The world of farming equipment is vast and complex, encompassing a variety of machines designed to optimize productivity in agricultural practices. Understanding the intricate design and functioning of these machines is essential for effective maintenance and repair. This section delves into the essential elements that make up a particular type of mower-conditioner, highlighting their significance in enhancing operational efficiency.

To navigate the nuances of machinery maintenance, it is crucial to familiarize oneself with the specific components that contribute to the overall performance. Each element plays a vital role in ensuring seamless operation, from cutting mechanisms to conditioning systems. Recognizing these individual parts facilitates informed decision-making when it comes to repairs and replacements.

In this exploration, we will provide a detailed overview of the layout and functionality of various machine components. This knowledge empowers users to troubleshoot issues effectively and maintain their equipment in optimal condition, ultimately leading to increased productivity and longevity of the machinery.

Overview of International 990 Haybine

This section provides a comprehensive look at a widely used agricultural implement designed for efficient mowing and conditioning of forage. It is engineered to streamline the process of cutting grass and legumes, ensuring optimal performance in various farming operations.

Equipped with advanced features, this machine enhances productivity while reducing operational costs. Its durable construction and innovative design make it suitable for different field conditions, allowing farmers to maximize their yields and maintain high-quality crops.

| Feature | Description |

|---|---|

| Cutting Width | Generous cutting width for effective coverage and faster operation. |

| Conditioning System | Integrated conditioning mechanism for optimal drying of cut materials. |

| Durability | Robust construction to withstand demanding agricultural tasks. |

| Maintenance | Designed for easy maintenance to ensure longevity and reliability. |

Key Components of Haybine Machinery

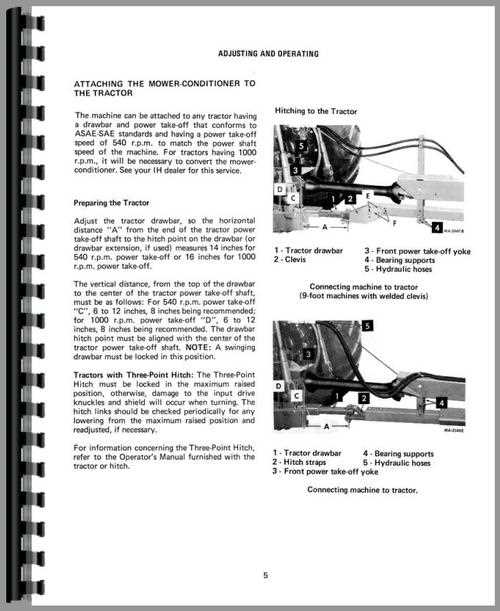

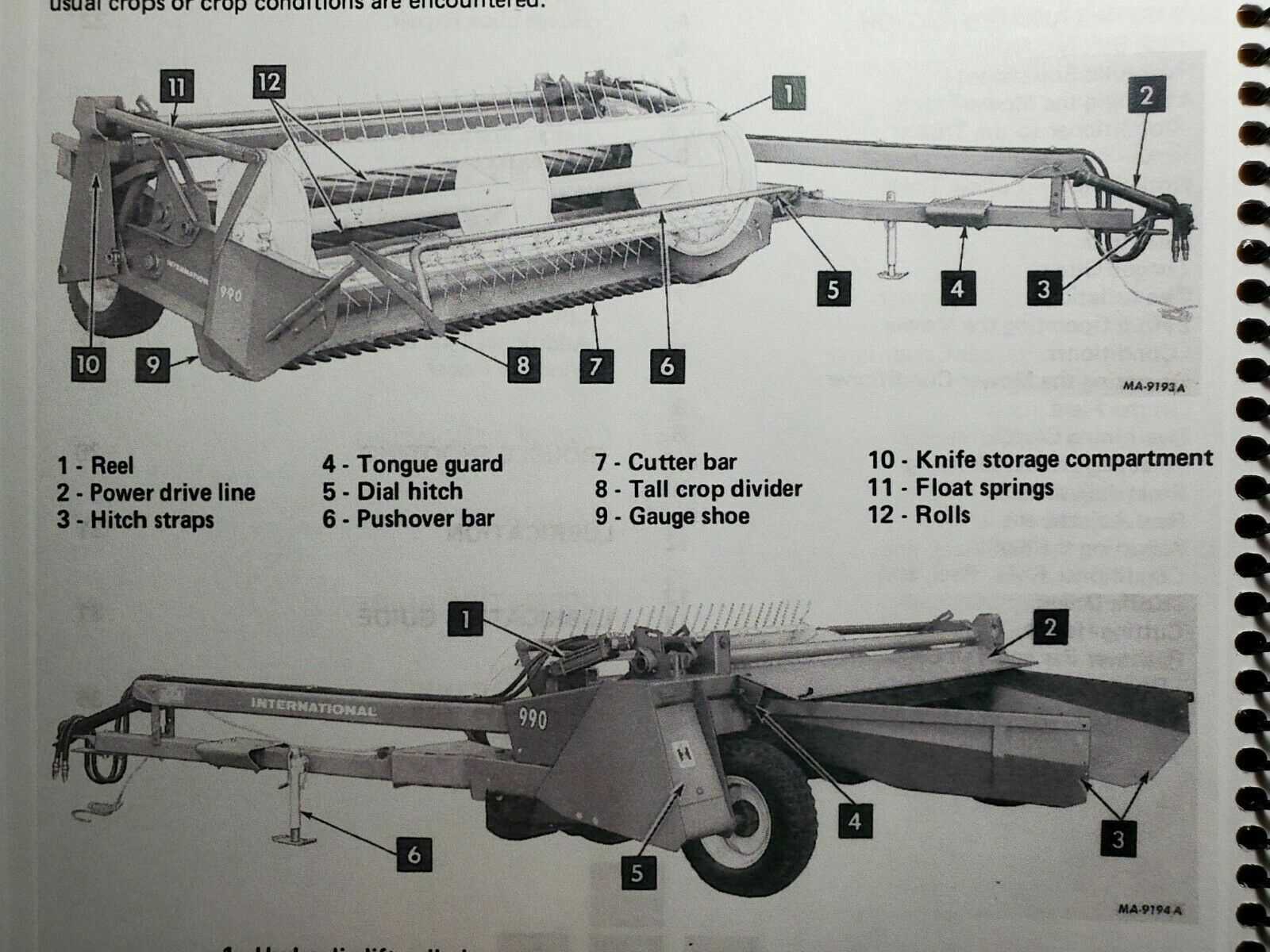

The machinery used for cutting and conditioning forage consists of several essential elements that work together to ensure efficient operation. Understanding these crucial components can aid in maintenance and troubleshooting, leading to improved performance and longevity of the equipment.

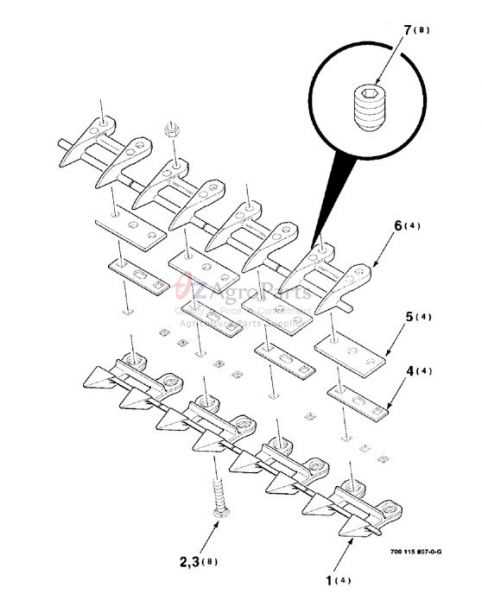

- Cutter Bar: This is the primary cutting mechanism responsible for slicing through the vegetation. It features sharp blades that can be adjusted for height, allowing for precise cutting depending on the type of crop.

- Conditioner Rollers: Positioned behind the cutter bar, these rollers help to crush and flatten the cut material, accelerating the drying process. They come in different configurations, including rubber and steel options.

- Frame Structure: The sturdy framework supports all components and ensures stability during operation. It is designed to withstand various field conditions and stresses encountered while working.

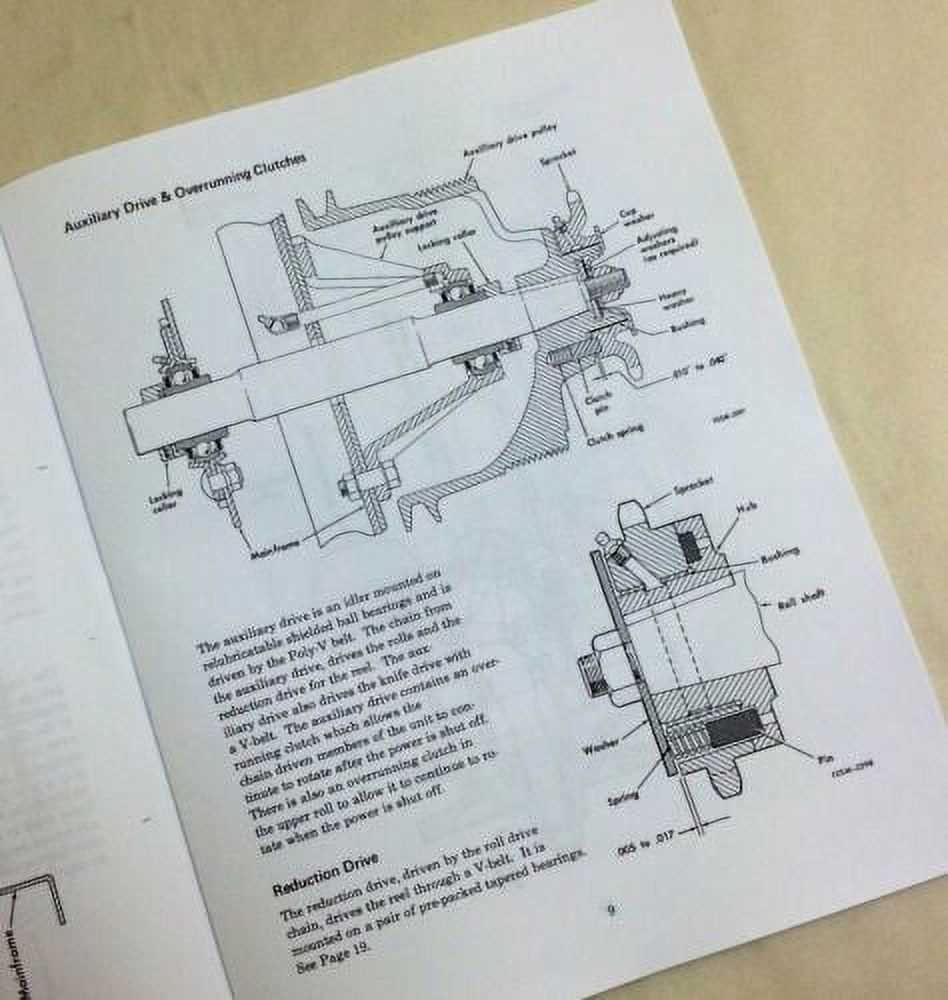

- Drive System: This includes the belts, pulleys, and gears that transmit power from the tractor to the cutting mechanism. A well-maintained drive system is vital for smooth operation and efficiency.

- Swath Board: This component directs the cut material into a uniform row, making it easier for subsequent harvesting processes. Its design can affect the width and shape of the swath.

- Transport Wheels: These wheels facilitate movement from one field to another. They can be adjusted to ensure proper ground clearance during transport.

Each of these components plays a significant role in the overall functionality of the machinery. Regular inspection and maintenance are essential to keep them in optimal working condition, ultimately enhancing productivity in forage harvesting operations.

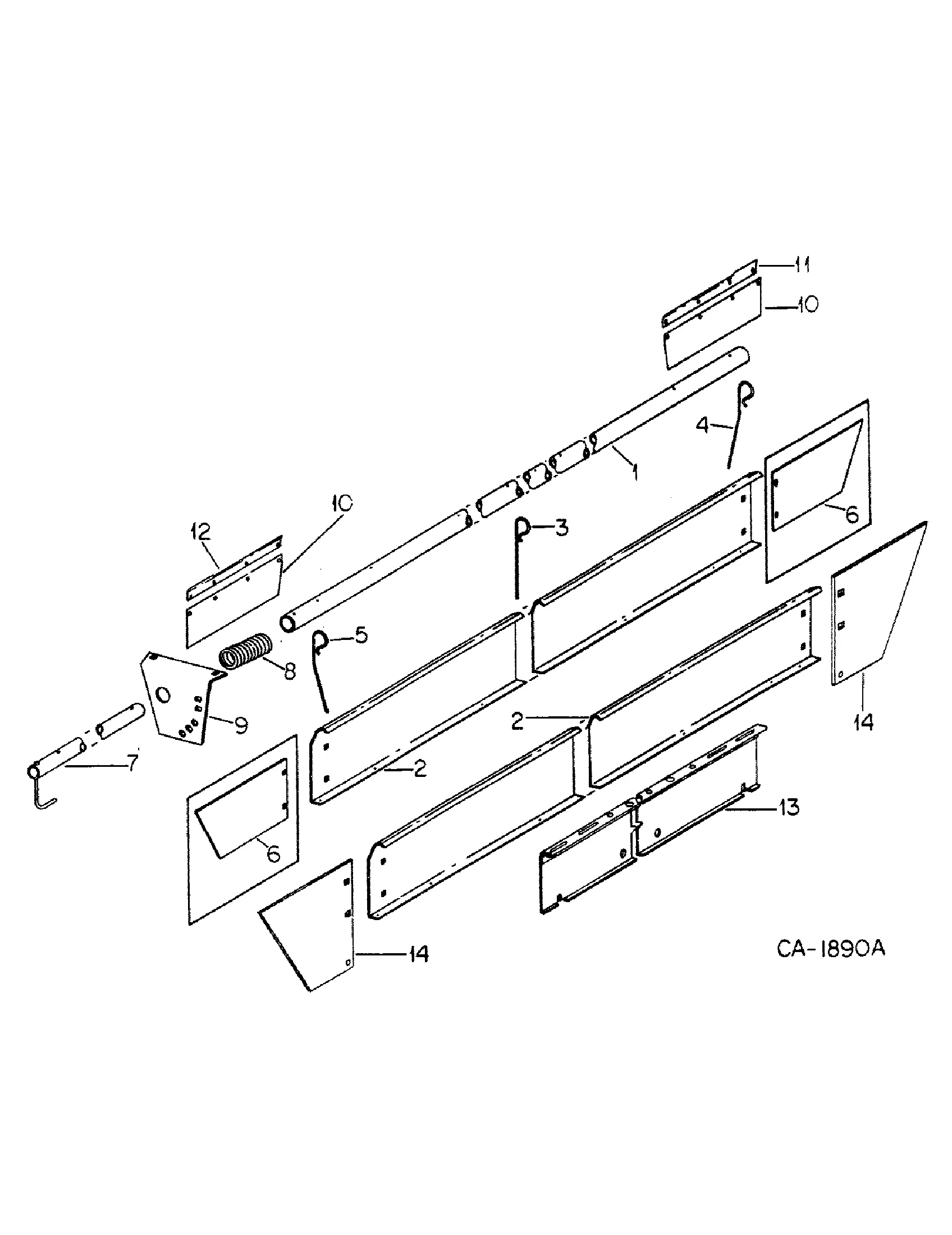

Understanding the Parts Diagram

Gaining insight into the assembly layout of agricultural machinery is essential for effective maintenance and repair. A visual representation serves as a valuable tool, illustrating the various components and their relationships within the equipment. This understanding aids operators and technicians in identifying parts quickly, ensuring proper functioning and longevity of the machinery.

Key Components and Their Functions

Each section of the visual guide highlights specific elements that contribute to the overall performance. Recognizing these individual units, such as the drive mechanism, cutting tools, and support structures, enables users to comprehend how each part interacts within the larger system. By familiarizing oneself with these components, operators can enhance their troubleshooting skills and streamline repair processes.

Benefits of Familiarity with the Layout

Being well-acquainted with the arrangement provides numerous advantages. It promotes efficient maintenance, reduces downtime, and minimizes the risk of errors during repairs. Moreover, understanding how to interpret the visual guide empowers users to make informed decisions when sourcing replacements or upgrades, ultimately leading to improved operational efficiency.

Maintenance Tips for Optimal Performance

Regular upkeep is crucial for ensuring the efficiency and longevity of agricultural machinery. By adhering to a consistent maintenance schedule, operators can minimize downtime, enhance productivity, and prolong the life of their equipment. This section outlines key practices that contribute to optimal functioning.

Routine Inspections

Conducting frequent evaluations of the machinery is essential. Look for signs of wear and tear, such as frayed belts or loose connections. Timely identification of issues can prevent more significant problems down the line. Always refer to the manufacturer’s guidelines for specific inspection intervals and areas to focus on.

Lubrication and Cleaning

Keep all moving parts well-lubricated to reduce friction and wear. Use high-quality lubricants as recommended. Additionally, maintaining cleanliness is vital; remove debris and dirt that can cause damage or impede performance. Regularly cleaning the components will not only ensure smooth operation but also make it easier to spot any potential issues early.

Common Issues and Solutions

In agricultural machinery, various challenges may arise during operation, impacting efficiency and performance. Identifying and addressing these problems promptly is essential for maintaining productivity and extending the lifespan of the equipment. Below are some prevalent issues and their respective solutions.

Frequent Challenges

| Issue | Description | Solution |

|---|---|---|

| Overheating | The machine may experience overheating due to insufficient lubrication or blocked cooling systems. | Regularly check and replace fluids, ensuring that all cooling vents are clear of debris. |

| Uneven Cutting | Cutting inconsistencies can occur from dull blades or improper height settings. | Inspect and sharpen blades regularly, and adjust the cutting height according to the desired level. |

| Mechanical Failures | Components may wear out or break over time, leading to unexpected breakdowns. | Conduct routine maintenance checks and replace worn parts as needed to avoid major repairs. |

| Hydraulic Issues | Hydraulic systems may lose pressure, affecting overall functionality. | Inspect hoses for leaks and ensure the hydraulic fluid is at the recommended level. |

Preventive Measures

To mitigate the risk of these common issues, it is advisable to implement a regular maintenance schedule. This should include routine inspections, timely replacements of worn components, and proper lubrication of moving parts. Keeping machinery in optimal condition not only enhances performance but also ensures safe operation in the field.

Replacement Parts and Their Availability

When it comes to maintaining agricultural machinery, understanding the availability of essential components is crucial for optimal performance. Ensuring that the right substitutes are accessible can significantly enhance the longevity and efficiency of the equipment. This section provides an overview of common substitutes and where to find them.

Common Components and Sources

Several key components often require replacement due to wear and tear during operation. The following table outlines typical items along with potential sources for acquiring these items:

| Component | Source |

|---|---|

| Cutting Blades | Local Dealers, Online Retailers |

| Drive Belts | Authorized Service Centers, Specialty Suppliers |

| Gearboxes | Manufacturer Websites, Aftermarket Providers |

| Hydraulic Cylinders | Heavy Equipment Stores, Online Auctions |

Tips for Finding Components

When searching for replacements, it is advisable to compare prices across multiple vendors to ensure cost-effectiveness. Additionally, consulting with experts or joining online forums dedicated to agricultural machinery can provide valuable insights and recommendations regarding reliable suppliers.

Assembly Instructions for New Parts

When incorporating new components into your machinery, it’s essential to follow a systematic approach to ensure proper functionality and longevity. This section provides a comprehensive guide to effectively assembling these elements, promoting optimal performance and reliability in your equipment.

Preparation Steps

Before beginning the installation, gather all necessary tools and components. Ensure your workspace is clean and organized to facilitate a smooth assembly process. Review the manufacturer’s guidelines to familiarize yourself with the specifications and requirements of the new components.

Installation Process

Start by carefully removing any existing components that need replacement. Utilize appropriate tools to avoid damaging surrounding areas. Align the new components with the designated slots and secure them using the provided fasteners. Double-check connections to ensure they are tight and correctly positioned. Once assembled, conduct a thorough inspection before operating the machinery to confirm everything is in place and functioning as intended.

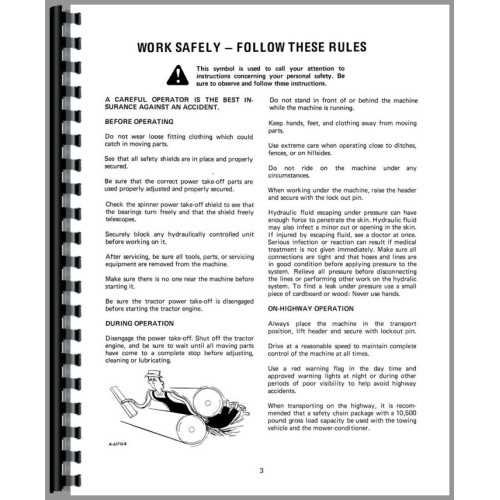

Safety Precautions While Operating

When engaging in the operation of agricultural machinery, it is essential to prioritize safety to prevent accidents and ensure a smooth workflow. Understanding potential hazards and implementing precautionary measures can significantly reduce risks associated with equipment use.

- Always wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and sturdy footwear to safeguard against injuries.

- Before starting the machinery, conduct a thorough inspection to check for any wear, damage, or loose components.

- Ensure that all safety guards and shields are in place and functioning correctly to provide maximum protection during operation.

It is crucial to maintain clear communication with all personnel in the vicinity while operating the equipment. This helps in ensuring that everyone is aware of the ongoing activities and potential hazards.

- Keep bystanders at a safe distance to avoid accidental injuries.

- Follow the manufacturer’s guidelines for operation and maintenance to ensure the equipment runs smoothly and safely.

- Never operate the machinery under the influence of alcohol or drugs, as this impairs judgment and reaction times.

In case of an emergency, familiarize yourself with the shut-off procedures and ensure that emergency equipment is accessible and in good working condition.

Comparative Analysis with Similar Models

This section delves into a detailed examination of equipment that shares similar characteristics and functionalities with the subject model. By analyzing various alternatives, users can better understand the strengths and weaknesses of each option, facilitating informed decisions based on specific needs and operational requirements.

| Model | Cutting Width | Weight | Features | Price Range |

|---|---|---|---|---|

| Model A | 9 ft | 1,500 lbs | Hydraulic drive, adjustable height | $15,000 – $18,000 |

| Model B | 10 ft | 1,600 lbs | Heavy-duty frame, quick attachment | $16,500 – $20,000 |

| Model C | 8 ft | 1,400 lbs | Foldable design, enhanced maneuverability | $14,000 – $17,000 |

In summary, evaluating these comparable models highlights key differences in dimensions, weight, and pricing. Each alternative presents unique features that may align better with certain operational demands. By considering these factors, users can select equipment that optimally suits their agricultural practices.

Enhancements and Upgrades for Efficiency

Improving the functionality and performance of agricultural machinery is essential for maximizing productivity and reducing operational costs. By focusing on various enhancements and upgrades, users can significantly elevate the efficiency of their equipment, ensuring they remain competitive in an ever-evolving industry. This section outlines several key modifications that can lead to better performance and increased reliability.

Implementing Advanced Components

One of the most effective ways to enhance equipment performance is by integrating advanced components. Upgrading to high-efficiency cutting systems can result in cleaner cuts and reduced energy consumption. Additionally, replacing standard bearings with high-performance alternatives can improve longevity and decrease maintenance needs, further optimizing the workflow during busy seasons.

Routine Maintenance and Calibration

Regular maintenance is crucial for sustaining equipment efficiency. Establishing a routine that includes checking fluid levels, inspecting belts, and calibrating settings can prevent minor issues from escalating into significant problems. Properly calibrated machinery operates more effectively, minimizing wear and tear while maximizing output, leading to greater overall productivity.

Resources for Further Research

For those seeking comprehensive information and insights regarding agricultural machinery, a variety of resources are available to enhance your understanding and support your research. These materials can provide valuable data on components, assembly, and maintenance practices, catering to both novices and seasoned professionals in the field.

Online Forums and Communities: Engaging with online communities dedicated to farming equipment can be particularly beneficial. Platforms such as discussion forums and social media groups allow users to share experiences, ask questions, and exchange knowledge about machinery specifications and troubleshooting methods.

Manufacturer Websites: Visiting the official websites of manufacturers can yield detailed technical documents and user manuals. These documents often include exploded views and specifications, aiding users in identifying components and understanding their functions.

Technical Manuals: Accessing printed or digital manuals can be invaluable for obtaining precise information about specific machinery. These resources typically cover assembly instructions, maintenance schedules, and part compatibility, ensuring that users have the correct data for repairs and modifications.

Local Dealerships: Connecting with local dealerships that specialize in agricultural equipment can provide firsthand insights. Experienced staff members can offer expert advice, assist with sourcing parts, and recommend relevant literature tailored to specific machinery models.

Workshops and Training Programs: Participating in workshops or training sessions focused on agricultural machinery can enhance practical knowledge. These programs often feature hands-on experiences and expert-led discussions, enabling participants to grasp complex concepts more thoroughly.