When it comes to maintaining and servicing agricultural machinery, having a clear view of how various mechanisms and elements are organized is essential. Proper knowledge of the structure helps ensure optimal performance and longevity, allowing operators to quickly identify areas that require attention or replacement. This section provides a detailed look at how key assemblies are arranged, highlighting their connectivity and function within the overall system.

Each section of the machinery is designed to work in harmony, with every element contributing to the efficiency of the entire setup. The way these components are arranged affects both the durability and the ease of operation, making it vital to understand their placement and role. Whether you’re looking to replace a single piece or conduct a thorough overhaul, having a comprehensive view of the layout is invaluable.

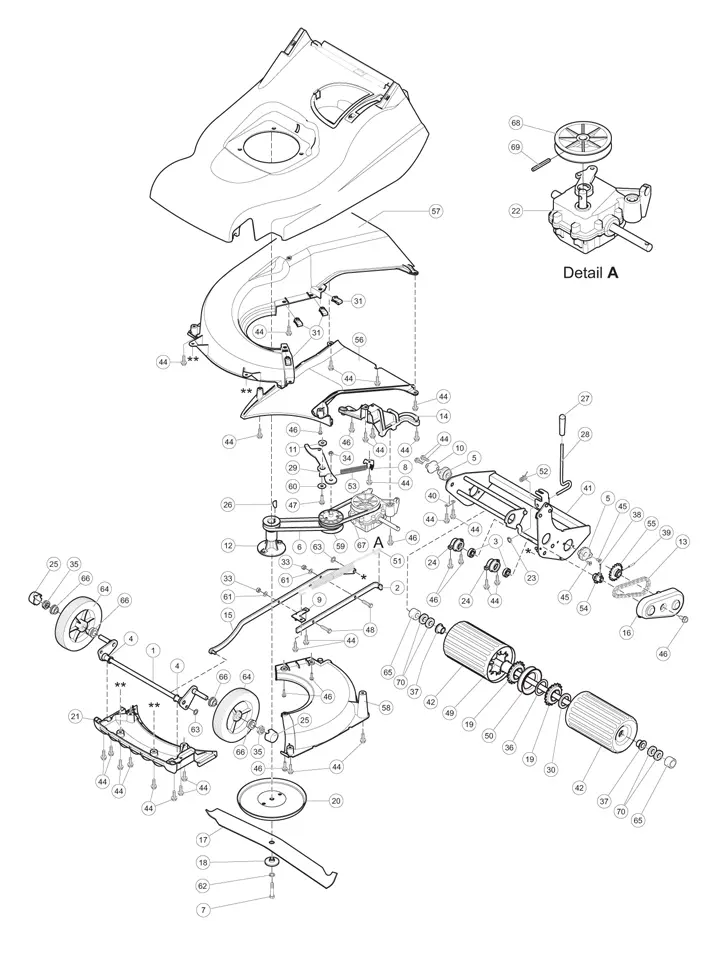

Overview of the 490 Disc Harrow Components

In agricultural machinery, understanding the individual elements of a harrow is crucial for effective use and maintenance. Each component plays a distinct role in ensuring the equipment functions smoothly in various soil conditions. From the cutting edges that engage the earth to the structural framework supporting the entire system, these elements work in unison to achieve efficient soil preparation.

The main structural sections include rotating sections designed to till the ground, along with support mechanisms that provide stability. The connecting joints and fasteners ensure that all moving parts stay aligned, reducing wear and tear over time. Maintenance of these sections is essential to prolong the equipment’s operational lifespan.

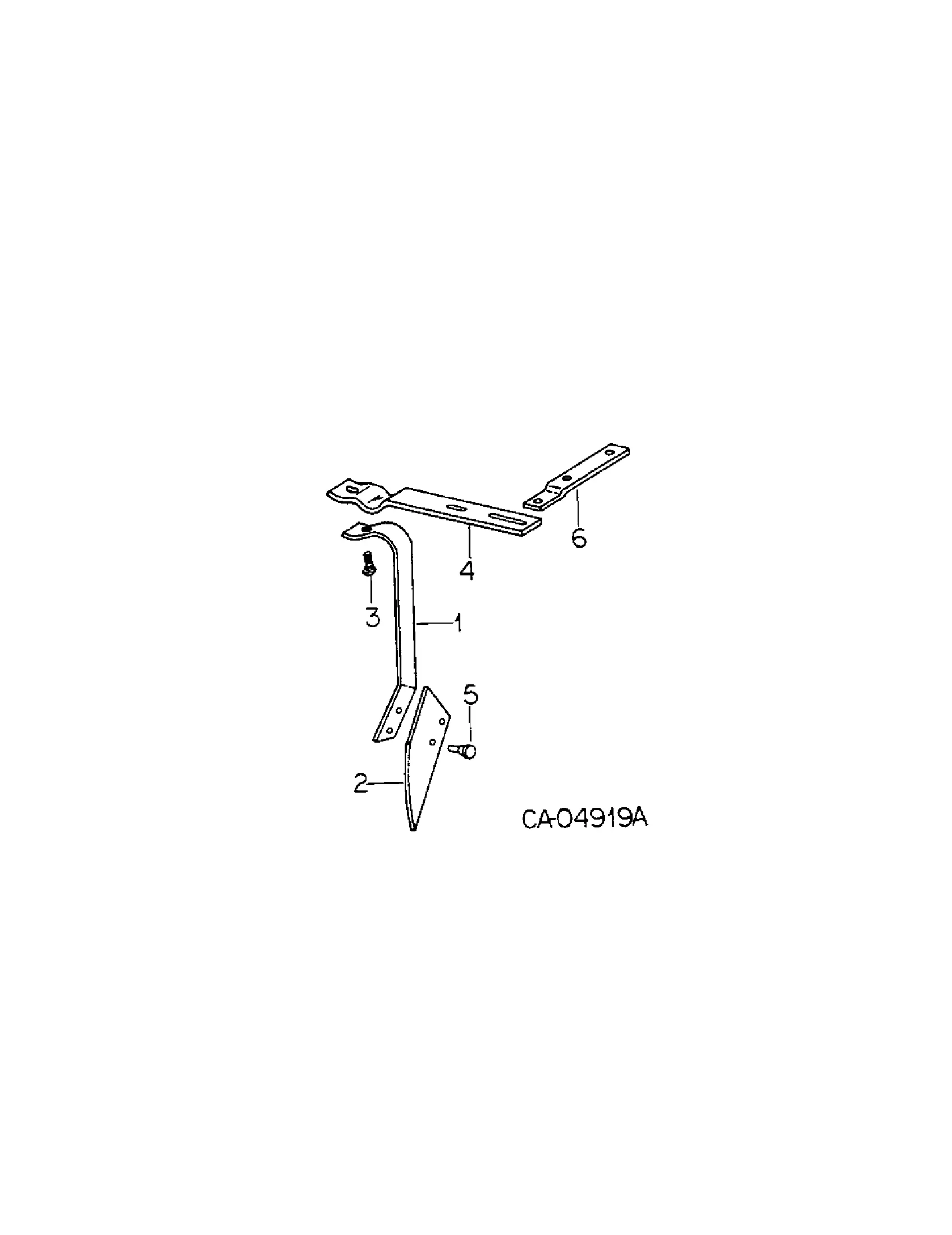

Main Frame Structure and Support

The core framework is designed to ensure stability and durability, acting as the foundation for all attached components. This robust skeletal structure plays a crucial role in distributing weight and managing the forces applied during operation, ensuring long-term reliability in various field conditions.

Strategically reinforced sections provide additional support where necessary, preventing strain and wear on key areas. The framework’s design emphasizes both strength and flexibility, allowing it to absorb shocks and adapt to uneven terrains without compromising its integrity.

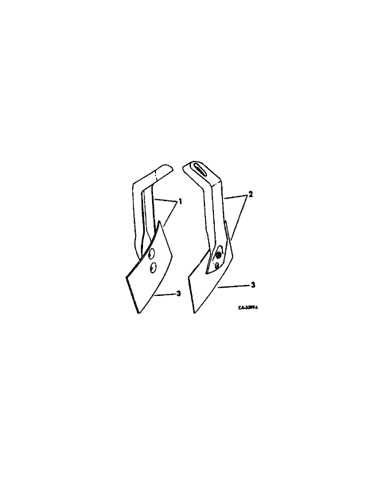

Blade Assembly and Alignment Techniques

Proper setup and adjustment of cutting components are essential for efficient operation. Each element must be securely mounted to ensure durability and optimal performance during use. This process involves the correct positioning of each cutting tool and fine-tuning the alignment for uniformity and effectiveness.

Step-by-Step Installation: Begin by securing each section onto the frame, ensuring all connections are firm. Carefully adjust the angle and depth, considering the type of surface and conditions where the equipment will operate.

Fine-Tuning for Maximum Efficiency: After installation, minor adjustments can significantly impact performance. Align all elements symmetrically and check for uniform spacing. This step ensures even coverage, preventing excess wear or inefficiency during operation.

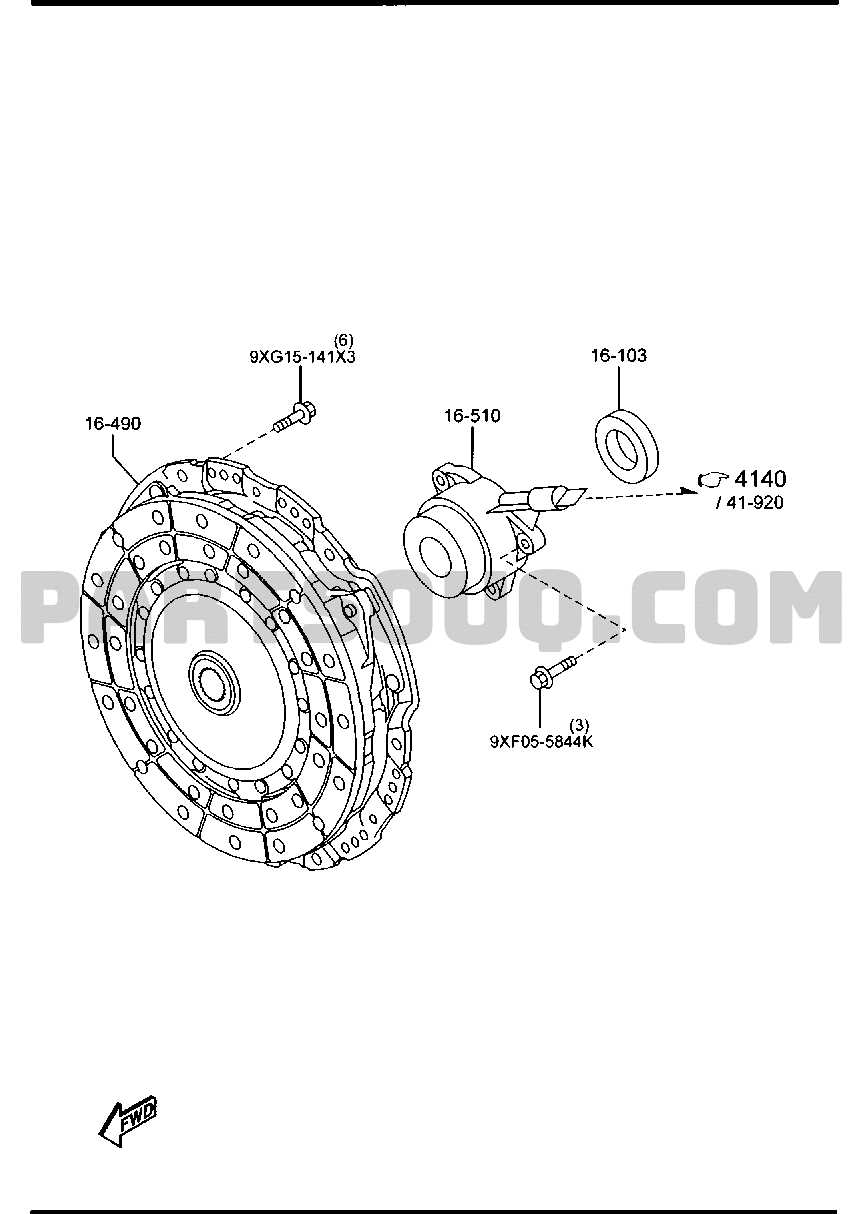

Understanding the Hub and Bearing Mechanism

The hub and bearing assembly is an essential component of agricultural equipment, providing smooth rotational motion while supporting various structural elements. This mechanism ensures the even distribution of force and minimizes friction, allowing for efficient operation under various conditions. Proper understanding of these components is crucial for maintaining overall functionality and longevity.

| Component | Description | |||||

|---|---|---|---|---|---|---|

| Hub | Acts as the central attachment point, ensuring rotational balance and stability of connected elements. | |||||

| Bearing | Reduces friction between the moving parts, enabling smooth and controlled movement during use. | |||||

| Axle and Disc Gang Configuration

The alignment and organization of the axle assembly along with the set of cutting components play a crucial role in the overall performance of agricultural tilling equipment. These components are meticulously arranged to ensure optimal soil penetration and even distribution of pressure, enhancing both efficiency and durability during field operations. Axle Assembly LayoutThe axle is the backbone that supports and connects the various elements. Its robust design allows for the proper alignment and rotation of the attached components, providing stability and smooth operation across various terrains. Ensuring correct spacing and placement of each element is essential for maintaining balance and preventing undue wear. Component ArrangementThe positioning of the cutting elements around the central axle is designed to achieve maximum soil disruption while minimizing drag. The spacing, angle, and rotation of each piece are carefully Adjustment Options for Tillage Depth

Proper management of soil disturbance is crucial for achieving optimal crop growth and maximizing yield. Various techniques and settings allow operators to modify the intensity of soil engagement, enabling better control over the cultivation process. Adjusting these parameters helps accommodate different soil types and conditions, ensuring effective performance across diverse agricultural environments. Mechanical AdjustmentsOne of the primary methods for regulating tillage depth involves mechanical alterations to the equipment. These modifications may include changing the position of the implement’s frame or altering the angle of the working components. By utilizing a combination of height settings and angle adjustments, operators can achieve the desired penetration level while maintaining consistent soil turnover. Hydraulic Control SystemsFor enhanced precision, hydraulic control systems provide a sophisticated means of adjusting tillage depth. Operators can make real-time changes to the depth settings from the tractor’s cabin, allowing for immediate responses to varying field conditions. This adaptability not only improves efficiency but also promotes uniformity in soil preparation, which is vital for successful planting. Inspection of Coulters and ScrapersRegular evaluation of cutting implements and cleaning devices is essential for optimal performance and longevity in agricultural equipment. These components play a crucial role in soil cultivation and residue management, directly affecting the efficiency of the machinery. Conducting thorough inspections helps identify wear, damage, or misalignment, ensuring that the implements function effectively. Key Inspection Areas

When assessing these components, focus on several critical areas to ensure they are functioning correctly:

Maintenance Recommendations

To maintain the functionality of cutting implements and cleaning devices, follow these recommendations:

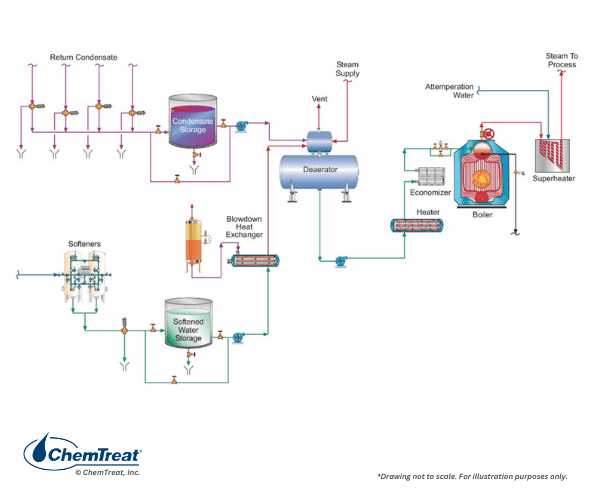

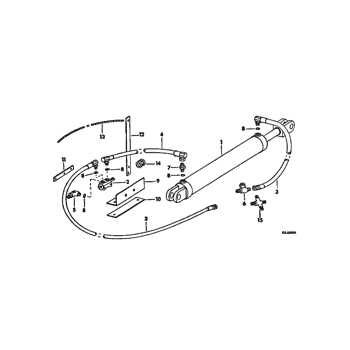

Hydraulic System and Cylinder Function

The hydraulic mechanism plays a crucial role in the operation of various machinery, enabling efficient movement and control through the use of fluid power. This system is designed to harness the pressure of hydraulic fluid to activate different components, ensuring seamless functionality and enhanced performance. At the heart of this mechanism are hydraulic cylinders, which convert hydraulic energy into linear motion. The following points outline their essential functions:

The hydraulic system typically consists of several key components, including pumps, valves, and reservoirs, each contributing to the overall efficiency and reliability of the machinery. Understanding the interrelation between these elements is vital for effective troubleshooting and maintenance. Overall, the hydraulic system and cylinders are integral to the performance of heavy equipment, enabling operators to achieve desired results with minimal effort and maximum reliability. Wear and Tear on Bearing Seals

The longevity of machinery often hinges on the condition of its sealing components, which play a crucial role in maintaining optimal performance. These elements are designed to prevent contaminants from entering critical areas, thereby ensuring smooth operation. However, over time, exposure to various environmental factors can lead to degradation, impacting the overall functionality. Factors Influencing Deterioration: Several aspects contribute to the wear of sealing mechanisms. Prolonged exposure to extreme temperatures, chemical substances, and physical stress can accelerate the breakdown of materials. Additionally, inadequate lubrication may exacerbate friction, leading to further damage. Signs of Damage: Identifying issues early can prevent more significant complications. Common indicators include abnormal noise, leaks, and decreased efficiency. Regular inspections are essential to detect wear patterns and assess the condition of seals, allowing for timely replacements and maintenance. Ultimately, understanding the importance of these components and the factors affecting their durability is vital for ensuring the reliability and longevity of machinery. Maintenance Tips for Disc Blade SharpnessEnsuring optimal sharpness of cutting edges is essential for effective soil cultivation. Regular maintenance not only enhances performance but also prolongs the lifespan of the equipment. Adopting a systematic approach to upkeep can lead to significant improvements in efficiency and results. Regular InspectionFrequent examination of the cutting implements is crucial for identifying wear and tear. Look for the following signs:

Sharpening TechniquesImplementing the right sharpening methods can restore cutting efficiency:

By following these practices, operators can maintain the effectiveness of their equipment and achieve better results in their agricultural endeavors. Common Replacement Parts for the 490 Model

For those maintaining agricultural machinery, understanding essential components is crucial for ensuring optimal performance. This section outlines frequently needed items that can help restore functionality and efficiency to the machinery. Blades are vital for effective soil tillage and should be checked regularly for wear and tear. Replacing these when they become dull can enhance cutting efficiency and reduce strain on the machine. Bearings are critical for smooth operation. Over time, they may experience deterioration, leading to increased friction and potential damage. Timely replacement can prevent more extensive repairs. Hubs are necessary for securing the blades. Any signs of damage or excessive wear should prompt immediate attention to maintain stability and performance. Spindles support the cutting mechanisms and can be subject to heavy loads. Regular inspection and replacement of worn spindles will contribute to the longevity and reliability of the equipment. In addition to these components, seals and gaskets are essential for preventing leaks and ensuring that the machinery operates smoothly. Maintaining these elements is key to overall equipment health. Troubleshooting Issues with Disc Gang Performance

Effective operation of the cutting assembly is crucial for achieving optimal results in agricultural practices. Various factors can hinder performance, leading to unsatisfactory outcomes. Identifying and resolving these issues ensures the machinery functions at its best, enhancing productivity and maintaining crop quality. Common Problems and Their Causes

Steps for Resolution

By systematically addressing these common issues, operators can restore efficiency to the cutting mechanism and ensure successful agricultural operations. |