Every lawn mower consists of various elements that work together to ensure optimal performance. Recognizing how these components interact can significantly enhance maintenance practices and troubleshooting efficiency. A comprehensive exploration of the machinery will provide insights into the functionality of each section, ultimately leading to a smoother mowing experience.

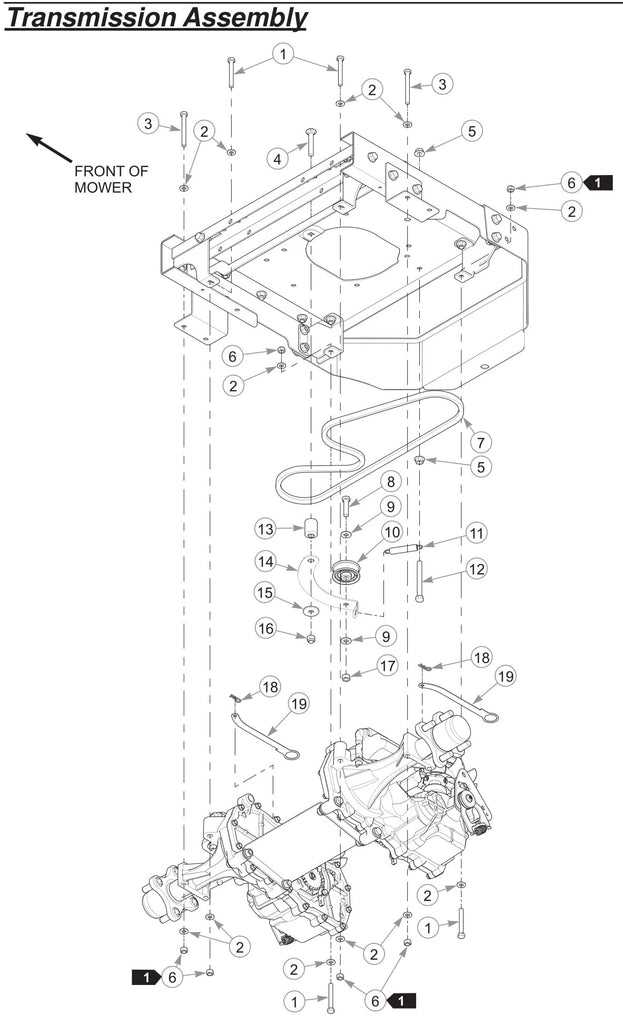

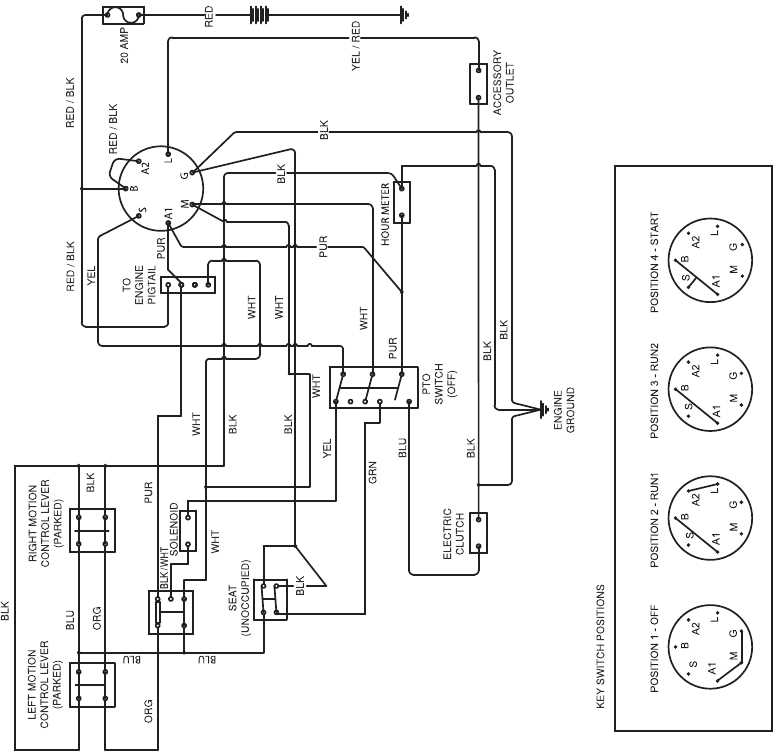

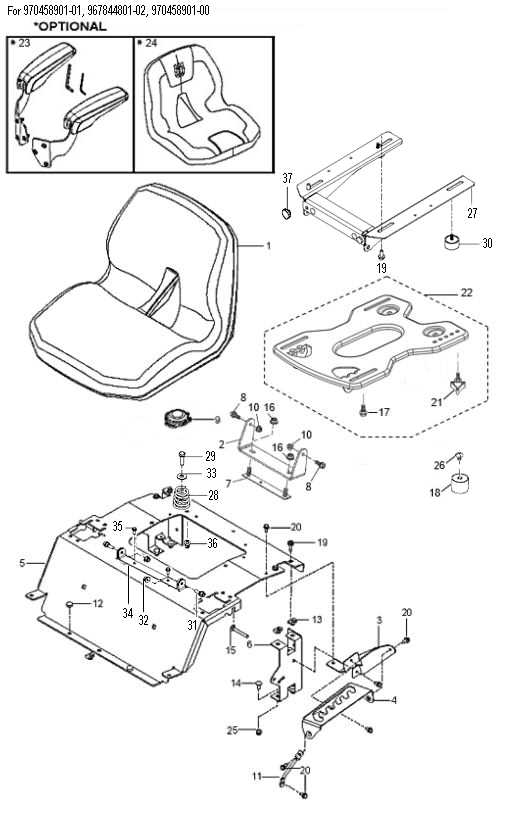

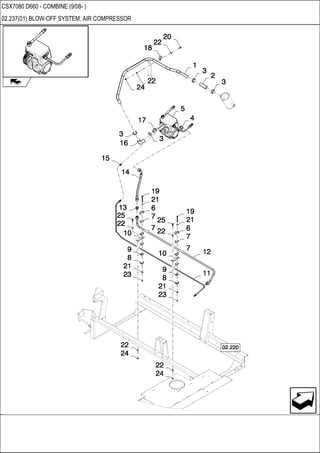

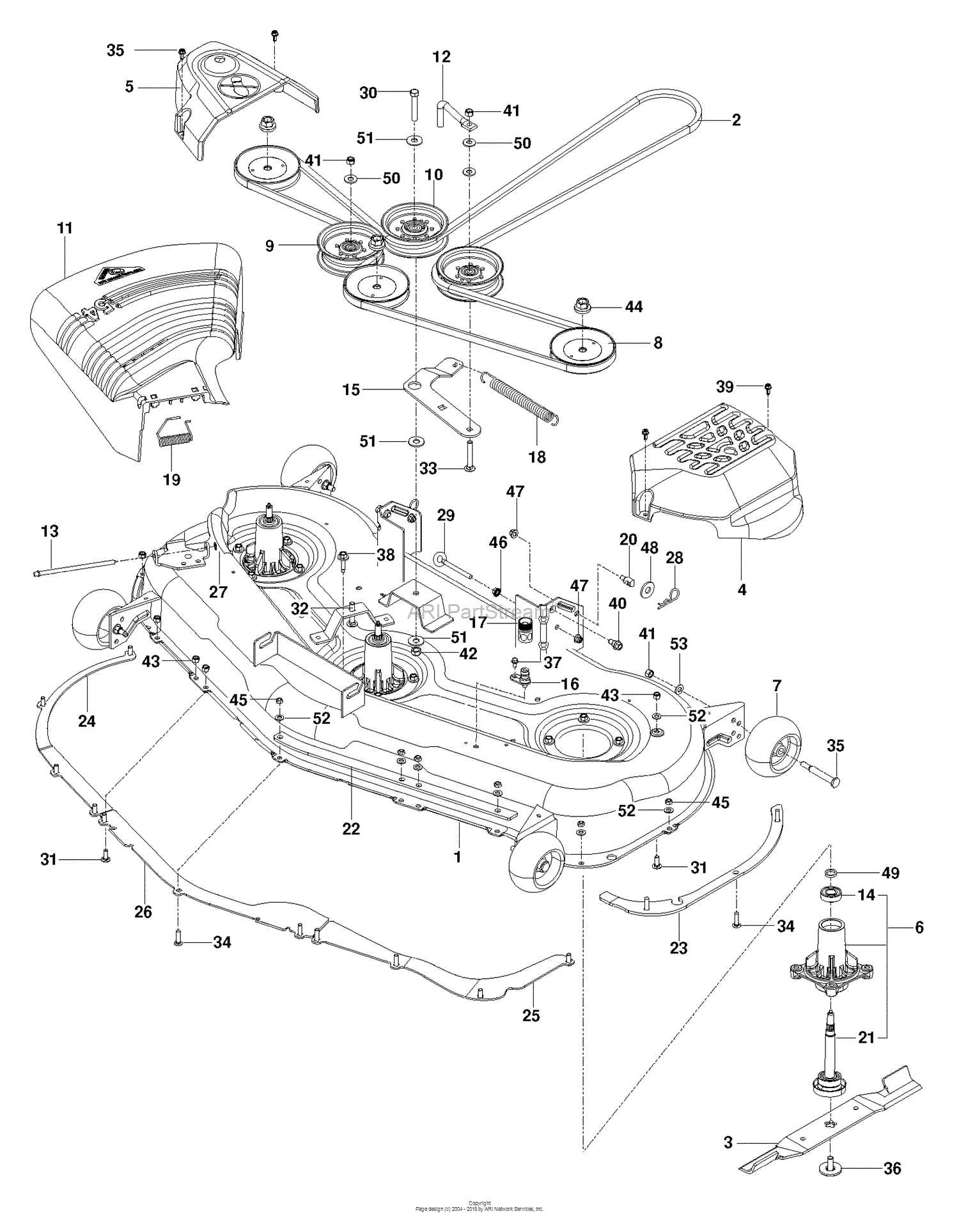

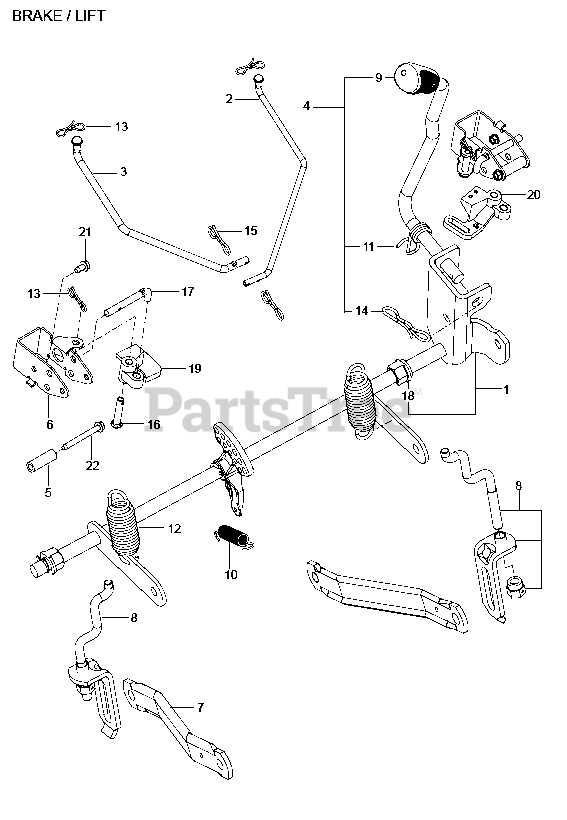

Detailed illustrations of the equipment’s structure reveal the arrangement and purpose of each piece. Such visuals serve as invaluable resources for those aiming to improve their knowledge of lawn care machinery. By familiarizing oneself with these illustrations, users can more effectively identify issues and perform necessary repairs, ensuring longevity and reliability of their equipment.

In the pursuit of maintaining a pristine lawn, understanding the intricate design of the machine can lead to more informed decisions regarding repairs and replacements. Equipped with this knowledge, individuals can confidently tackle maintenance tasks, contributing to the overall efficiency and performance of their lawn care tools.

The efficiency and performance of any machine rely heavily on its essential elements. Understanding these crucial components can enhance maintenance and improve functionality. This section outlines the primary features that contribute to the optimal operation of this model, emphasizing their roles and interconnections.

| Component | Description |

|---|---|

| Engine | Powers the entire system, providing the necessary energy for operation. |

| Deck | Houses the cutting blades, ensuring even and efficient grass cutting. |

| Transmission | Transfers power from the engine to the wheels, affecting speed and maneuverability. |

| Wheels | Facilitate movement and stability across various terrains. |

| Handlebars | Provide control and direction, enhancing user comfort and ease of operation. |

Importance of Parts Identification

Recognizing individual components within machinery is crucial for effective maintenance and repair. Understanding each element’s role allows for timely troubleshooting and enhances overall functionality. Accurate identification minimizes the risk of using incorrect replacements, which can lead to further complications and costly repairs.

In addition, familiarizing oneself with the various elements can significantly improve operational efficiency. When users can easily locate and assess components, it streamlines the maintenance process, allowing for quicker resolutions to issues. This knowledge not only saves time but also extends the longevity of the equipment by ensuring that all parts are functioning optimally.

Furthermore, clear comprehension of all elements aids in communication with service providers and suppliers. When discussing repairs or replacements, being able to specify the exact components needed ensures that the right items are acquired without unnecessary delays. Overall, a thorough understanding of each element plays a vital role in maintaining the performance and reliability of machinery.

Common Replacement Parts for Z254

Regular maintenance of your lawn mower ensures optimal performance and longevity. Understanding the essential components that may need to be replaced can help in keeping the equipment in top shape. Here are some frequently required items that contribute to the efficient operation of your machine.

- Blades: Dull or damaged blades can affect cutting efficiency. Replacing them regularly ensures a clean cut and healthier grass.

- Filters: Air and fuel filters prevent dirt and debris from entering the engine. Regular replacement helps maintain engine performance.

- Belts: Drive and mower belts can wear out over time. Inspecting and replacing them as needed is crucial for reliable operation.

- Spark Plugs: These components are essential for ignition. Replacing spark plugs periodically ensures smooth starts and optimal engine performance.

- Batteries: If your mower is equipped with an electric start, a fully functioning battery is vital. Ensure it is in good condition or replace it when necessary.

Investing in high-quality replacements enhances the efficiency and reliability of your equipment. Regularly inspecting these components can prevent unexpected breakdowns and prolong the life of your machine.

How to Read the Diagram

Understanding an assembly illustration is crucial for anyone looking to maintain or repair their equipment effectively. These illustrations provide a visual representation of the various components, their locations, and how they fit together. Grasping this information allows users to identify parts, troubleshoot issues, and perform necessary replacements with confidence.

Key Elements of the Illustration

When examining the illustration, focus on the following aspects:

- Labels: Each component is usually accompanied by a unique identifier or label, making it easier to reference specific items.

- Connections: Pay attention to how different elements are connected. Lines often indicate relationships between parts, guiding you on how they interact.

- Orientation: The layout can show the arrangement of parts in relation to one another, providing a clearer understanding of the overall assembly.

Using the Information Effectively

Once familiar with the layout, you can effectively use the information for repairs or upgrades. Refer to the identifiers to order replacements or to seek further information on a specific element. This knowledge empowers users to carry out maintenance tasks independently, ultimately prolonging the lifespan of their equipment.

Maintenance Tips for Z254 Parts

Regular upkeep is crucial for optimal performance and longevity of your equipment. Implementing a consistent maintenance routine can significantly enhance efficiency and prevent potential issues. Attention to specific components can ensure they operate smoothly and effectively throughout their lifespan.

Consider these essential guidelines for maintaining your machinery:

| Component | Maintenance Tip |

|---|---|

| Engine | Change the oil and filter regularly to ensure smooth operation. |

| Blades | Sharpen blades frequently to maintain cutting efficiency and reduce strain on the engine. |

| Air Filter | Inspect and clean the air filter to prevent dirt and debris from affecting performance. |

| Fuel System | Use fresh fuel and check for leaks in the fuel lines to maintain optimal fuel delivery. |

| Batteries | Keep connections clean and ensure batteries are charged to avoid starting issues. |

By following these maintenance suggestions, you can prolong the life of your equipment and ensure it remains in peak condition for various tasks. A proactive approach to care will lead to fewer repairs and greater efficiency.

Finding OEM Parts for Husqvarna

Locating original equipment manufacturer components is essential for maintaining optimal performance in outdoor machinery. Ensuring the quality and compatibility of replacement items can significantly enhance the longevity and reliability of the equipment.

To begin, consider utilizing authorized dealers or official websites that specialize in genuine replacements. These sources often provide comprehensive catalogs and technical support, facilitating the selection process. Additionally, exploring local retailers that focus on outdoor tools may yield valuable options.

Another effective method is engaging with online forums and communities dedicated to outdoor equipment enthusiasts. Members often share insights on where to find specific components, ensuring that users can obtain the most suitable replacements. Utilizing these resources not only aids in finding the right items but also fosters a sense of community among owners.

Lastly, verifying the compatibility of any selected replacement with the specific model is crucial. Cross-referencing model numbers and specifications will help ensure that the chosen components meet the required standards, ultimately supporting the efficient operation of the machinery.

Aftermarket Parts: Pros and Cons

Utilizing replacement components from third-party manufacturers can be a viable option for many machinery owners. These alternatives often come with various advantages and disadvantages that can significantly impact performance, reliability, and cost-effectiveness. Understanding these factors is essential for making informed decisions.

Benefits: One of the primary advantages of aftermarket options is the potential for cost savings. Many third-party suppliers offer products at a lower price compared to original equipment manufacturers (OEM), making maintenance and repairs more affordable. Additionally, aftermarket components can provide enhanced performance features, often tailored to specific user needs or preferences.

Drawbacks: However, there are notable downsides to consider. The quality of aftermarket items can vary significantly; some may not meet the same standards as OEM equivalents, potentially leading to premature wear or failure. Moreover, using non-OEM components might void warranties or create compatibility issues, resulting in further expenses or complications down the line.

Ultimately, weighing these pros and cons will help users determine the best approach for their specific situations. It is crucial to research and select reputable suppliers to ensure the reliability and longevity of the machinery.

Assembly Instructions for Z254 Parts

Proper assembly of components is essential for optimal performance and longevity of your equipment. Understanding the arrangement and function of each element will aid in achieving a seamless integration. Follow the outlined steps carefully to ensure a successful assembly process.

1. Gather Necessary Tools: Before beginning, ensure you have all the required tools readily available. This typically includes wrenches, screwdrivers, and any specialized equipment necessary for your specific model.

2. Identify Components: Carefully examine each individual component. Familiarize yourself with their respective functions and how they interact within the overall system. This will streamline the assembly process and minimize errors.

3. Follow Assembly Order: Adhere to the recommended assembly order. Start with the base components, ensuring they are securely attached. Gradually add subsequent pieces, checking for alignment and fit as you progress.

4. Secure Fasteners: Ensure all screws, bolts, and fasteners are tightened appropriately. Avoid over-tightening, as this can lead to damage. It’s advisable to use a torque wrench if specifications are provided.

5. Final Check: Once assembly is complete, conduct a thorough inspection. Verify that all components are securely attached and that there are no loose parts. This step is crucial to prevent operational issues during use.

By following these guidelines, you can achieve a reliable assembly that maximizes the efficiency of your equipment.

Common Issues with Z254 Components

Understanding the frequent challenges faced by various components in lawn care equipment is essential for effective maintenance and optimal performance. Identifying these issues can help users troubleshoot effectively and prolong the lifespan of their machines. Common problems often arise from wear and tear, improper adjustments, or environmental factors.

Frequent Problems Encountered

Some of the prevalent issues include:

| Component | Common Issue | Symptoms |

|---|---|---|

| Engine | Overheating | Reduced power, unusual noises |

| Blades | Worn edges | Uneven cuts, clumping grass |

| Fuel System | Clogged filter | Starting issues, stalling |

| Transmission | Slipping | Inconsistent speed, difficulty in acceleration |

Maintenance Tips

Regular inspections and timely replacements of worn components are vital. Keeping the equipment clean and ensuring proper lubrication can significantly reduce the occurrence of these issues. Following manufacturer guidelines for maintenance will also enhance overall performance and reliability.

Repairing vs. Replacing Components

When faced with malfunctioning machinery, one of the key decisions is whether to mend the existing elements or to invest in new replacements. Each approach carries its own set of advantages and considerations that can significantly impact performance and cost-efficiency.

Repairing components can be beneficial in several ways:

- Cost Savings: Fixing a damaged item often incurs lower expenses compared to purchasing new ones.

- Sustainability: Repairing promotes environmental responsibility by reducing waste.

- Quick Solutions: Sometimes, a simple repair can restore functionality without lengthy downtime.

On the other hand, replacing components may be the preferred choice in specific scenarios:

- Improved Performance: New parts can enhance efficiency and reliability, particularly in older equipment.

- Warranty Protection: New components often come with warranties, ensuring peace of mind against future failures.

- Time Considerations: In some cases, sourcing a new item might be faster than attempting a repair, especially for critical functions.

Ultimately, the choice between repairing and replacing hinges on factors such as the severity of the damage, financial implications, and the intended longevity of the equipment. Evaluating these elements can lead to a more informed decision that aligns with the needs of the user.

Resources for Husqvarna Z254 Owners

Owning a high-performance lawn care machine requires access to reliable information and materials. Having the right resources ensures optimal maintenance and longevity, allowing users to maximize the capabilities of their equipment. Below are valuable sources for those seeking assistance and guidance.

Online Communities

Engaging with fellow enthusiasts can provide insights and support. Consider exploring the following platforms:

- Online forums dedicated to lawn care machinery

- Social media groups where owners share tips and experiences

- Video tutorials on platforms like YouTube for visual guidance

Official Documentation

Access to official materials can enhance understanding and performance. Recommended resources include:

- Owner’s manuals providing detailed operation instructions

- Maintenance guides outlining routine care and troubleshooting

- Manufacturer websites for updates on recalls and improvements

Benefits of Regular Maintenance Checks

Routine inspections and upkeep of machinery play a crucial role in ensuring optimal performance and longevity. Regular assessments allow for the identification of potential issues before they escalate into significant problems, saving time and costs associated with major repairs.

One of the primary advantages of consistent maintenance is enhanced efficiency. Well-maintained equipment operates more smoothly, leading to improved productivity. Moreover, regular checks help to maintain safety standards, reducing the risk of accidents caused by malfunctioning components.

Additionally, frequent evaluations can extend the lifespan of the equipment. By addressing wear and tear promptly, owners can avoid premature replacements and ensure that their investment continues to yield returns. Ultimately, a commitment to regular maintenance fosters reliability and peace of mind for users.