In the world of energy solutions, having a clear understanding of the various elements that make up your equipment is essential for optimal performance. This section aims to shed light on the intricate network of components that work together to ensure efficiency and reliability. By grasping the relationships between these elements, users can enhance their experience and extend the lifespan of their machinery.

Whether you’re troubleshooting issues or performing routine maintenance, being able to visualize how each piece fits into the larger picture is invaluable. Comprehensive illustrations and detailed explanations provide insights into how the individual sections interact, making it easier to identify potential areas for improvement or repair.

Equipped with this knowledge, users will find themselves better prepared to tackle any challenges that arise. Understanding the layout and functionality of each component not only promotes better decision-making but also fosters a deeper appreciation for the technology that powers our daily lives.

Understanding Hyundai Generators

This section aims to provide insights into the various components and functionality of portable power sources. Whether for residential use or outdoor activities, comprehending how these devices operate can enhance efficiency and reliability.

Key Components and Their Functions

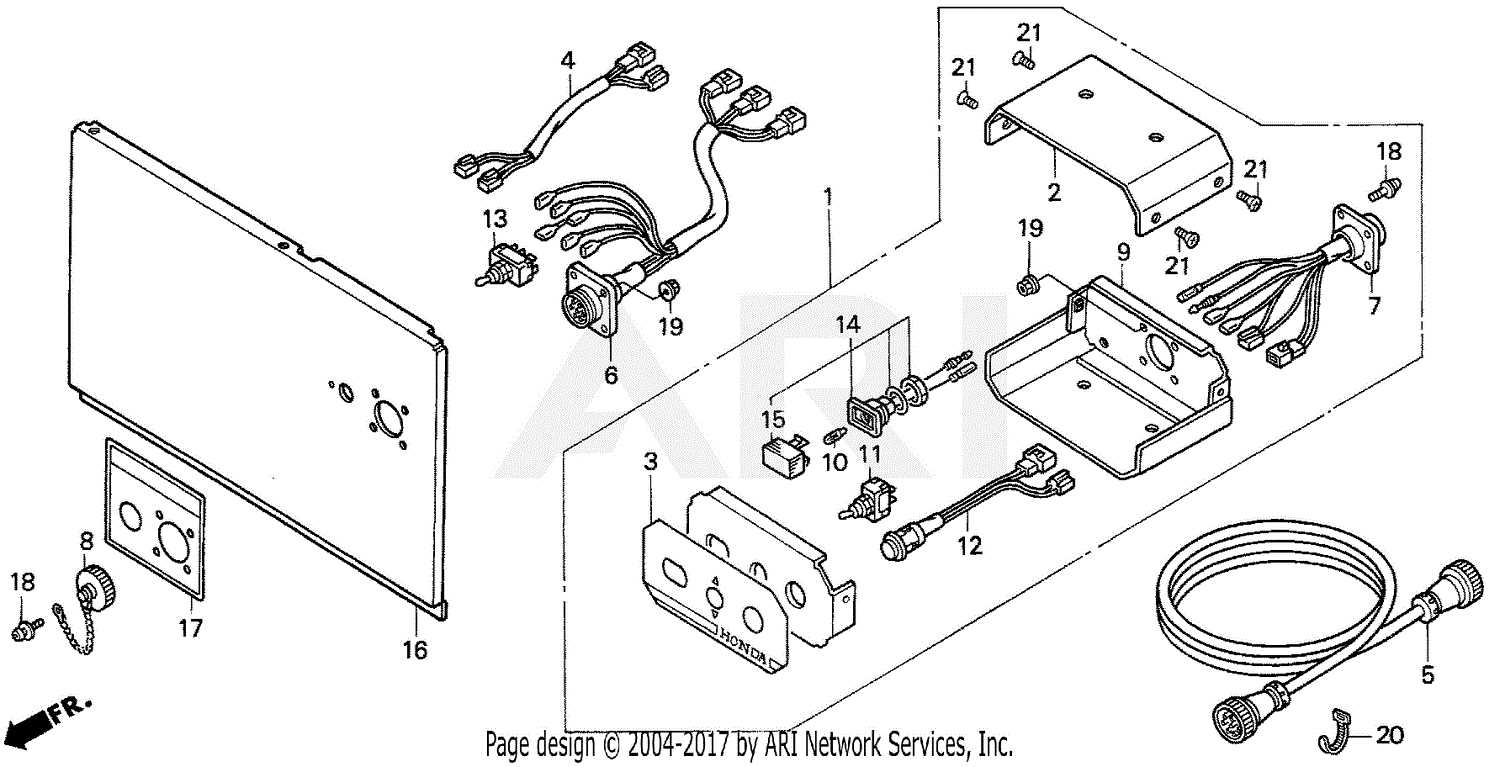

Every power supply unit consists of essential elements that work together to produce electricity. The engine is the heart, converting fuel into mechanical energy, while the alternator transforms this mechanical energy into electrical energy. Additional systems, such as the fuel system and control panel, ensure optimal performance and user control.

Maintenance and Troubleshooting

Regular upkeep is crucial for longevity. Keeping the unit clean, checking oil levels, and replacing filters are fundamental practices. In case of issues, identifying problems often involves inspecting the fuel supply, electrical connections, and the starting mechanism. Knowing how to address these aspects can prevent downtime and extend the life of your equipment.

In summary, understanding the intricacies of these power sources not only maximizes their effectiveness but also empowers users to perform necessary maintenance and repairs.

Importance of Generator Parts Diagrams

Understanding the intricacies of machinery components is crucial for effective maintenance and troubleshooting. Visual representations of these elements provide a clear overview, allowing users to identify and comprehend the relationships between different sections. This knowledge not only enhances the efficiency of repairs but also contributes to the longevity of the equipment.

Enhanced Troubleshooting

Having a visual reference simplifies the process of diagnosing issues. When individuals can see how each element interacts with others, it becomes easier to pinpoint the source of a malfunction. This approach minimizes downtime and reduces the likelihood of costly errors during repairs.

Efficient Maintenance Practices

Regular upkeep is essential for optimal performance. Visual aids serve as a guide for routine inspections and preventive measures. By following a structured layout, users can systematically check each section, ensuring that all components function as intended. This proactive approach ultimately leads to better reliability and efficiency in operations.

Common Components of Hyundai Generators

Understanding the essential elements that make up portable energy sources is crucial for efficient operation and maintenance. These devices consist of various interconnected units, each playing a vital role in overall functionality. Familiarity with these components can help users troubleshoot issues and enhance performance.

| Component | Description |

|---|---|

| Engine | The core unit that converts fuel into mechanical energy. |

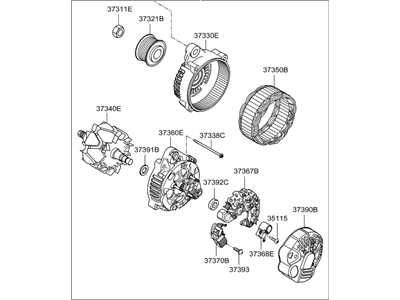

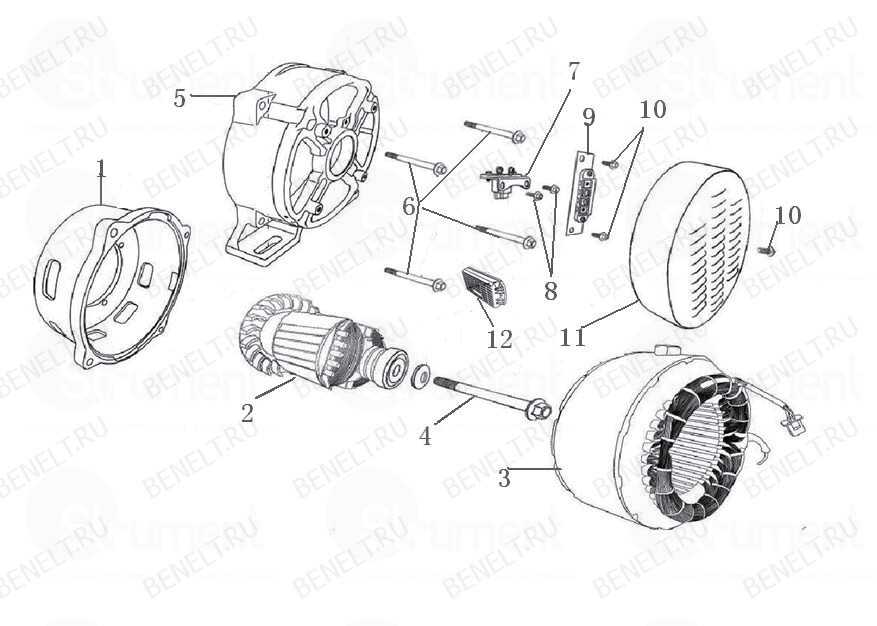

| Alternator | Transforms mechanical energy from the engine into electrical energy. |

| Fuel System | Manages the supply and regulation of fuel to the engine. |

| Cooling System | Prevents overheating by dissipating heat generated during operation. |

| Control Panel | Allows users to monitor and manage operational settings and performance metrics. |

| Frame | Provides structural support and portability, housing all internal components. |

| Exhaust System | Directs harmful gases away from the unit and reduces noise levels. |

Familiarity with these key components not only aids in effective usage but also contributes to longevity and reliability in energy production. Proper maintenance and understanding of each unit’s function can significantly enhance overall performance.

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair tasks. These visual guides provide a simplified representation of complex machinery, enabling users to identify individual components and their relationships. By familiarizing yourself with the elements and symbols used in these visuals, you can streamline your repair processes and ensure accuracy.

Here are some key steps to help you navigate these illustrations:

| Step | Description |

|---|---|

| 1 | Familiarize yourself with the legend or key, which explains symbols and designations used in the illustration. |

| 2 | Identify the main assembly and its subcomponents. Focus on how they fit together and their functions. |

| 3 | Take note of any part numbers or specifications that may be crucial for ordering replacements. |

| 4 | Understand the flow of operation by following arrows or indicators that show the movement or interaction of elements. |

| 5 | Refer to additional documentation if needed for detailed explanations or troubleshooting tips related to specific components. |

By following these guidelines, you can effectively interpret technical illustrations and improve your maintenance efficiency.

Identifying Essential Parts for Repairs

Understanding the critical components of your machine is vital for effective maintenance and troubleshooting. By familiarizing yourself with the key elements, you can streamline repair processes and enhance the overall performance of your equipment. Each component plays a specific role, and recognizing their functions can save both time and resources during repairs.

Start by identifying the main sections, such as the power unit, control panel, and fuel system. Each of these areas houses components that are essential for operation. For instance, the power unit is crucial for generating energy, while the control panel allows for regulation and monitoring. The fuel system ensures that the machine receives the necessary resources for functioning efficiently.

Next, consider the wear and tear that different parts can experience over time. Regular inspection of items such as filters, belts, and electrical connections is important for maintaining optimal performance. Knowing the signs of deterioration will enable you to address issues proactively, preventing more extensive damage down the line.

Lastly, obtaining a comprehensive understanding of how these components interact can provide valuable insights during repairs. Each piece contributes to the whole, and recognizing their interdependencies will aid in diagnosing problems accurately. With this knowledge, you will be better equipped to manage maintenance and ensure the longevity of your machinery.

Maintenance Tips for Generator Longevity

Ensuring the extended lifespan of your energy supply equipment involves regular upkeep and careful attention to various components. By following specific practices, you can prevent premature wear and ensure reliable performance when needed most.

Regular Inspections

Conducting frequent evaluations is essential. Look for signs of wear, corrosion, or any unusual sounds during operation. Pay attention to fluid levels and check for leaks, as maintaining proper levels is crucial for optimal functionality.

Proper Storage and Usage

When not in use, store your equipment in a dry, cool place to protect it from environmental factors. Additionally, ensure that you operate it under recommended conditions. Using it within specified limits not only enhances efficiency but also prolongs its life.

Replacement Parts: What to Consider

When it comes to maintaining machinery, understanding the intricacies of components is essential. Choosing the right substitutions can significantly impact performance and longevity. This section delves into the key factors that should guide your decision-making process when seeking replacements.

Quality and Compatibility

- Material Quality: Opt for high-quality materials to ensure durability and reliability.

- Brand Compatibility: Always verify that the replacement is compatible with your specific model.

- Performance Standards: Look for components that meet or exceed the manufacturer’s performance criteria.

Cost and Warranty

- Budget Considerations: Evaluate the cost-effectiveness of the replacements. Sometimes, a higher initial investment can lead to savings in the long run.

- Warranty Terms: Check if the new components come with a warranty, which can provide peace of mind and protection against defects.

By carefully considering these factors, you can ensure that your equipment operates smoothly and efficiently, ultimately enhancing its lifespan and performance.

Where to Find Parts Diagrams

Locating detailed visual guides for components can significantly streamline the maintenance and repair process. These resources offer a clear overview of various elements, making it easier to identify specific pieces and their functions within a larger assembly.

Here are some reliable sources for accessing these visual aids:

- Manufacturer Websites: Many manufacturers provide downloadable resources directly on their official sites. Check the support or resources section for relevant materials.

- User Manuals: Comprehensive guides often include illustrations of components. These can usually be found in the original packaging or requested online.

- Online Forums: Community-driven platforms can be invaluable. Users frequently share their insights and resources, including links to diagrams.

- Retailer Sites: E-commerce platforms that specialize in equipment often have detailed images and breakdowns of various models.

- Technical Service Providers: Some service companies offer access to parts information as part of their support services. Contacting them can yield useful resources.

Using these sources can enhance your understanding and help you find the information you need more efficiently.

Common Issues with Hyundai Generators

Various types of portable power sources can encounter specific challenges during operation. Understanding these issues can help users ensure optimal performance and longevity of their equipment.

- Fuel Supply Problems: Inadequate fuel flow can lead to starting difficulties or inconsistent power output.

- Electrical System Failures: Issues such as blown fuses or faulty connections may disrupt the flow of electricity.

- Overheating: Excessive heat can result from prolonged use or blocked ventilation, causing safety hazards.

- Oil Leaks: Insufficient maintenance might lead to oil seepage, affecting overall efficiency and performance.

- Starting Issues: Difficulties in ignition can arise from battery problems, spark plug wear, or fuel quality.

Addressing these common challenges requires regular maintenance, timely repairs, and proper usage practices. Awareness of potential issues can significantly enhance the reliability of your equipment.

DIY Repairs vs. Professional Help

When faced with mechanical issues, individuals often find themselves weighing the merits of self-service against enlisting the expertise of a professional. Each approach carries its own set of advantages and drawbacks, making the decision largely dependent on the specific situation and personal preferences.

Here are some factors to consider when deciding between DIY fixes and seeking professional assistance:

- Cost:

- DIY can be more budget-friendly if you have the necessary skills and tools.

- Hiring an expert often involves labor charges that can add up quickly.

- Time:

- Self-repair may require a significant time investment, especially for those unfamiliar with the process.

- Professionals can often complete the job more swiftly due to their experience.

- Skill Level:

- Those with a background in mechanics may find DIY tasks straightforward and rewarding.

- For individuals lacking expertise, errors can lead to further complications and expenses.

- Safety:

- Some repairs involve risks that could lead to injury or property damage if not handled correctly.

- Professionals are trained to manage these hazards effectively.

Ultimately, the choice between tackling repairs independently or hiring a specialist hinges on evaluating these factors and understanding one’s own capabilities. Each method has its place, and sometimes a combination of both approaches can yield the best results.

Safety Precautions During Maintenance

When conducting upkeep on machinery, ensuring safety is paramount. Proper precautions can significantly reduce the risk of accidents and injuries. It is essential to be aware of the potential hazards and to take the necessary steps to mitigate them.

Preparation and Awareness

Before beginning any maintenance tasks, familiarize yourself with the specific equipment you are working on. Always consult the manufacturer’s guidelines and safety manuals. Wearing appropriate personal protective equipment (PPE) such as gloves, goggles, and hearing protection is crucial to safeguard against injuries.

Safe Work Practices

Maintain a clean and organized workspace to prevent slips and trips. Ensure that tools are in good condition and used correctly. Always disconnect power sources before performing any repairs to avoid electric shocks. If working in confined spaces, ensure proper ventilation to prevent the buildup of harmful gases.

Comparing Parts for Different Models

When evaluating components across various models, it’s essential to recognize the similarities and differences that influence performance and compatibility. Each version is designed with specific features that cater to distinct requirements, making understanding these variations crucial for optimal functioning.

Key Differences in Components

- Power Output: Variations in wattage affect suitability for different applications.

- Fuel Type: Some models operate on gasoline, while others may use propane or diesel.

- Cooling Systems: Air-cooled vs. liquid-cooled systems can impact efficiency and longevity.

Compatibility Considerations

- Model Specifications: Always refer to the manufacturer’s guidelines for compatibility.

- Connector Types: Ensure that connectors match to avoid installation issues.

- Maintenance Requirements: Different units may have unique upkeep needs affecting longevity.

By understanding these aspects, users can make informed decisions that enhance the reliability and efficiency of their equipment.

Understanding Warranty and Support Options

When investing in equipment, knowing the available guarantees and assistance can significantly enhance your experience. Proper support and assurance can protect your investment and ensure the longevity and efficiency of your machinery. This section delves into the essential aspects of these options, highlighting the importance of understanding what is offered.

Types of Warranty Coverage

Warranties typically come in various forms, each catering to different needs and circumstances. Here’s a brief overview of common types:

| Type of Warranty | Description |

|---|---|

| Limited Warranty | Covers specific components for a defined period, usually against manufacturing defects. |

| Extended Warranty | Offers additional coverage beyond the standard period, often at an extra cost. |

| Full Warranty | Provides comprehensive coverage for parts and labor, ensuring complete peace of mind. |

Support Services Available

In addition to warranty options, various support services can enhance the user experience. These services may include troubleshooting assistance, maintenance tips, and repair services. Understanding the support structure can help you utilize the equipment more effectively and resolve any issues that arise.