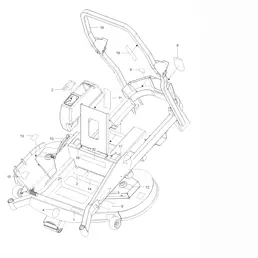

The intricate assembly of outdoor machinery is essential for maintaining optimal performance and longevity. By exploring the individual components and their arrangements, one can gain valuable insights into how each part contributes to the overall functionality of the equipment.

In this section, we will delve into the various elements that make up this specific model, providing a comprehensive view of their interconnections and roles. This knowledge will not only assist in troubleshooting but also enhance the understanding of maintenance procedures.

Additionally, recognizing the significance of each component will empower users to make informed decisions regarding repairs and replacements. Through this exploration, we aim to facilitate a deeper appreciation for the mechanics behind effective operation.

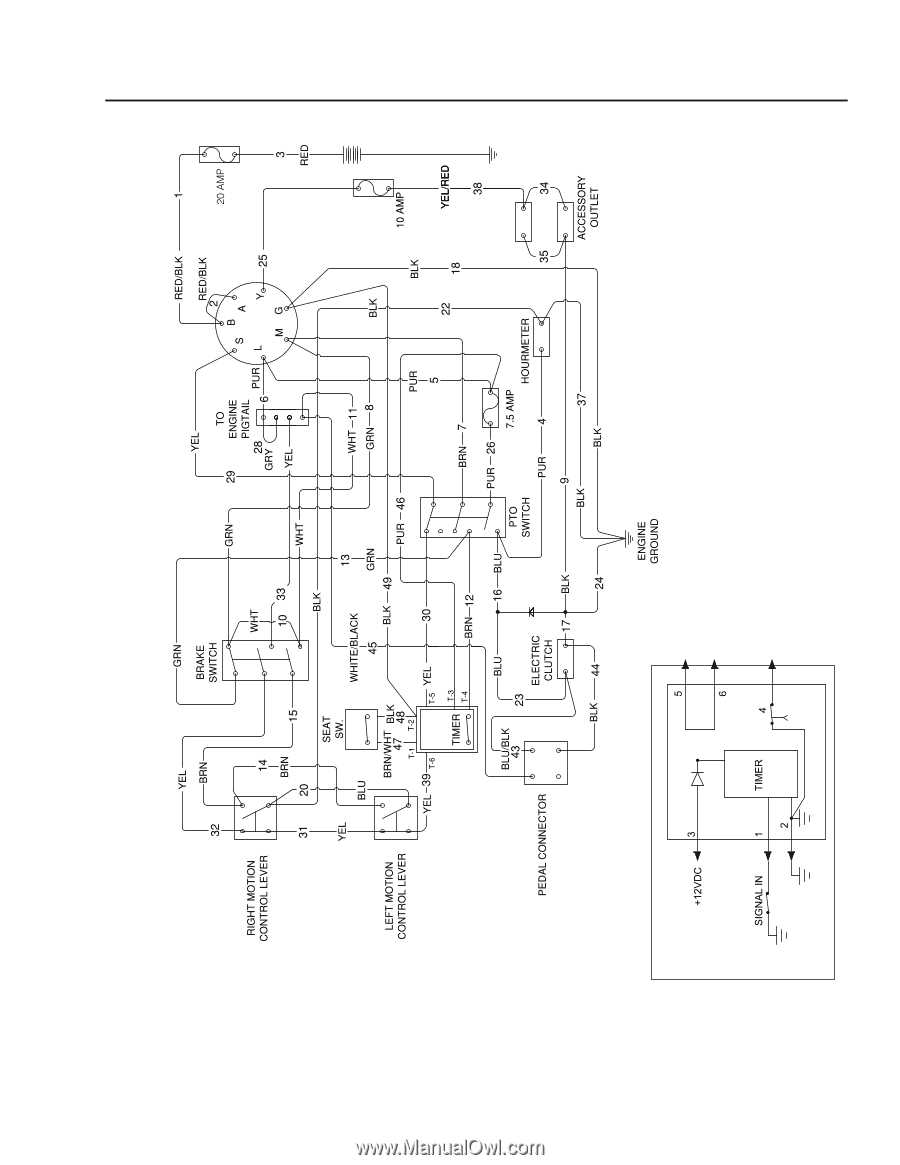

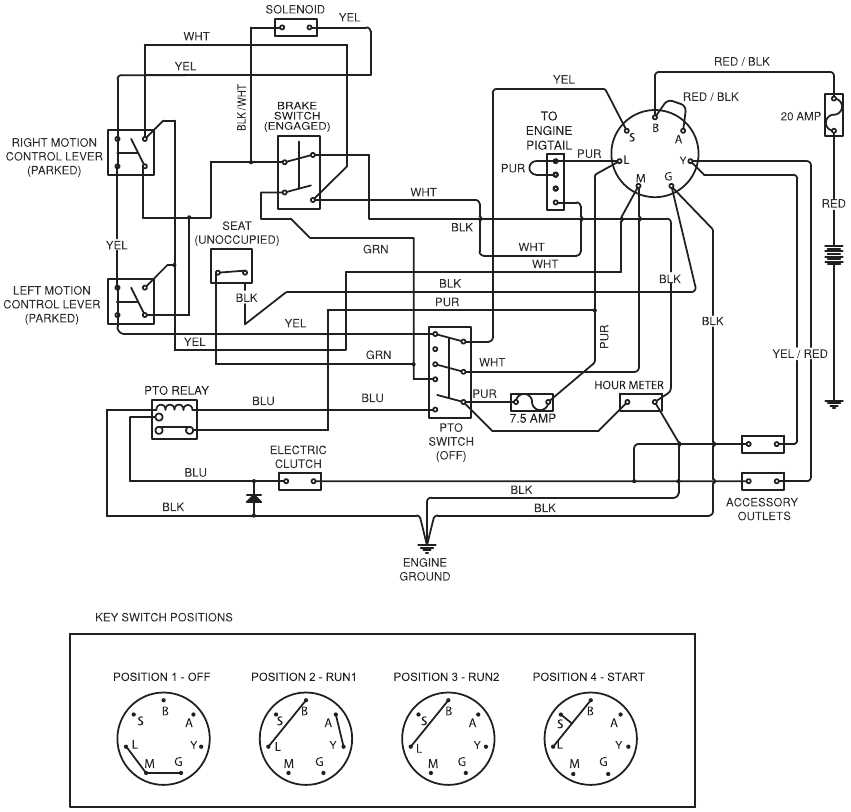

This section aims to provide insights into the visual representation of components and their interrelations in a specific machine. By analyzing this schematic, users can gain a deeper understanding of how each element functions within the overall assembly.

Importance of the Visual Representation

A comprehensive illustration of components serves multiple purposes:

- Facilitates the identification of individual elements.

- Shows the assembly order for effective repairs.

- Highlights the relationships and connections between different parts.

Key Features to Consider

When examining the visual representation, keep in mind the following aspects:

- Labels: Clear markings can assist in understanding each part’s function.

- Connections: Arrows and lines often indicate how components are linked.

- Grouping: Similar parts may be clustered, reflecting their operational unity.

Commonly Replaced Components

Regular maintenance and occasional replacements are essential for keeping equipment in optimal working condition. Certain parts tend to wear out more frequently due to their functionality and exposure to various environmental factors. Identifying these components can help ensure efficient operation and extend the lifespan of the machinery.

| Component | Symptoms of Wear | Replacement Frequency |

|---|---|---|

| Blades | Dullness, uneven cuts | Every season or after 25 hours of use |

| Belts | Squeaking noises, slippage | Every 100 hours of use |

| Filters | Reduced airflow, clogging | Every 50 hours of use |

| Batteries | Difficulty starting, low power | Every 2-3 years |

| Wheels | Cracks, wobbling | As needed, depending on terrain |

By keeping track of these commonly replaced parts, users can maintain peak performance and prevent unexpected breakdowns during use.

Identifying Replacement Parts

Understanding the components of your equipment is crucial for maintaining its performance and longevity. Recognizing when to replace elements can prevent larger issues down the line.

To accurately identify the necessary components, consider the following steps:

- Consult the user manual for specific information on your model.

- Inspect the equipment for visible signs of wear or damage.

- Note any unusual sounds or performance issues that may indicate a failing component.

Additionally, utilizing online resources can be invaluable:

- Search for forums or communities dedicated to your equipment.

- Watch tutorial videos that showcase common replacements.

- Refer to manufacturer websites for detailed specifications and guides.

By following these steps, you can ensure that you are well-informed when seeking the ultimate replacement elements for your machinery.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and efficiency of your outdoor equipment. By implementing consistent maintenance practices, you can enhance performance, reduce the likelihood of breakdowns, and extend the lifespan of your machinery. Here are some key strategies to consider for optimal care.

Regular Cleaning

Keeping your equipment clean is crucial. Debris, dirt, and grass clippings can accumulate and impede functionality. After each use, take a moment to remove any buildup. Use a soft brush or a cloth to wipe down surfaces, ensuring all components remain unobstructed.

Routine Inspections

Conducting periodic checks on your machinery can help identify potential issues before they escalate. Look for signs of wear and tear, such as frayed cables or loose screws. Addressing minor problems early can save you time and resources in the long run. Always refer to your user manual for specific inspection guidelines.

Incorporating these practices into your maintenance routine will significantly enhance the reliability and performance of your outdoor equipment.

Tools Needed for Repairs

When undertaking maintenance or fixing equipment, having the right instruments is crucial for ensuring efficiency and effectiveness. A well-equipped toolbox not only speeds up the process but also enhances safety and accuracy during repairs.

Basic Hand Tools: Essential items such as wrenches, screwdrivers, and pliers are fundamental for most repair tasks. These tools allow for adjustments and replacements of various components.

Specialized Equipment: Depending on the type of machinery, specific tools may be required. This could include torque wrenches for precise tightening or diagnostic tools for troubleshooting issues.

Safety Gear: Always prioritize safety. Protective gloves, goggles, and ear protection should be on hand to safeguard against potential hazards during repairs.

Cleaning Supplies: Keeping the workspace tidy and components clean is vital. Having brushes, rags, and appropriate cleaning agents can aid in maintaining the equipment’s longevity.

With the right tools and preparations, any repair task can be tackled efficiently and safely, ensuring that the machinery operates smoothly for years to come.

Safety Precautions During Repairs

When engaging in maintenance or repair tasks, ensuring safety is paramount to prevent injuries and accidents. Adhering to specific guidelines can significantly reduce risks while working with machinery and tools.

- Always wear appropriate personal protective equipment, including gloves, goggles, and steel-toed boots.

- Ensure the machine is powered off and disconnected from any power source before beginning repairs.

- Familiarize yourself with the equipment’s manual and safety instructions prior to starting any work.

Moreover, consider the following best practices:

- Keep your workspace clean and organized to avoid tripping hazards.

- Use tools that are suitable for the task at hand, avoiding makeshift solutions.

- Never work alone; have someone nearby in case of emergencies.

By following these safety measures, you can delve into repairs with confidence, ensuring both efficiency and well-being throughout the process.

Finding OEM vs. Aftermarket Parts

When it comes to maintaining your equipment, understanding the differences between original manufacturer components and those produced by third-party suppliers is crucial. Each option offers distinct advantages and potential drawbacks that can influence performance, cost, and longevity.

Here are some key considerations to help you decide:

- Quality: Original components are typically manufactured to the exact specifications set by the original equipment maker, ensuring a precise fit and reliable performance. In contrast, third-party alternatives may vary in quality, so research and reviews are essential.

- Cost: While original components often come at a premium price, aftermarket options can be more budget-friendly. However, be cautious of excessively low prices that may indicate inferior quality.

- Availability: Original components can sometimes be harder to find, especially for older models. Third-party suppliers often provide a broader range of options, making it easier to locate what you need.

- Warranty and Support: Original components usually come with manufacturer warranties, providing peace of mind. Many aftermarket options do not offer the same level of support or guarantees.

- Compatibility: Ensure that any third-party components are compatible with your specific model. Many aftermarket parts are designed to fit multiple models, but not all will perform equally well.

Ultimately, the choice between original and aftermarket components depends on your specific needs, budget, and preferences. Weigh the pros and cons carefully to make an informed decision that best suits your requirements.

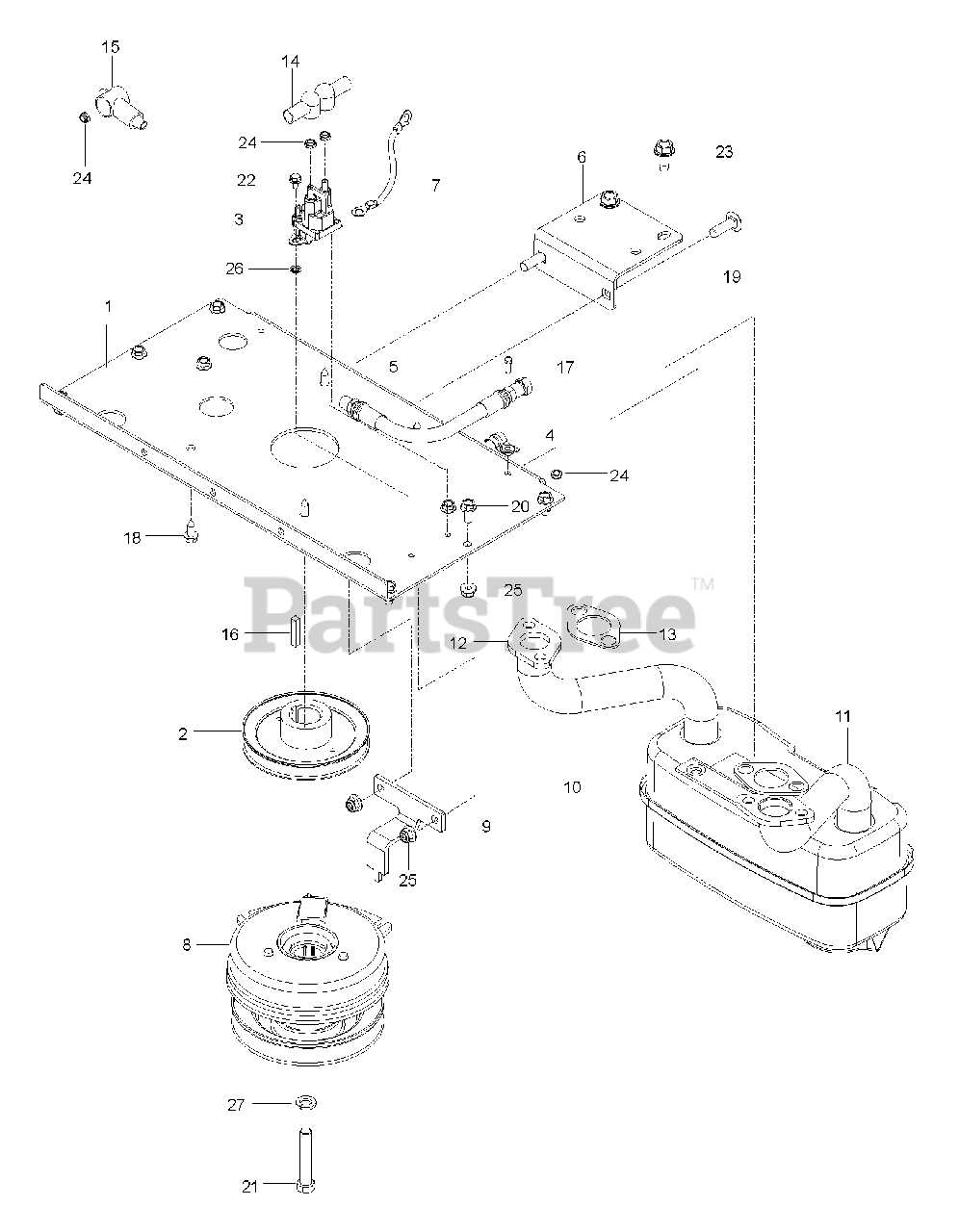

Installation Instructions for Key Parts

Ensuring the proper installation of essential components is crucial for optimal performance and longevity of your equipment. This section outlines the steps necessary for correctly fitting these elements, enabling you to maintain your machinery effectively.

| Component | Installation Steps |

|---|---|

| Blade Assembly |

1. Begin by securing the machine on a flat surface. 2. Remove the safety cover. 3. Align the blade with the mounting bracket. 4. Tighten the bolts evenly to ensure stability. 5. Reattach the safety cover. |

| Fuel Filter |

1. Locate the fuel tank and drain any existing fuel. 2. Remove the old filter from the fuel line. 3. Install the new filter in the correct orientation. 4. Refill the tank with fresh fuel. |

| Air Cleaner |

1. Open the air cleaner housing. 2. Remove the old filter and clean the housing. 3. Insert the new filter, ensuring a snug fit. 4. Close the housing securely. |

Following these instructions will help ensure that your equipment operates smoothly and efficiently, minimizing the risk of damage and enhancing overall functionality.

Troubleshooting Common Issues

When operating outdoor machinery, encountering difficulties is not uncommon. Understanding how to identify and resolve these problems can greatly enhance the performance and longevity of your equipment. This section aims to provide insights into typical malfunctions and effective solutions to restore functionality.

Engine Performance Problems

One of the most frequent issues is related to engine performance. Symptoms may include stalling, difficulty starting, or reduced power. Start by checking the fuel system; ensure that there is an adequate supply of clean fuel and that the filters are free of clogs. Inspecting spark plugs for wear or damage is also essential, as faulty plugs can hinder ignition. Regular maintenance, such as replacing air filters, will help prevent these issues.

Mechanical Failures

Another common challenge involves mechanical components. Users might experience unusual noises, vibrations, or inconsistent operation. In such cases, inspecting belts and cables for signs of wear or misalignment is crucial. Additionally, checking for loose or damaged hardware can prevent further complications. Keeping parts lubricated and in good condition is key to smooth operation and can often resolve these mechanical concerns.

Customer Support and Resources

Access to reliable assistance and comprehensive resources is essential for maintaining and enhancing the performance of your equipment. This section provides valuable information on where to find support, manuals, and other helpful materials to ensure you have everything you need for optimal operation.

For inquiries regarding your machinery, expert support is available through various channels. These include online platforms, dedicated hotlines, and authorized service centers. Whether you have questions about functionality or require troubleshooting assistance, these resources are designed to help you resolve issues efficiently.

Additionally, accessing user manuals and instructional guides can provide insights into proper usage and maintenance. These documents often contain detailed information that can enhance your understanding and ensure longevity of your device.

| Support Resource | Description | Contact Method |

|---|---|---|

| Online Help Center | A comprehensive database of FAQs and troubleshooting tips. | Visit the official website |

| Customer Service Hotline | Direct access to knowledgeable representatives. | Call the support number |

| Authorized Service Centers | Professional technicians for repairs and maintenance. | Locate a center near you |

| User Manuals | Detailed guides on usage and care. | Download from the website |

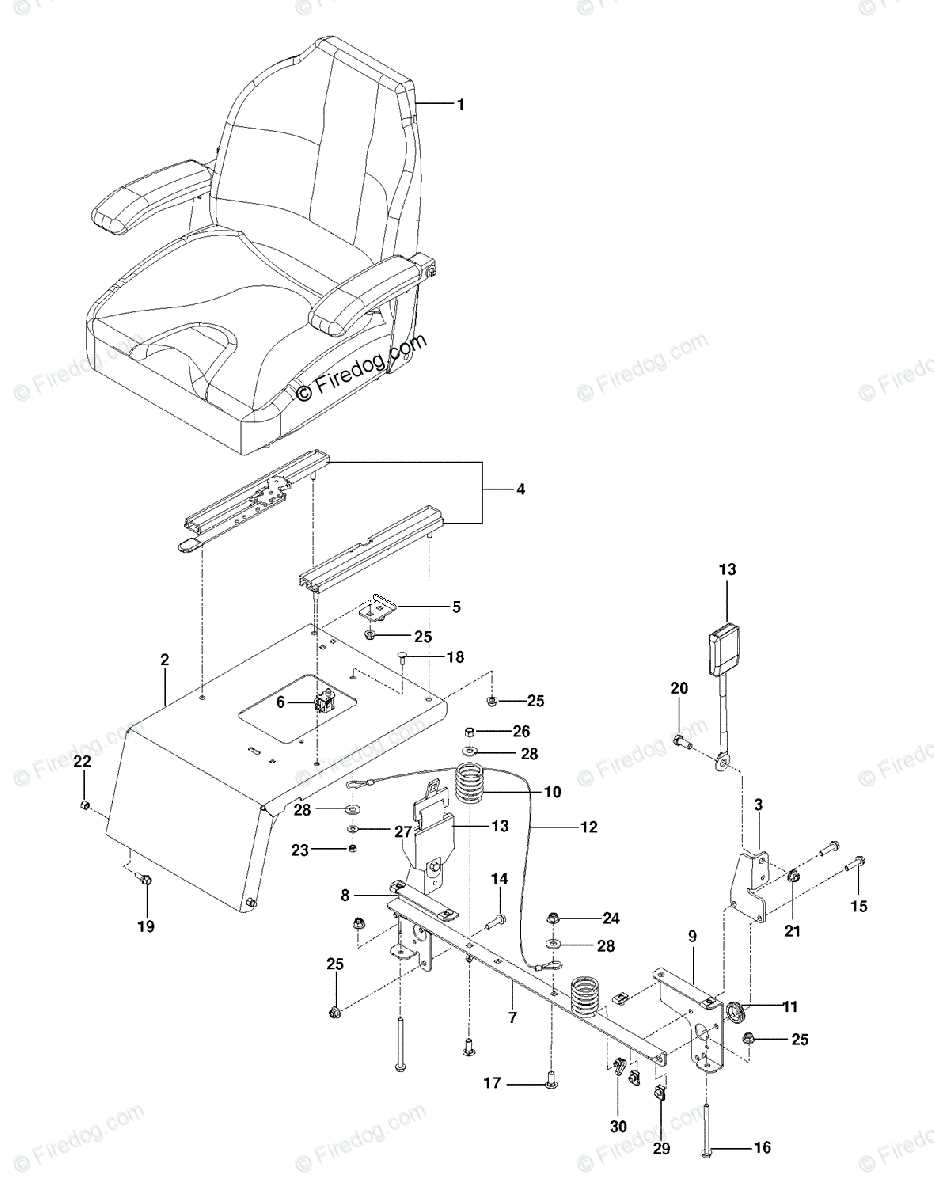

Upgrades and Accessories for M-ZT 61

Enhancing your machine can significantly improve its performance and versatility. With the right upgrades and additional features, you can tailor your equipment to meet specific needs, ensuring that it operates at its ultimate efficiency while delivering an exceptional experience.

Performance Enhancements

Consider investing in advanced blades and cutting decks that can provide a cleaner cut and improved durability. Upgrading the engine or adding a high-capacity fuel tank can also enhance overall performance, allowing for longer operation times without frequent refueling.

Convenience Features

Accessories such as mulching kits, baggers, and rear hitch attachments can transform your machine into a multifunctional tool. Additionally, comfort upgrades like seat cushions and ergonomic steering wheels can make long hours of use more enjoyable.