The efficiency and reliability of any power equipment heavily rely on the intricate interplay of its various components. A thorough grasp of these elements not only aids in maintenance but also enhances performance. By familiarizing oneself with the structure of such tools, users can ensure optimal functionality and longevity.

Exploring the intricate layout of a specific cutting device reveals the crucial roles played by each segment. From the engine to the blade assembly, every piece contributes to the overall effectiveness. Understanding these roles facilitates timely repairs and replacements, minimizing downtime during crucial tasks.

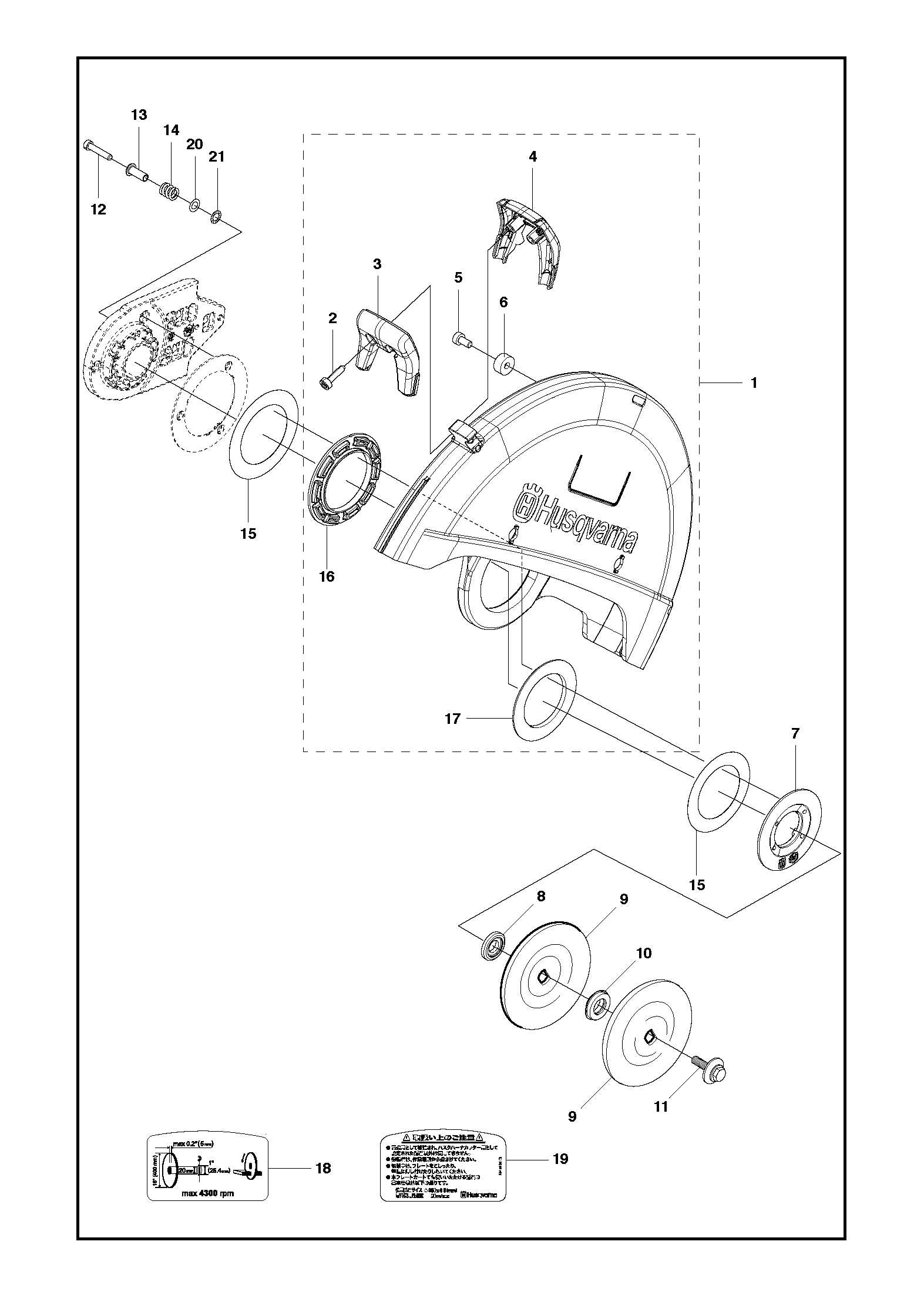

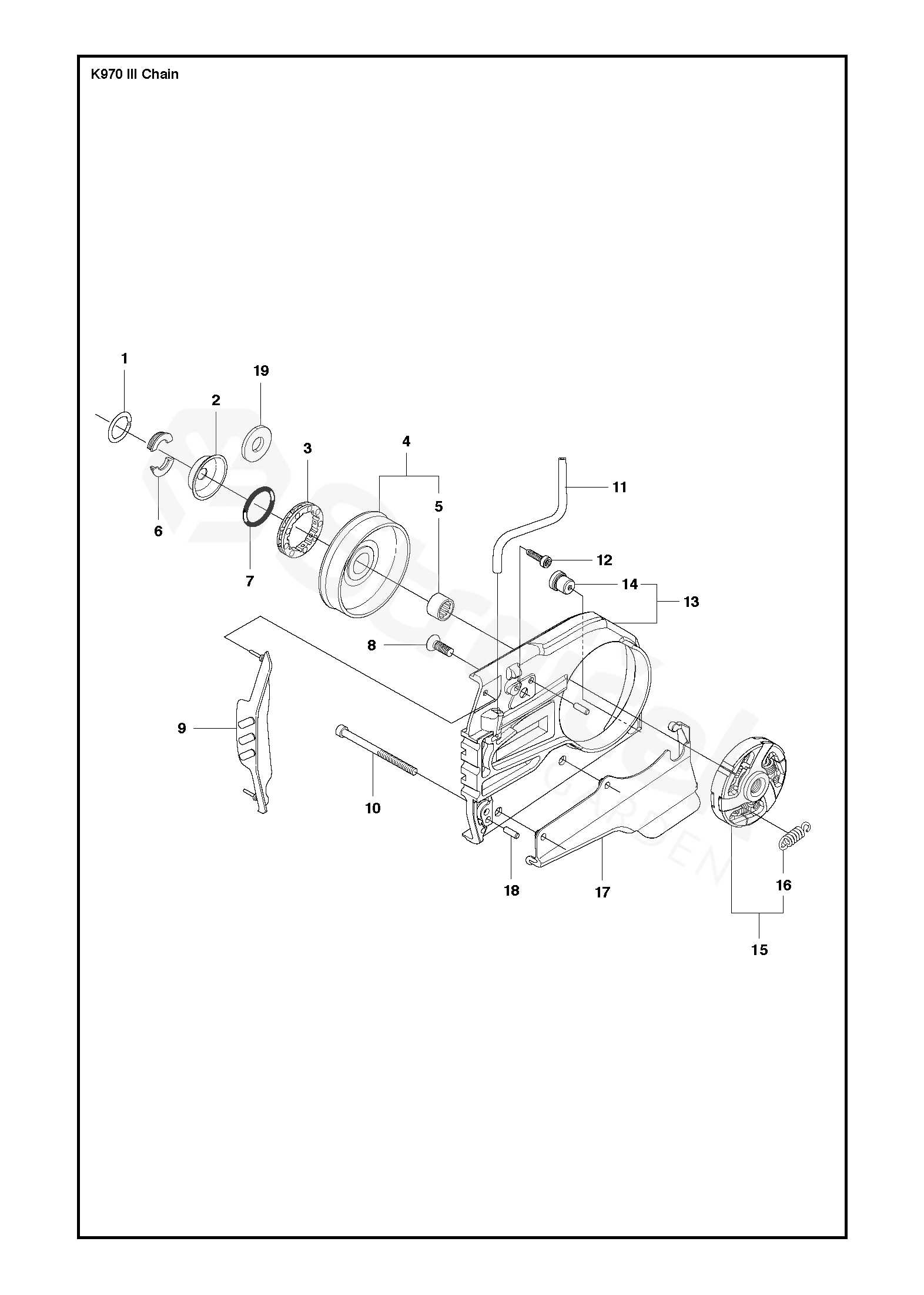

Visual representations of the component layout serve as invaluable references. They provide clarity in identifying specific parts and their interactions. Whether for troubleshooting or routine maintenance, these illustrations can significantly simplify the process, empowering users to take control of their equipment’s upkeep.

Understanding the Husqvarna K970 Components

To effectively operate and maintain a powerful cutting tool, it is essential to familiarize oneself with its key elements. Each component plays a vital role in the overall functionality and efficiency, ensuring optimal performance during use. This section will explore the various parts, their purposes, and how they contribute to the machine’s effectiveness.

Key Elements and Their Functions

Every tool consists of critical components that work in harmony. The engine provides the necessary power, while the cutting mechanism is designed for precision and durability. Additionally, the chassis supports structural integrity, enabling stability during operation. Understanding these elements allows users to troubleshoot issues and enhance performance.

Maintenance and Upkeep

Regular inspection and maintenance of these essential parts are crucial for longevity and reliability. Users should pay attention to wear and tear, replacing components as needed to prevent malfunctions. By delving into the specifics of each part, one can achieve the ultimate efficiency and performance of the tool.

Importance of a Parts Diagram

Understanding the components of machinery is essential for effective maintenance and repair. A visual representation of each element serves as a valuable tool, enabling users to identify and locate specific items easily. This clarity promotes efficiency and minimizes errors during service procedures.

Enhanced Troubleshooting: When issues arise, a visual reference allows for quicker diagnostics. Users can pinpoint problematic areas without unnecessary guesswork.

Streamlined Repairs: Having a clear outline aids in reassembly, ensuring that each part is returned to its proper place. This ultimately reduces the risk of reassembly mistakes.

Overall, an effective visual representation fosters confidence and precision, which are critical for optimal machinery performance.

Key Features of the K970 Model

This exceptional tool stands out due to its robust construction and versatility, making it suitable for various cutting tasks. Designed with efficiency in mind, it offers users the ultimate performance, whether in professional settings or DIY projects.

Powerful Engine: Equipped with a high-performance engine, this model ensures optimal power output, allowing for quick and effective cutting through various materials.

Lightweight Design: Its ergonomic and lightweight structure enhances maneuverability, reducing operator fatigue during prolonged use.

Advanced Cooling System: The innovative cooling mechanism helps maintain consistent performance, preventing overheating and ensuring durability during demanding tasks.

Easy Maintenance: Designed for convenience, the model features easily accessible components, making routine checks and maintenance straightforward.

Enhanced Safety Features: Safety is prioritized with integrated mechanisms that protect the operator, providing peace of mind during operation.

How to Read the Diagram

Understanding a schematic representation is crucial for effective maintenance and repair of machinery. This visual guide provides detailed information about various components and their relationships within the equipment. Familiarity with this layout can significantly enhance troubleshooting and part replacement processes.

Key Elements of the Visual Representation

- Component Labels: Each part is typically marked with a unique identifier, allowing for easy reference.

- Connections: Lines or arrows often indicate how different elements are connected or interact with one another.

- Assembly Order: Some diagrams may include numbers or sequences, which help illustrate the order in which parts should be assembled or disassembled.

Steps to Interpret the Visual Layout

- Start by locating the legend or key, which explains the symbols and abbreviations used.

- Identify the main components relevant to your task.

- Trace the connections to understand how parts fit together and function in relation to one another.

- Use the assembly order, if available, to guide your repair or maintenance efforts.

By following these steps, you can effectively navigate the schematic and ensure a thorough understanding of the equipment’s structure and function.

Common Replacement Parts Overview

Maintaining the efficiency of cutting tools often involves replacing certain components that experience wear over time. Understanding which elements may need substitution can help ensure optimal performance and longevity of the equipment.

Key Components

- Blades

- Filters

- Drive belts

- Fuel lines

- Starter mechanisms

Signs of Wear

- Decreased cutting efficiency

- Unusual noises during operation

- Difficulty starting the engine

- Frequent overheating

Maintenance Tips for K970 Owners

Proper upkeep of your cutting tool is essential for optimal performance and longevity. Regular maintenance not only enhances efficiency but also ensures safety during operation. By following a few straightforward guidelines, you can keep your equipment in excellent condition.

Regular Cleaning

After each use, thoroughly clean the machine to remove dust, debris, and residue. Pay special attention to the air filter and cooling fins, as accumulated dirt can hinder performance and lead to overheating.

Inspect and Replace Components

Frequent inspection of essential components is vital. Check the blade for wear, ensure that all bolts are secure, and replace any damaged parts promptly. Keeping spare items on hand can minimize downtime and ensure smooth operation.

Finding Genuine Husqvarna Parts

Locating authentic components for your equipment is crucial for optimal performance and longevity. Using reliable parts ensures safety and efficiency, preventing potential issues that may arise from counterfeit alternatives. This guide will help you navigate the process of acquiring genuine replacements for your tools.

Where to Look

Trusted dealers and official retailers are the best sources for quality components. Additionally, authorized online platforms offer a wide selection with assurance of authenticity. Always check for certifications or seals of approval when purchasing.

Understanding Compatibility

Before making a purchase, verify that the component matches your machine’s specifications. Cross-referencing model numbers and consulting documentation can save time and resources in the long run.

| Source | Description |

|---|---|

| Authorized Dealers | Directly provide genuine components with warranty. |

| Online Retailers | Wide selection with customer reviews for reliability. |

| Manufacturer Websites | Official listings and guides for accurate purchases. |

Assembly and Disassembly Procedures

This section outlines the essential steps for the proper assembly and disassembly of the equipment, ensuring optimal performance and longevity. Following these procedures meticulously will facilitate maintenance and repairs, ultimately enhancing operational efficiency.

Before starting, gather the necessary tools and safety gear. A well-organized workspace will help streamline the process.

- Preparation:

- Disconnect power supply.

- Remove any attachments or accessories.

- Disassembly:

- Begin by loosening fasteners in a specific order to prevent damage.

- Carefully separate components, keeping track of their arrangement.

- Inspect parts for wear or damage as they are removed.

- Assembly:

- Clean all parts before reassembly.

- Follow the reverse order of disassembly, ensuring all fasteners are tightened securely.

- Reattach any accessories as needed.

- Final Checks:

- Inspect the entire unit for proper alignment and secure fittings.

- Reconnect the power supply and conduct a test run.

Adhering to these steps will ensure a smooth process, enhancing both safety and efficiency.

Identifying Wear and Tear Signs

Understanding the indicators of deterioration is essential for maintaining the efficiency and safety of your equipment. Regular inspection can help you catch issues before they lead to significant damage, ensuring prolonged usability and optimal performance. Recognizing these signs early can save both time and resources in the long run.

Common Signs to Look For

When examining your machinery, pay close attention to specific indicators that suggest wear and tear. Here are some typical signs to consider:

| Sign | Description |

|---|---|

| Cracks | Visible fractures on the surface may indicate structural weaknesses. |

| Excessive Vibration | Unusual vibrations can signal misalignment or internal damage. |

| Rust | Corrosion on metal parts compromises durability and function. |

| Worn Edges | Flattened or rounded edges on blades suggest the need for replacement. |

Regular Maintenance Tips

To prolong the life of your equipment, implement a routine maintenance schedule. This should include cleaning, lubrication, and timely replacements of worn components. Regular checks will help you stay ahead of potential problems and maintain peak performance.

Frequently Asked Questions About Parts

This section addresses common inquiries related to components essential for optimal performance and maintenance. Understanding these elements can help ensure longevity and efficiency in usage.

What should I do if I need a replacement component? Always consult the user manual or official resources to identify the correct item, and consider purchasing from authorized dealers for quality assurance.

How can I identify worn or damaged items? Regular inspections are crucial. Look for signs of wear such as cracks, discoloration, or unusual sounds during operation.

Are there any tips for maintaining components? Routine cleaning and proper storage can significantly extend the lifespan of essential elements. Always follow manufacturer guidelines for care.

Can I use aftermarket items instead of originals? While compatible alternatives may exist, it’s recommended to use original components to avoid potential issues with performance and warranty.

How often should I replace critical components? It varies based on usage and conditions. Monitor performance and replace items as necessary, typically after a set number of hours or visible degradation.

Resources for Further Information

This section aims to provide valuable materials and links for those seeking to enhance their knowledge about equipment maintenance and repair. By exploring various resources, users can find comprehensive guides, tutorials, and community support that facilitate a deeper understanding of their tools.

Online Guides and Manuals

Accessing detailed manuals and instructional materials is essential for effective maintenance. Below are some recommended platforms:

| Resource | Description |

|---|---|

| Manufacturer’s Website | Official manuals and product specifications. |

| YouTube | Video tutorials for hands-on repair techniques. |

| DIY Forums | Community discussions and troubleshooting tips. |

Parts and Accessories Suppliers

Finding reliable suppliers for components and accessories is crucial. Here are some popular options:

| Supplier | Specialty |

|---|---|

| Local Hardware Stores | Common parts and tools for repairs. |

| Online Retailers | Wide selection of components and shipping options. |

| Specialty Shops | Expertise in specific equipment and rare parts. |

Customer Reviews and Experiences

This section highlights the thoughts and feedback from users regarding their experiences with their equipment. Understanding real-life usage can provide valuable insights for potential buyers and enthusiasts alike.

- Durability: Many users praise the robustness of their machines, noting they withstand heavy-duty tasks without significant wear.

- Ease of Use: Customers frequently mention the intuitive design, making operation simple even for those with limited experience.

- Maintenance: Reviews often emphasize the straightforward maintenance procedures, allowing for hassle-free upkeep.

- Performance: Users consistently highlight the power and efficiency, making it suitable for various projects.

Overall, customer experiences shed light on the reliability and functionality of the equipment, guiding future users in their purchasing decisions.