The intricate design of machinery often requires a detailed examination of its various elements. This exploration enables users to gain insights into the assembly and functionality of each segment, ensuring optimal performance and longevity.

In the realm of agricultural equipment, having a clear visualization of the interconnected systems is crucial. By analyzing a detailed representation, operators can identify the relationships between different components, making maintenance and repairs more efficient.

Ultimately, a comprehensive understanding of these layouts can significantly enhance productivity. As enthusiasts and professionals delve into this subject, they uncover valuable information that aids in both everyday operation and troubleshooting of complex machinery.

Understanding International 444 Components

Grasping the intricacies of a machinery unit requires familiarity with its essential elements. Each component plays a vital role in the overall functionality, contributing to the effective operation of the entire system. This knowledge not only enhances maintenance practices but also facilitates troubleshooting and repairs.

Below is a breakdown of the key components commonly found in such machinery:

| Component | Description |

|---|---|

| Engine | Serves as the primary source of power, converting fuel into mechanical energy. |

| Transmission | Transfers power from the engine to the wheels, allowing for movement and speed control. |

| Hydraulic System | Utilizes fluid power to perform various functions, such as lifting and steering. |

| Chassis | Provides the structural framework that supports all components and systems. |

| Electrical System | Controls the operation of lights, ignition, and other electronic features. |

| Cooling System | Regulates the engine temperature to prevent overheating and ensure efficient operation. |

Understanding these components not only aids in optimizing performance but also empowers operators to make informed decisions regarding maintenance and repairs.

Overview of the 444 Tractor

This section provides a comprehensive look at a classic agricultural machine known for its reliability and efficiency in various farming tasks. Designed with robust engineering, it has become a staple for many farmers seeking to enhance productivity.

Key Features

- Powerful engine for optimal performance

- Versatile attachments for diverse applications

- Durable construction for longevity

Applications

- Field plowing and cultivation

- Crop harvesting and transport

- Landscaping and maintenance tasks

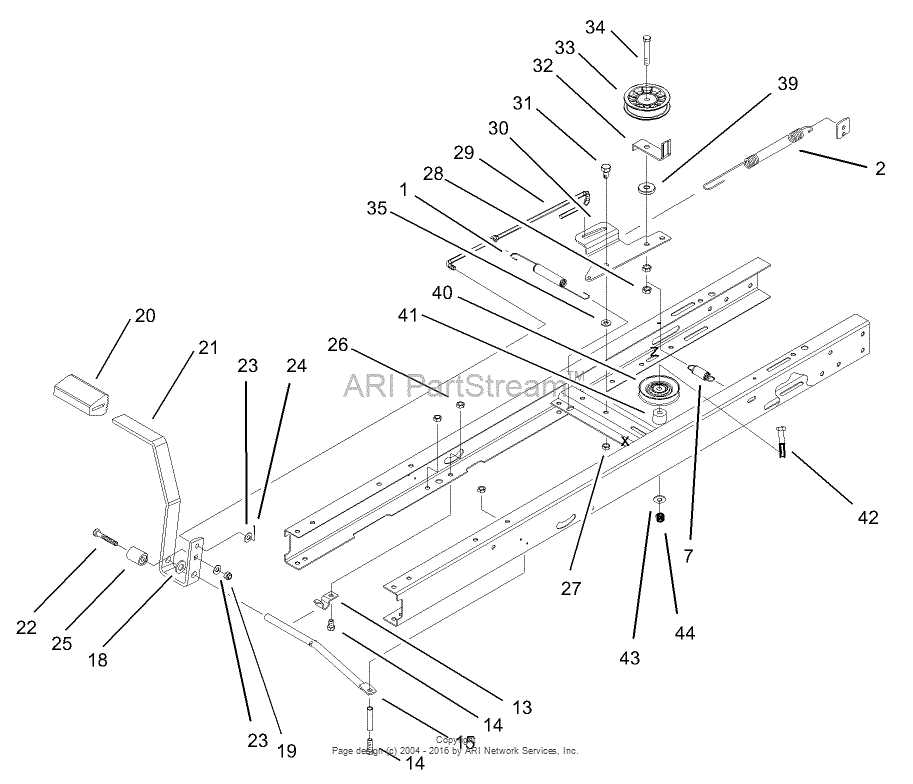

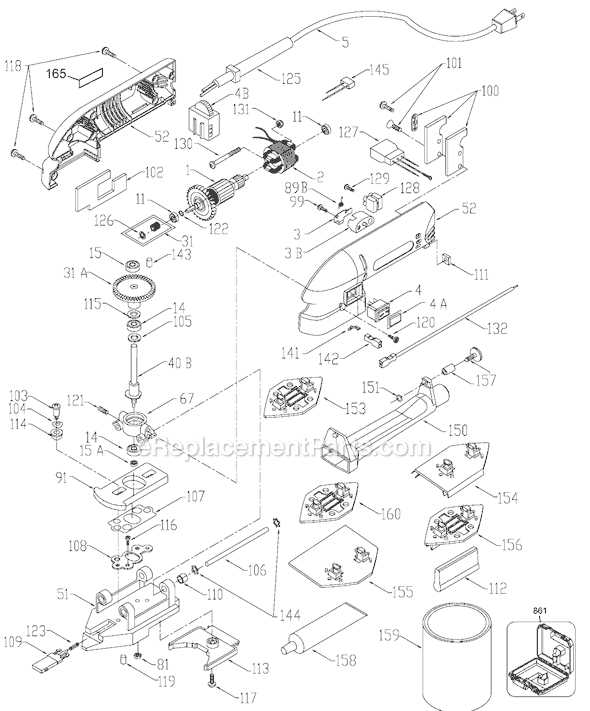

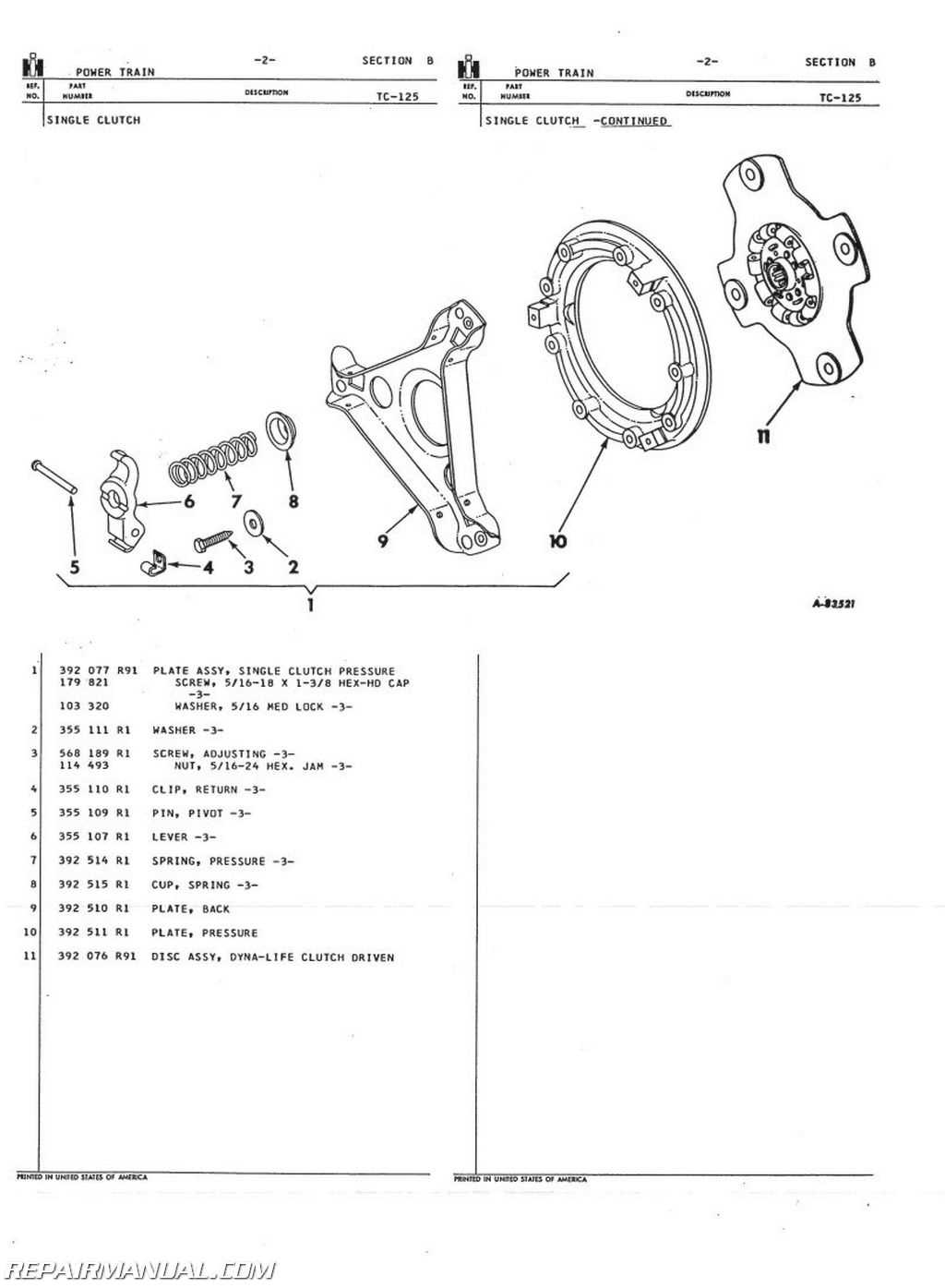

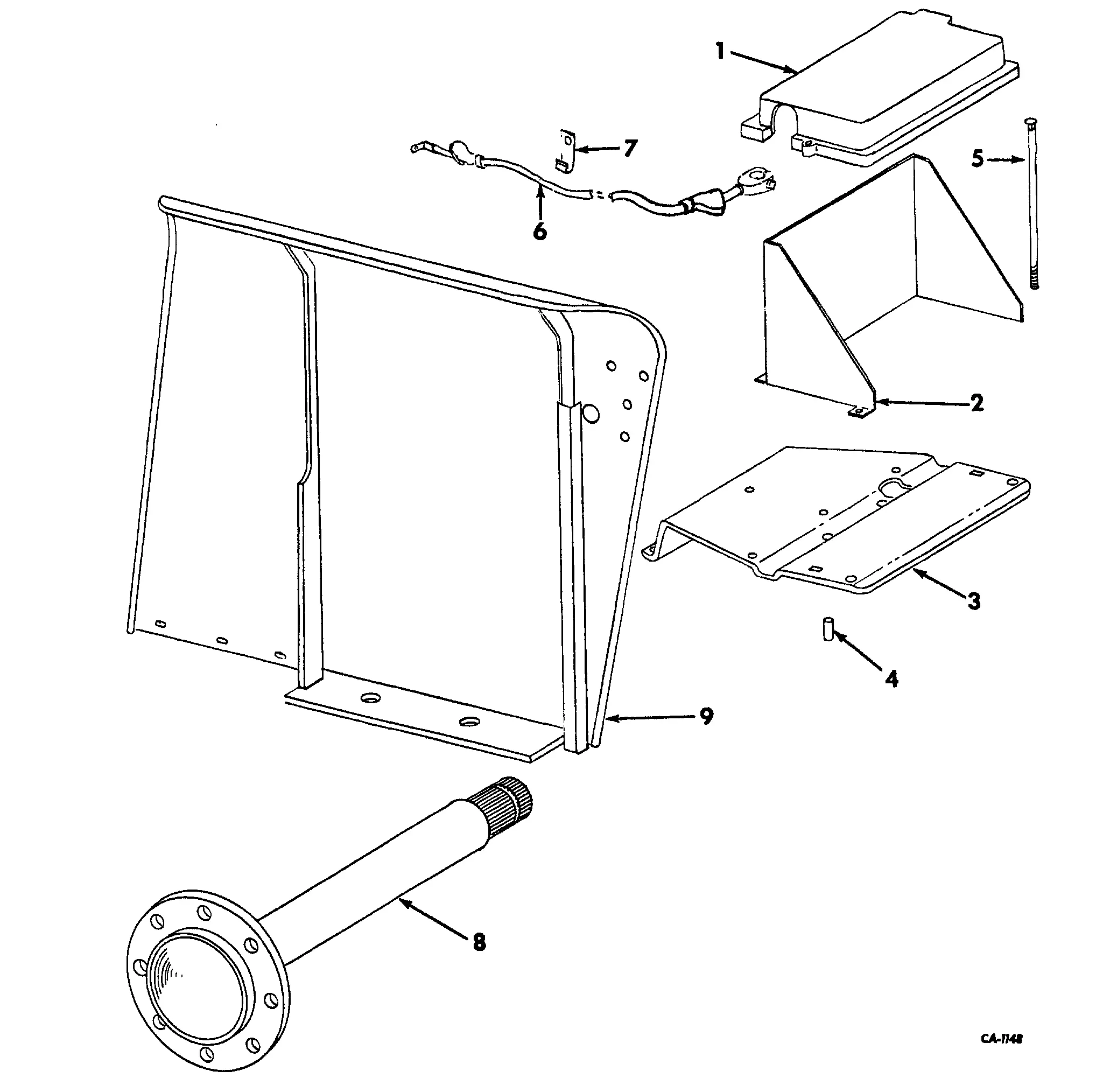

Importance of Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair of machinery. These illustrations not only provide clarity on the arrangement and function of various elements but also serve as essential tools for technicians and engineers. Understanding these representations can significantly enhance efficiency and accuracy in handling mechanical tasks.

Enhanced Understanding

By depicting intricate details, these visual aids allow individuals to quickly grasp the relationships between different components. This clarity reduces confusion during assembly or disassembly processes and ensures that every piece is correctly identified and handled.

Efficient Troubleshooting

Having access to well-structured visuals simplifies the diagnosis of issues. Technicians can easily pinpoint areas of concern, leading to quicker resolutions and minimizing downtime. This efficiency is vital in maintaining optimal performance and extending the lifespan of equipment.

| Benefit | Description |

|---|---|

| Clarity | Provides a clear view of component relationships. |

| Speed | Facilitates quicker identification of parts. |

| Accuracy | Enhances precision during maintenance tasks. |

| Training | Serves as an educational tool for new technicians. |

Key Components of the 444 Model

The essence of this model lies in its intricate assembly of vital elements that contribute to its overall functionality and efficiency. Understanding these components is crucial for anyone looking to appreciate the design and operational capabilities of the machine.

Engine and Transmission

At the heart of the system is the powerful engine, delivering reliable performance and efficiency. Coupled with a robust transmission, these elements ensure smooth operation across various terrains, making the machinery versatile and dependable.

Hydraulic System

The hydraulic system plays a pivotal role in enhancing the machine’s lifting and digging capabilities. By utilizing pressurized fluid, it allows for precise control and increased power, essential for handling demanding tasks effectively.

Engine Specifications and Parts

This section delves into the intricate components and characteristics that define the performance and functionality of the engine in question. Understanding these specifications is crucial for maintenance, repair, and overall efficiency.

Performance Metrics: The engine boasts impressive metrics, including horsepower and torque ratings that contribute to its robust capabilities. These figures are essential for evaluating the overall power output and operational efficiency.

Components Overview: Key elements such as the cylinder head, crankshaft, and valvetrain play significant roles in the engine’s performance. Each component is meticulously designed to ensure optimal functionality and durability, reflecting the engineering prowess behind its creation.

Fuel System: The fuel injection system is critical for delivering the right mixture of air and fuel, enabling efficient combustion and minimizing emissions. Proper functioning of this system is vital for maintaining peak performance.

Cooling Mechanism: An effective cooling system is indispensable to prevent overheating, ensuring longevity and reliability. It is designed to regulate the engine’s temperature, allowing it to operate within safe limits.

Maintenance Considerations: Regular inspections and timely replacements of vital components can greatly enhance the lifespan of the engine. Understanding the specifications aids in identifying potential issues before they escalate, ensuring smooth operation.

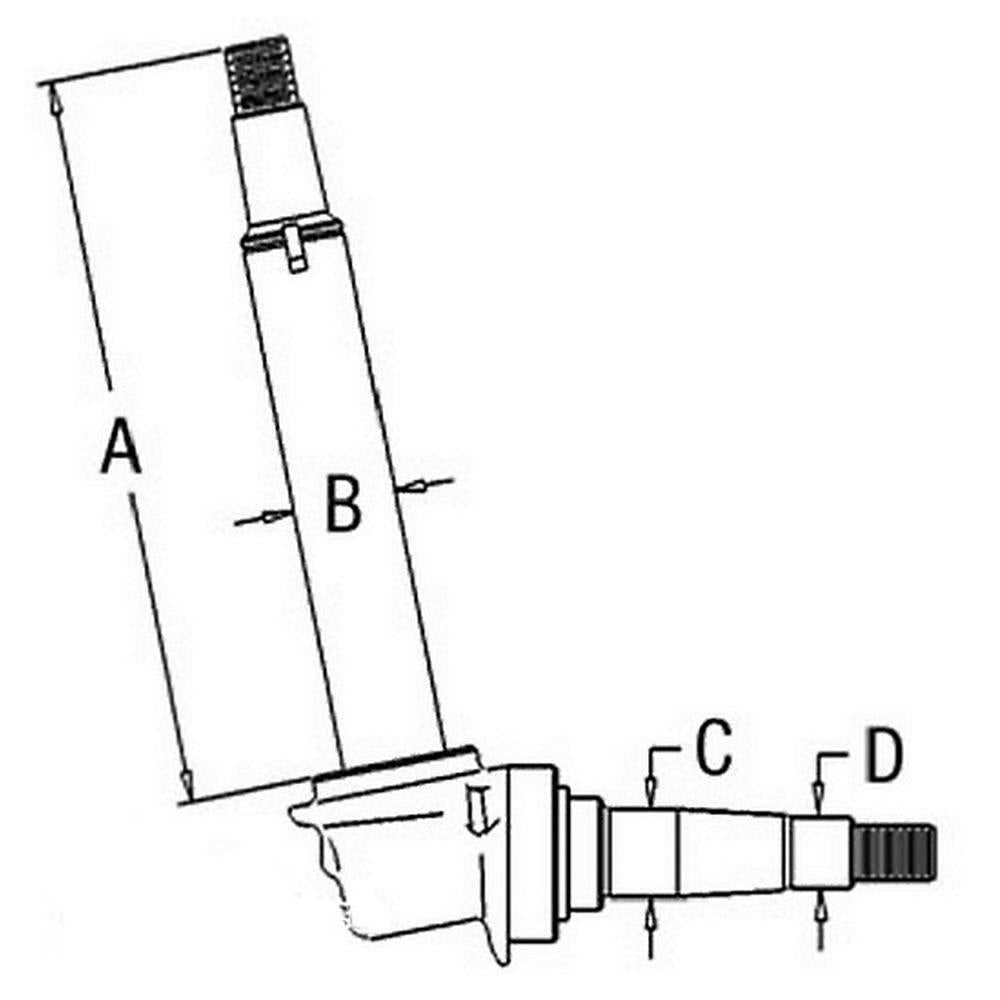

Transmission System Explained

The transmission system serves as the essential link between power generation and movement. It enables the efficient transfer of energy from the engine to the wheels, allowing for optimal performance across various conditions. Understanding its components and functions is crucial for maintaining the vehicle’s operational integrity.

Key Components

The primary elements of the transmission system include the gearbox, clutch, and driveshaft. The gearbox adjusts the torque and speed, while the clutch facilitates smooth engagement and disengagement of gears. The driveshaft then transmits this adjusted power to the wheels, ensuring proper traction and stability.

Operational Mechanics

When the engine generates power, it is routed through the transmission system, where the gearbox modifies its characteristics based on driving demands. This intricate process allows the vehicle to accelerate, decelerate, and maintain speed efficiently, contributing to the overall driving experience.

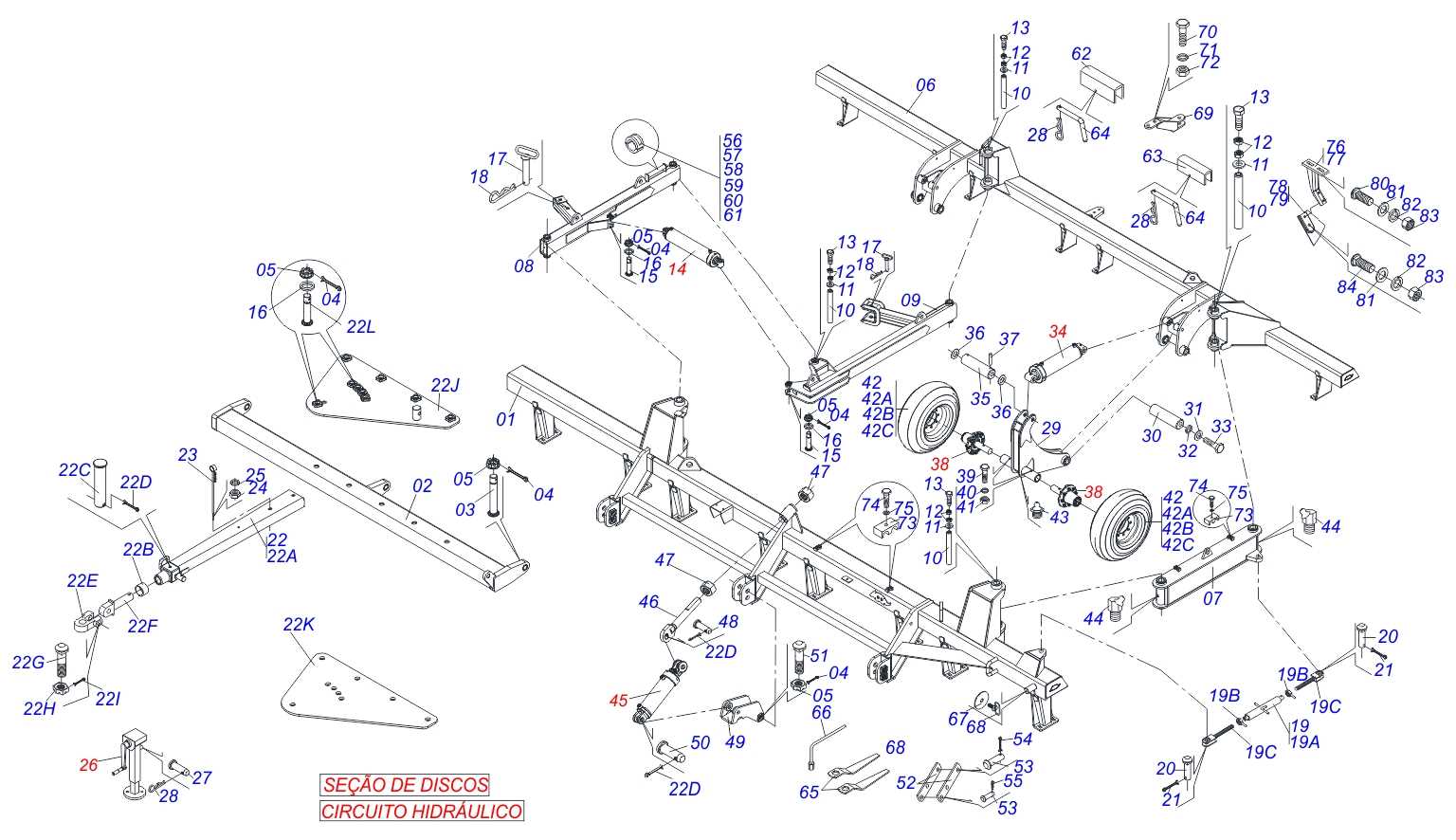

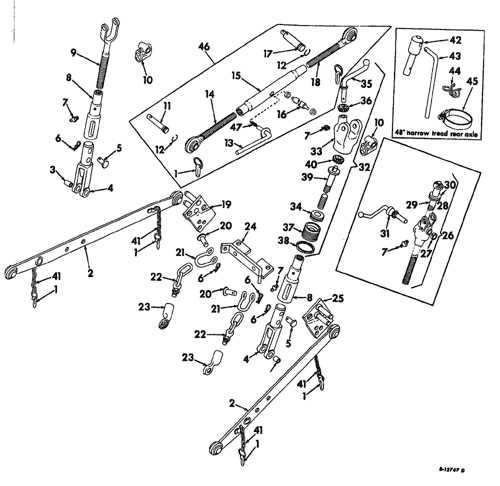

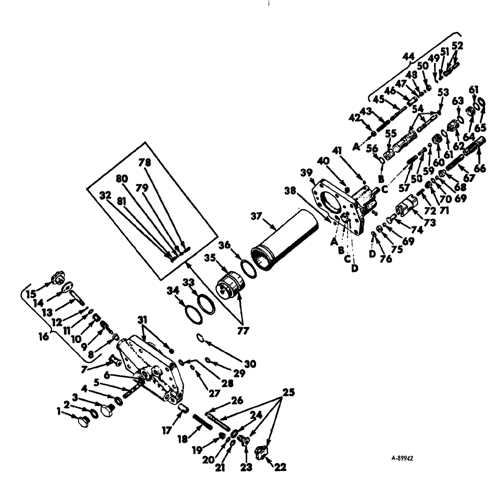

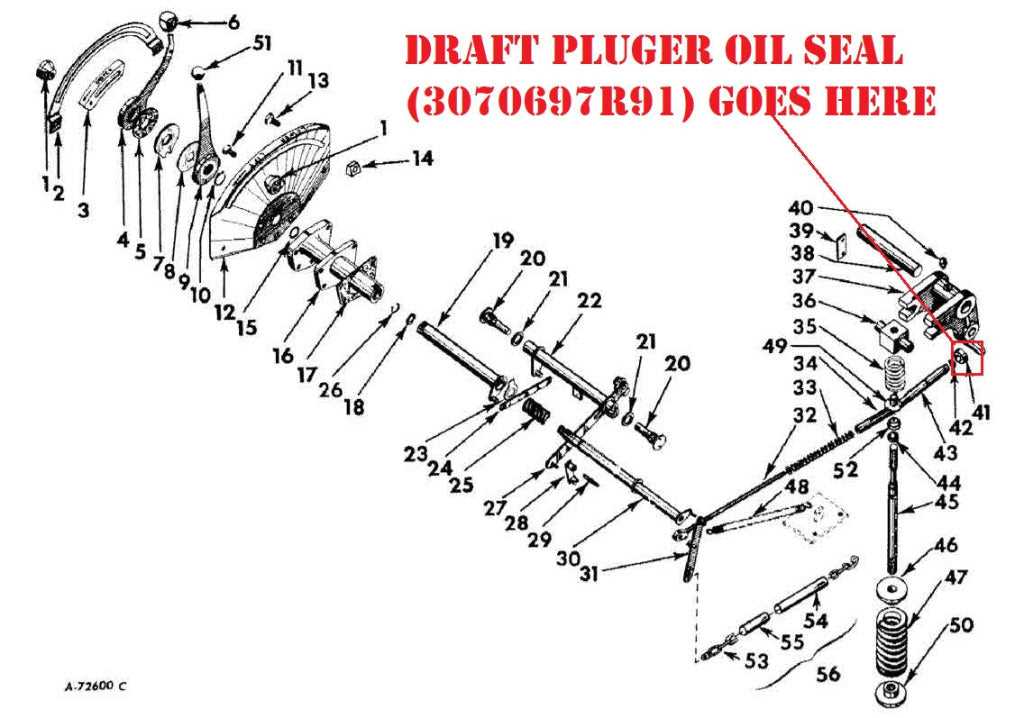

Hydraulic System Breakdown

The hydraulic system serves as a crucial component in machinery, providing the necessary force to execute various tasks. Understanding its structure and functionality is essential for troubleshooting and maintenance. This section will delve into the intricate workings of this system, highlighting key elements and their interrelations.

Key Components

At the heart of the hydraulic mechanism are several vital components. These include the pump, which generates fluid flow; the actuators, responsible for converting hydraulic energy into mechanical motion; and the valves that regulate fluid distribution. Each part plays a specific role, ensuring efficient operation and response to the operator’s commands.

Common Issues and Solutions

Over time, hydraulic systems may encounter various challenges such as leaks, pressure drops, or component wear. Identifying these issues early can prevent significant downtime and costly repairs. Regular inspections and maintenance, including fluid replacement and seal checks, are essential for optimal performance. When issues arise, understanding the layout and function of each element will aid in effective troubleshooting.

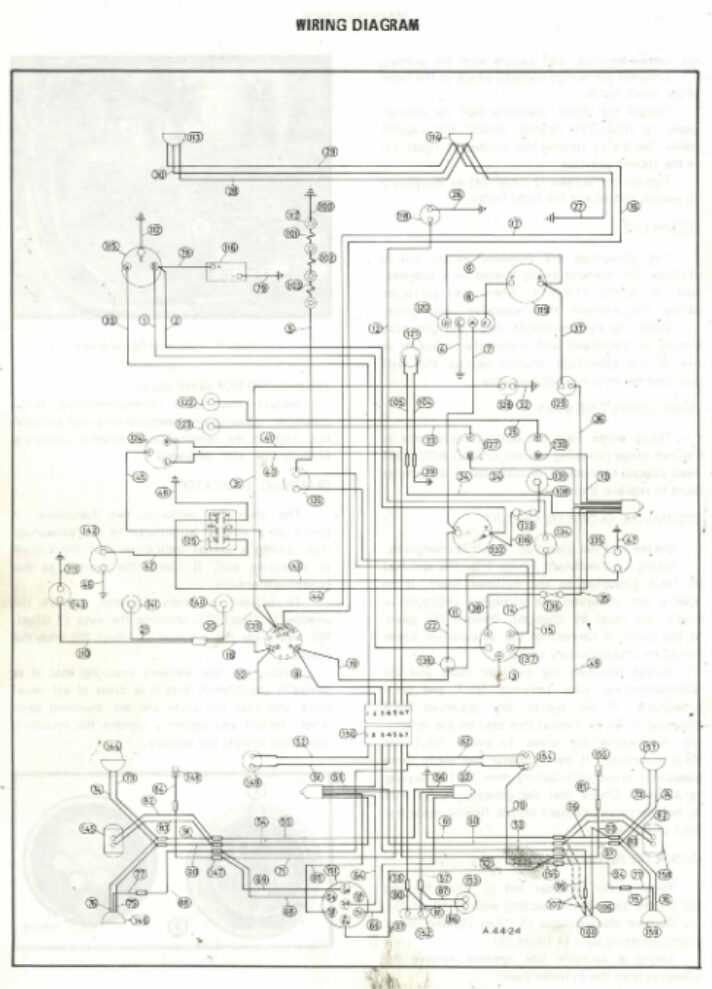

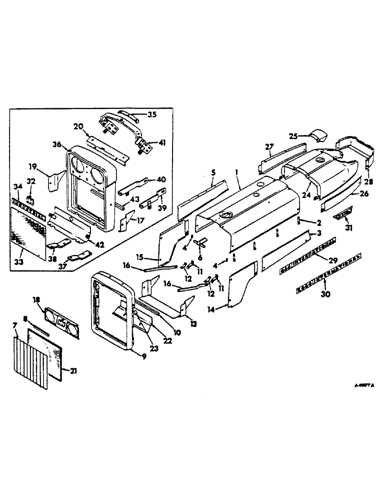

Electrical Components Overview

This section provides a comprehensive look at the various electrical elements found within agricultural machinery. Understanding these components is essential for effective maintenance and troubleshooting, ensuring optimal performance and longevity of the equipment.

Electrical systems in machinery typically consist of a variety of parts, each playing a critical role. From power supply units to circuit breakers, these elements work together to manage and distribute electrical energy throughout the system. Key components include switches, relays, and wiring harnesses, all of which facilitate the flow of electricity and enable the operation of various functions.

Additionally, sensors and control modules are vital for monitoring and regulating the machinery’s performance. These devices gather data and make real-time adjustments, enhancing efficiency and safety. Understanding how these components interact and function collectively is crucial for operators and technicians alike.

Regular inspection and maintenance of these electrical elements can prevent unexpected failures and reduce downtime. By familiarizing oneself with the layout and role of each component, users can ensure their machinery operates at peak performance.

Maintenance and Repair Insights

Regular upkeep and timely fixes are essential for ensuring the longevity and efficiency of any machinery. Understanding the fundamental components and their functions allows operators to address issues before they escalate. Proper maintenance not only enhances performance but also minimizes unexpected downtimes, ensuring smooth operation over the long term.

Routine checks play a critical role in the maintenance process. By frequently inspecting various systems, one can identify wear and tear or any signs of malfunction. For instance, monitoring fluid levels, filters, and belts can help maintain optimal functioning and prevent larger complications. Keeping a detailed maintenance log can also provide insights into patterns, aiding in predictive maintenance.

Repair strategies should be implemented as soon as a problem is detected. Addressing minor issues promptly can save time and resources in the long run. Familiarity with the machinery’s structure and the ability to consult accurate technical references can significantly enhance repair effectiveness. Moreover, investing in quality tools and parts ensures that replacements contribute to overall performance and reliability.

Ultimately, a proactive approach to care and repair not only preserves the machine’s integrity but also supports safety and operational efficiency. By prioritizing these aspects, operators can foster a more productive working environment.

Common Issues and Solutions

This section addresses frequent problems encountered with agricultural machinery and offers effective solutions. Understanding these challenges can enhance performance and extend the lifespan of your equipment.

Engine Performance Problems

One of the main issues operators face is reduced engine efficiency. This can be due to clogged air filters or fuel contamination. Regular maintenance, including changing filters and using quality fuel, can significantly improve functionality.

Hydraulic System Failures

Hydraulic failures often stem from leaks or low fluid levels. Inspect hoses and connections regularly, and ensure fluid is topped up to avoid potential damage. Addressing these issues promptly can prevent costly repairs and downtime.

Finding Replacement Parts

Locating suitable components for machinery can be a straightforward yet crucial task. Whether you’re performing routine maintenance or addressing unexpected breakdowns, having the right elements on hand ensures optimal performance and longevity.

Begin by consulting the user manual or manufacturer resources for specifications. Online marketplaces and specialized suppliers often carry a vast selection, making it easier to find what you need. Joining forums and communities dedicated to equipment can also provide insights and recommendations from fellow users who have navigated similar challenges.

Consider the option of salvaging from older models if new items are hard to come by. Additionally, maintaining a detailed inventory of your equipment can streamline the process, helping you quickly identify and order necessary replacements when needed.

Resources for Diagrams and Manuals

Accessing accurate visual aids and instructional guides is essential for effective maintenance and repair. Numerous platforms offer detailed resources that cater to both enthusiasts and professionals, ensuring a comprehensive understanding of machinery and its components.

Online forums and communities often serve as valuable hubs for sharing insights, with members frequently posting links to manuals and schematics. Additionally, manufacturer websites typically provide downloadable resources that are essential for troubleshooting and part identification.

For those seeking printed materials, bookstores and specialty shops may offer a range of handbooks, while libraries often house technical literature that can be invaluable. Exploring these diverse options will enhance one’s knowledge and facilitate successful projects.

Tips for Effective Repairs

Successful maintenance and restoration of machinery require careful planning and a thorough understanding of the components involved. By approaching repairs systematically, one can ensure efficiency and longevity in the equipment’s performance.

First, always consult the manufacturer’s manual for specific instructions and diagrams, as they provide invaluable insights into assembly and disassembly processes. Second, gather all necessary tools and replacement elements before starting, minimizing interruptions and maintaining focus. Additionally, label and organize components as they are removed to avoid confusion during reassembly.

It’s also crucial to inspect all parts for wear and tear regularly. Identifying potential issues early can prevent more extensive damage later. When working, keep a clean and organized workspace to enhance safety and efficiency. Lastly, don’t hesitate to seek advice from professionals or experienced peers when facing complex problems; collaboration can often lead to the most effective solutions.