In the world of lawn care equipment, comprehending the intricate layout of various components is essential for effective maintenance and repair. A thorough understanding of these assemblies allows users to diagnose issues more efficiently and ensure their machines operate at peak performance.

Each model features a unique configuration of parts that work harmoniously to deliver reliable functionality. By familiarizing oneself with these arrangements, operators can better grasp how each element contributes to the overall performance of their machine.

Moreover, recognizing the specific roles of individual pieces aids in identifying wear and tear, ultimately prolonging the lifespan of the equipment. Whether you’re a seasoned professional or a weekend warrior, mastering the anatomy of your machine can lead to enhanced productivity and satisfaction in your lawn care endeavors.

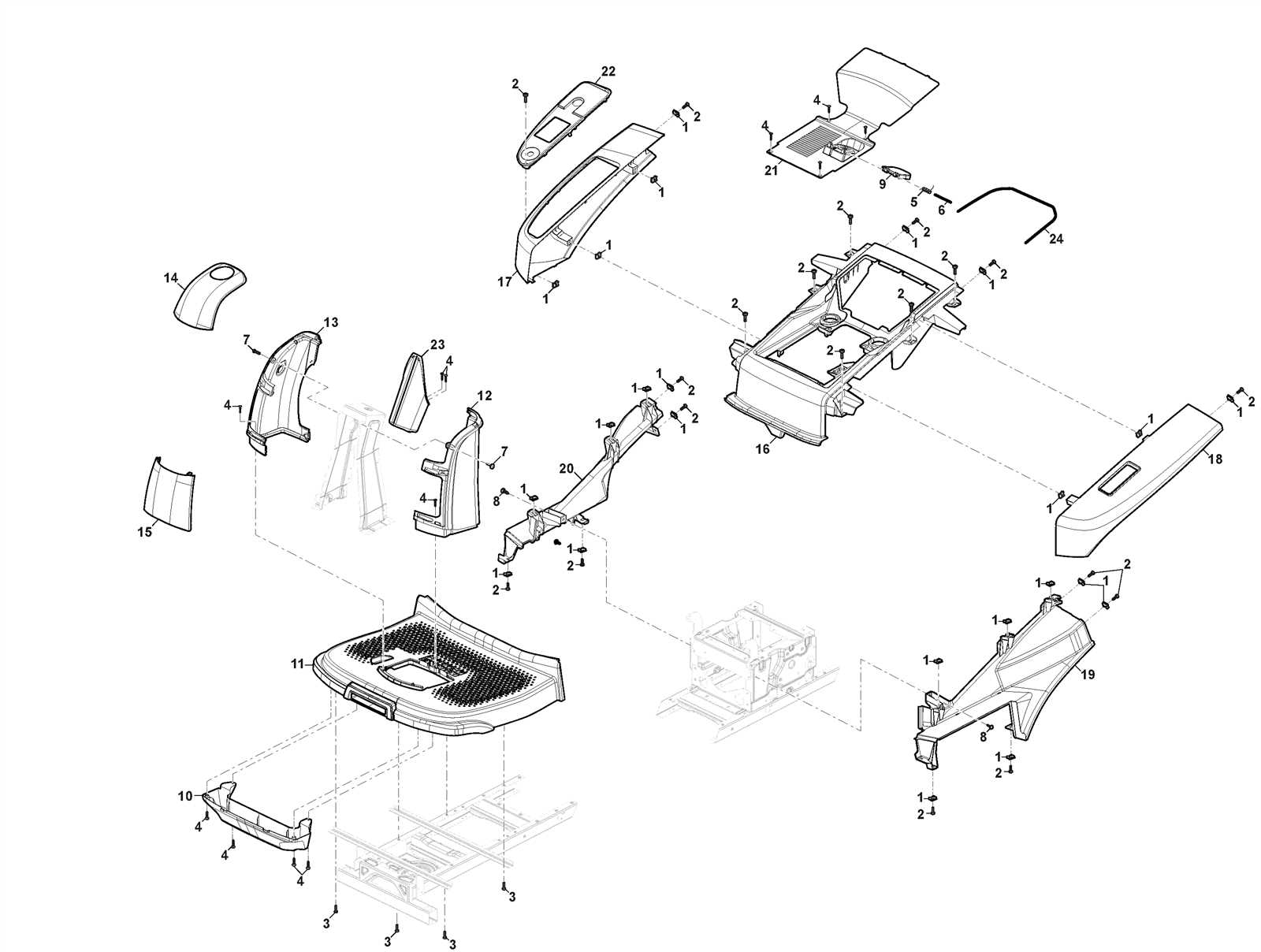

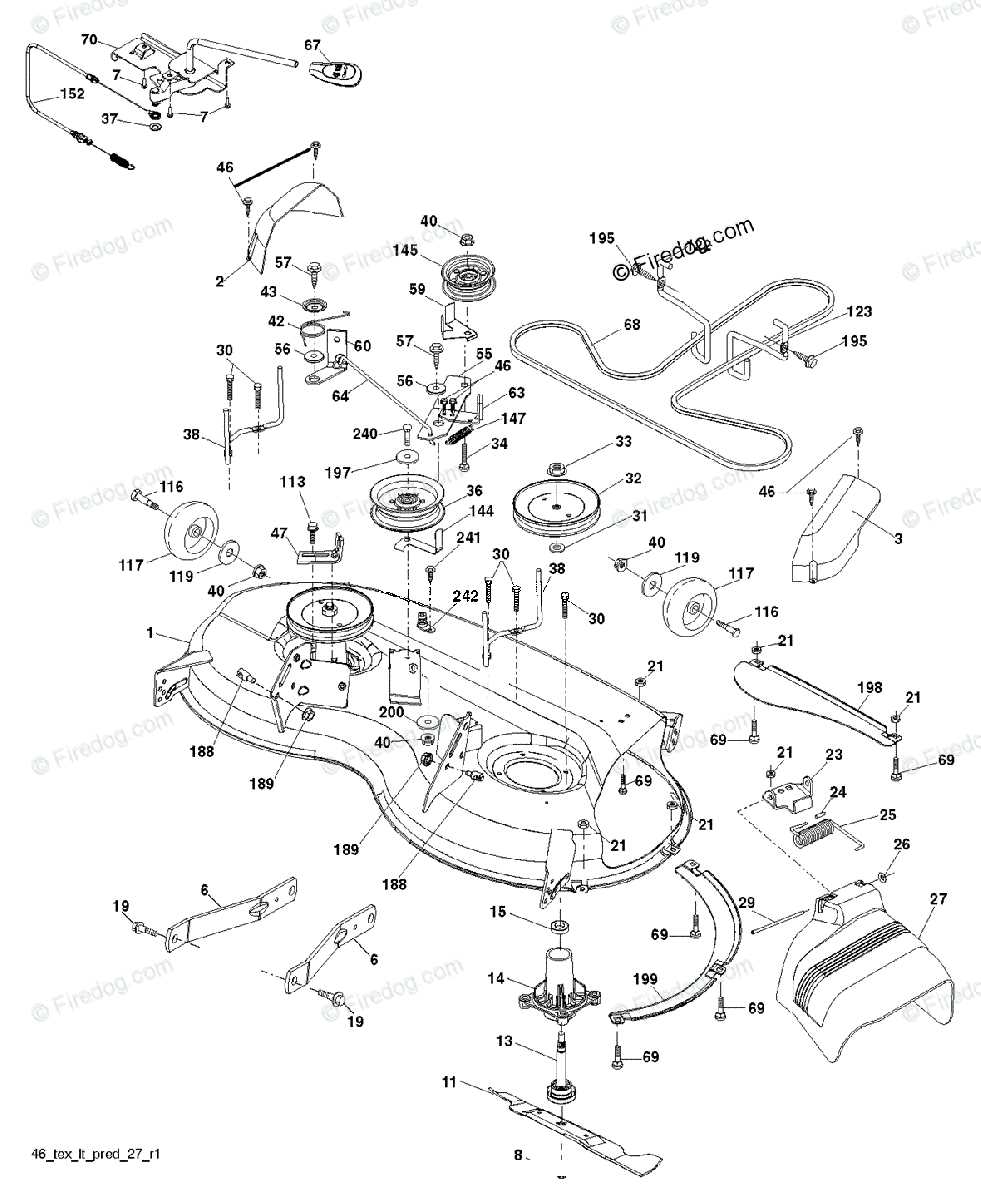

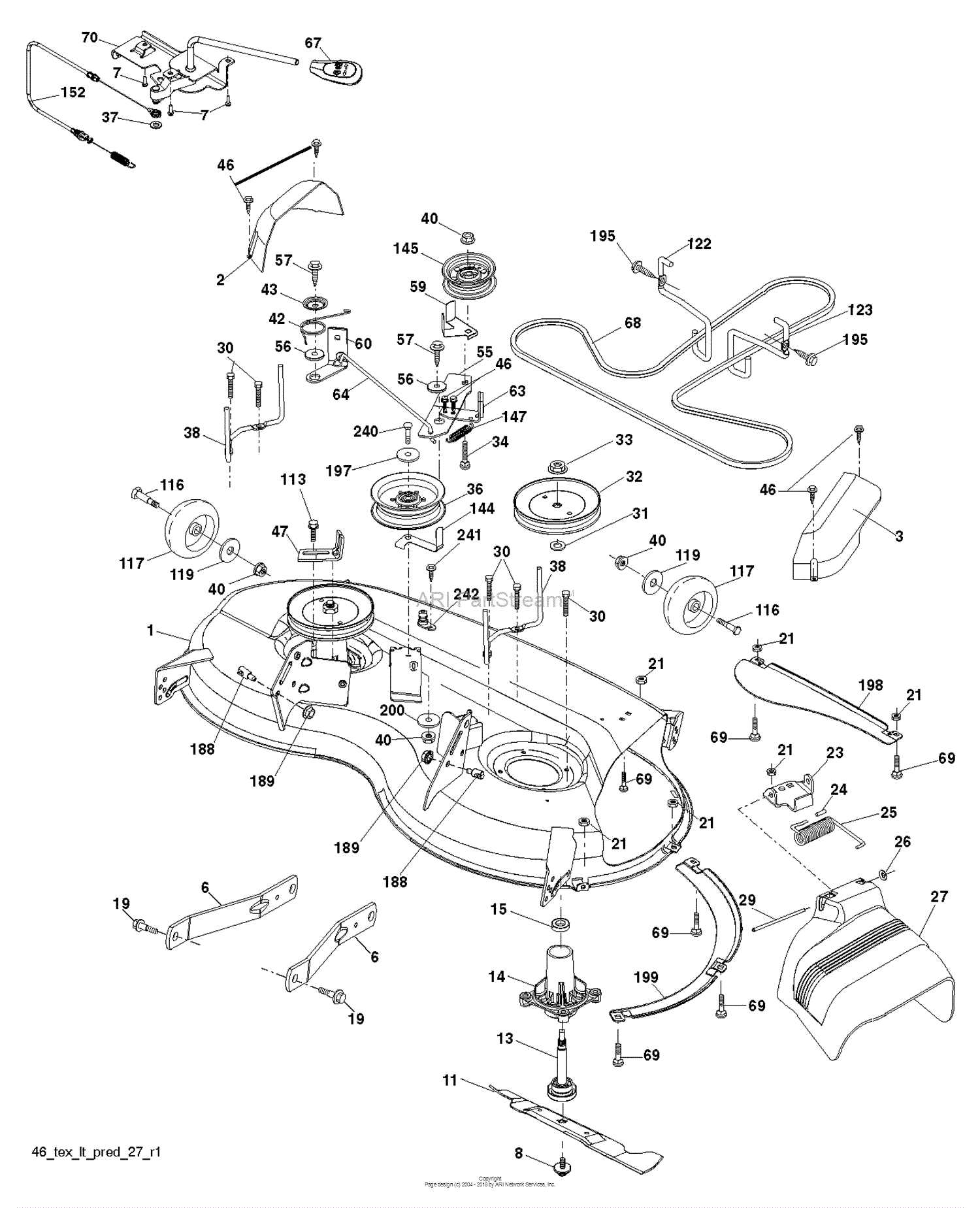

Understanding Husqvarna YTH20K46 Components

Gaining insight into the various elements of a lawn mower can enhance your maintenance and repair capabilities. Each component plays a vital role in the overall functionality of the machine, contributing to its efficiency and performance. Familiarity with these parts can also simplify troubleshooting processes when issues arise.

Key Components

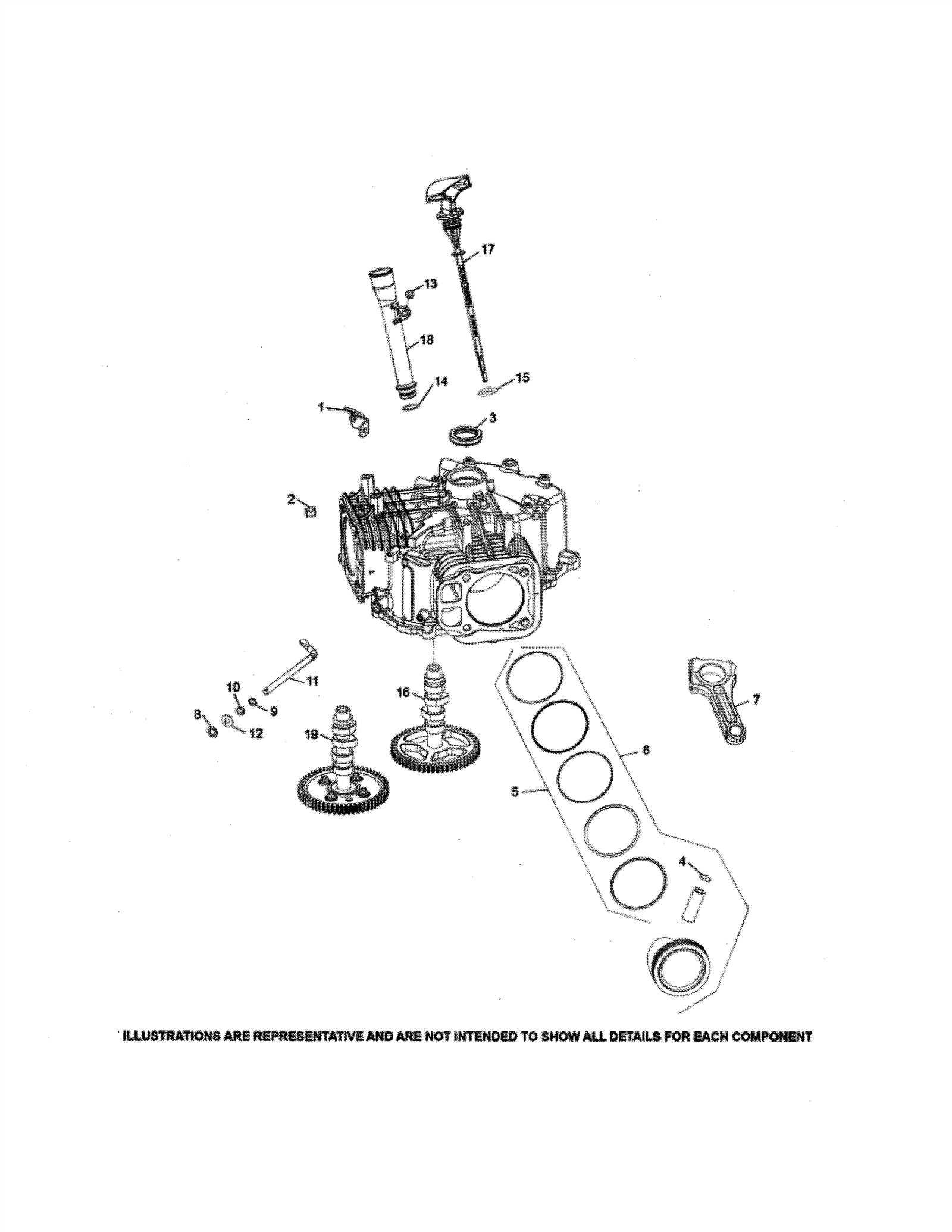

- Engine: The powerhouse that drives the mower, responsible for generating the necessary force for cutting grass.

- Deck: The housing that contains the cutting blades, designed for optimal airflow and grass discharge.

- Blades: Sharp instruments that perform the cutting action, available in various designs for different grass types.

- Transmission: A system that transmits power from the engine to the wheels, influencing speed and maneuverability.

- Fuel System: Includes the tank and lines that deliver fuel to the engine, essential for operation.

- Wheels: Critical for mobility, ensuring smooth navigation over diverse terrains.

Maintenance Tips

- Regularly inspect and sharpen the blades to ensure clean cuts.

- Check the oil levels and change the oil according to the manufacturer’s guidelines.

- Keep the deck clean to prevent grass buildup that can affect performance.

- Examine the fuel system for leaks or blockages that may hinder engine function.

- Inspect the wheels for wear and proper inflation to maintain optimal traction.

Understanding these fundamental parts and their maintenance needs will help ensure your mowing machine remains in peak condition, allowing for a well-manicured lawn and efficient operation.

Essential Parts for Lawn Maintenance

Effective lawn upkeep relies on a variety of components that work together to ensure a healthy and vibrant outdoor space. Understanding these key elements can enhance the efficiency and longevity of your gardening tools.

- Blades: Sharp and durable blades are crucial for achieving a clean cut.

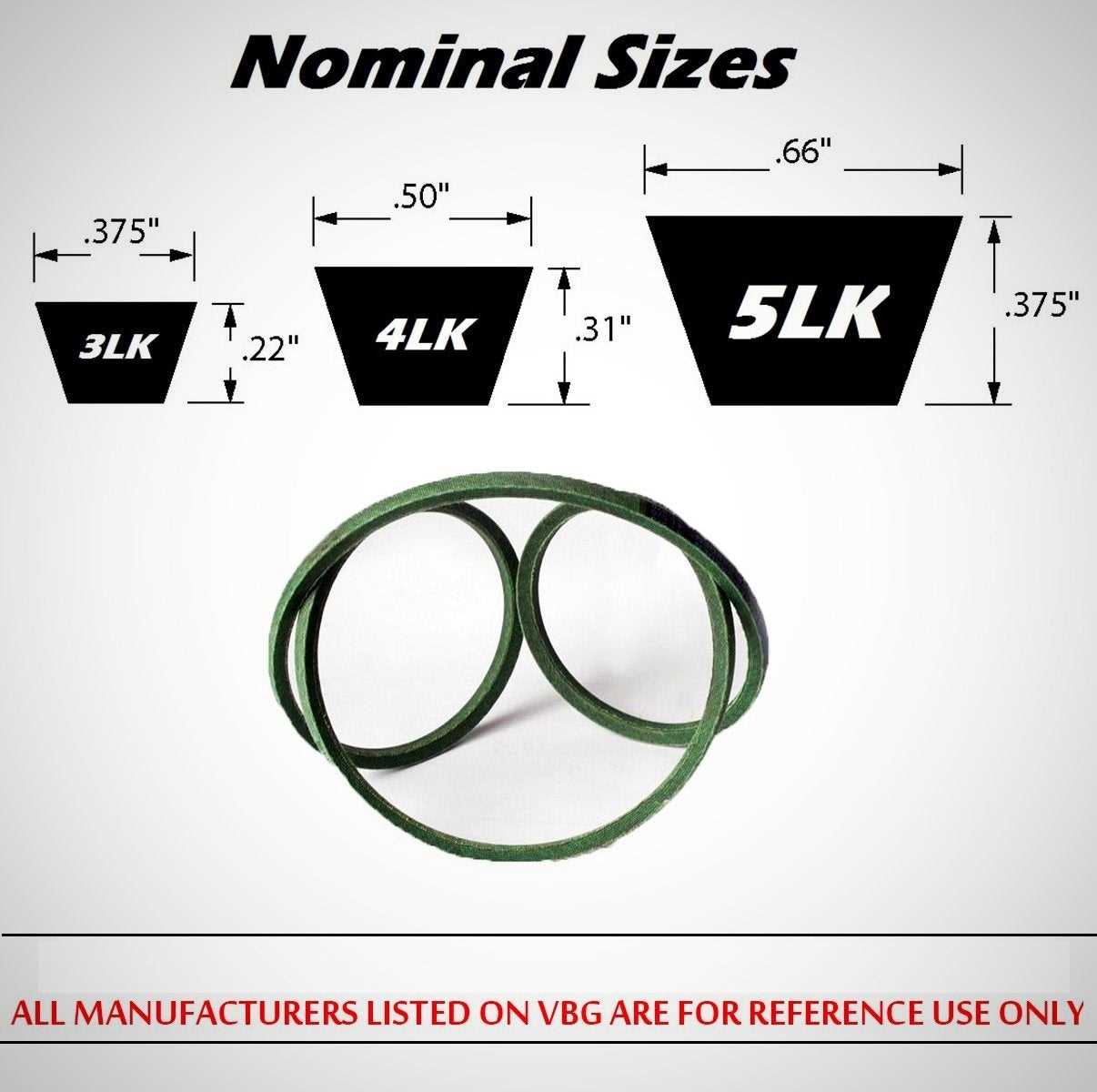

- Belts: These components facilitate smooth operation and power transfer.

- Filters: Air and fuel filters maintain optimal engine performance.

- Wheels: Quality wheels enhance maneuverability and stability on uneven terrain.

By focusing on these vital parts, you can delve into effective strategies for maintaining your lawn equipment and achieving the ultimate garden aesthetics.

How to Access the Parts Diagram

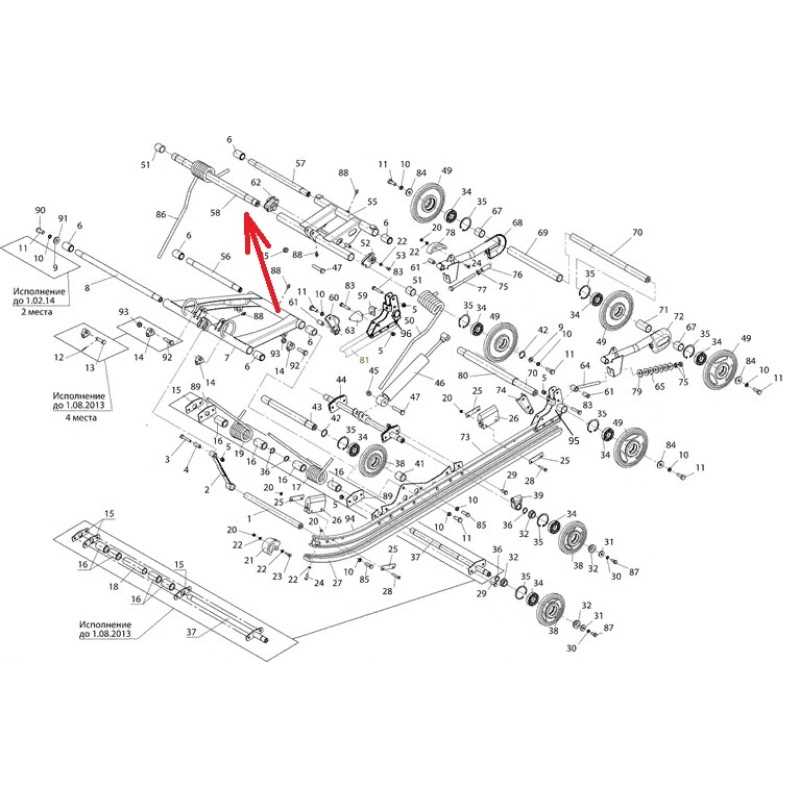

Finding the schematic for your equipment is essential for maintenance and repairs. Accessing these visual guides can simplify the identification of components, ensuring you have the right information at your fingertips.

To begin, visit the manufacturer’s official website or authorized service portals. There, you can typically find a dedicated section for resources, including illustrations and technical documents. Enter the model number of your equipment to narrow down the search.

If online resources are not available, consider reaching out to local dealers or service centers. They often possess printed materials or can provide digital copies of the necessary schematics. Additionally, forums and community websites can be invaluable for obtaining shared resources from fellow users.

Finally, ensure you have a clear understanding of your equipment’s specific components before diving into the visuals. Familiarizing yourself with the machine will enhance your ability to navigate the schematic effectively.

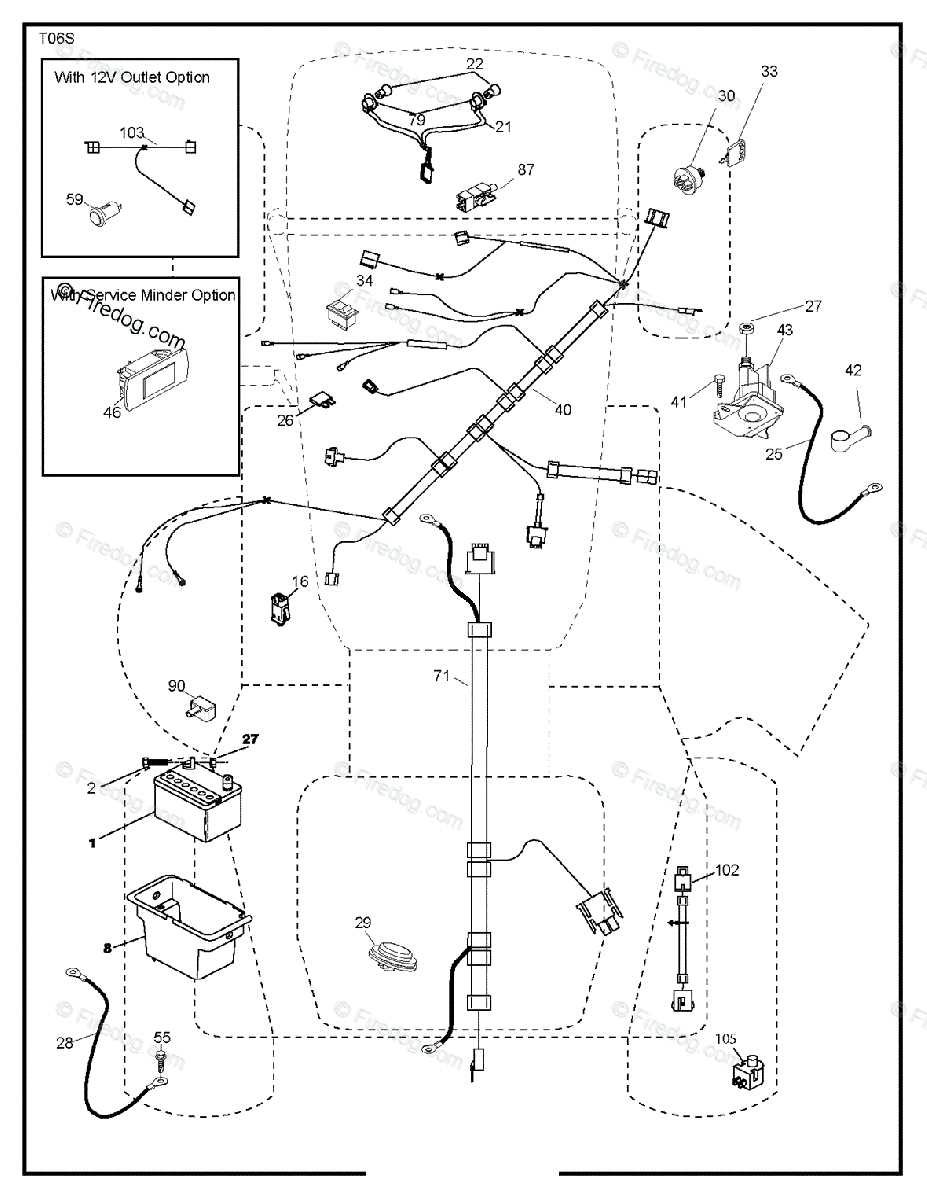

Common Issues with YTH20K46 Parts

When maintaining outdoor machinery, users often encounter various challenges related to components. Understanding these common issues can help in efficient troubleshooting and ensure optimal performance.

- Wear and Tear: Over time, certain elements may deteriorate, affecting functionality.

- Misalignment: Components may become misaligned, leading to operational inefficiencies.

- Corrosion: Exposure to moisture can cause rust and degradation of metal parts.

Regular inspection and proactive measures can mitigate these problems. Here are some frequent concerns:

- Fuel System Blockages: Accumulation of debris can hinder fuel flow.

- Electrical Failures: Wiring issues often result in starting difficulties.

- Blade Damage: Dull or damaged blades can lead to poor cutting performance.

Addressing these issues promptly is essential for maintaining the longevity and effectiveness of the equipment.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the prolonged efficiency and performance of your equipment. By adhering to a consistent maintenance routine, you can prevent potential issues and extend the lifespan of your machine. Here are some practical strategies to keep in mind.

Routine Checks

- Inspect belts and cables for signs of wear or damage.

- Ensure that all fluid levels are adequate and topped up as needed.

- Clean air filters regularly to maintain optimal airflow.

- Examine tires for proper inflation and tread wear.

Seasonal Maintenance

- Sharpen blades at the beginning of each season to ensure a clean cut.

- Change oil and replace filters to keep the engine running smoothly.

- Check battery health and connections, especially before winter.

- Store equipment in a dry place to prevent rust and corrosion.

By implementing these tips, you can significantly enhance the durability and performance of your machinery, ensuring it serves you well for years to come.

Identifying Replacement Parts Easily

Finding the right components for your machinery can be a daunting task. Understanding how to navigate the vast array of options available is essential for effective maintenance. A clear approach can save time and ensure that you acquire the correct items without unnecessary hassle.

Start by familiarizing yourself with the model’s specifications. Knowing the exact type and features will help narrow down your search significantly. Consulting a comprehensive reference guide can provide valuable insights into compatible components.

Additionally, using visual aids such as charts or illustrations can greatly assist in identifying the specific elements you need. These resources typically highlight the various parts and their functions, making it easier to pinpoint the required replacements.

Engaging with online forums and communities dedicated to machinery maintenance can also be beneficial. Here, you can gain firsthand experiences and recommendations from fellow enthusiasts who may have faced similar challenges.

Comparison of OEM and Aftermarket Parts

When considering replacement components for your machinery, the choice between original and third-party alternatives can significantly impact performance and longevity. Understanding the differences between these options is crucial for making an informed decision.

Original equipment manufacturer (OEM) components are designed specifically for a particular machine, ensuring optimal compatibility and reliability. These parts are usually produced to meet the highest standards of quality, often backed by warranties that provide peace of mind.

On the other hand, aftermarket alternatives can offer cost savings and a wider variety of options. However, the quality may vary significantly among different brands, and it’s essential to research thoroughly. Some aftermarket options can outperform OEM counterparts, while others may lead to issues down the line.

Ultimately, the decision should be based on a careful assessment of your needs, budget, and the specific demands of your equipment. Delve into reviews and recommendations to find the best fit for your situation.

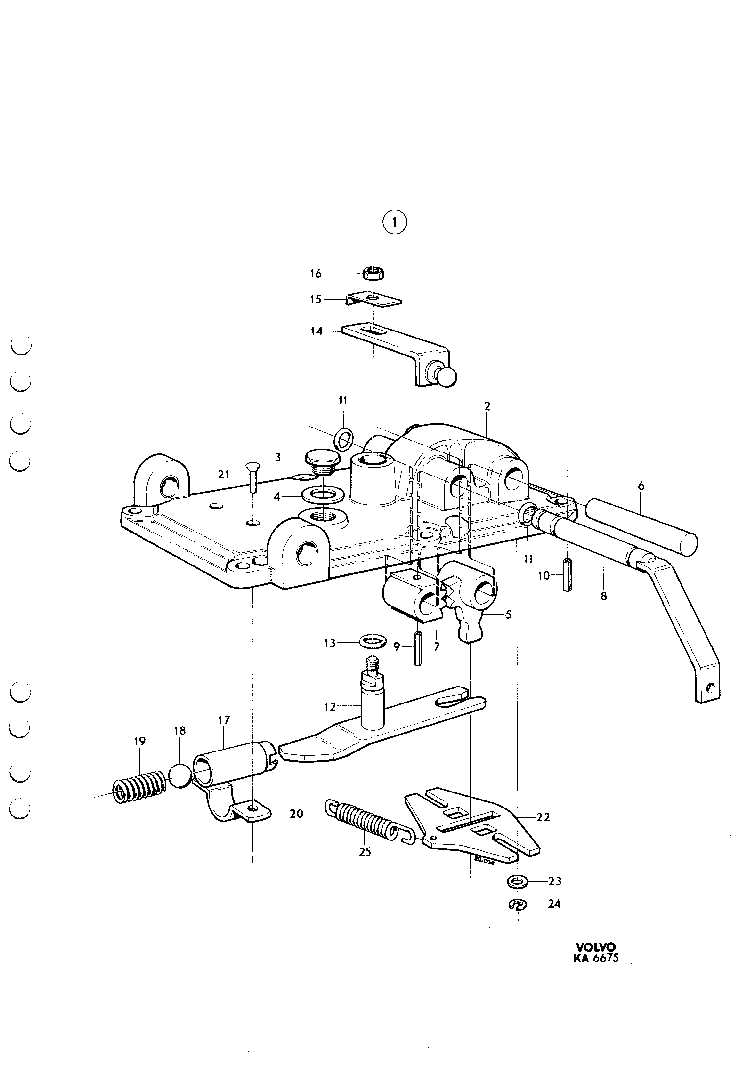

Step-by-Step Repair Instructions

This section provides a comprehensive guide to assist you in troubleshooting and fixing your equipment effectively. By following these detailed steps, you can ensure optimal performance and longevity of your machine.

Tools Required

| Tool | Purpose |

|---|---|

| Screwdriver | To remove and secure screws |

| Wrench | For tightening bolts |

| Socket Set | To reach tight spaces |

| Multimeter | For electrical testing |

Repair Process

Begin by disconnecting the power source to ensure safety. Next, assess the components and identify any visible wear or damage. Carefully disassemble the necessary parts, keeping track of screws and small items. Replace any faulty components with new ones, then reassemble the unit. Finally, conduct a test run to verify that everything operates smoothly.

Tools Required for Parts Replacement

Replacing components in machinery can be a straightforward process if you have the right instruments at hand. This section outlines essential tools that will facilitate the smooth removal and installation of various elements, ensuring efficiency and accuracy during the task.

Essential Hand Tools

Having a well-equipped toolkit is crucial for any maintenance job. Common hand tools include wrenches, screwdrivers, and pliers. These items allow you to loosen and tighten fasteners effectively. Additionally, a socket set can provide the versatility needed for different sizes of nuts and bolts, making it easier to access hard-to-reach areas.

Power Tools for Efficiency

For those looking to speed up the replacement process, power tools are invaluable. A power drill can quickly drive screws and remove them with minimal effort, while an impact wrench can handle stubborn fasteners that resist manual tools. Always ensure you have the appropriate bits and attachments to match the task at hand.

Where to Buy Husqvarna Parts

Finding the right components for your outdoor equipment can enhance performance and longevity. Various sources are available to help you acquire the necessary items efficiently.

| Source | Description |

|---|---|

| Official Retailers | Authorized dealers often provide a wide range of original components and can offer expert advice. |

| Online Marketplaces | Websites like Amazon and eBay offer convenience and competitive prices, with user reviews to guide your choices. |

| Local Repair Shops | Independent mechanics may carry essential items and provide tailored support for your specific needs. |

| Manufacturer’s Website | Direct purchasing from the producer ensures authenticity and often features special deals or discounts. |

Benefits of Regular Parts Inspection

Conducting routine evaluations of machinery components plays a crucial role in ensuring optimal performance and longevity. By systematically checking various elements, one can identify potential issues before they escalate into significant problems, ultimately saving time and resources.

One of the primary advantages of consistent assessments is the enhancement of efficiency. Well-maintained components operate more smoothly, reducing wear and tear. This not only prolongs the life of the equipment but also improves its overall functionality, allowing for more effective operation.

Furthermore, regular evaluations contribute to safety. By identifying worn or damaged components early, the risk of accidents and malfunctions decreases significantly. This proactive approach fosters a safer working environment for operators and users alike.

Additionally, staying on top of inspections can lead to cost savings in the long run. Addressing minor issues promptly prevents them from developing into major repairs, which can be both time-consuming and financially burdensome. This strategic foresight enables better budgeting and resource allocation.

In summary, prioritizing the examination of machinery elements ensures enhanced performance, improved safety, and reduced costs, making it an essential practice for effective equipment management.

Understanding Warranty and Service Options

When investing in outdoor equipment, it is essential to be informed about the protection and maintenance options available. A solid warranty can provide peace of mind, while reliable service channels ensure that your machine remains in optimal condition throughout its lifespan. Understanding these aspects will help you make informed decisions regarding your purchase and future care.

Warranty Coverage and Duration

Warranties typically cover manufacturing defects and certain failures that occur during normal use. The duration of coverage can vary, often extending for several years. It is important to carefully review the terms to understand what is included, such as parts replacement, labor costs, and any exclusions that might apply. Extended warranty options may also be available, providing additional protection beyond the standard period.

Service and Maintenance Support

Access to professional service is crucial for maintaining the efficiency and longevity of your equipment. Many manufacturers offer authorized service centers that provide expert repairs and routine maintenance. Regular servicing can help prevent issues before they arise, ensuring that your machine operates smoothly. Additionally, customer support lines are often available for troubleshooting and guidance on usage.