Maintaining outdoor machinery can seem daunting, yet grasping the arrangement of its components is essential for effective upkeep. An in-depth examination of the individual elements will enable users to identify and address issues more efficiently. This knowledge not only enhances the longevity of the equipment but also ensures optimal performance throughout its use.

By delving into the layout of these elements, operators can better comprehend how each part contributes to the overall functionality of the machinery. Familiarity with the assembly assists in troubleshooting potential problems and facilitates informed decisions when it comes to repairs or replacements. This insight transforms maintenance from a chore into a manageable task, empowering users to take control of their outdoor equipment.

As you explore the intricate relationships between these components, you will uncover the significance of each one in ensuring seamless operation. Understanding how the machinery is constructed will allow for smoother maintenance processes and ultimately enhance your outdoor experience. Embracing this knowledge will pave the way for a more proficient approach to caring for your lawn care tools.

This section aims to provide a comprehensive overview of the essential elements that comprise a specific model of a lawn care machine. Understanding these components is vital for effective maintenance and troubleshooting, enabling users to keep their equipment in optimal working condition.

The following are key components found in this particular model:

- Engine: The powerhouse that drives the machine, responsible for its performance and efficiency.

- Chassis: The main frame that supports various parts and provides structural integrity.

- Deck: The cutting mechanism that determines the quality of the grass cut and overall functionality.

- Transmission: The system that transfers power from the engine to the wheels, enabling movement.

- Control Panel: The interface used to operate the machine, allowing users to adjust settings easily.

Each of these elements plays a crucial role in the overall operation of the equipment, contributing to its efficiency and effectiveness. Familiarizing oneself with these components can lead to better care and longevity of the machine.

Identifying Key Parts and Functions

Understanding the essential components of your lawn care machine is crucial for efficient operation and maintenance. Each element plays a specific role, contributing to the overall functionality and performance of the equipment. This section will explore these vital components and their significance in ensuring smooth performance.

Main Components

- Engine: The powerhouse of the machine, responsible for providing the necessary energy for operation.

- Transmission: This mechanism transfers power from the engine to the wheels, enabling movement and maneuverability.

- Deck: The housing that contains the cutting blades, designed to effectively trim grass at various heights.

- Wheels: Essential for mobility, the wheels support the machine’s weight and facilitate movement across different terrains.

Supportive Elements

- Battery: Supplies the electrical energy needed to start the engine and power various components.

- Fuel Tank: Stores the liquid energy source required for the engine to operate.

- Cables and Wiring: These connect different parts, allowing for the transmission of signals and power.

- Controls: The interface used by the operator to manage the machine’s functions and settings.

Familiarizing yourself with these essential components will enhance your understanding of how the equipment functions and assist in troubleshooting any issues that may arise.

Understanding the MZ54 Assembly Layout

The configuration of machinery components plays a crucial role in ensuring optimal performance and efficiency. Familiarizing oneself with the structural organization of these elements is essential for proper maintenance and operation. This section aims to provide insights into the assembly framework, highlighting key areas and their functions.

| Component | Description | Function |

|---|---|---|

| Chassis | The main structure that supports all other components. | Provides stability and durability. |

| Engine | The power source driving the equipment. | Converts fuel into mechanical energy. |

| Transmission | Mechanism that transfers power from the engine to the wheels. | Enables speed regulation and directional control. |

| Deck | The platform housing the cutting mechanism. | Facilitates efficient grass cutting and discharge. |

| Wheels | Support and enable mobility. | Ensure smooth navigation across various terrains. |

Common Replacement Parts for MZ54

Regular maintenance of outdoor power equipment often involves replacing various components to ensure optimal performance and longevity. Understanding the essential items that require occasional substitution can greatly enhance the efficiency of your machine. Below are key elements that commonly need attention and may require replacement over time.

- Blades: Dull or damaged cutting blades can significantly affect the quality of the cut. It’s advisable to check and replace them regularly.

- Batteries: The power source may lose its ability to hold a charge, necessitating a new unit for reliable operation.

- Filters: Air and fuel filters play a crucial role in maintaining engine efficiency. Regular replacement can prevent debris from affecting performance.

- Belts: Worn or frayed drive belts can hinder the functioning of the mower. Inspecting and replacing these components can prevent further damage.

- Tires: Maintaining proper tire pressure and tread is essential for stability and maneuverability. Replacing tires that show signs of wear is crucial.

By staying aware of these vital components and addressing their condition proactively, users can ensure their machinery remains in excellent working order. Regular inspections and timely replacements can help prevent more significant issues down the line.

Maintenance Tips for MZ54 Components

Proper upkeep of your machinery’s elements is crucial for ensuring longevity and optimal performance. By following a few essential guidelines, you can enhance the reliability and efficiency of your equipment, preventing unnecessary breakdowns and costly repairs.

Regular inspection and care of the various components will help identify potential issues before they escalate. Here are some tips to keep your system running smoothly:

- Check and clean the air filters regularly to maintain airflow and prevent debris buildup.

- Examine the blades for sharpness and damage, sharpening or replacing them as necessary for efficient cutting.

- Inspect belts for wear and tension, adjusting or replacing them if they show signs of cracking or fraying.

- Ensure all bolts and screws are secure to prevent loosening during operation.

- Regularly lubricate moving parts to reduce friction and wear, using the appropriate lubricant for each component.

- Monitor fluid levels, including oil and fuel, refilling or changing as specified in the user manual.

Adhering to these maintenance practices will not only prolong the life of your equipment but also enhance its performance, allowing for a more productive and enjoyable experience.

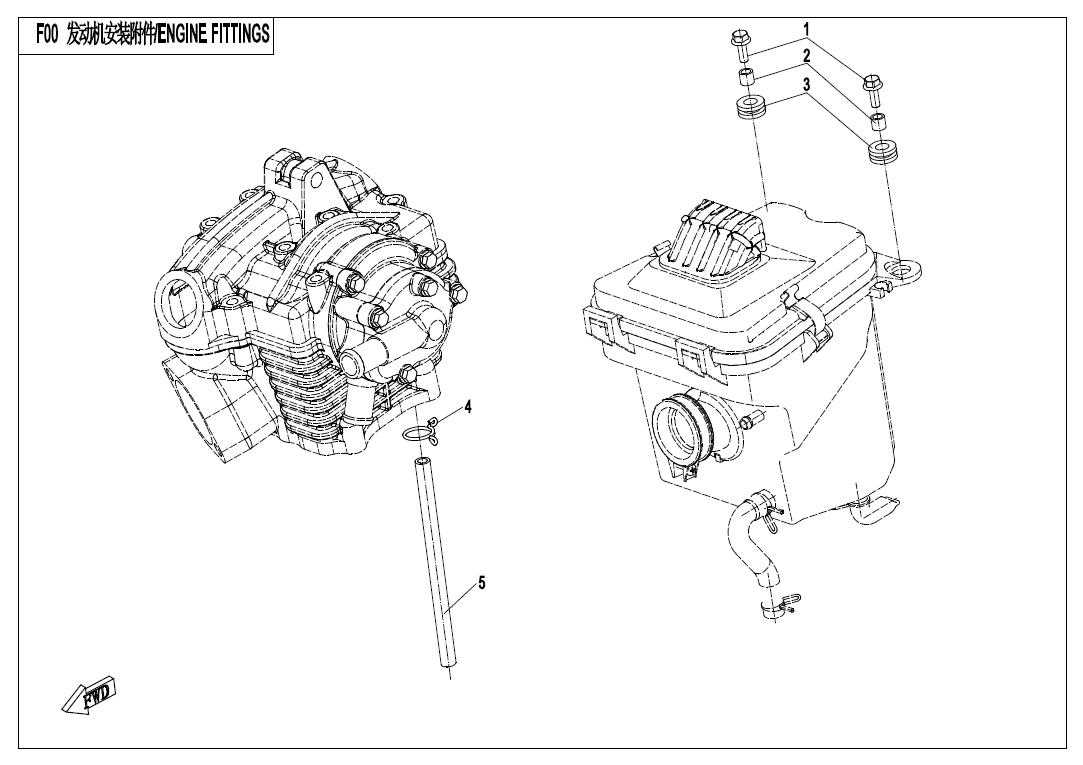

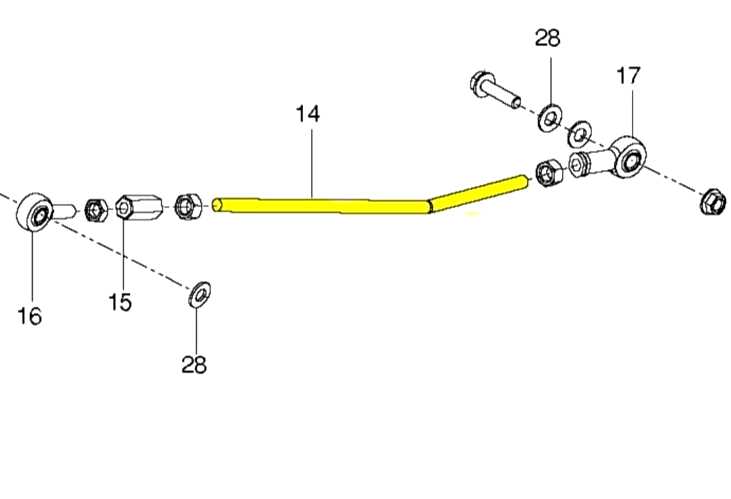

How to Read a Parts Diagram

Understanding an assembly illustration is crucial for effective maintenance and repair of any machinery. These visual representations provide detailed information about the various components and their connections, helping users identify specific elements and their functions within the overall system.

To begin interpreting an assembly illustration, familiarize yourself with the layout and symbols used. Each element is typically labeled with unique identifiers, which correspond to a legend or list, offering a comprehensive description of each part. Pay attention to the scale of the image, as this affects the size and placement of the components.

Next, look for any grouping or sections within the illustration. Components are often categorized by their function, which aids in understanding how different parts interact. Take notes on the relationships between parts, noting any assemblies or subassemblies that may be highlighted. This will provide clarity on how to proceed with repairs or replacements.

Locating Genuine Husqvarna Parts

Finding authentic components for your outdoor equipment is essential to ensure optimal performance and longevity. Quality parts contribute to the reliability of your machinery and can prevent costly repairs in the future. This section will guide you through the best methods to source original replacements for your machine.

Authorized Retailers

One of the most reliable ways to obtain genuine components is through authorized dealers. These retailers specialize in specific brands and provide a wide selection of original items. When shopping with authorized vendors, you can be confident in the quality and compatibility of the products.

Online Resources

In the digital age, many online platforms offer authentic components. Official websites and reputable e-commerce platforms often carry a comprehensive inventory of necessary items. It’s advisable to read customer reviews and verify the authenticity of the seller before making a purchase.

DIY Repair Guide for MZ54

Embarking on a do-it-yourself repair journey for your outdoor equipment can be both rewarding and cost-effective. Understanding the various components and their functions is essential for maintaining optimal performance. This guide aims to provide insights into troubleshooting and fixing common issues, empowering you to take control of your machine’s upkeep.

Start by familiarizing yourself with the essential elements of your equipment, including the engine, transmission, and cutting mechanism. Each component plays a vital role in overall functionality. Begin by identifying any visible signs of wear or damage. Regular inspection can help you catch potential problems early, preventing more extensive repairs down the line.

When undertaking repairs, having the right tools and supplies on hand is crucial. Basic tools such as wrenches, screwdrivers, and pliers are often all that is needed for minor fixes. Always refer to the user manual for specific instructions related to your model, ensuring you follow proper safety protocols throughout the process. Whether you’re replacing a belt, adjusting the cutting height, or changing the oil, a systematic approach will yield the best results.

Additionally, consider joining online forums or local repair groups for support and shared experiences. Engaging with fellow enthusiasts can provide valuable tips and insights, making your repair efforts more effective and enjoyable. By taking the initiative to address repairs yourself, you not only save money but also gain a deeper understanding of your equipment, ensuring its longevity and efficiency.

Tools Required for MZ54 Maintenance

Regular upkeep of outdoor machinery is essential for optimal performance and longevity. Having the right equipment on hand simplifies maintenance tasks and ensures that everything functions smoothly. Below is a comprehensive list of essential tools to assist in the routine care and servicing of your machine.

| Tool | Description |

|---|---|

| Socket Set | Useful for loosening and tightening bolts in various components. |

| Screwdriver Set | Required for adjusting or replacing smaller screws in the machinery. |

| Wrench Set | Essential for securing or removing nuts on the equipment. |

| Grease Gun | For applying lubrication to moving parts, reducing wear and tear. |

| Cleaning Brush | Helps in removing debris and dirt from hard-to-reach areas. |

| Oil Can | Facilitates easy application of oil to various parts as needed. |

| Safety Gear | Includes gloves and goggles for personal protection during maintenance tasks. |

Equipping yourself with these tools not only streamlines the maintenance process but also enhances the overall efficiency and reliability of your machinery.

Exploring the MZ54’s Engine Specs

This section delves into the intricacies of the power unit designed for optimal performance and efficiency. Understanding the characteristics of this machine’s engine provides valuable insights into its capabilities and functionality, enhancing the overall user experience.

The heart of the machine is built to deliver impressive power, ensuring effective operation across various terrains. Key specifications include:

- Engine Type: A robust, air-cooled unit designed for durability.

- Cylinder Capacity: This aspect influences the power output and efficiency levels.

- Horsepower Rating: Reflects the engine’s capability to handle demanding tasks.

- Fuel System: An efficient system that optimizes fuel usage and minimizes emissions.

These features are critical for those who seek reliability and performance in their outdoor equipment. Additionally, regular maintenance and proper usage of the power unit can significantly enhance its lifespan and efficiency.

Frequently Asked Questions About MZ54

This section addresses common inquiries related to the mower model, providing essential insights for users. Whether you’re a seasoned operator or new to this machine, understanding its features and components is crucial for optimal performance.

What maintenance should I perform regularly?

Routine care is vital for ensuring the longevity of your mower. Regularly check the oil levels, clean or replace the air filter, and inspect the blades for sharpness. Adhering to a maintenance schedule can help prevent major issues.

How do I troubleshoot starting problems?

If the mower refuses to start, check the fuel supply and ensure there’s enough gas. Examine the battery and connections for any signs of wear or corrosion. Sometimes, a simple reset can resolve electrical issues.

Where can I find replacement components?

Replacement components can be sourced from authorized dealers or online retailers specializing in outdoor equipment. It’s essential to confirm compatibility with your specific model to ensure proper fit and functionality.

How often should I sharpen the blades?

Blade sharpening is recommended after every 20-25 hours of use or at the beginning of the mowing season. Keeping blades sharp ensures a clean cut, which is healthier for your lawn.

What is the average lifespan of this mower?

With proper maintenance, these mowers can last over a decade. Regular servicing and timely replacements of worn-out parts contribute significantly to their longevity.