Understanding how various elements are arranged and interconnected is crucial when it comes to the upkeep of mechanical systems. A well-organized schematic can provide a clear view of each section and its function, aiding in the identification of potential issues and improving the speed of repairs.

By studying detailed layouts, technicians can grasp how individual elements cooperate to achieve the desired operation. Such knowledge not only simplifies troubleshooting but also ensures smoother integration of new elements when necessary.

This section delves into a specific configuration, focusing on the key structural aspects that define the performance and reliability of the equipment. Proper interpretation of these layouts is essential for maintaining peak efficiency and extending the lifespan of machinery.

Overview of the Equipment Breakdown

This section provides a detailed examination of the key components and how they are structured within the machinery. Understanding the configuration and the relationship between various elements is essential for proper maintenance and troubleshooting.

Key Structural Components

The machinery is composed of several interconnected modules, each responsible for specific functions. These components are designed to work in harmony, ensuring optimal performance under varying conditions. Identifying these sections allows for better diagnosis of any potential issues that may arise during operation.

Functional Layout

The layout of the system is based on logical groupin

Exploring the Main Assemblies

Understanding the key structures of complex machinery is essential for effective maintenance and repair. By examining each significant component, it becomes possible to grasp how these elements interact and contribute to the overall function. This section focuses on dissecting the major units, providing insights into their individual roles within the system.

The primary sections include several interconnected modules, each designed for specific operational tasks. Mechanical frameworks are responsible for foundational support, while power transfer systems ensure energy flows smoothly throughout. Additionally, control mechanisms regulate performance, offering precision and adaptability in various conditions.

Each of these assemblies plays a critical role, working together to maintain efficiency and reliability, thus making regular analysis and upkeep of these components vital for prolonged functionality.

Key Components of the Engine System

The engine system is composed of various critical elements that work together to ensure smooth and efficient performance. Each of these components plays a distinct role in powering the machinery and maintaining operational stability. Understanding the functionality and interaction of these parts is essential for optimal performance.

Cylinder Assembly forms the core of the system, where combustion takes place, converting energy into mechanical movement. The assembly consists of a chamber where fuel is ignited, creating pressure to drive motion.

Fuel Delivery Mechanism ensures the correct amount of fuel reaches the system. It regulates the flow and mixture, maintaining efficiency and preventing overloading. Proper calibration of this component is vital for maintaining consistent power.

Cooling Circuit helps dissipate excess heat generated

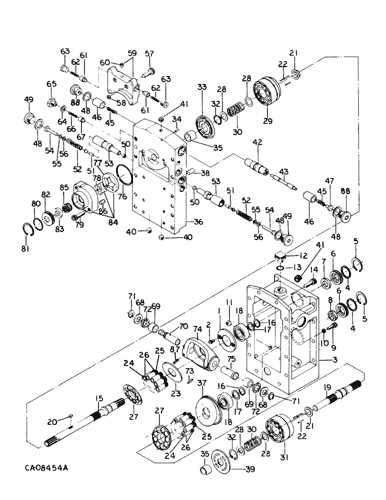

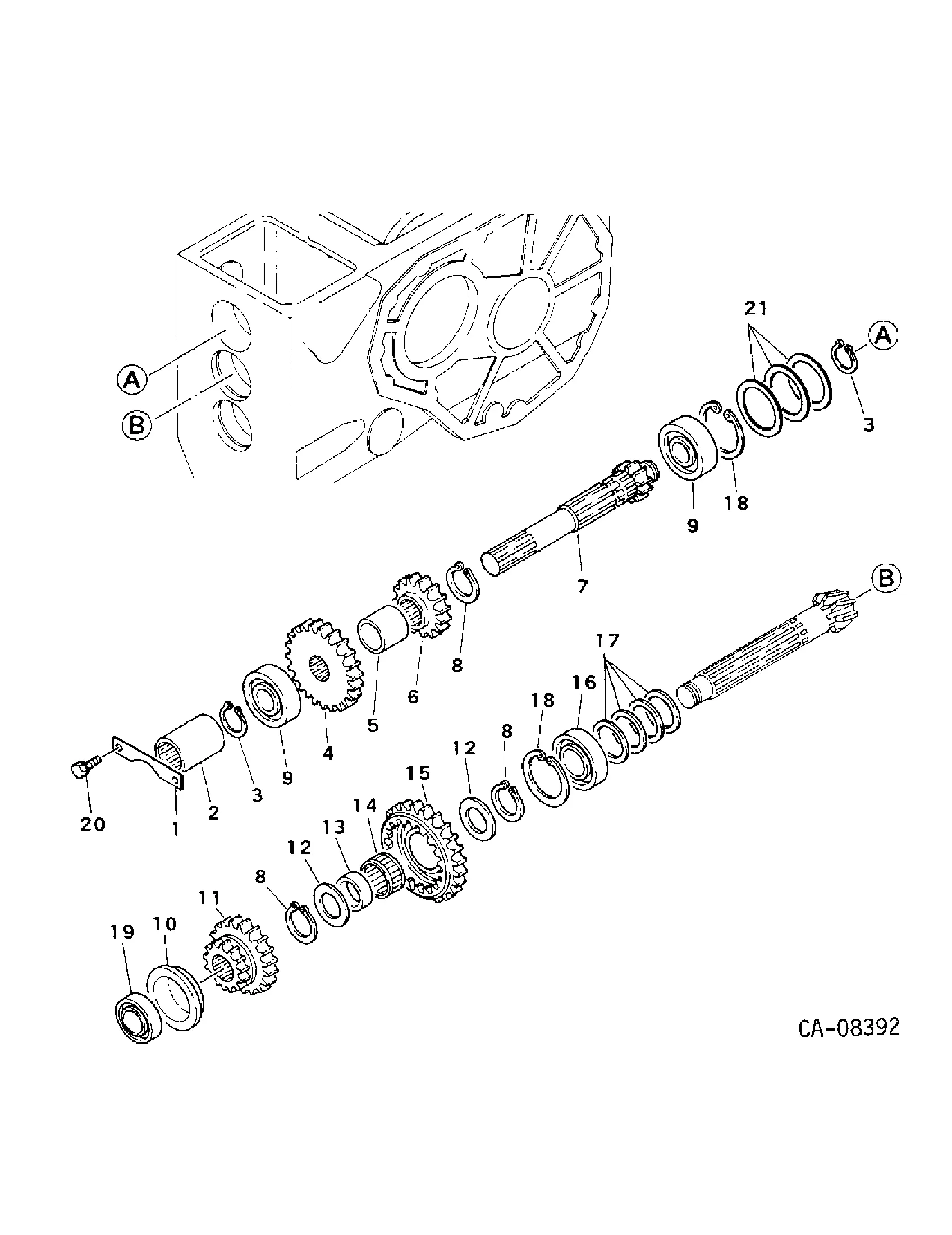

Detailed View of the Transmission Layout

The internal structure of the power transfer mechanism is crucial for smooth and efficient operation. Understanding the arrangement of the components within this system allows for better maintenance and optimization. The intricate alignment of gears, shafts, and connectors is what ensures a seamless flow of mechanical power throughout the entire machine.

Key Components and Their Placement

- Main Gear Assembly: Positioned centrally, this segment is responsible for managing the input and output ratios.

- Shafts and Bearings: These elements support rotational movement and stabilize the alignment of the primary components.

- Clutch Mechanism: A vital part that allows smooth engagement and disengagement, ensuring controlled power distribution.

Operational Flow

Once

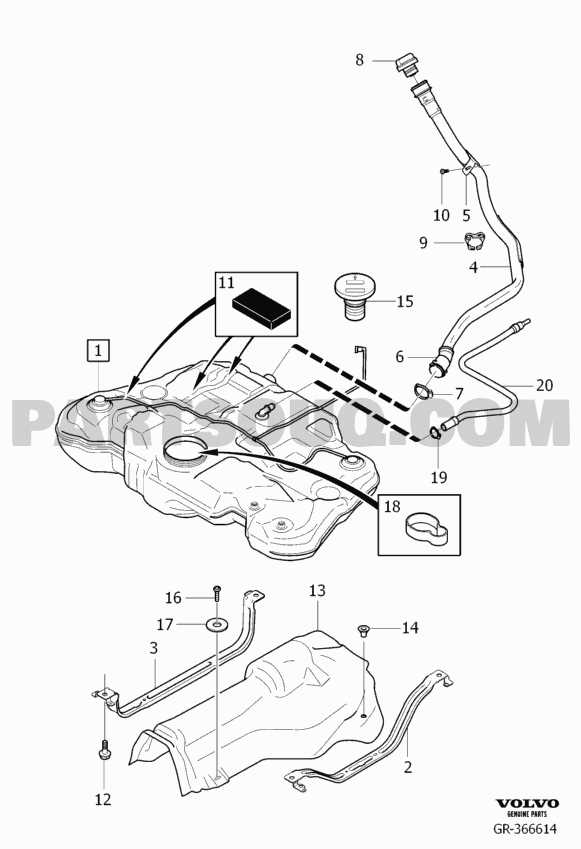

Understanding the Hydraulic System Components

The hydraulic system is a crucial mechanism responsible for transmitting force through fluid movement. It relies on the precise coordination of multiple elements to function efficiently, enabling machinery to perform a range of tasks, from lifting heavy loads to providing smooth movement.

Pumps are at the core of the system, generating the pressure needed to move the fluid through the system. These units convert mechanical power into hydraulic energy, ensuring that force is distributed where needed.

The valves serve as regulators, controlling the flow and direction of the fluid. They ensure that the system operates at optimal efficiency, allowing precise control of various functions.

Another key element is the cylinder, which transforms the fluid’s energy

Examination of the Electrical Connections

This section delves into the intricacies of electrical linkages within a specific machinery model. Understanding these connections is crucial for effective operation and maintenance, as they play a pivotal role in ensuring the proper functioning of various components. A comprehensive analysis of these connections can lead to enhanced performance and reduced risks of failure.

Key Components of Electrical Linkages

Identifying the fundamental elements of electrical connections is essential for troubleshooting and repairs. The main components include:

- Connectors: Facilitate the joining of wires and ensure secure communication between parts.

- Cables: Transmit electrical signals and power between different sections of the system.

- Terminals: Provide a point of connection for various electrical pathways.

- Grounding Points: Essential for safety, these connections prevent electrical shock and interference.

Importance of Proper Connections

Maintaining accurate and secure electrical connections has several benefits:

- Enhanced Reliability: Reduces the likelihood of unexpected malfunctions.

- Improved Efficiency: Ensures optimal power distribution across the system.

- Safety Assurance: Prevents hazards associated with loose or damaged connections.

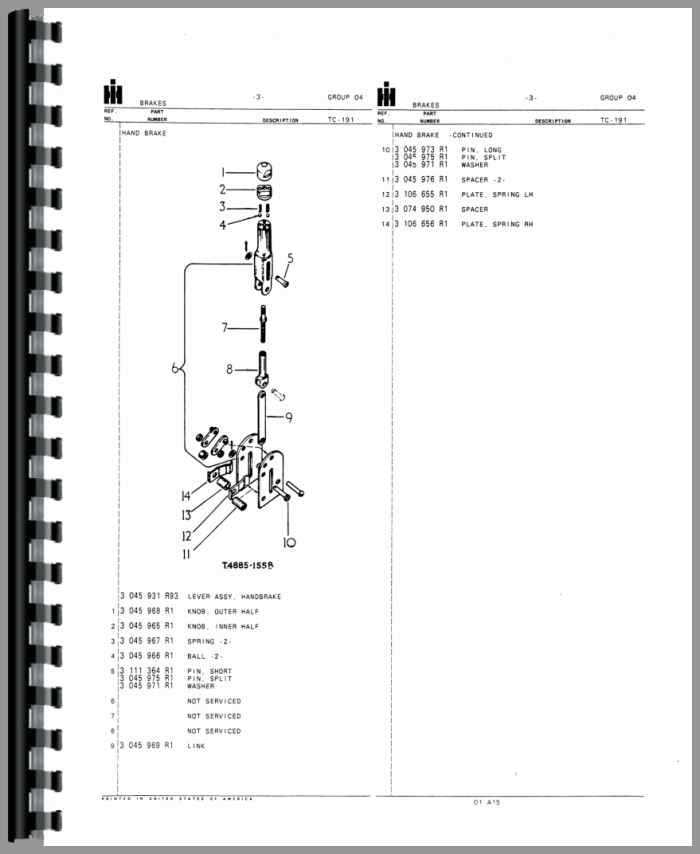

Breaking Down the Steering Mechanism

The steering system of a vehicle is crucial for maintaining control and maneuverability. It translates the driver’s input into directional movement, ensuring a smooth and responsive driving experience. Understanding this mechanism involves examining its various components and their interconnections, which work together to provide precise handling.

Key Components

At the heart of the steering system lies the steering wheel, which serves as the primary interface for the operator. This component is connected to a steering column, which transmits motion to the steering gear. The steering gear is responsible for converting the rotational movement of the wheel into lateral motion, allowing the vehicle to turn. Other essential elements include tie rods and knuckles, which facilitate the actual movement of the wheels based on the driver’s input.

Functionality and Operation

The efficiency of the steering mechanism is largely dependent on the proper functioning of each part. When the steering wheel is turned, the column rotates, engaging the gear mechanism. This action initiates movement in the tie rods, which in turn pivot the wheels at the desired angle. Regular maintenance and adjustments are vital to ensure the longevity and reliability of this system, preventing issues that could compromise safety.

Structural Layout of the Chassis

The framework of any vehicle serves as its backbone, providing support and stability for various components. Understanding the arrangement of this framework is crucial for maintenance and modifications. This section explores the design elements and structural components that contribute to the overall integrity and functionality of the vehicle’s chassis.

Main Components of the Framework

The structural framework consists of several key elements that work together to ensure strength and durability. These components include beams, cross members, and mounting points, each playing a vital role in the overall architecture. Their arrangement is designed to withstand the stresses encountered during operation while maintaining a balanced weight distribution.

The configuration of the structural layout is influenced by design principles that prioritize safety, performance, and efficiency. Engineers meticulously plan the positioning of each element to optimize the chassis’s response to various driving conditions. This careful consideration not only enhances the vehicle’s handling but also contributes to its longevity.

| Component | Description |

|---|---|

| Beams | Longitudinal members providing primary support and load distribution. |

| Cross Members | Transverse supports that enhance rigidity and stability. |

| Mounting Points | Attachments for various components, ensuring secure placement. |

| Reinforcements | Additional supports to enhance strength in high-stress areas. |

Critical Elements of the Cooling System

The efficiency of an engine’s thermal management relies heavily on several key components. These elements work in unison to regulate temperatures, ensuring optimal performance and longevity. Understanding their roles is crucial for effective maintenance and troubleshooting.

Radiator: This essential component dissipates heat from the coolant, allowing it to return to the engine at a lower temperature. The efficiency of the radiator is vital for maintaining appropriate operating temperatures.

Water Pump: The water pump circulates coolant throughout the engine and the cooling system. A reliable pump is crucial for ensuring that the coolant flows effectively, preventing overheating.

Thermostat: Acting as a temperature regulator, the thermostat opens and closes to maintain the desired coolant temperature. A malfunctioning thermostat can lead to inadequate heating or excessive cooling.

Coolant: The fluid used in the system plays a significant role in heat transfer. Using the correct mixture of coolant and water helps to prevent corrosion and freezing, ensuring optimal performance.

Hoses and Connections: These components facilitate the movement of coolant between the engine, radiator, and other parts of the system. Ensuring they are free from leaks and blockages is essential for the system’s overall functionality.

In summary, a well-functioning thermal management system is crucial for engine performance. Regular inspections and maintenance of these critical elements can prevent overheating and extend the life of the engine.

Suspension and Axle Configuration

The configuration of the suspension and axle plays a crucial role in the overall performance and stability of vehicles. This system is designed to provide support, enhance handling, and improve ride comfort by absorbing shocks from uneven surfaces. Understanding the intricacies of this setup can help in maintaining optimal functionality and ensuring safety during operation.

Suspension systems are typically composed of various components that work together to minimize the impact of road imperfections. These may include springs, dampers, and linkages that allow for controlled movement of the chassis relative to the wheels. The effectiveness of these elements directly influences how the vehicle responds to different driving conditions.

In addition to the suspension, the axle assembly is fundamental in transferring power from the engine to the wheels. A well-engineered axle configuration ensures that the vehicle can handle loads effectively while maintaining stability during turns and acceleration. The relationship between the axle and suspension systems is vital for optimal weight distribution and overall vehicle dynamics.

Moreover, specific adjustments to the suspension and axle can enhance performance characteristics tailored to various applications, from agricultural tasks to transportation needs. Regular inspection and maintenance of these components are essential to prevent wear and ensure reliable operation throughout the vehicle’s lifespan.

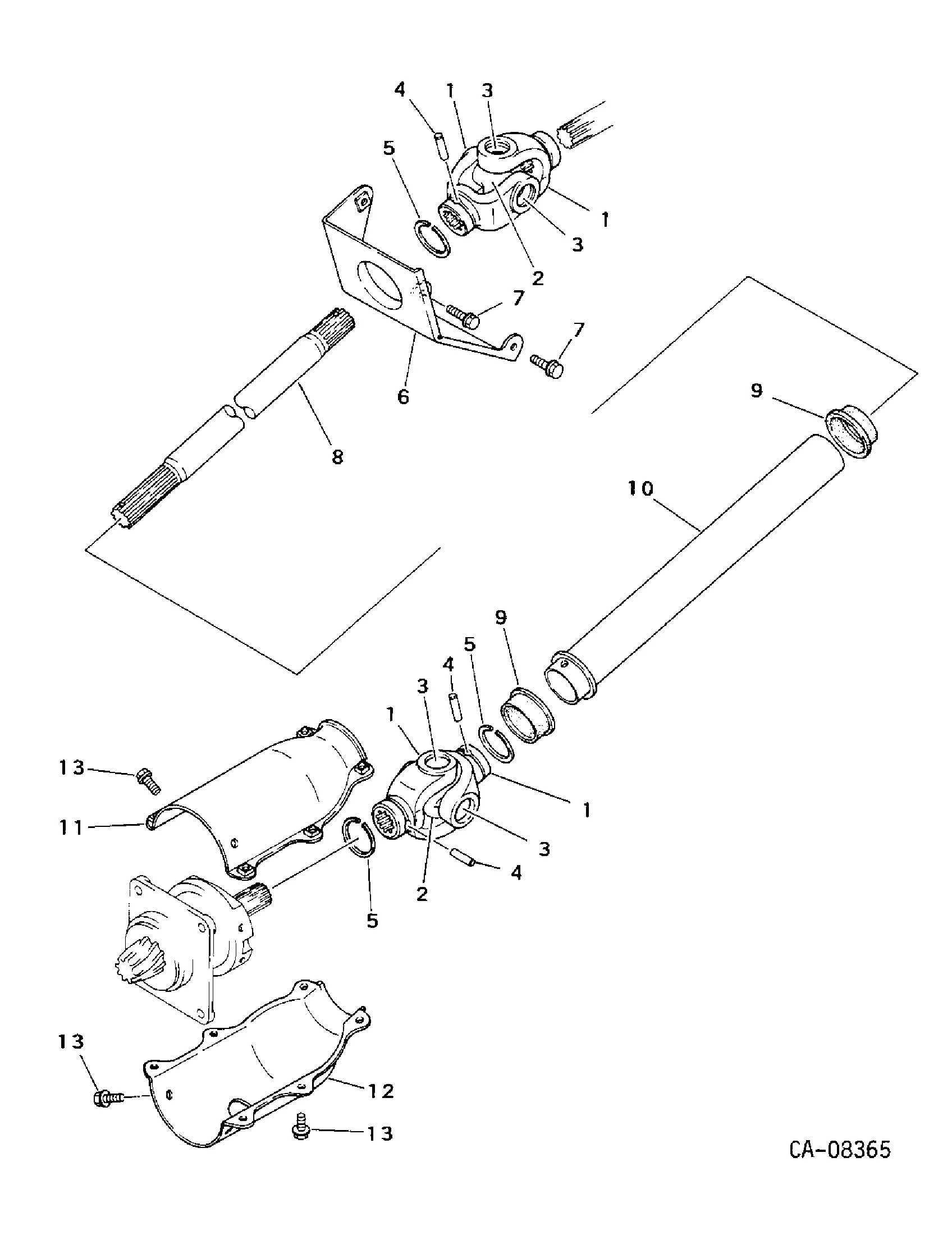

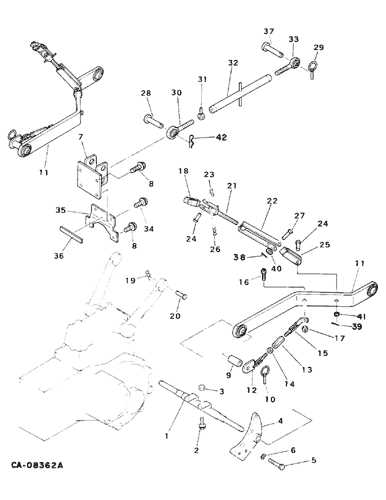

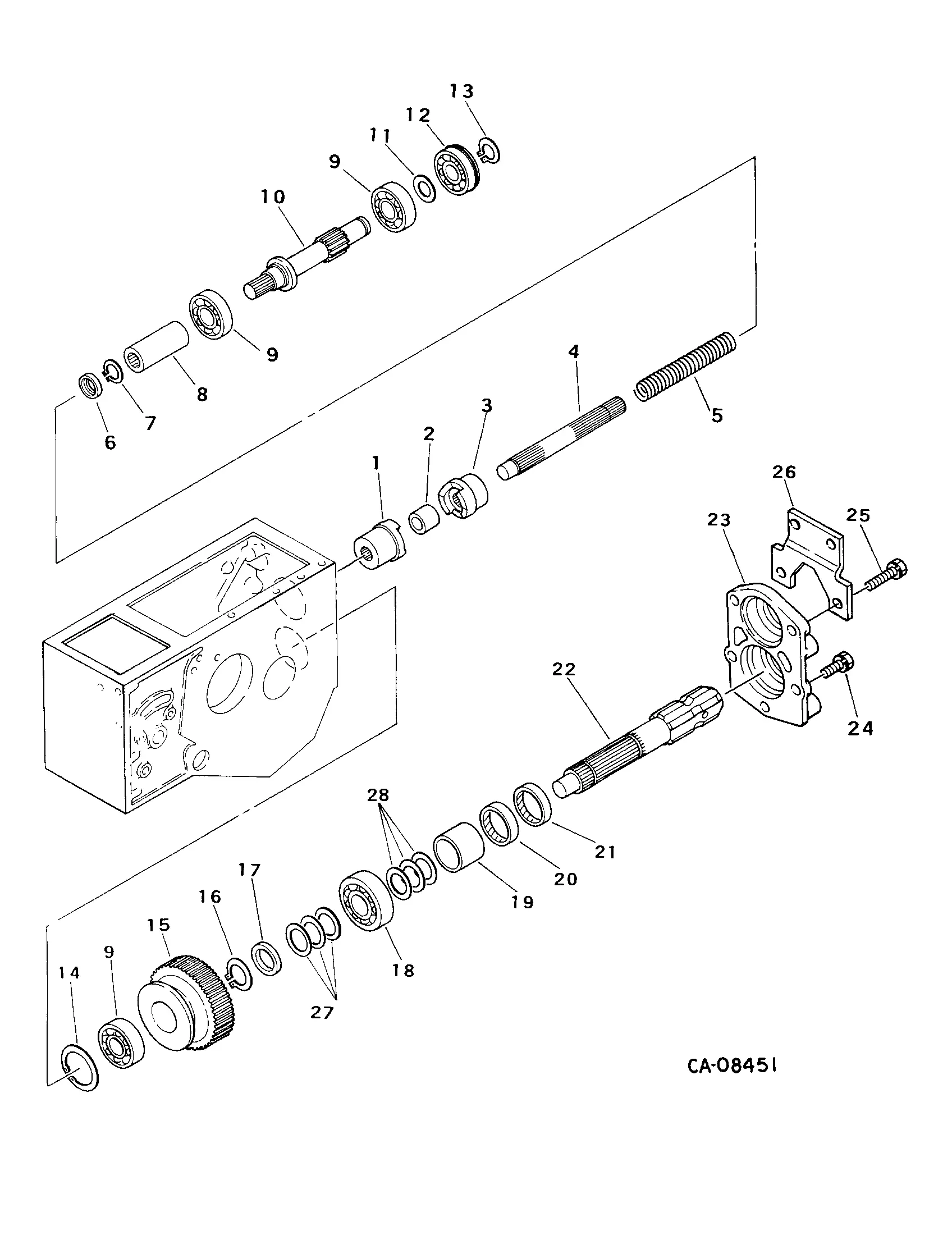

Analysis of the PTO System

The Power Take-Off (PTO) system plays a crucial role in the functionality of agricultural machinery, enabling the transfer of mechanical energy from the engine to various implements. This system enhances versatility, allowing operators to utilize different tools effectively, thereby optimizing productivity in various farming tasks.

Key Components and Functionality

At the heart of the PTO system are several essential components, including the drive shaft, clutch, and gear mechanisms. These elements work together to facilitate smooth power transfer, ensuring that attachments operate efficiently. Understanding how these components interact is vital for maintaining the overall performance of the machinery.

Importance of Regular Maintenance

To ensure the longevity and reliability of the PTO system, regular maintenance is imperative. This includes routine inspections, lubrication, and timely repairs of any wear and tear. Neglecting maintenance can lead to decreased efficiency and potential failures, impacting overall operational productivity. By prioritizing upkeep, operators can safeguard their equipment and enhance its operational lifespan.