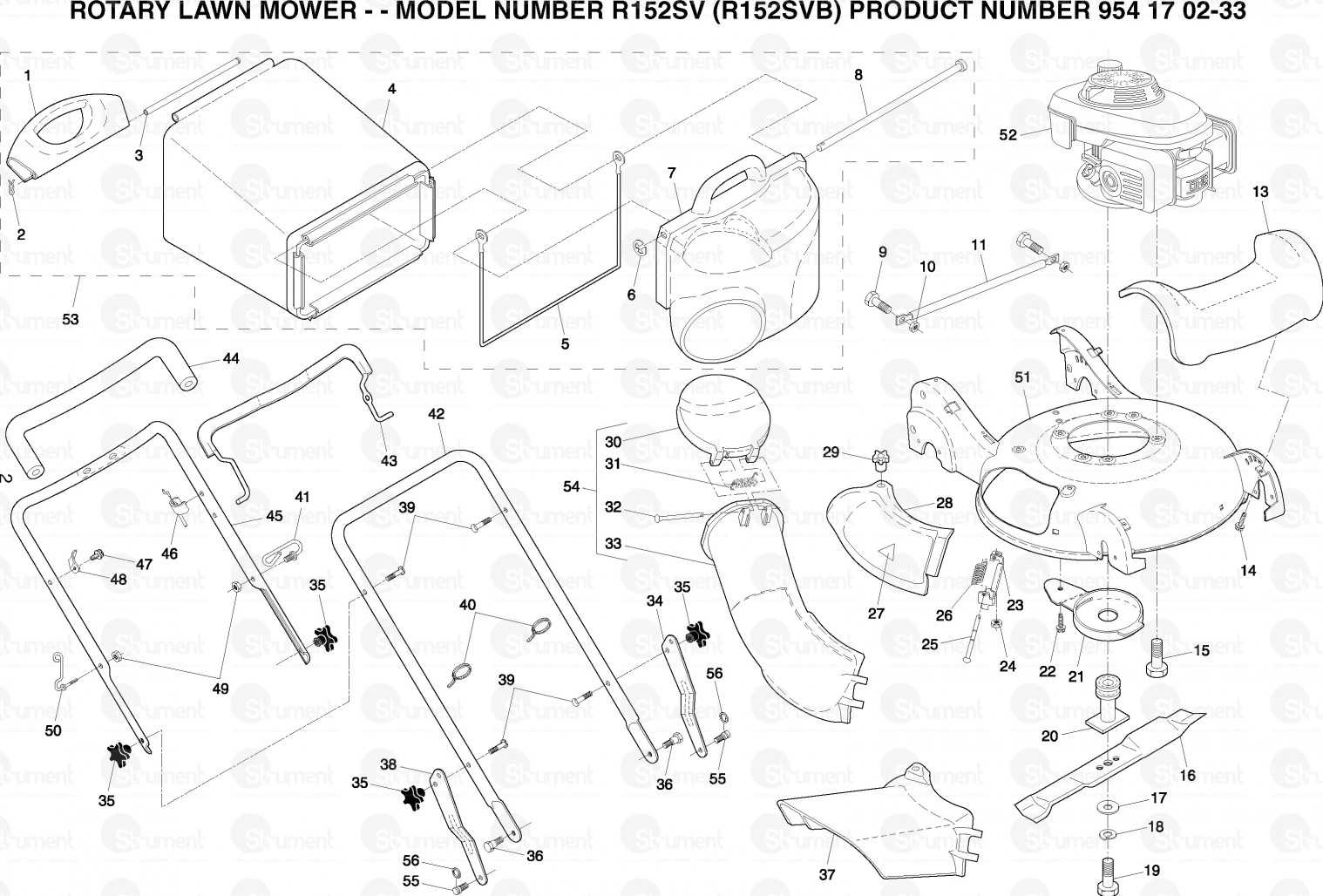

Maintaining your outdoor machinery is crucial for optimal performance and longevity. A comprehensive guide to the various components of your device can enhance your ability to troubleshoot and repair issues efficiently. Familiarity with the structure and function of each element ensures that you can address any concerns swiftly.

By examining a detailed illustration that showcases the intricate layout of these components, you can gain valuable insights into their interactions and importance. This knowledge empowers you to conduct routine maintenance, identify wear and tear, and replace faulty pieces effectively, ultimately leading to improved performance and durability.

Whether you are a seasoned technician or a passionate DIY enthusiast, understanding the arrangement of these crucial elements will facilitate smoother operations. This exploration will equip you with the information needed to tackle repairs with confidence, ensuring that your equipment remains in top condition throughout its lifespan.

Understanding Husqvarna 5521P Parts

This section provides an insightful look into the various components of a lawn maintenance machine, emphasizing their roles and interconnections. Knowing the functionality of each element is crucial for effective operation and maintenance.

Key Components

- Engine: Powers the entire unit, crucial for performance.

- Blades: Essential for cutting grass efficiently.

- Wheels: Facilitate movement across various terrains.

- Handle: Provides control and maneuverability.

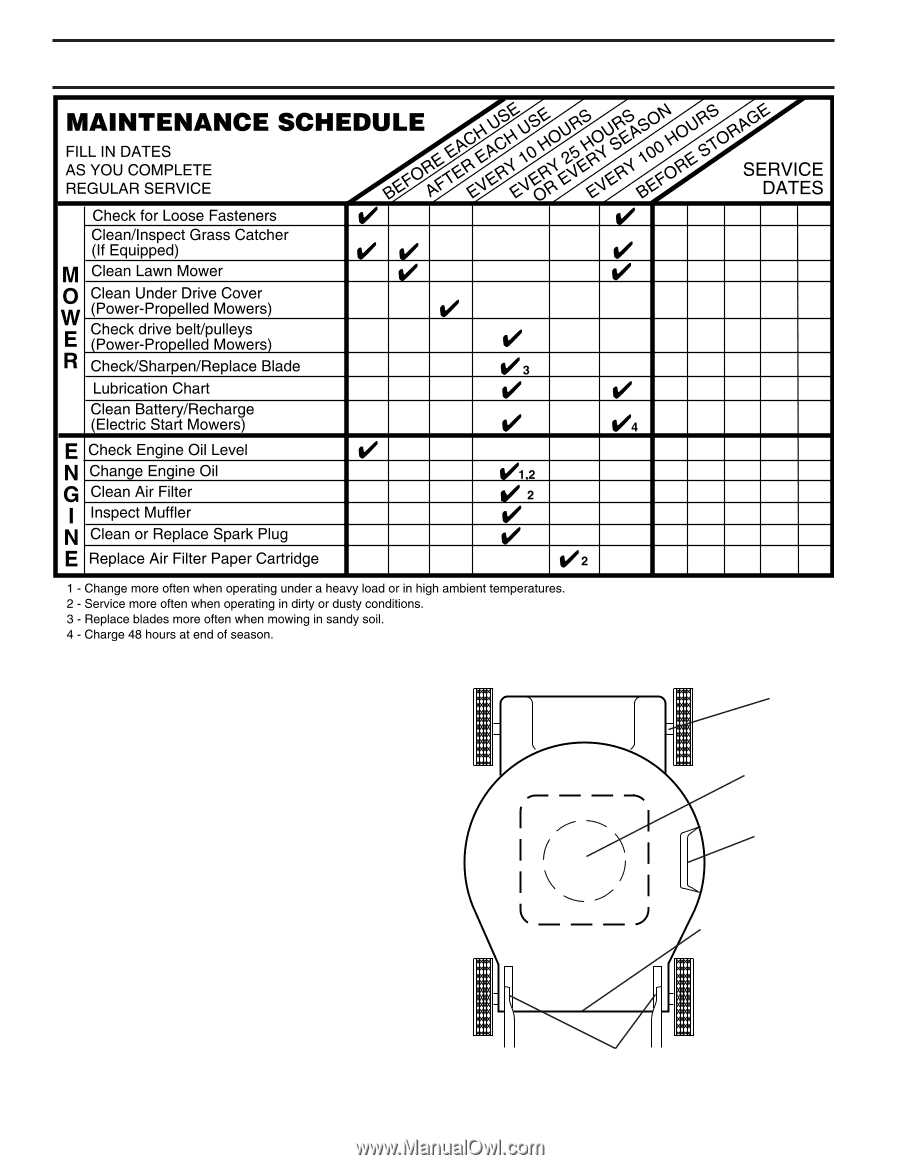

Maintenance Tips

- Regularly inspect the engine for optimal performance.

- Keep blades sharp for clean cuts.

- Check wheels for proper inflation and wear.

- Clean the handle to ensure a firm grip.

Importance of Parts Diagrams

Understanding the layout and function of components is crucial for efficient maintenance and repair of machinery. Visual representations of these elements serve as invaluable resources for both professionals and enthusiasts, ensuring that tasks are completed with precision and clarity.

Enhanced Understanding

Visual aids provide an intuitive grasp of how each component interacts within a system. Key benefits include:

- Clear identification of each element and its purpose.

- Easier troubleshooting by pinpointing specific areas that may require attention.

- Improved assembly and disassembly processes, minimizing the risk of errors.

Streamlined Maintenance

Efficient upkeep of equipment is vital for longevity and performance. Visual schematics contribute by:

- Facilitating accurate ordering of replacements, reducing downtime.

- Allowing for a systematic approach to repairs, enhancing overall productivity.

- Providing a reference that aids in understanding the manufacturer’s recommendations.

Key Components of Husqvarna 5521P

Understanding the essential elements of this lawn maintenance tool is crucial for optimal performance and longevity. Each component plays a significant role in ensuring efficiency and reliability during operation.

Main Elements

- Engine: Powers the unit and determines its cutting ability.

- Cutting Deck: Affects the width of the cut and overall maneuverability.

- Wheels: Impact stability and ease of movement across various terrains.

- Handle: Provides control and comfort during use.

- Grass Bag: Collects clippings for a tidy finish.

Maintenance Parts

- Air Filter: Ensures clean airflow to the engine.

- Spark Plug: Crucial for ignition and performance.

- Blades: Essential for achieving a clean cut.

- Belt: Transfers power from the engine to the cutting mechanism.

Where to Find Diagrams

Locating visual representations of mechanical components is essential for maintenance and repairs. These illustrations provide crucial information that simplifies the understanding of assembly and disassembly processes.

Online Resources

Various websites offer comprehensive libraries of illustrations, often searchable by model or type. These platforms can be invaluable for DIY enthusiasts and professionals alike.

Manufacturer’s Website

The official website of the manufacturer typically features downloadable resources. These often include high-quality visuals that are accurate and up-to-date.

| Resource Type | Description |

|---|---|

| Manufacturer Site | Direct access to accurate and detailed visuals. |

| Repair Forums | User-shared visuals and advice based on personal experience. |

| Online Retailers | Often provide visuals alongside product listings for easy reference. |

Common Issues and Solutions

In the realm of outdoor equipment, various complications can arise that hinder performance and efficiency. Recognizing these frequent problems and understanding how to address them is essential for maintaining optimal functionality. This section explores typical challenges encountered and their corresponding solutions to ensure a smoother operation.

Frequent Complications

Users often report issues such as difficulty starting, uneven cutting, and reduced power. These can stem from several underlying causes, which can usually be resolved with a bit of troubleshooting.

Solutions and Recommendations

Here are some common problems along with practical solutions:

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Difficulty Starting | Clogged fuel lines, old fuel, or faulty spark plug | Replace fuel, clean lines, or install a new spark plug |

| Uneven Cutting | Dull blades or incorrect height settings | Sharpen or replace blades, adjust cutting height |

| Reduced Power | Dirty air filter or clogged exhaust | Clean or replace air filter, inspect and clear exhaust |

By addressing these common issues promptly, users can enhance the longevity and efficiency of their equipment.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring that your equipment remains in optimal condition for years to come. Regular maintenance not only enhances performance but also prolongs the lifespan of the machine, reducing the need for frequent repairs.

Routine Checks

- Inspect air filters regularly and replace them as needed.

- Check spark plugs for wear and replace them if they show signs of damage.

- Examine the blades for dullness and sharpen or replace them when necessary.

Cleaning and Storage

- Clean the exterior after each use to prevent debris buildup.

- Store the machine in a dry place to avoid rust and corrosion.

- Cover the equipment when not in use to protect it from dust and moisture.

Ordering Replacement Parts Online

In today’s digital age, acquiring necessary components for outdoor equipment has never been easier. Online platforms provide a vast selection of items, allowing users to conveniently find and purchase what they need without leaving home. This method streamlines the process, saving both time and effort while ensuring you have the right elements for your machinery.

Finding the Right Components

Before making a purchase, it’s crucial to identify the exact elements required for your equipment. Utilize model numbers and detailed descriptions to ensure accuracy. Most retailers offer search filters that help narrow down options, making it simpler to locate the precise items needed.

Ensuring Quality and Compatibility

When selecting components, prioritize quality and compatibility with your device. Read customer reviews and product specifications to gauge reliability. Additionally, consider purchasing from reputable suppliers who provide clear return policies, ensuring a smooth transaction in case of discrepancies.

Tools Needed for Repairs

Effective maintenance and repair of outdoor equipment require a selection of essential implements. Having the right tools ensures that the tasks can be executed efficiently and safely, leading to optimal performance.

- Screwdrivers: Both flathead and Phillips for various screws.

- Wrenches: Adjustable and socket types for loosening and tightening bolts.

- Torque wrench: Ensures proper tightness of fasteners.

- Pliers: Useful for gripping and manipulating small components.

- Cleaning brush: Helps in removing debris and buildup from parts.

- Oil can: For lubrication of moving parts.

Gathering these implements before starting the repair will help in navigating the process smoothly and achieving the ultimate results.

Step-by-Step Repair Guide

This guide will walk you through the process of troubleshooting and fixing common issues with your lawn maintenance equipment. Following these steps carefully can help restore functionality and extend the life of your machine.

Preparation Steps

Before you begin the repair process, ensure you have the necessary tools and a clean workspace. Gather the following items:

| Tool | Purpose |

|---|---|

| Screwdriver Set | To remove and tighten screws |

| Wrench | For loosening and tightening bolts |

| Replacement Parts | To replace any damaged components |

| Cleaning Cloth | To wipe down parts and tools |

Repair Process

Once you are prepared, follow these steps to perform the repair:

- Disconnect the power source to ensure safety.

- Inspect all components for wear or damage, noting any parts that need replacement.

- Carefully remove the damaged parts using the appropriate tools.

- Install the new parts, ensuring they fit securely and are aligned correctly.

- Reassemble the equipment, double-checking that all screws and bolts are tightened properly.

- Reconnect the power source and perform a test run to ensure everything functions as expected.

Comparing Models and Parts

Understanding the differences between various lawn equipment models is essential for optimal performance and maintenance. Each model comes with unique features and components that can influence usability and efficiency. By examining these elements, users can make informed decisions about which equipment best suits their needs.

Key Features to Consider

- Engine power and efficiency

- Cutting width and height adjustments

- Durability of materials used

- Ease of maintenance and repair options

- Weight and maneuverability

Common Components Across Models

- Blades: Variations in design and sharpness affect cutting quality.

- Wheels: Different sizes and treads provide various levels of traction.

- Handles: Ergonomic designs enhance user comfort during operation.

- Decks: Material and design influence durability and cutting performance.

Expert Advice on Upgrades

Enhancing the performance and longevity of your equipment can lead to a more efficient and enjoyable experience. With a few strategic modifications, you can elevate functionality and adapt to specific needs. Below are some valuable tips for making impactful improvements.

- Assess Current Performance: Before considering upgrades, evaluate the existing capabilities. Identify any limitations or areas that could benefit from enhancement.

- Research Compatible Enhancements: Look into available modifications that align with your equipment. Ensure compatibility to avoid issues during installation.

- Prioritize Quality Parts: Invest in high-quality components. This not only boosts performance but also extends the lifespan of your machinery.

When selecting upgrades, consider the following factors:

- Purpose: Define the primary goals for the upgrades. Are you aiming for better efficiency, increased power, or improved ease of use?

- Budget: Establish a budget for your enhancements. This will help narrow down options and prevent overspending.

- Installation Requirements: Some modifications may require professional installation. Be prepared to seek expert assistance if needed.

Finally, always consult user manuals or expert guides to ensure proper installation and maintenance of any upgrades. By carefully selecting improvements, you can maximize the effectiveness and satisfaction of your equipment.

FAQs About Husqvarna 5521P

This section addresses common inquiries regarding a popular lawn care tool. Whether you are a seasoned user or a newcomer, understanding its features and maintenance can enhance your experience and ensure optimal performance.

Common Questions

- What type of fuel is recommended for optimal operation?

- How often should I perform maintenance on my equipment?

- What are the signs that my tool needs repair?

- Can I use aftermarket accessories, or should I stick to original components?

Maintenance and Care

- Regularly check and clean the air filter to ensure efficient airflow.

- Sharpen the blades periodically for better cutting performance.

- Inspect the spark plug and replace it if it shows signs of wear.

- Store the device in a dry place to prevent rust and damage.